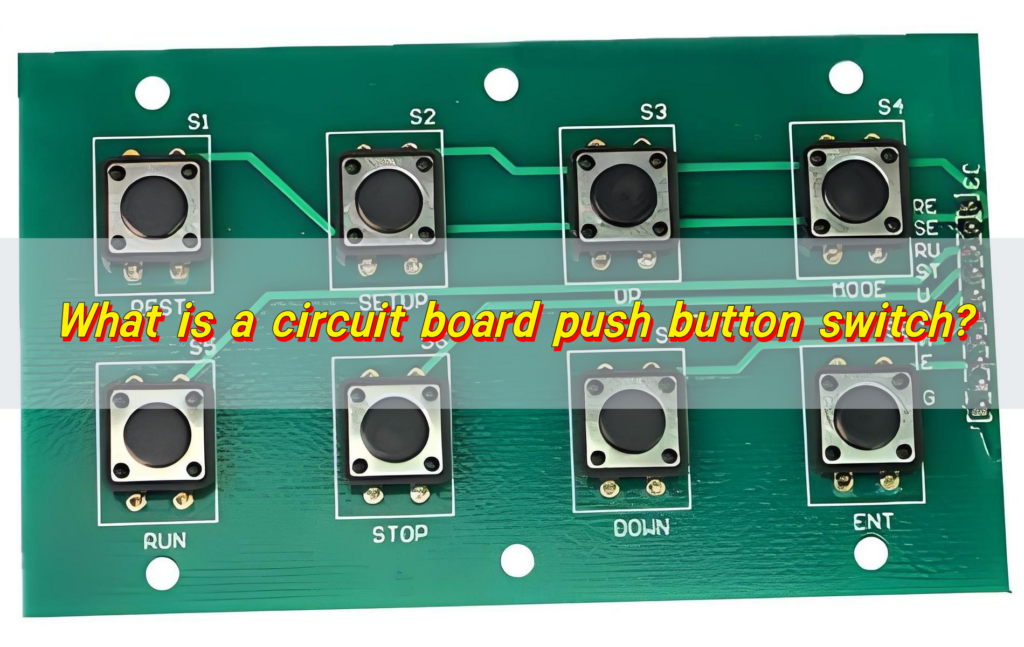

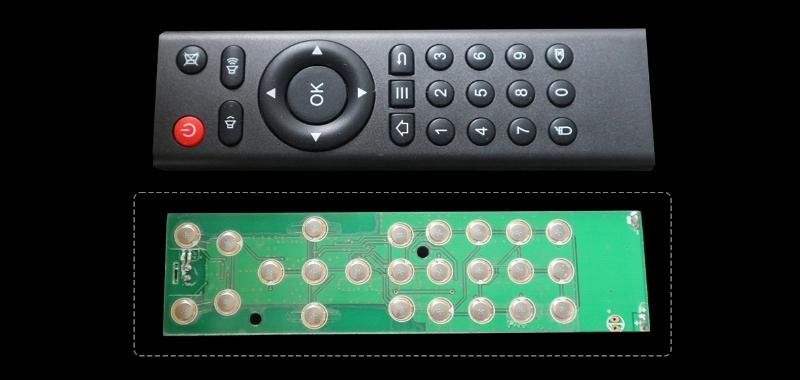

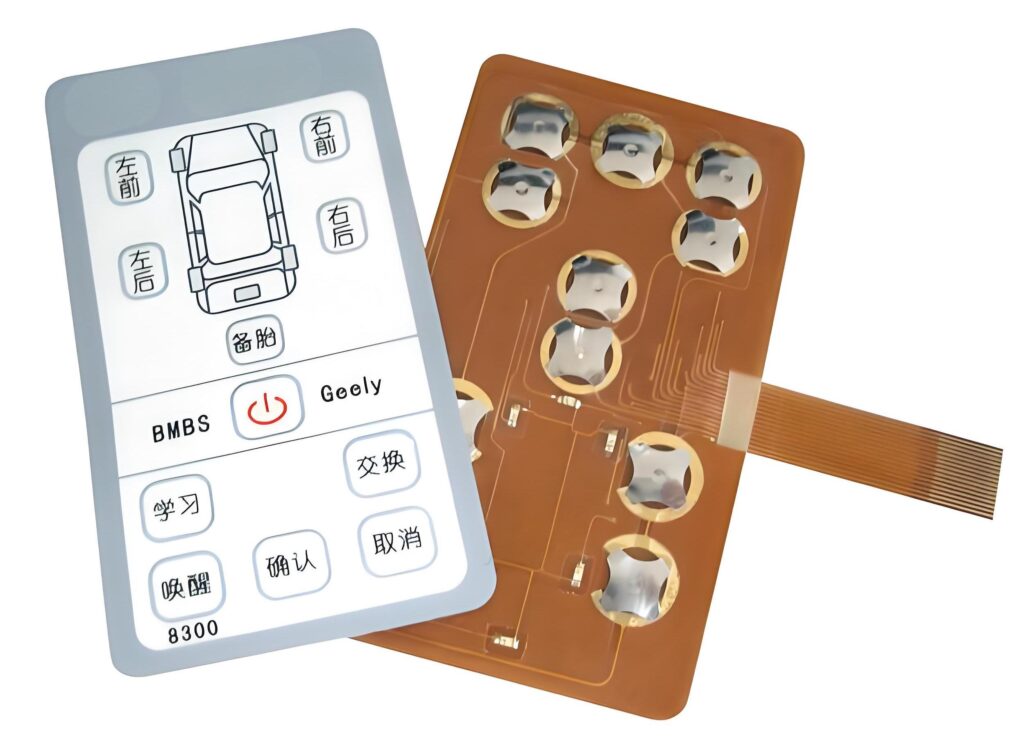

Circuit board push button switch is a switch that is directly mounted on a circuit board and switches the circuit on and off by pressing. It has the characteristics of simple structure, convenient operation, and strong durability, and is widely used in various electronic devices. This switch usually consists of a button, a spring and a circuit. When the button is pressed, it contacts the circuit, and when it is released, the spring returns to its original state, ensuring the stability and reliability of the circuit.

How does a push button switch work?

Push button switch works by completing or interrupting an electrical circuit. When pressed, it allows current to flow. Release it, and the current stops.

Most push button switches are designed to be momentary. That means they only stay active while you’re pressing them. As soon as you let go, they spring back into their original state. It’s quick, direct, and incredibly reliable.

This simple mechanism is built for endurance. A tactile push button switch, for instance, offers a satisfying click. That click is not just feedback—it’s a sign that the circuit is doing exactly what it should.

How does a push button work on a circuit board?

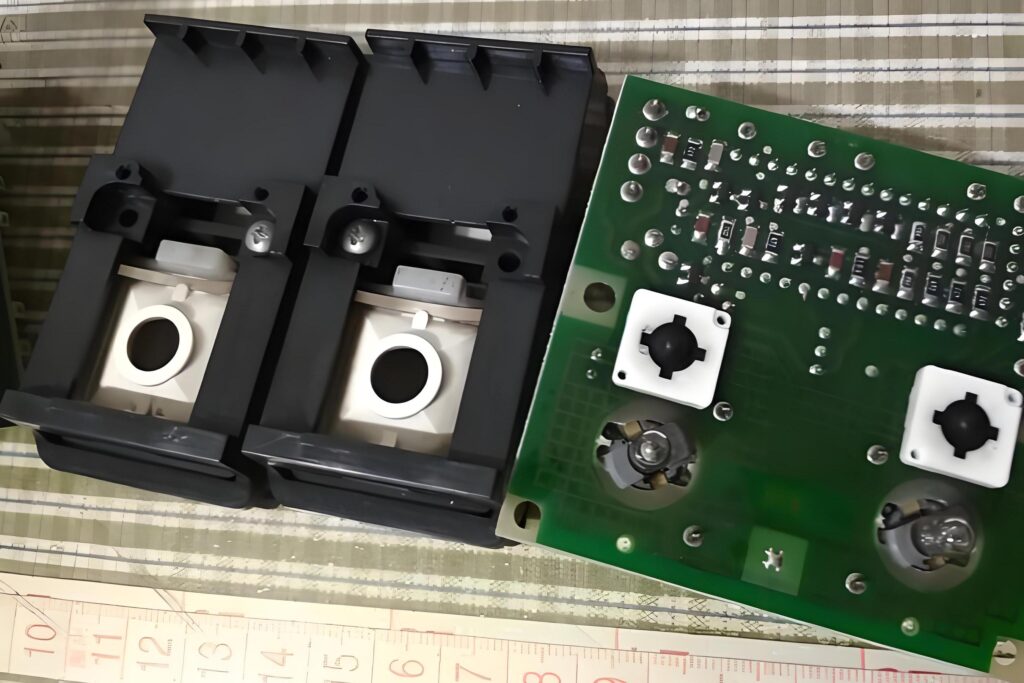

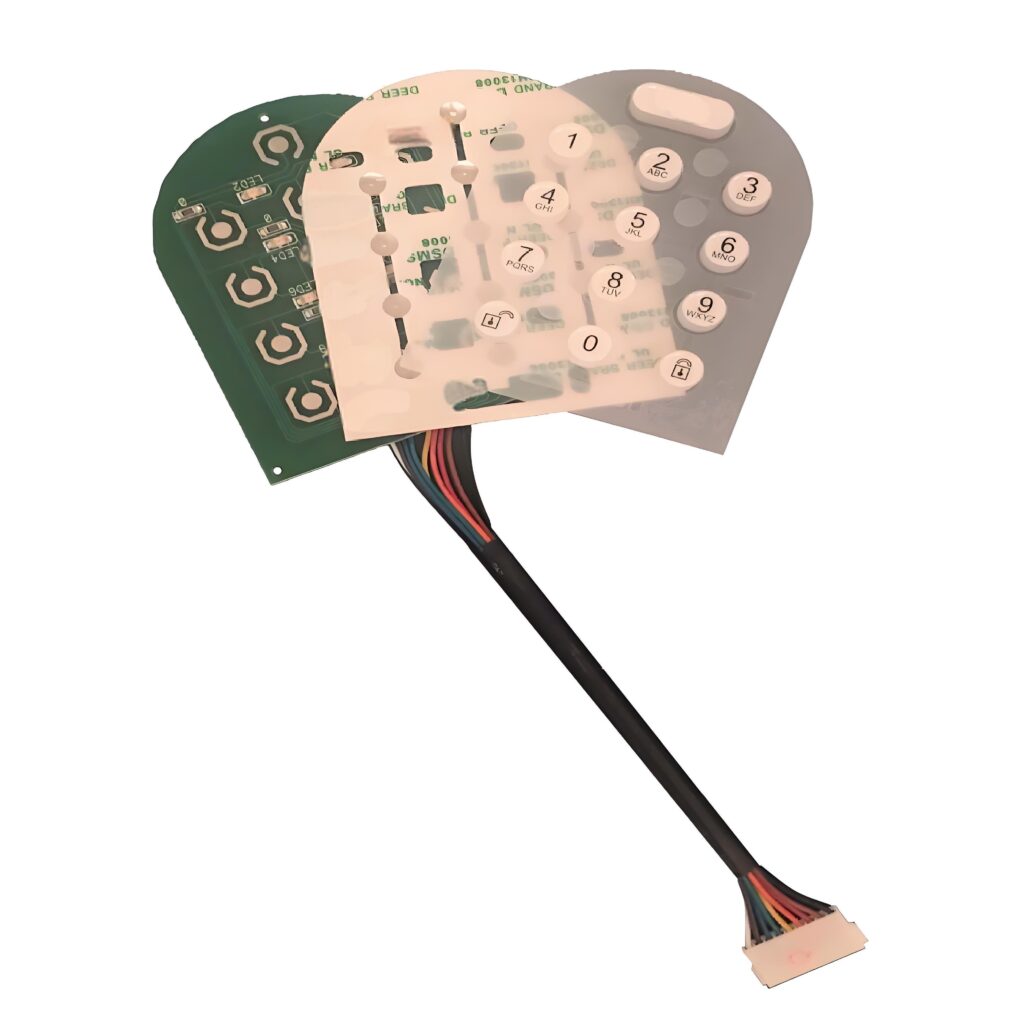

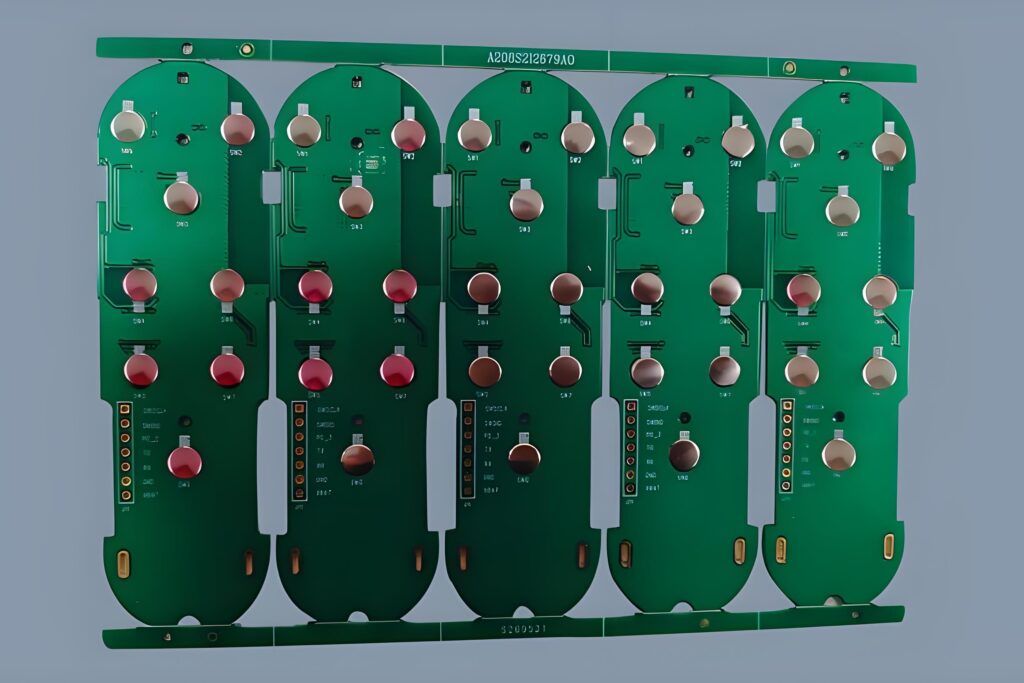

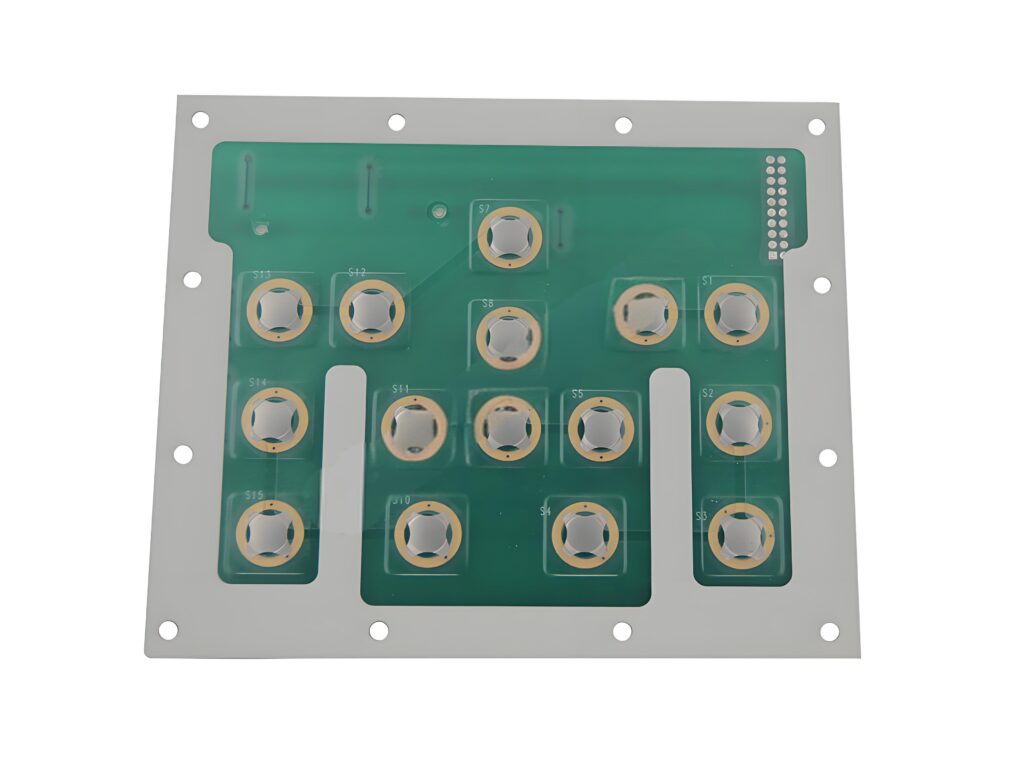

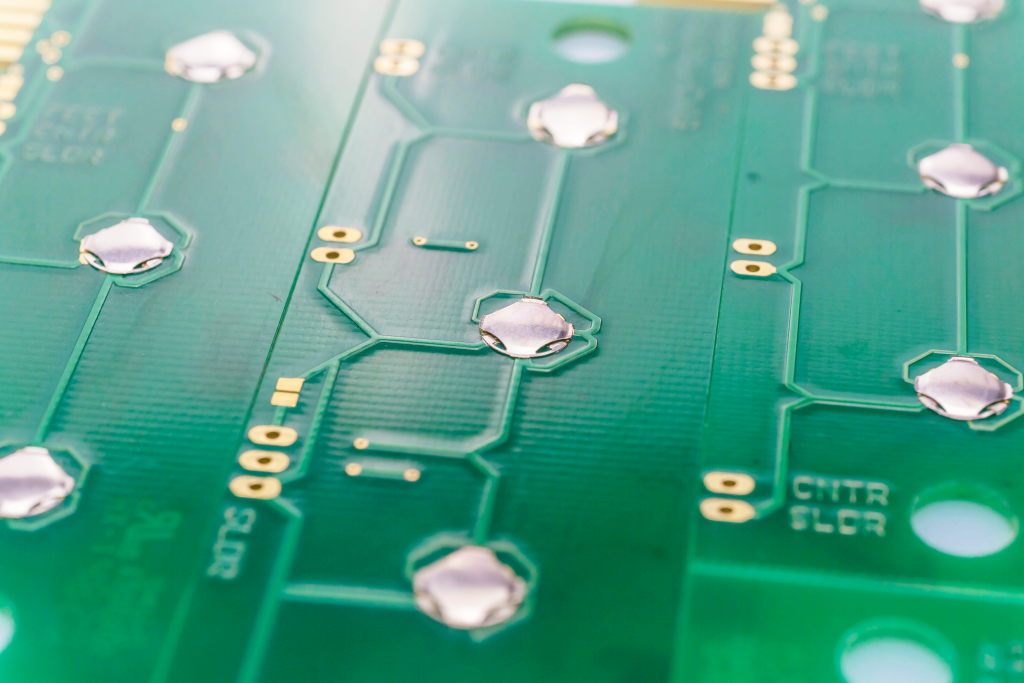

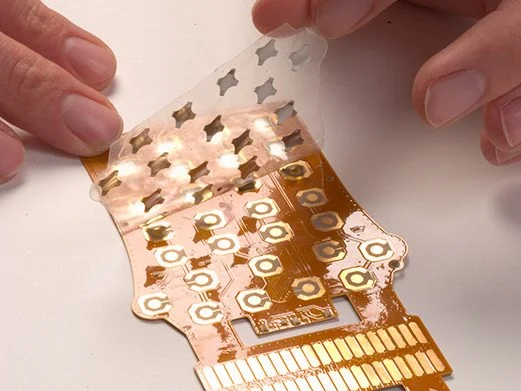

Circuit board push button switch is soldered onto a PCB (Printed Circuit Board). Once mounted, it connects to the traces on the board, which act like roads for electrical signals. When you press the button, you close the circuit, allowing electricity to move across the traces.

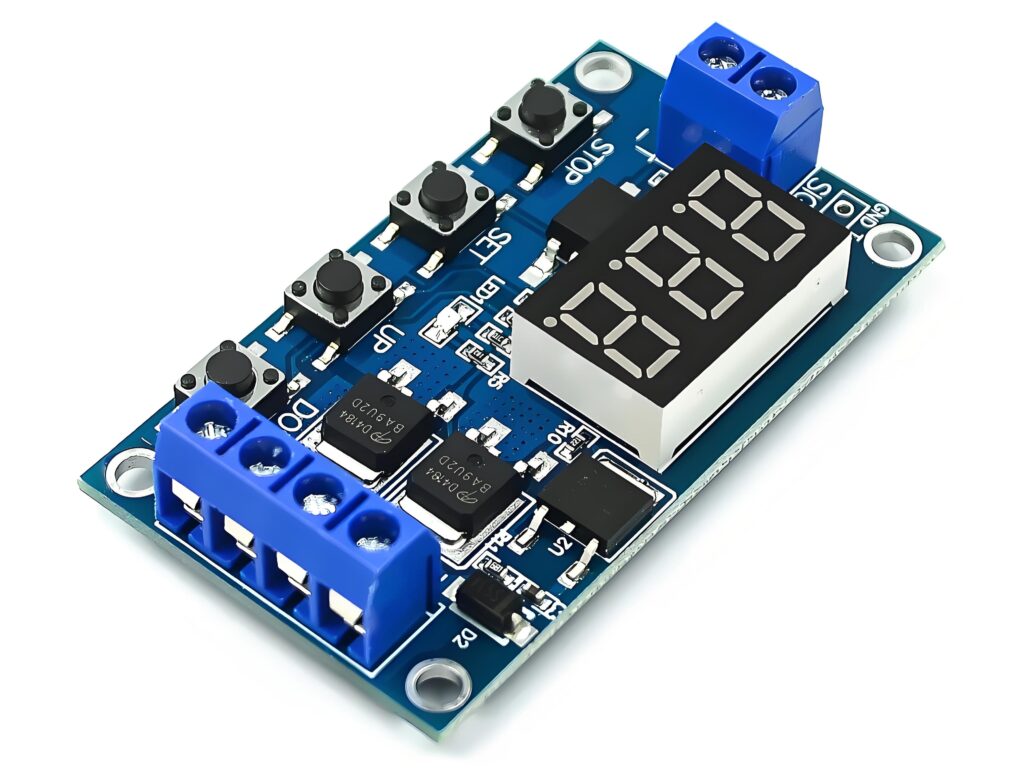

These buttons can control LEDs, buzzers, relays, and more. Each press sends a signal that tells the system what to do. In some devices, it might power the unit on. In others, it could send a command, toggle a setting, or activate a function.

Push button switch circuit boards are designed with precision. Engineers carefully map out where each switch sits, ensuring every click leads to the right outcome. It’s not just about turning things on—it’s about control, interaction, and performance.

How to tell if a push button switch is bad?

Here’s how to know when your circuit board push button switch might be failing:

- No response: Press it, and nothing happens. No click. No action.

- Stuck in position: If it doesn’t spring back, that’s a red flag.

- Inconsistent behavior: Sometimes it works, sometimes it doesn’t. That’s a warning sign.

- Physical damage: Cracks, corrosion, or missing parts are clear indicators.

You can also use a multimeter to test the function. Set it to continuity mode. Touch the probes to the switch terminals. Press the button. If there’s no beep or reading, the switch may need replacing.

What does a push button switch do in a circuit?

Push button switch controls the flow of electricity. It acts as a gate that opens and closes depending on your action.

In a simple LED project, for example, the push button lets you control when the light turns on. Press it, and the current flows through the bulb. Release it, and the light goes off.

In complex systems, the push button may send signals to a microcontroller. This small command can trigger bigger actions—starting motors, activating alarms, or launching software routines. It all starts with a single press.

Does a push button need a resistor?

Yes, in most cases, a resistor is essential. It helps manage the current and prevents damage to sensitive components.

Without a resistor, too much current might flow through the button or the connected circuit. That could cause overheating, short circuits, or long-term damage.

In digital circuits, resistors are also used as pull-up or pull-down resistors. They keep the input pins stable when the switch is not pressed. Without them, the signal could float, causing random or unstable behavior.

So while the button may look simple, it often works hand-in-hand with resistors for reliable operation.

What are the different types of push button switches?

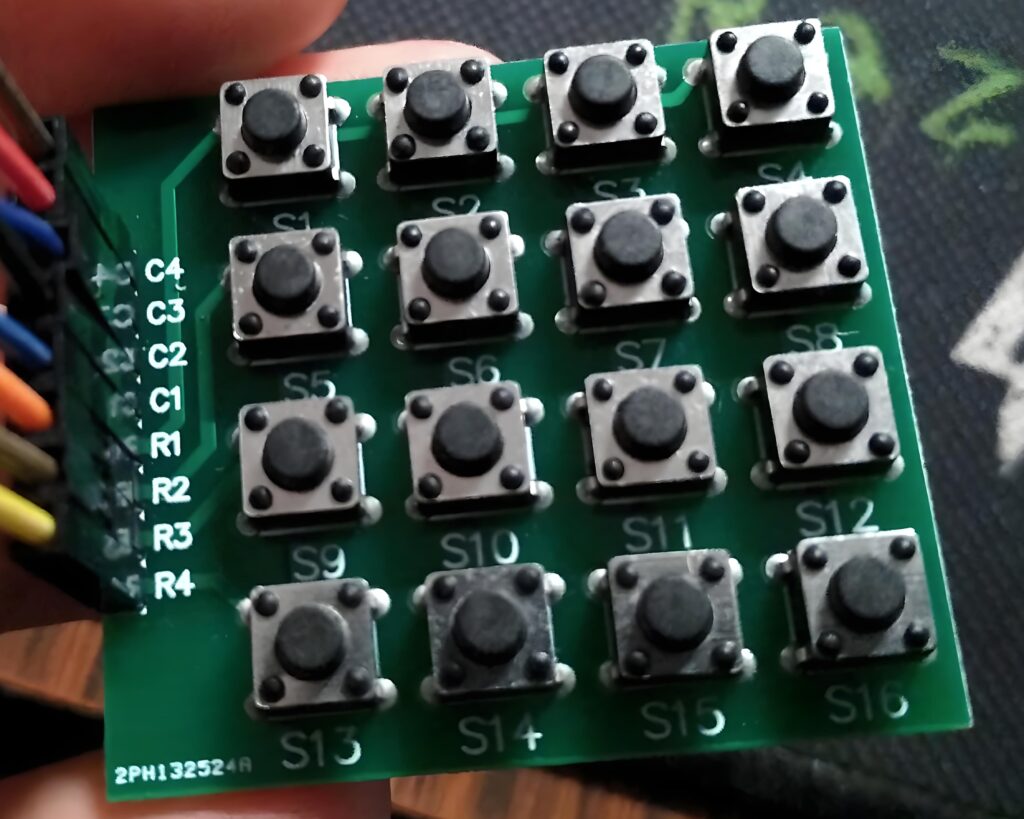

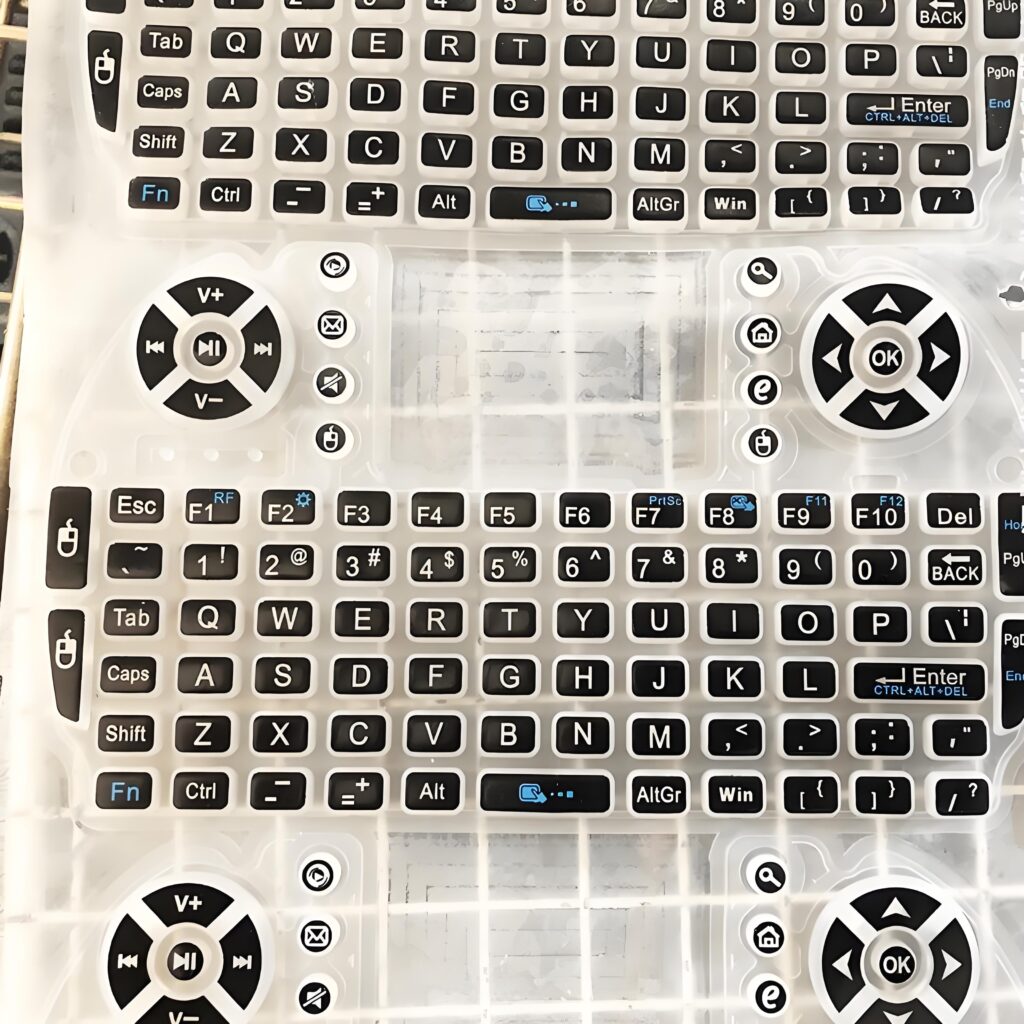

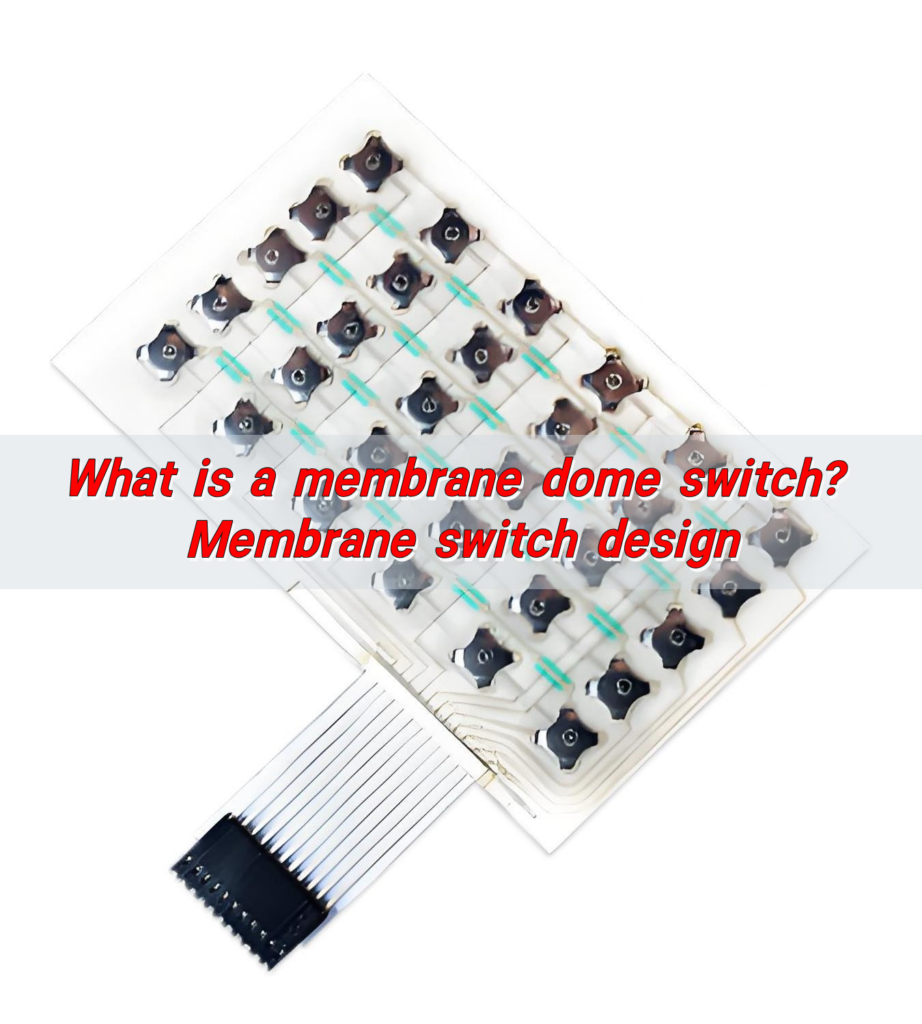

Not all push buttons are created equal. Different designs serve different purposes. Here’s a quick breakdown of circuit board switch types you might come across:

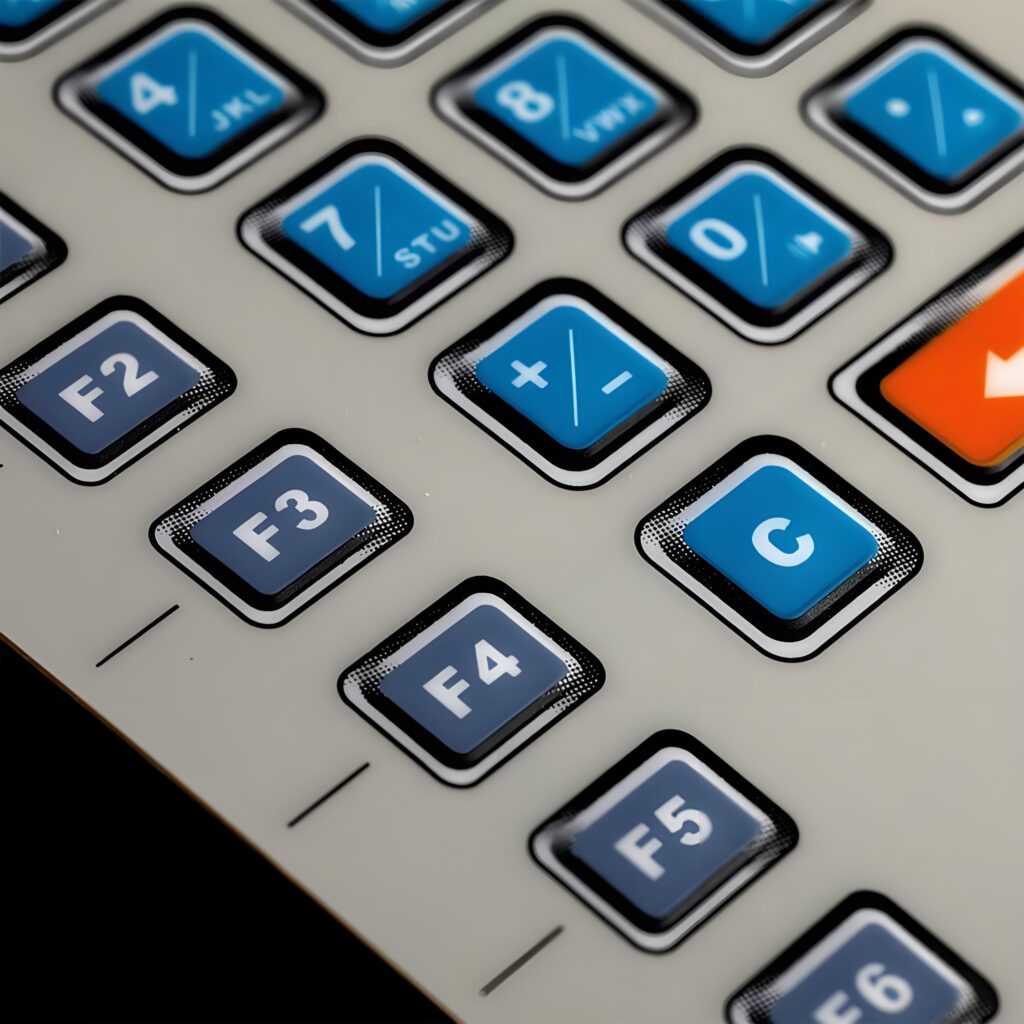

- Momentary Switches: The most common type. Active only while being pressed. Found in calculators, keypads, and remote controls.

- Latching Switches: Press once to turn on. Press again to turn off. Like a flashlight button.

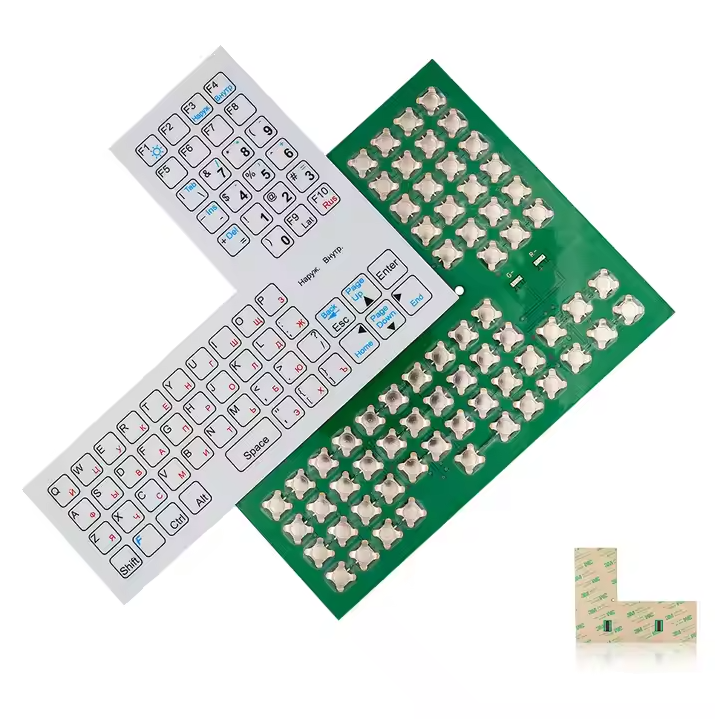

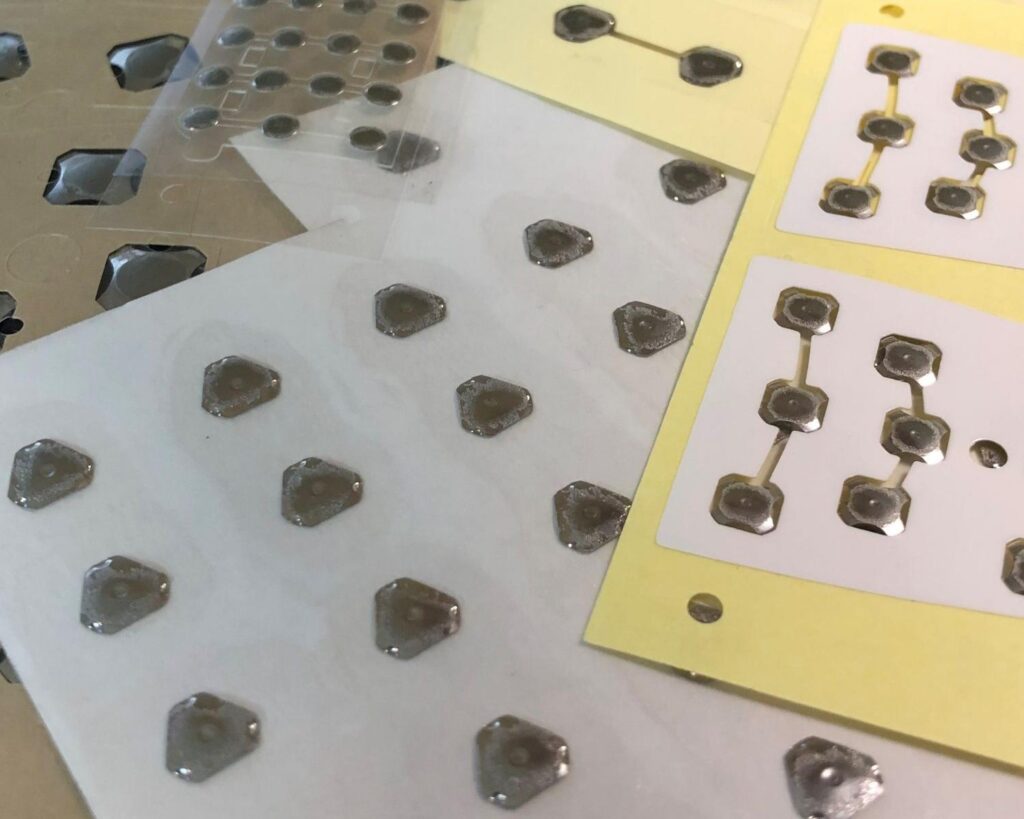

- Tactile Push Button Switches: Provide a click feel. Ideal for precise feedback. Used in keyboards and control panels.

- Illuminated Switches: Have built-in lights. They signal status or draw attention.

- Dual Action Switches: Two functions in one button. Often used in special-purpose devices.

Each type fits a unique use case. When designing a product or choosing a replacement, picking the right one matters.

How many terminals does a push button switch have?

Most push button switches have two or four terminals. The number depends on the function and design.

Two-terminal switches are simple on-off devices. When you press the button, the two terminals connect and let current flow.

Four-terminal switches offer more flexibility. They can be used for cross connections, redundancy, or better PCB mounting.

Some complex switches might have more, especially if they include LEDs or multiple contact points.

The terminal layout determines how you connect it to the push button switch circuit board. Solder it properly, and it becomes a powerful, reliable tool.

What is a momentary switch vs push button?

Momentary switch only stays active while pressed. Let go, and it turns off. It’s fast, simple, and reactive. on the other hand, toggles its state. Press once to turn on. Press again to turn off.

So when someone says “push button,” they might mean either type. But technically, it’s a broader term. Momentary is more specific.

In many modern gadgets, momentary switches are preferred. They offer precision, speed, and a satisfying tactile feel.

Conclusion:

The circuit board push button switch might be small, but it plays a mighty role. From triggering a light to starting a process, it’s all about control. Its design, feel, and function shape how we interact with technology every day.

Got more questions? Need premium push button switches for your next project? Reach out to us at sales@metal-domes.com