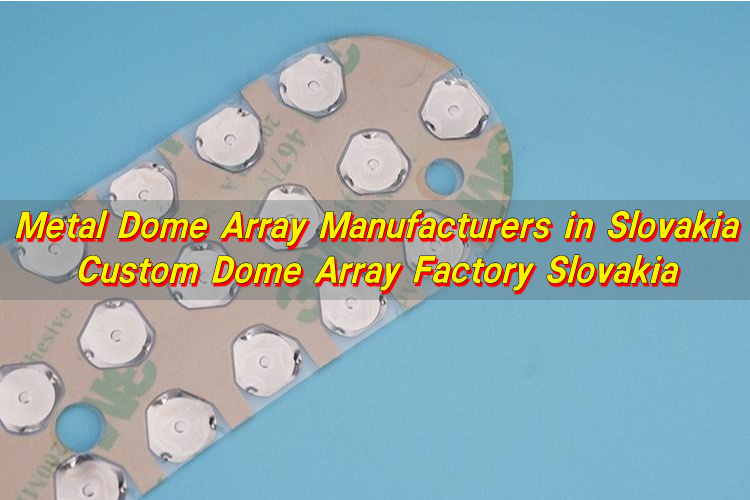

This guide introduces reliable Metal dome array manufacturers in Slovakia and explains how to evaluate suppliers for prototyping, design, mass production, quality control, and delivery. If you are sourcing tactile metal dome arrays for industrial control, automotive electronics, or medical devices, understanding the local supply landscape and global options is critical.

Are you facing these problems?

- Long prototyping cycles, making it difficult to quickly verify designs for small-batch projects

- Insufficient design support, leading to unstable tactile feel and lifespan of metal domes

- Poor consistency, with significant variations in actuation force between different batches

- High prices from local suppliers, resulting in uncontrolled costs for mass production

- Incomplete compliance documents such as RoHS/REACH, affecting end-customer certification

End-to-End Solution from Requirements to Delivery: Our Solution

As a professional Metal Dome Array manufacturer, EBest Circuit (Best Technology) provides a one-stop service from requirements analysis, structural design, mold development, material selection, automated assembly, lifespan testing to final packaging and international logistics. Through standardized engineering processes and an SMT-level manufacturing system, we ensure that every dome array maintains high consistency in tactile feel, conductivity reliability, and long-term stability.

We are not simply a “contract manufacturer,” but an engineering collaborative supplier: we participate in the design process at an early stage, optimizing array layout, tolerance control, and installation methods to help customers reduce rework risks and overall costs, giving you higher yield rates and more controllable delivery times during mass production.

Why Choose Us? EBest Circuit (Best Technology)’s core advantages

- 20+ years of experience in metal dome and array manufacturing, serving global industrial, automotive, and medical customers

- ±0.05 mm array alignment accuracy, ensuring high-speed assembly stability

- Design capability for over 1,000,000 press cycles

- Tape & Reel automated packaging solution, increasing assembly efficiency by more than 4 times

- Free initial samples + complete technical parameter package (including RoHS/REACH)

- 48-hour engineering response mechanism, with regular delivery within 7 days

Top 10 metal dome array manufacturers in Slovakia

| Company Name | Process Capability | Main Advantage |

|---|---|---|

| Best Circuit (Best Technology) Co., Ltd. | Metal dome stamping, array lamination, automated Tape & Reel packaging, SMT-compatible design | Focus on metal dome arrays, high precision, fast delivery, supports OEM/ODM |

| Foxconn Slovakia | EMS assembly, SMT, system integration | Strong large-scale manufacturing capability |

| Continental Automotive Slovakia | Automotive electronic module manufacturing | Automotive-grade quality system |

| Siemens Slovakia | Industrial electronics manufacturing | Rich experience in industrial controls |

| Bosch Slovakia | Electronic control unit production | High degree of automation |

| Delta Electronics Slovakia | Power supply and control module manufacturing | Strong stability |

| Visteon Slovakia | Automotive electronic systems | Automotive industry customer resources |

| ZKW Electronics | Electronic components and modules | Integration of optoelectronics and control systems |

| Sanmina Slovakia | EMS manufacturing | Global supply chain network |

| Kimball Electronics Slovakia | PCBA and electronic assembly | Flexibility for small/medium batches |

How to Choose a Slovakia Metal Dome Array Manufacturer?

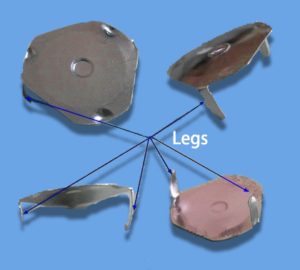

- Does the manufacturer possess engineering design capabilities for metal dome materials and rebound curves?

- Does it support array tolerance control and compatibility with automated assembly?

- Does it provide life cycle testing and consistent pressure force data?

- Does it have certifications such as RoHS / REACH / ISO9001?

- Does it support small-batch trial production to large-scale mass production?

- Can it provide stable delivery times and long-term supply capabilities?

Why is EBest Circuit (Best Technology) the best choice?

Since 2006, EBest Circuit (Best Technology) has focused on metal dome and array products, possessing not only a mature mold and material database but also a complete reliability testing system (force decay, fatigue life, environmental adaptability).

We can participate in array layout optimization during the design phase, reducing the number of PCB revisions for customers; during the manufacturing phase, we use automated assembly and Tape & Reel packaging to ensure high consistency and low defect rates; during the delivery phase, we provide clear batch traceability and technical document support to meet the quality audit requirements of international customers.

Core Pain Points of Slovakia Metal Dome Array Manufacturers

- Lack of professionalism, only capable of simple assembly, lacking metal dome engineering design capabilities

- Weak array precision control, high assembly offset rate

- Poor production batch stability, noticeable fluctuations in tactile feel

- Delivery times are greatly affected by raw materials and labor

- Incomplete international certifications and technical documentation

EBest Circuit (Best Technology)’s Solution:

- Ensuring consistent force and rebound through our own mold and material selection system

- Adopting a ±0.05 mm precision array design standard

- Fully automated assembly process to reduce human error

- Long-term inventory of key materials to avoid supply interruptions

- Standardized output of complete compliance and test documents to support quick customer audits

How to Analyze the Production Capacity of a Slovakia Metal Dome Array Manufacturer?

- Monthly production capacity (pcs / arrays)

- Ratio of automated equipment

- Mold development capabilities

- Material types and inventory stability

- Yield and rework rate

- Does it support multi-specification parallel production?

- Size of the engineering team

EBest Circuit (Best Technology) has mature metal dome stamping lines, array bonding lines, and Tape & Reel automated packaging lines, capable of handling multiple specifications simultaneously while maintaining stable yield and scalable delivery capabilities.

How to Evaluate the Delivery Time of a Slovakia Metal Dome Array Manufacturer?

- Is the sampling cycle clearly defined?

- Is the mass production schedule transparent?

- Does the manufacturer have its own raw material inventory? Do you support expedited orders?

- Is your logistics solution well-established?

- Do you provide periodic progress updates?

EBest Circuit (Best Technology) completes sample or urgent batch deliveries within 2-3 days for regular projects, and provides stable mass production cycles and international logistics support to help customers quickly advance project milestones.

Slovakia Metal Dome Array Manufacturer Frequently Asked Questions (FAQ)

- Q1: Are small batch orders likely to be rejected?

A: Many local manufacturers prefer large-volume orders, while EBest Circuit (Best Technology) supports orders ranging from dozens of samples to millions of units in mass production.

- Q2: What if the tactile feel is inconsistent?

A: This requires control over material thickness, heat treatment, and stamping precision. We provide complete test data for comparison.

- Q3: How to solve the problem of array misalignment during assembly?

A: Using Tape & Reel and standardized positioning hole design can significantly reduce the risk of misalignment.

- Q4: How to confirm the reliability of the lifespan?

A: Require the supplier to provide a million-cycle press test report and batch sampling mechanism.

- Q5: Are international certifications necessary?

A: This is crucial for export products. It is recommended to choose a manufacturer that provides ROHS/REACH and ISO system certifications.

Conclusion:

If you are looking for one of the top 10 metal dome array manufacturers in Slovakia, you should not only consider the scale of local electronics manufacturing companies but also evaluate their professional expertise and long-term stability in the field of metal dome arrays.

Choosing a partner with engineering design, automated manufacturing, and rapid delivery capabilities will significantly reduce project risks and improve product quality. For customers seeking high consistency, long lifespan, and fast delivery, EBest Circuit (Best Technology) remains one of the most competitive choices globally.