Metal dome buttons have a very wide range of applications, second only to touch key switches. They are widely used in mechanical appliances such as large machine tools or daily electronic products. Because the metal dome of the metal push button switch is very corrosion-resistant and dust-proof and waterproof, and the dome array and internal metal dome structure result in a long service life. The main supporting fields of illuminated metal button switches are electronic control equipment, lifting equipment, heavy machine tool equipment, power electronic equipment, transportation vehicles, aerospace, ships, household appliances, etc.

The metal dome button is a switch that conducts a small current when pressed. It can be used as an operating signal input switch for various electronic devices. The metal dome button conducts a circuit by pressing it. It opens and closes the internal contact points by applying a small force on its external contact surface.

Such contact points are usually made of metal materials and have high durability and reliability. The metal dome button is turned on and off by pressing the metal dome. It has the characteristics of simple structure, compact size, flexible operation, stable and reliable performance.

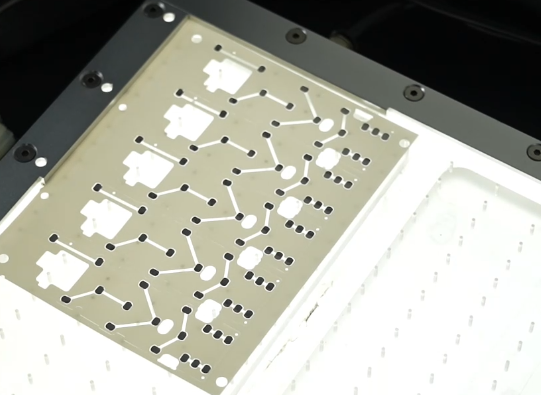

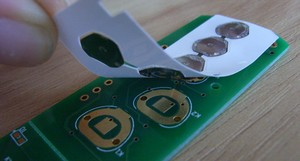

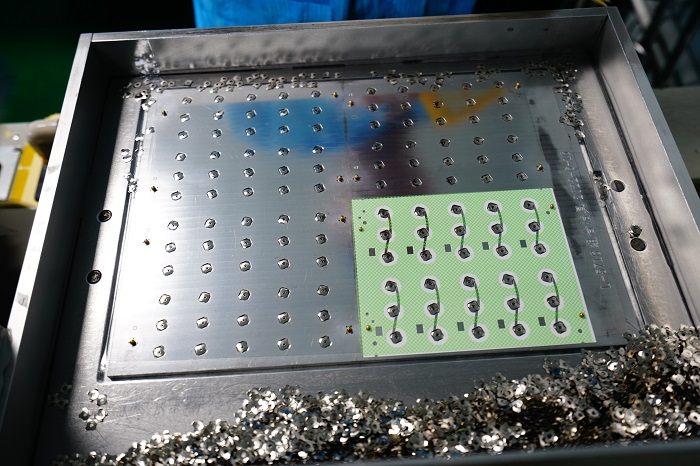

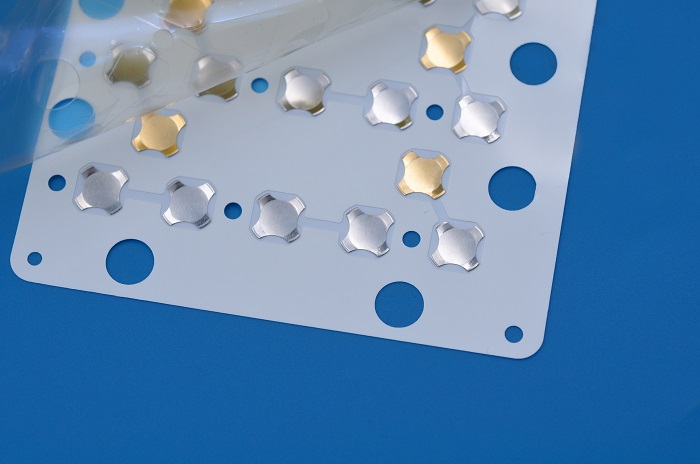

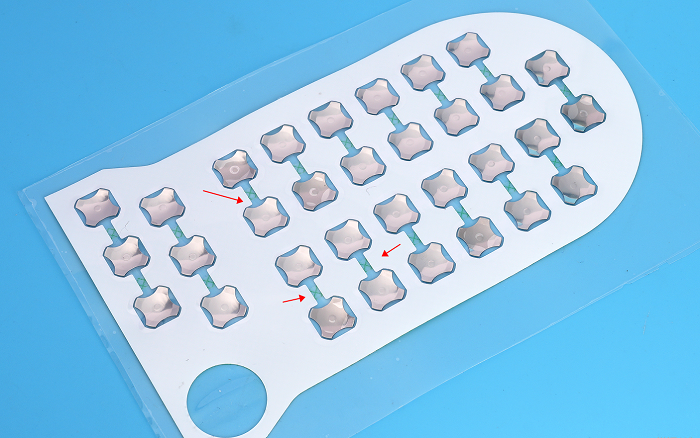

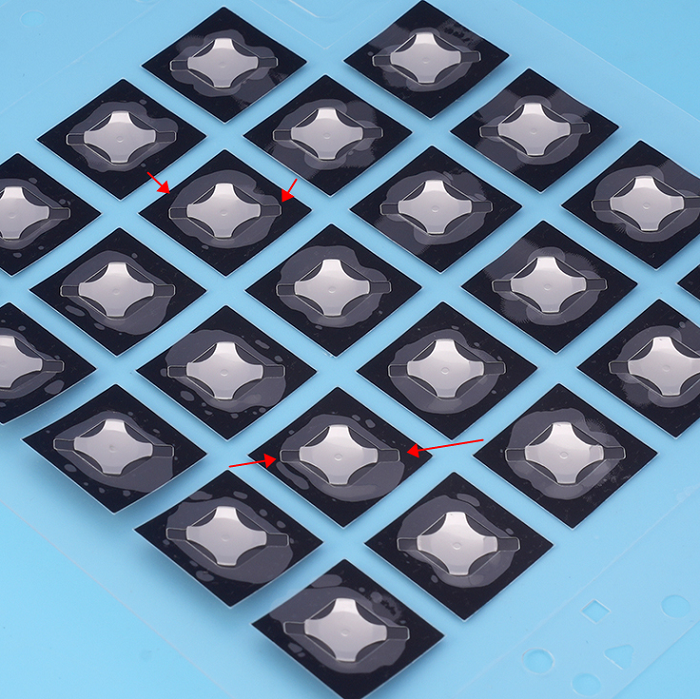

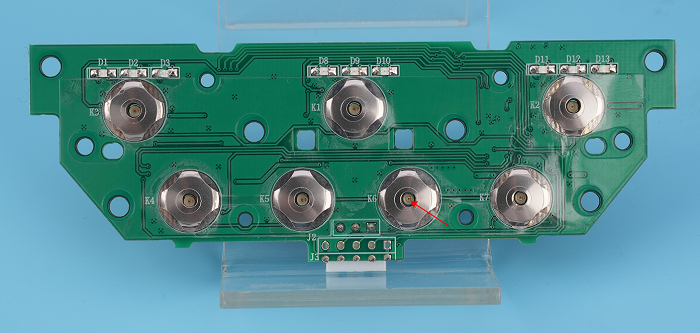

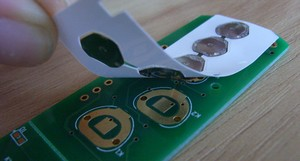

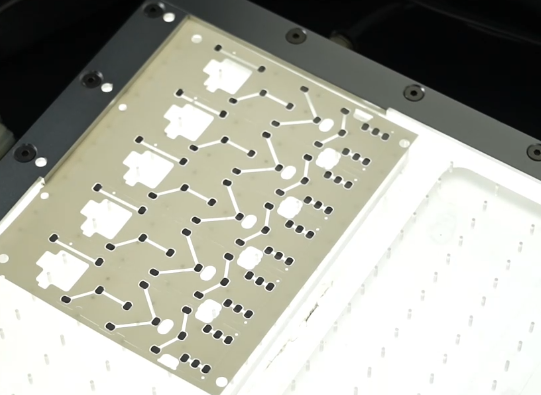

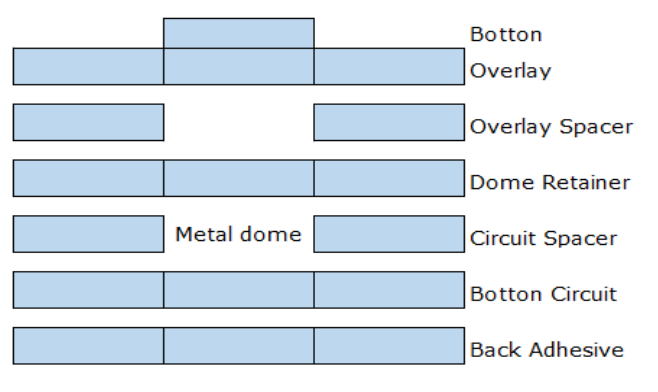

Metal dome buttons are usually composed of PET outer layer, dome, contacts and other parts. The PET outer layer fixes the position of the metal dome, which is installed on the machine and can be assembled with the PCB to form a membrane switch device. 3M glue is used to combine the dome array with the PCB and can be installed directly in the machine. The contact is the core component that realizes the switch function. It usually consists of two metal sheets, one of which is a fixed contact and the other is a moving contact.

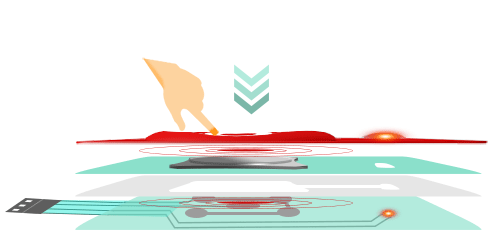

When the switch button is pressed, the dome is deformed by external force and contacts the circuit board downwards, causing the two sets of pins of the switch to be connected, thus making the circuit conductive. When the switch button is released, the spring piece returns to its original shape and breaks contact with the circuit board, causing the circuit to be in a cut-off state. This kind of tactile switch has a good feel. When you press the button to a certain extent, there will be a ticking sound, and you can feel the clear operating touch.

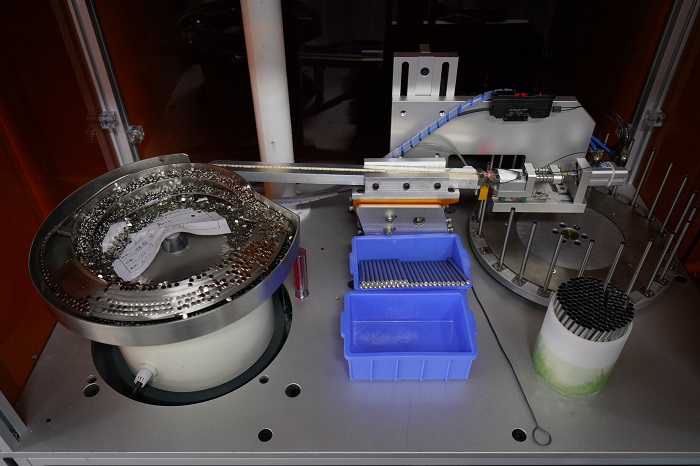

The biggest feature of the metal dome button is that it uses very small pressing force and generates tactile feedback, so that the user can feel the pressing effect, and the switch function can be realized by pressing the button. In addition, tact switches also have the characteristics of stability and long life. Best Technology has more than ten years of production experience in the production of metal domes, dome arrays, and membrane switches. If your product has requirements for metal dome buttons and dome array, you can directly contact us salesperson for enquiry.