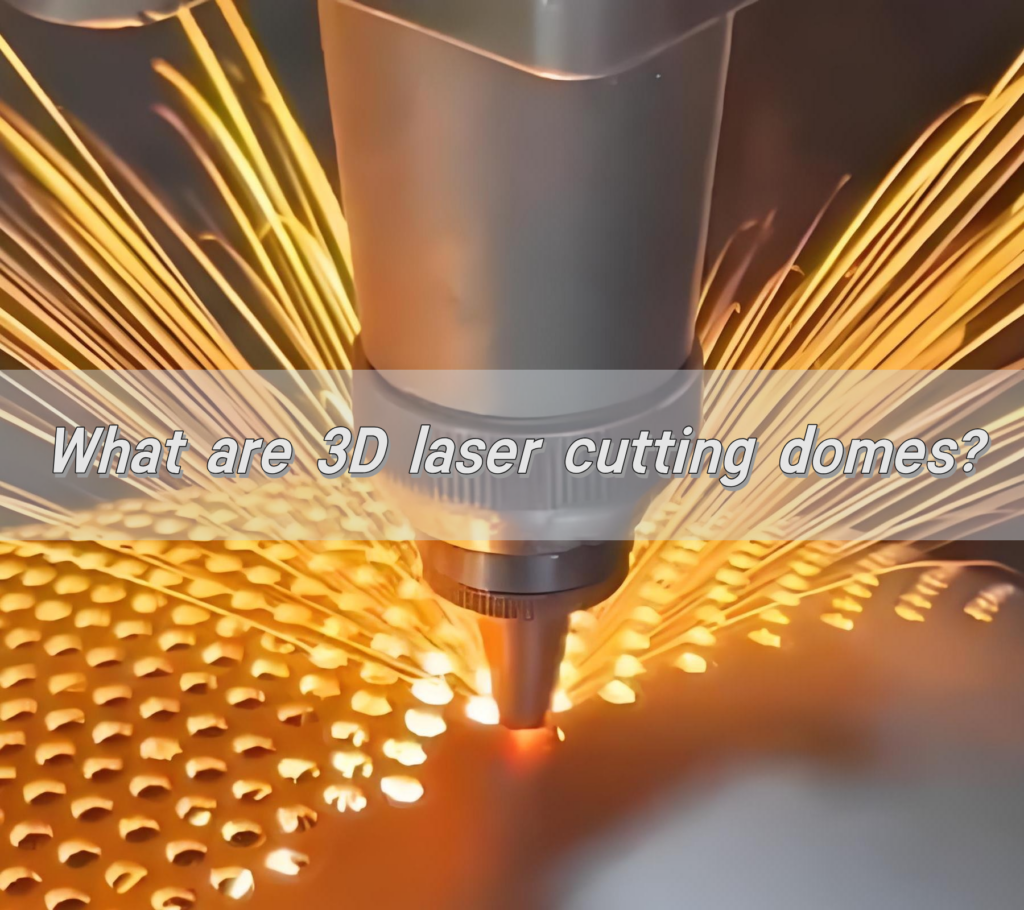

3D laser cutting domes are metal dome made using advanced laser technology. Its manufacturing process uses a high-precision laser beam to cut metal materials in three dimensions to achieve complex shapes and high-precision designs. This technology not only improves the accuracy and consistency of the dome, but also can cut complex geometric shapes that are difficult to achieve with traditional methods. It is widely used in electronic equipment, automotive manufacturing, aerospace and other fields.

What are the methods for cutting metal dome?

Cutting metal domes requires extraordinary accuracy. Traditional methods like mechanical punching and stamping have long been the industry standard. These approaches are reliable but come with limitations—like tool wear, restricted design flexibility, and slower output. Chemical etching and die cutting also make the list, offering cleaner edges and finer details.

However, they still face challenges in speed and adaptability, especially for complex shapes.

Then comes 3D laser cutting. Unlike older methods, it doesn’t rely on physical force or molds. It uses focused laser beams to slice through metal with incredible accuracy.

How does 3D laser cutting work for domes?

A highly focused laser beam targets the metal sheet, guided by computer-controlled paths. This beam vaporizes material along exact lines, achieving ultra-precise cuts. The whole process is contact-free. That means no pressure, no deformation, and no damage to surrounding surfaces.

For domes, which are tiny and highly sensitive, this is vital. The beam can maneuver in three dimensions, creating both flat and curved profiles.

So, even the smallest dome designs can be executed with surgical precision. And it all happens in one smooth, uninterrupted flow.

Can 3D laser cutting create custom dome shapes?

Absolutely. That’s one of its biggest strengths. 3D laser cutting doesn’t just follow a template. It reads digital designs and turns them into reality—fast.

This flexibility allows BEST Technology to create dome switches that align perfectly with unique application needs. Whether for a medical device, military equipment, or automotive controls, custom shapes are now easy to produce without added tooling costs. And since it’s all digital, you can modify designs on the fly.

What are the benefits of 3D laser cutting for domes?

Let’s start with precision. Every cut is perfect—clean, sharp, and free of defects. This improves tactile response, which is critical in dome switches. Next, there’s speed.

Compared to manual or semi-automated methods, laser cutting slashes production time. No molds. No setup delays. Just load the file and start cutting.

Then there’s consistency. Every dome looks and feels exactly like the last one. That’s crucial for large production runs. You also get material efficiency.

Laser paths are optimized to reduce waste, saving money and cutting down on environmental impact. On top of that, there’s almost zero maintenance. Unlike mechanical dies, laser heads don’t degrade with each use.

In short, you get higher quality, faster production, and lower costs. That’s the power of 3D laser cutting.

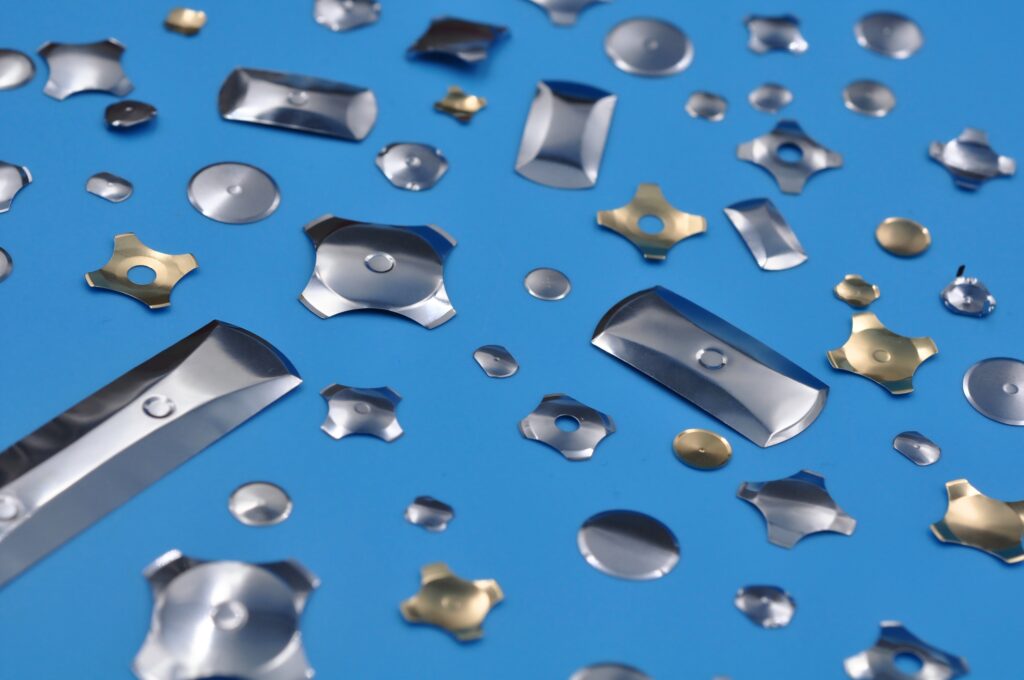

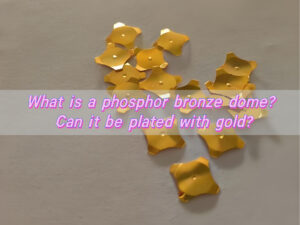

What types of domes can be produced by 3D laser cutting?

Thanks to its flexibility, this technology can produce nearly every type of metal dome. Round domes, four-leg domes, triangle domes, cross domes, and custom profiles—all can be shaped precisely.

The thickness of the metal doesn’t pose a problem either. Whether working with ultra-thin stainless steel or thicker metal layers for more robust switches, the laser adapts without breaking a sweat. This means it can produce domes for both light-touch applications and heavy-duty environments.

What is the production speed of 3D laser cutting domes?

Since there’s no need for tooling changes, each new batch begins almost instantly. Transitioning between designs is seamless, cutting down downtime to almost zero. A high-powered laser can cut thousands of domes per hour—flawlessly.

Compared to traditional punching or stamping, this is a massive leap forward. You get faster turnaround, greater throughput, and the ability to scale up production quickly without sacrificing quality.

Does 3D laser cutting improve dome switch quality?

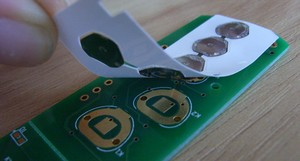

Yes, and dramatically so. Let’s start with edges—laser-cut domes have cleaner, smoother edges that eliminate burrs. This ensures safer handling and better user experience. Each dome also has uniform thickness and pressure points, which results in consistent tactile feedback.

Furthermore, laser-cutting reduces mechanical stress. Traditional methods often deform edges or weaken the dome over time. With 3D laser cutting, the structure stays intact. That leads to longer life cycles, more reliable switches, and a better end product.

What industries use 3D laser cut domes?

Nearly every high-performance industry today taps into this technology. The automotive industry uses laser-cut domes in dashboards and control panels. They demand fast response and durability—something 3D laser cutting delivers with ease.

Medical devices rely heavily on tactile feedback. Here, precision isn’t just a feature—it’s a necessity. From diagnostic machines to surgical equipment, 3D laser-cut domes help ensure accuracy and safety.

Consumer electronics also benefit. Smartphones, wearables, and remote controls use these domes for their responsive touch. And let’s not forget industrial equipment. Heavy-duty machines need dome switches that can survive rough environments without failure. With 3D laser-cut domes, reliability is built-in.

Even the military and aerospace sectors lean on this tech for mission-critical controls where every press counts.

Conclusion:

3D laser cutting domes are revolutionizing the way we manufacture tactile components. Unlike older methods, this technique offers precision, speed, and adaptability in one complete package. Whether it’s creating intricate custom designs, boosting production efficiency, or ensuring every dome meets the highest quality standards, this technology is raising the bar across every industry.

If you’re ready to elevate your product’s performance with next-gen dome solutions, reach out to us. Contact us at: sales@metal-domes.com