In electronic product production applications, dome array installation on PCB has become a topic of concern. In complex printed circuit boards (PCBs), there are some issues that continue to attract attention – the problem of dome array installation tilt. Best Technology decided to explain this phenomenon and give you an in-depth introduction to dome array.

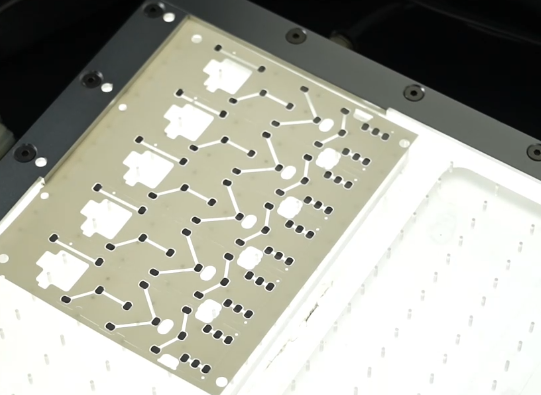

Whether it is the selection of materials, the stamping technology of the dome, or precision manufacturing, any lax operation will affect the subsequent application of the metal dome or dome array. During the assembly process, the dome array needs to remain stable and flat on the PCB board. However, some manufacturers have encountered a troublesome situation where the dome array is initially flat when assembled but gradually tilts over time. This tilt creates the risk of dust penetrating the dome array, causing conduction damage and potential operational issues.

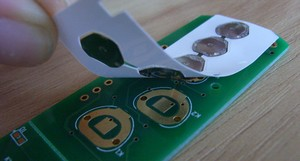

Often to improve performance and durability, metal domes require a coating, usually involving gold or nickel plating. This protective layer protects the dome from corrosion and wear, ensuring continued functionality over the long term. At the same time, during the assembly process, the metal dome needs to be assembled first onto a double-layer structure, usually consisting of an upper polyester film and a lower spacer layer.

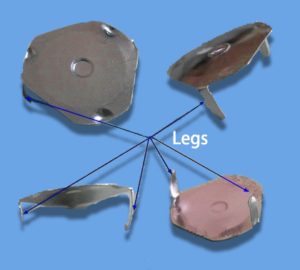

Looking closely, for the dome array assembled onto the PCB board, the root cause of this problem lies in the construction of the double-layer structure dome array. Specifically for the dome array, the thickness of the upper polyester film layer is approximately 0.05mm, and the thickness of the lower spacer layer is approximately 0.075mm. When using a high-height metal dome, such as a triangular or four-legged metal dome (height range is 0.4mm to 0.7mm), the height difference between the dome and the spacer layer is relatively large. Once the dome is close to the edge, it will cause shrapnel The patch becomes warped.

So how to solve this problem?

To solve this problem, we can start from two aspects, a two-pronged solution: first, the supplier provides drawings, and when designing, the shrapnel should not be too close to the edge, leaving enough space to prevent warping. Second, we can thicken and add Glue the spacer layer to prevent the elastic patch from lifting. This modification ensures a more secure connection, prevents dome array tilting and maintains optimal performance.

Dome array is a main component in electronic products, so it must undergo strict production to ensure the production quality of the product. At the same time, designers with rich experience are required to design solutions more accurately and avoid problems encountered in applications. Also selecting a dome with appropriate height specifications can help manufacturers proactively address tilt issues. Best Technology strictly controls quality control to ensure that metal dome arrays meet the necessary standards and can provide reliability and longevity in electronic applications.

In short, understanding the difference between the structure and production process of metal dome arrays and dome specifications is crucial to solving the installation and use problems of dome arrays in PCB boards. The problems that may be encountered when applying in products are some minor problems. This can be avoided with minor design changes. Reliability and suitability for dome array applications are ensured through thoughtful design and functional enhancements within the structure.

The above is a detailed introduction to how to deal with the installation tilt problem of metal dome array in PCB board. If you have other questions about metal dome or dome array, please leave us a message.