The main requirements for the use of metal domes are the strength, rebound effect, service life and feel of the dome. In response to these problems, Best Technology conducts continuous research on material selection, design, production and testing when producing metal domes. The current sound production process and plan have been formed. The following is a detailed introduction to the key factors that need to be paid attention to during the production of metal domes:

Material selection: Choose high-quality metal materials, such as stainless steel or nickel silver, for durability and corrosion resistance. The material should be able to withstand repeated use without deformation.

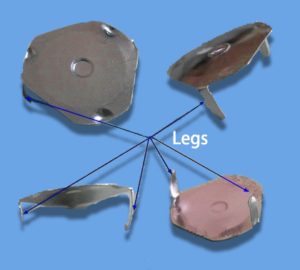

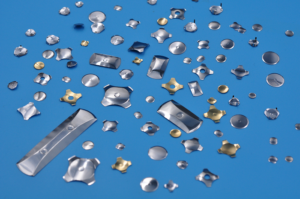

Size and shape: Design shapes according to customer needs and carry out mass production. Make sure the metal dome is manufactured in a uniform size and shape to maintain button consistency. Changes in size or shape may result in differences in tactile feedback and user experience.

Tactile feedback: The metal dome is used to provide tactile feedback when the button is pressed. Designing a dome with the proper snap and tactile response is critical to ensure a satisfying user experience while not being too hard or too soft to press.

Durability and Reliability: The metal dome is life tested to withstand five million actuations without losing elasticity or tactile feedback to ensure its durability and reliability.

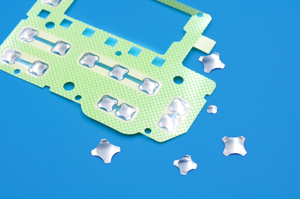

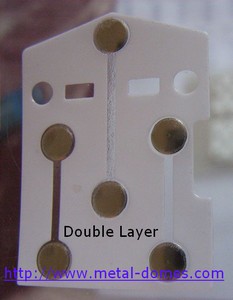

Placement and Adhesion: Proper placement and adhesion of metal domes to the button substrate, or production dome array, is critical to preventing them from shifting or shifting during use. Use strong 3M glue to make it stick firmly and avoid falling off.

Environmental considerations: Consider the operating environment in which the buttons will be used. Make sure the metal dome can withstand temperature changes, humidity and other environmental factors without degrading performance.

Manufacturing Process Control: Best Technology implements strict quality control measures throughout the entire manufacturing process to maintain consistency and adhere to specifications. This includes monitoring the dimensions, material properties and tactile characteristics of the metal domes.

By paying attention to these factors during the production of metal domes for buttons, a high-quality product with reliable performance and user satisfaction is ensured. Metal domes have a relatively higher upfront cost compared to other types of buttons, but are more cost-effective in terms of long-term durability and reliability over the entire life of the electronic device. Maintenance and replacement costs are reduced, and the overall quality of customer products is improved. If you are interested in Best Technology metal dome and dome array, you can contact us for a detailed consultation.