A membrane switch is a type of user interface that consists of several layers of flexible materials sandwiched together. It is commonly used in electronic devices and control panels to provide a user interface for input or control. The layers typically include a graphic overlay, circuit layer, and adhesive layer, and assemble them into a whole product that is called membrane switch.

Before dive into the assemble process, we should know the structure composition about a membrane switch. In generally, all the tactile switches are made by six layers, whatever it is the simplest PET membrane switch or the complex fiber optical tactile switch. The six layers are including:

1.Graphic overlay

The graphic overlay is on the top side of the membrane switch, which can be designed various legends and colors on it. There are commonly two printing methods that print the graphic, one is traditional screen printing, and another is digital printed technology. Both two are excellent way to print, but digital printed is mainly used for printing the gradient colors, like dark blue to light blue. By this way, the overlay can be shown a more beautiful and advanced appearance.

2.Overlay spacer

The overlay spacer is typically a layer that provides separation between the graphic overlay (the visible top layer with the buttons or graphics) and the circuit layer (the layer containing the conductive traces). This spacer layer is crucial for preventing unintended contact between the overlay and the circuit layer, ensuring that the switch functions properly and only registers press when intended.

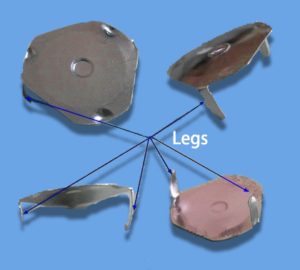

3.Dome retainer

The dome retainer is a part of the membrane switch that helps hold the metal dome onto the correct place, ensuring they are properly aligned with the corresponding circuit traces. It can help to maintain the integrity of the switchâs design and misalignment or unintended actuation.

4.Circuit spacer

A circuit spacer just like the overlay spacer in a membrane switch, it refers to a material that is used to create separation between the dome retainer and lower circuit layer. When a user presses a key or activates a specific area on the graphic overlay, allowing the conductive elements on the overlay to make contact with the corresponding traces on the circuit layer beneath.

5.Lower circuit

This layer usually consists of a flexible circuit board (FPC) or a polyester (PET) or the printed circuit board (PCB) that has circuit traces or conductive elements printed or etched onto it. These traces serve as the conductive pathways for transmitting the electrical signals generated by the user’s input to the electronic device or system connected to the membrane switch. It plays a crucial role in the functionality of the switch by facilitating the completion of electrical circuits when the switch is pressed, thereby registering the desired input.

6.Back adhesive

The back adhesive is the bottom layer of the membrane switch, we always use the 3M adhesive as the bottom layer. The primary purpose of the back adhesive is to provide a strong and reliable bond between the membrane switch and the substrate or surface to which it is applied. This adhesive layer ensures that the membrane switch stays in place during regular use and does not peel off or detach.

The choice of adhesive is crucial, as it needs to adhere well to various materials, including metals, plastics, or other surfaces commonly found in electronic devices or equipment. Additionally, the adhesive should be durable enough to withstand environmental conditions and temperature variations.

These are the basic layers of the tactile membrane switches, if you have more questions about the structure, welcome to contact us.