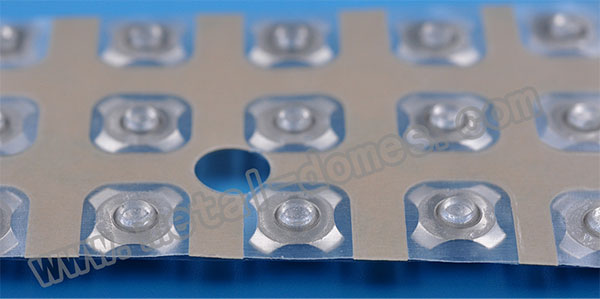

Namely, 3M adhesive dome array uses the 3M adhesive instead of the common adhesive used in the dome array. 3M adhesive is a little bit thick. Some of them even have the ability of high temperature resistance. So, it should be produced by opening a mold, while cannot be processed by laser. The processing steps are as follows.

The process of manufacturing the 3M adhesive dome array:

- Cover one side of the double-side non-adhesive PET with the 3M adhesive.

- Punch the dome holes.

- Cover with Mylar.

- Punch the outline.

And it is noteworthy that although the material used is 3M adhesive, whose viscosity is better, it is indistinguishable from appearance compared with the dome array using common adhesive on account of its transparent color.

Moreover, the model of 3M adhesive dome array can be customized depending on clientâs request. But on account of the difference of the specific type and minimum order quantity, it does not necessarily fit with non-adhesive PET, hence circumstances after cases.

At Best Technology, with more than 15 years of experience, we are fully equipped to handle your metal dome or dome array manufacturing requirements. In case if you have any questions, please feel free to contact us via email at sales@metal-domes.com or call us on +86-755 2909-1601/1602/1603.