Recently we received a customer complaint, he said some metal domes arrays couldn’t work with required (normal) force and need higher push force, and even more some metal domes are locked and no response.

The metal domes customer uses is S6F-160-D-Ni, mean F-leg, diameter 6mm, force 160gf, with a dimple in center and nickel plated. The normal force is 160gf before assemble, but it seemed force changed a lot after assemble on PCB, and need higher force.

Before seeing customer’s products, we also couldn’t find the root reason, we checked and tested our metal domes before assembly, it’s no problem, but after saw customer’s finished product, we understood why this issue happened, because customer’s design housing design is not suitable with metal domes array.

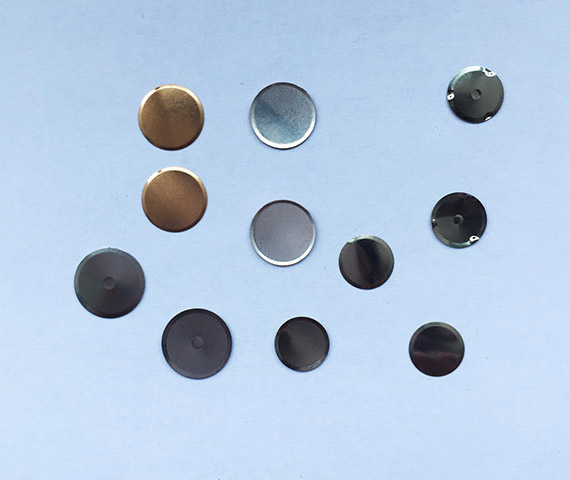

customer’s original metal dome array

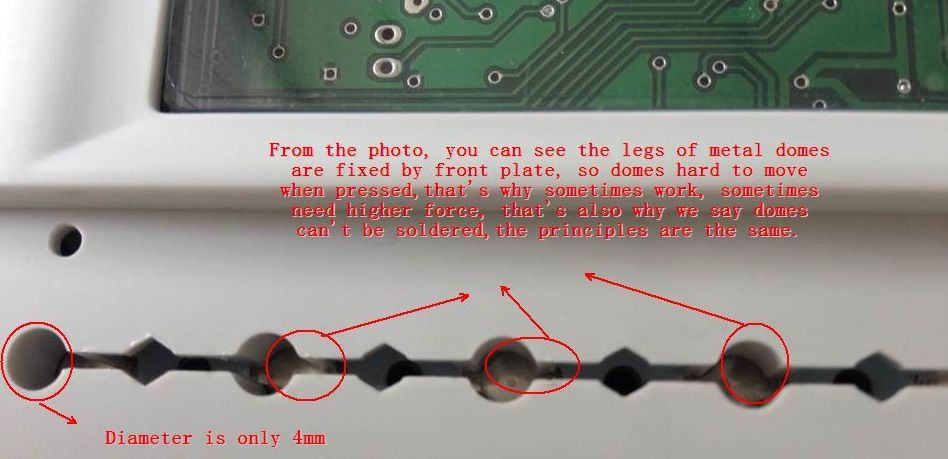

Firstly, we checked customer’s assembled unit, obviously we found that four legs of metal domes are pressed and fixed by the front plate housing after assembly, so when people pressed the center of metal dome, the legs of metal dome can’t be extended peripherally as its original design, that means the front plate stop metal dome becoming collapse, so you have to press metal dome use much higher force than the designed force (160gf for that metal dome) to force it become collapsed.

But in most of cased, people don’t know that and still press metal dome use designed force (160gf) and then he will found out that metal dome will not work. And then he have to increase the force, then bigger force damage metal dome original structure, and then will change the force, and in most of case means reducing the clicking feeling. That’s also why we say metal dome can’t be soldered. (See more how metal domes work).

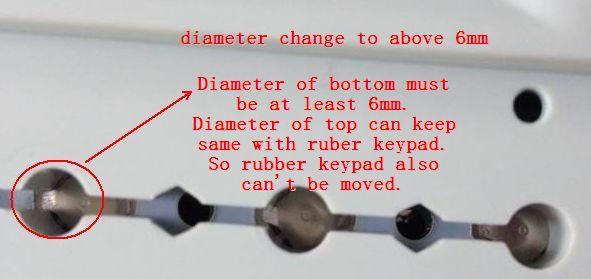

Second, we measured the diameter of plunger on front plate, it’s only 4mm, but the diameter of metal dome is 6mm, you can see, obviously front plate will press the inner function ring metal dome.

plunger of front plate

Third, we measured the diameter of rubber keypad, it’s 3mm, that’s too large, the larger stress area is, the higher push force will be needed. For 6mm metal dome, the recommend size is 1.5mm (25%-30%*diameter of metal dome).

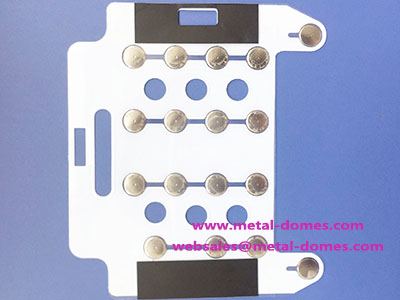

Suggestions:

metal dome array assembly suggestiong

- Customer need to use front plate to fix the rubber keypad, but this front plate can’t lock metal dome, so bottom diameter of front plate should be more than 6mm, then metal dome will not be fixed by the front plate.

- Use the suitable plunger to touch and press metal dome, 25%-30% of diameter of metal dome.

We hope above will be clear for people whom encountered the similar issues.

-dome-array-8-s.jpg)