The metal dome can be used in tact switches and key switches, which are electronic switches with integrated panel and switch functions. The metal dome is mainly composed of four parts: panel, upper circuit, isolation layer, and lower circuit. When the Poly dome membrane switch is pressed, the contacts of the upper circuit deform downward and make contact with the plates of the lower circuit. After releasing the finger, the contacts of the upper circuit bounce back, the circuit is disconnected, and the circuit triggers a signal.

In the production of metal domes, the stamping method can be used to mass-produce metal domes. Stamping has strict requirements on size. For products with a small quantity, a knife mold can be used. During the production process, our inspectors will use calipers to check from time to time to see if the dimensions of the metal domes are accurate. At the same time, check whether the mold is deformed. If the mold is deformed, production should be stopped immediately and a new mold should be made. For products with a larger quantity, steel molds are used, which have less deformation and more accurate dimensions.

The metal dome also needs to be tested after production. The first is functional testing. Here, the strength and feel of the metal dome are mainly tested. The pressing force of the dome will affect the use of the product. When installed in a Poly dome membrane switch, if the pressing force of the dome is inappropriate, it will affect the user’s experience, or there will be no effect after pressing. Functional testing is to sort out unqualified products. Best Technology has rich production experience, so in the testing of dome strength, the pass rate is greatly improved.

The life test of the dome is also part of the test, but the life test takes a longer time than other tests, because when pressing the traditional Chinese medicine to simulate the normal pressing force, you have to wait for the dome to rebound before continuing to press. Therefore, the entire testing process takes a while, so the spot check testing method is used in life testing. Best Technology’s metal dome has a service life of up to 5 million times. Therefore, it is very popular among suppliers in the metal dome industry.

When a metal dome is installed in a Poly dome membrane switch, various uncertain factors will affect the service life of the dome. After testing, our Poly dome membrane switch has a service life of at least 1 million times. Therefore, whether installed in machine operation interfaces or frequently used switches, domes can perform their functions stably.

Main features of metal domes

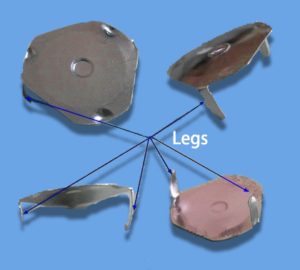

The metal dome is compact and portable, easy to carry and pack, bears less express delivery costs and is cost-effective. Metal domes can be designed in different shapes and heights according to different requirements. If you need to install LED lights for light transmission, the metal dome can be designed to be hollow to facilitate light transmission. In short, we can design a suitable metal dome according to the user’s product needs.

The metal dome needs to be sealed during use. Improper use of the metal dome will also affect the service life of the metal dome. Best Technology has decades of production experience in the dome industry. For the production, testing, and packaging of metal domes, it has always been Best’s production goal to ensure the quality of the products through quality inspection. If you have needs for metal domes, welcome contact us!