What is a dome switch in arcade machines?

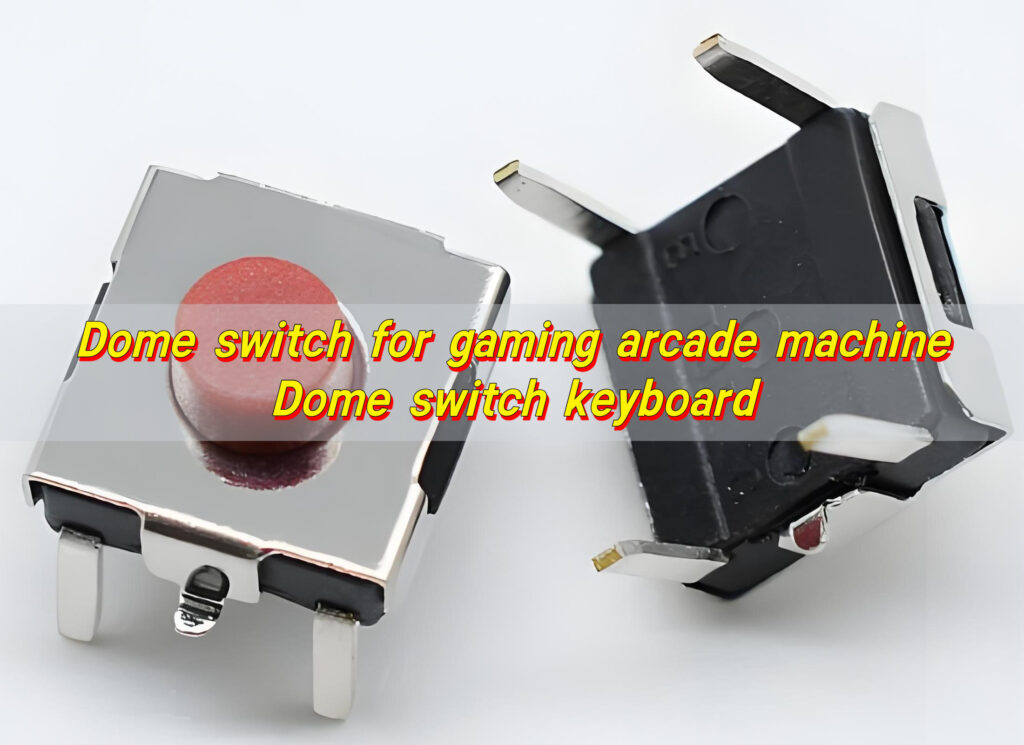

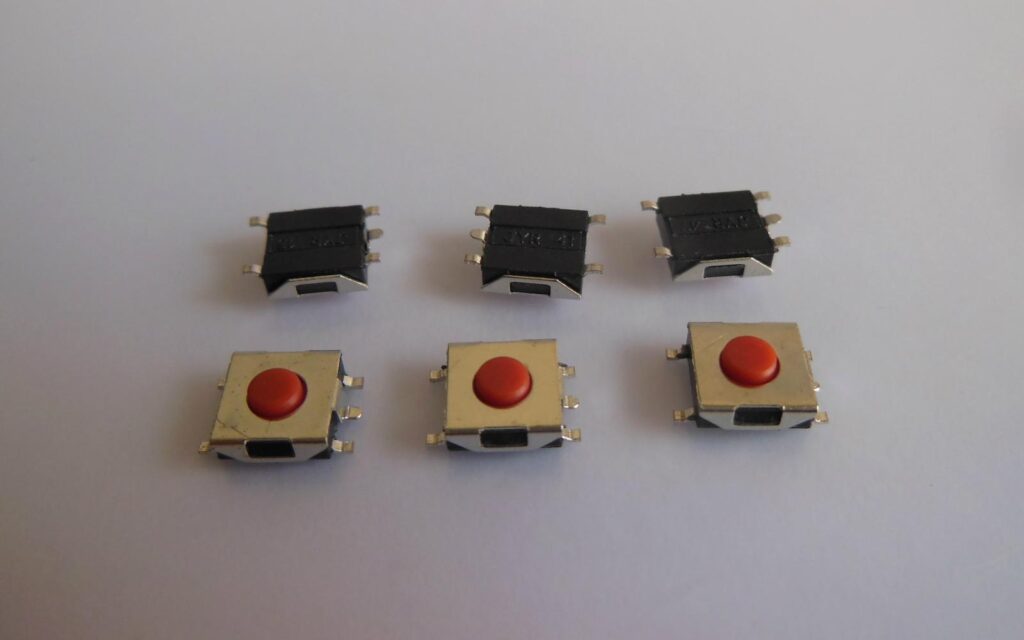

Dome switch is a small metal or polyester dome used as a switch element. When pressed, it completes an electrical circuit and sends a signal to the game board. The shape of the dome allows it to snap back to its original position after release.

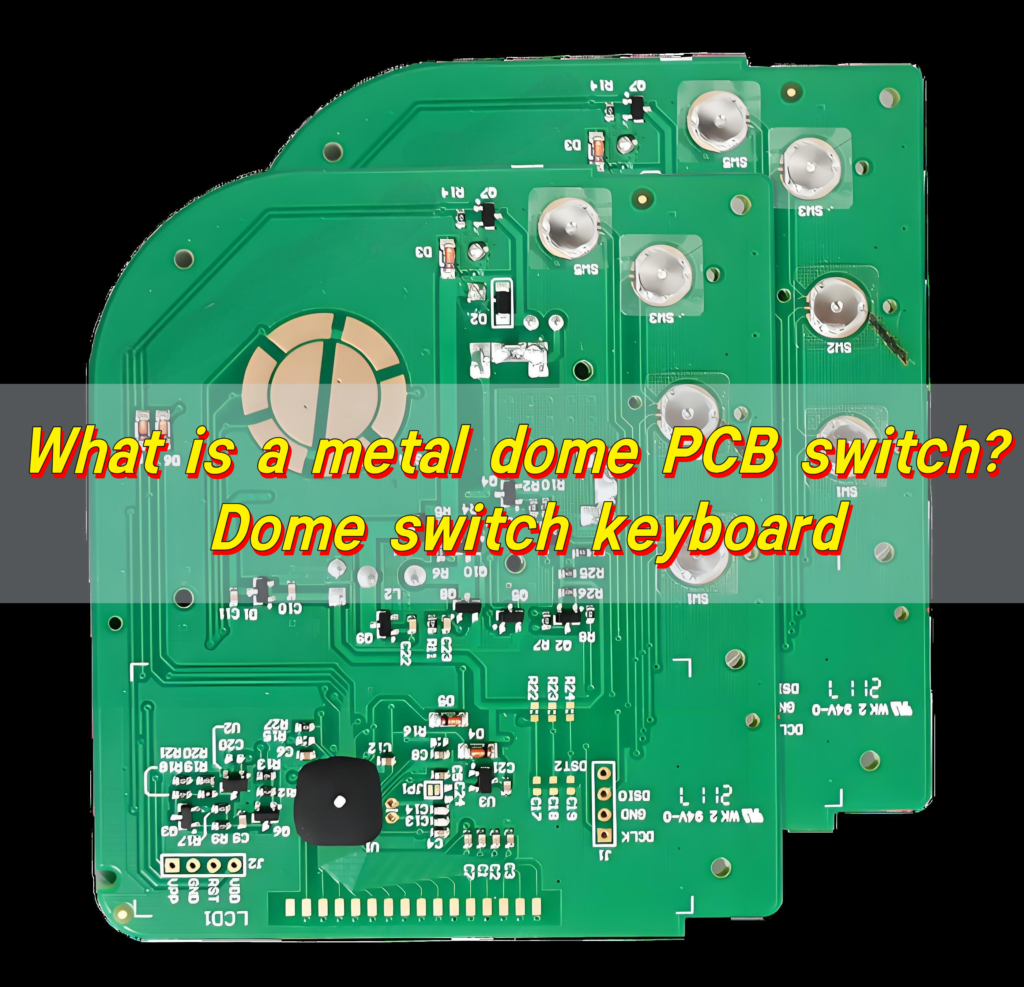

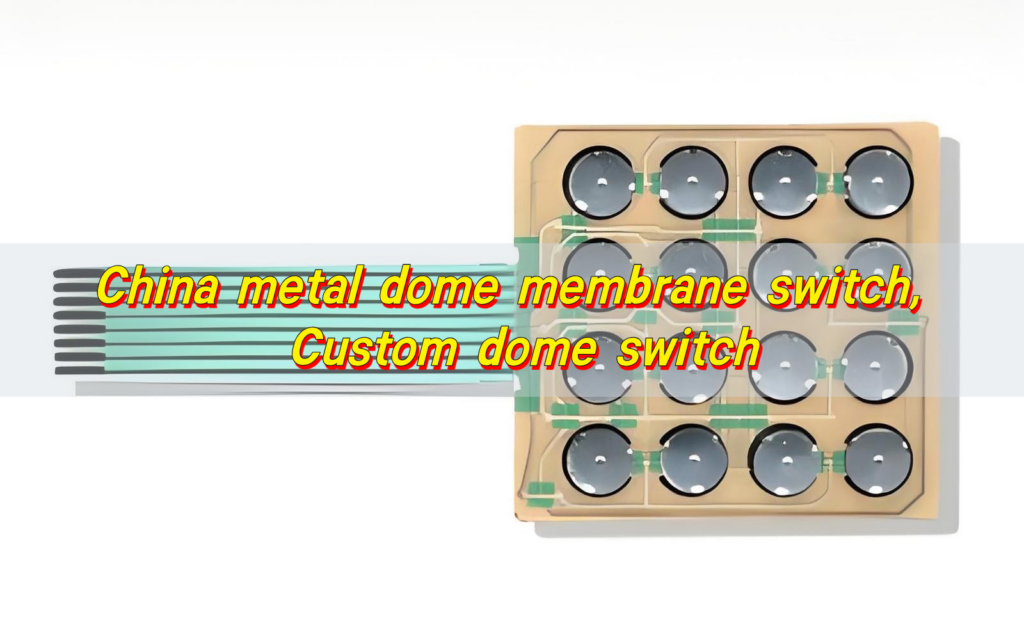

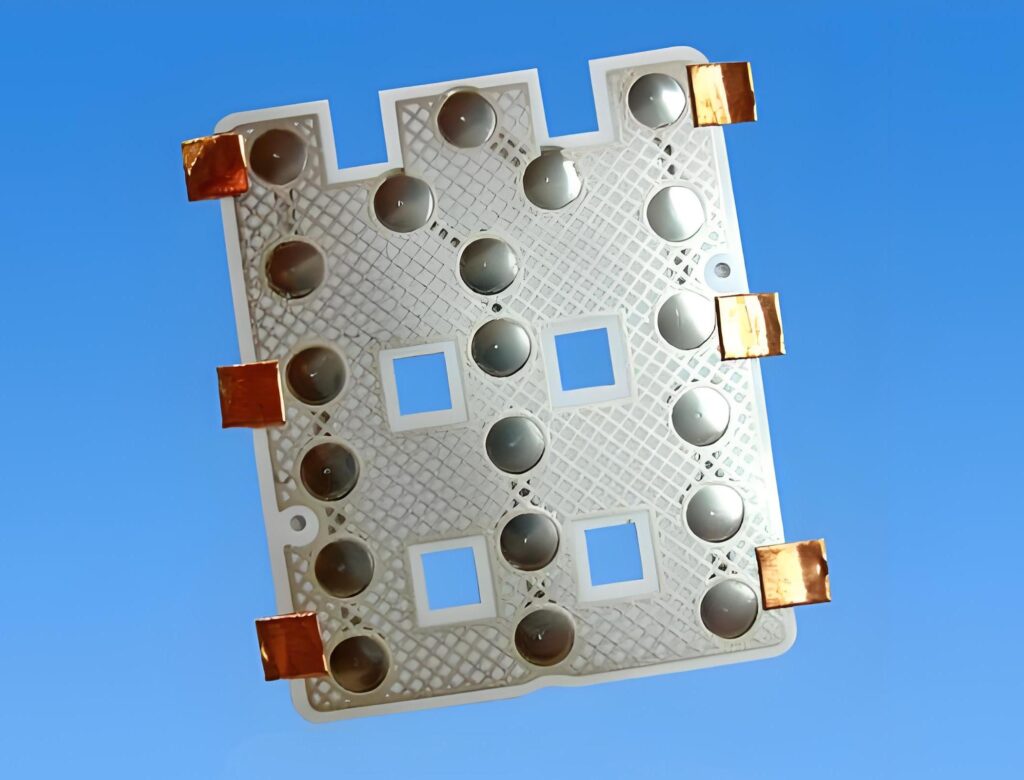

Arcade machines often use a dome switch keyboard. Here, several dome switches are arranged on a panel. Each dome represents a button for a specific function like shoot, move, or jump. These keyboards are compact, reliable, and built for heavy use in gaming environments.

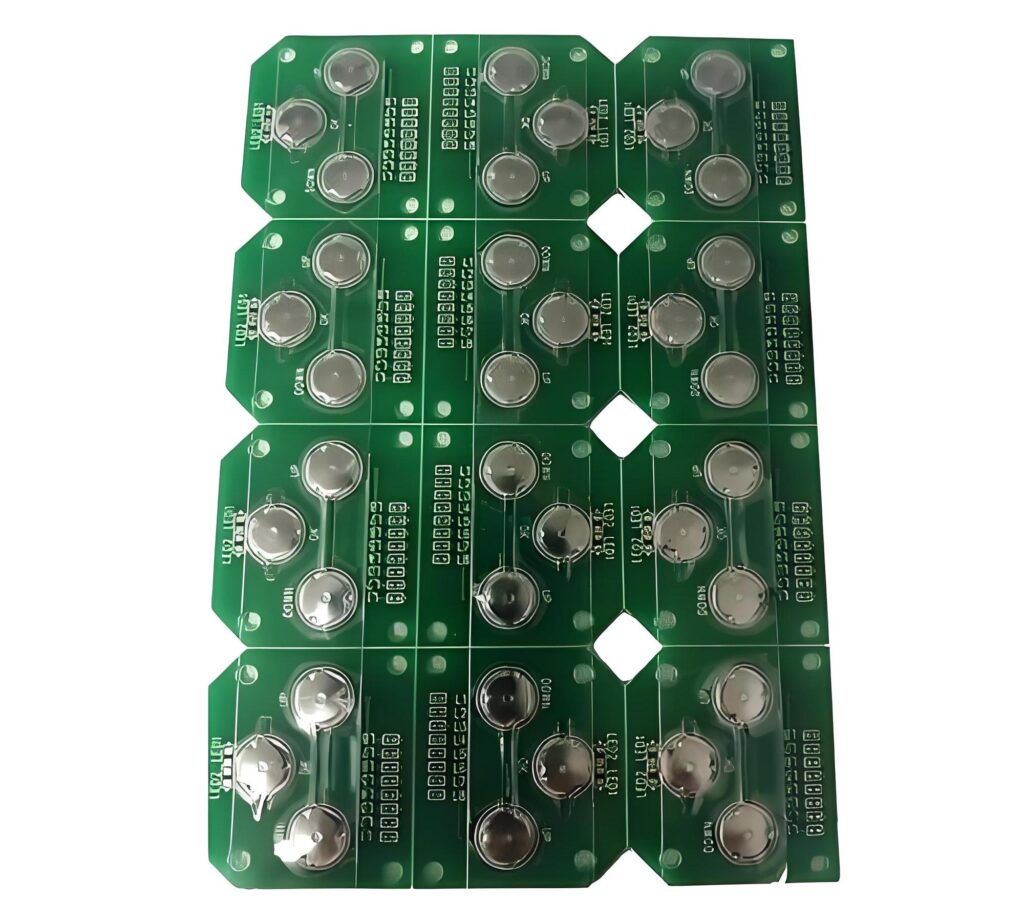

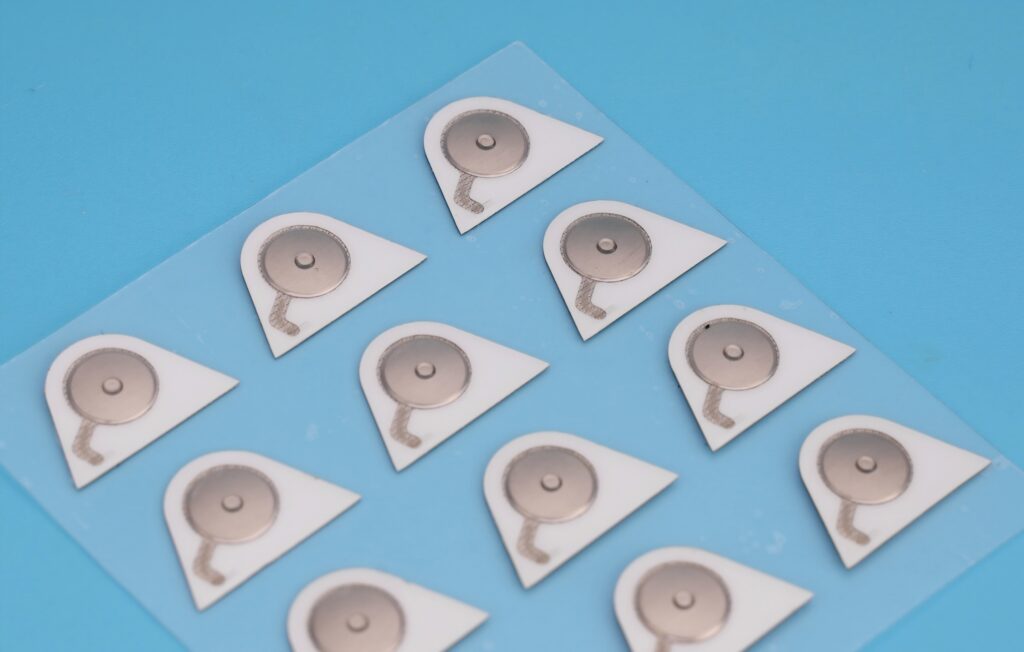

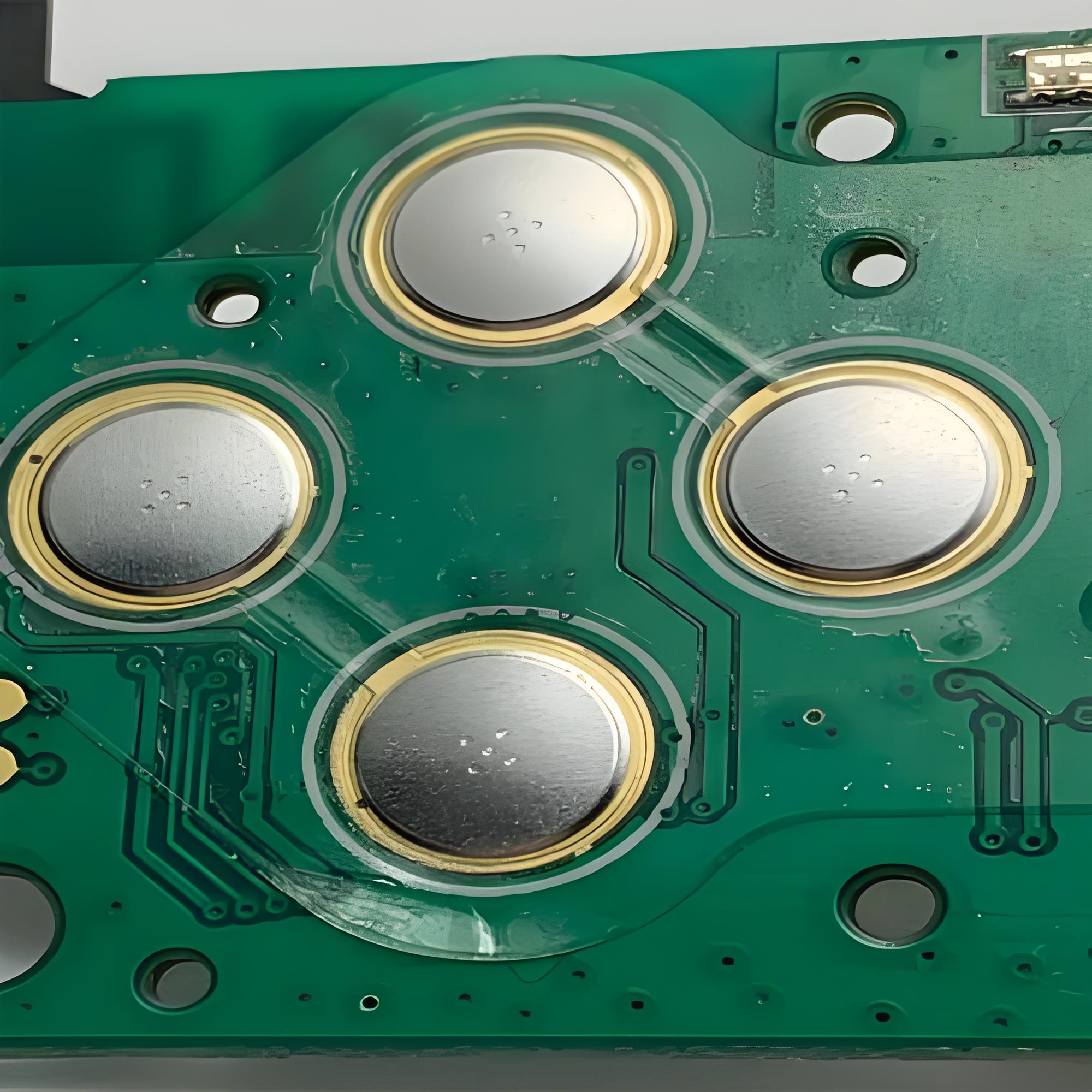

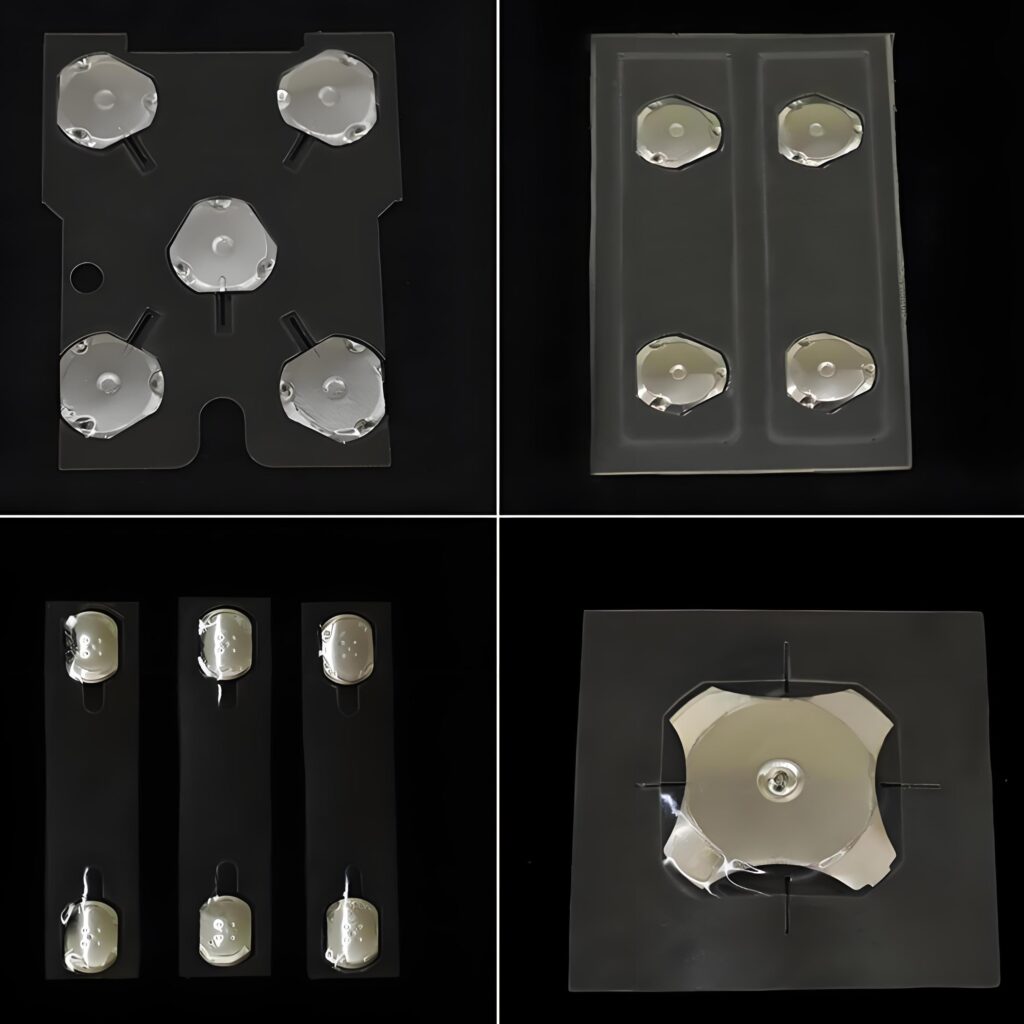

The switch itself is made with precise design. Metal domes, usually stainless steel, are common because of their high durability, fast response, and consistent tactile feel. They are placed on a PCB or flexible circuit with adhesive tape or mounted under overlays.

Unlike standard buttons that rely on springs, dome switches give a direct tactile response. This response is essential for gamers. It confirms every action instantly without delay.

Why use dome switches for arcade gaming?

Arcade machines face intense and repeated use every day. Players hit buttons hard during long gaming sessions. So, components need to be tough and reliable. Dome switches meet these requirements perfectly.

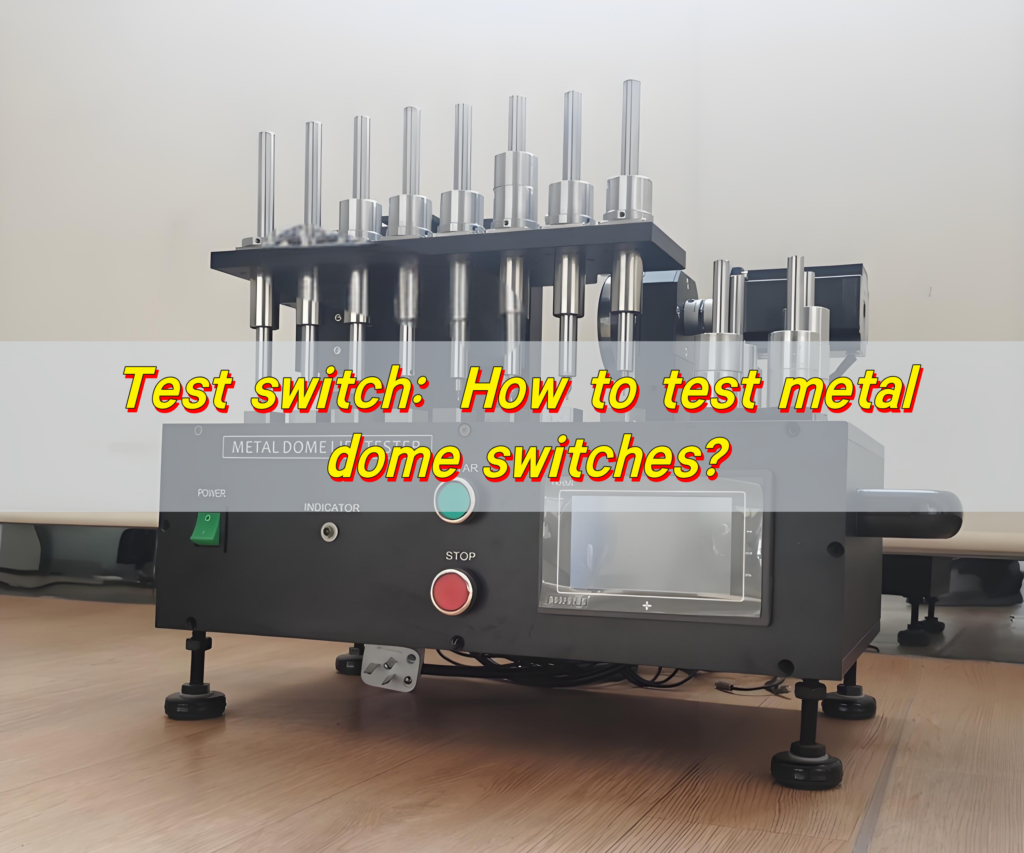

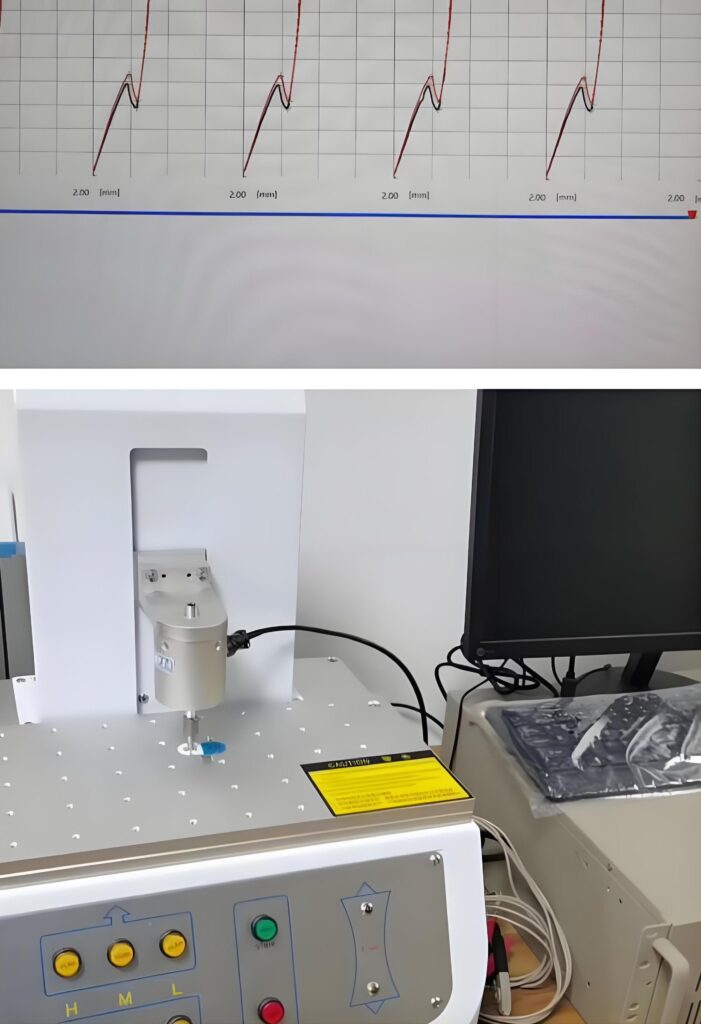

- High Reliability: A dome switch lasts for millions of cycles. Even under constant pressure, it stays responsive.

- Consistent Performance: Dome switches deliver fast, consistent signals every time. A slight delay or missed input ruins the experience.

- Compact and Lightweight: Arcade control panels need multiple buttons. Dome switches allow compact layouts without adding extra bulk.

- Low Cost with High Value: Compared to complex mechanical systems, dome switches are affordable yet durable.

- Better Player Experience: Smooth, responsive buttons keep players happy.

Do dome switches give good tactile feedback?

Yes! Tactile feedback is one of the biggest reasons dome switches are popular in arcade machines. When a player presses a button, the dome snaps and gives a noticeable click feel.

Without tactile feedback, players may press harder or repeatedly, which can cause frustration. Dome switches remove that uncertainty. The audible click and crisp feel improve confidence in every move.

In fact, gamers love the feedback so much that many home arcade setups now also use dome switch keyboards.

Do dome switches last long in arcade machines?

Absolutely! Durability is a strong point of dome switches. Most metal dome switches are rated for 1 million to 10 million actuations. That means they can handle intense gaming environments for years.

Factors like humidity, dust, and temperature changes do not affect them much if they are well-sealed. BEST Technology often design dome switch keyboards with protective layers to keep moisture and dirt out.

Compared to traditional rubber switches, metal domes have a longer life span and better stability. Even after millions of presses, the tactile feel stays consistent.

Benefits of dome switch keyboards in gaming

Arcade game panels often use dome switch keyboards instead of individual switches. Here’s why:

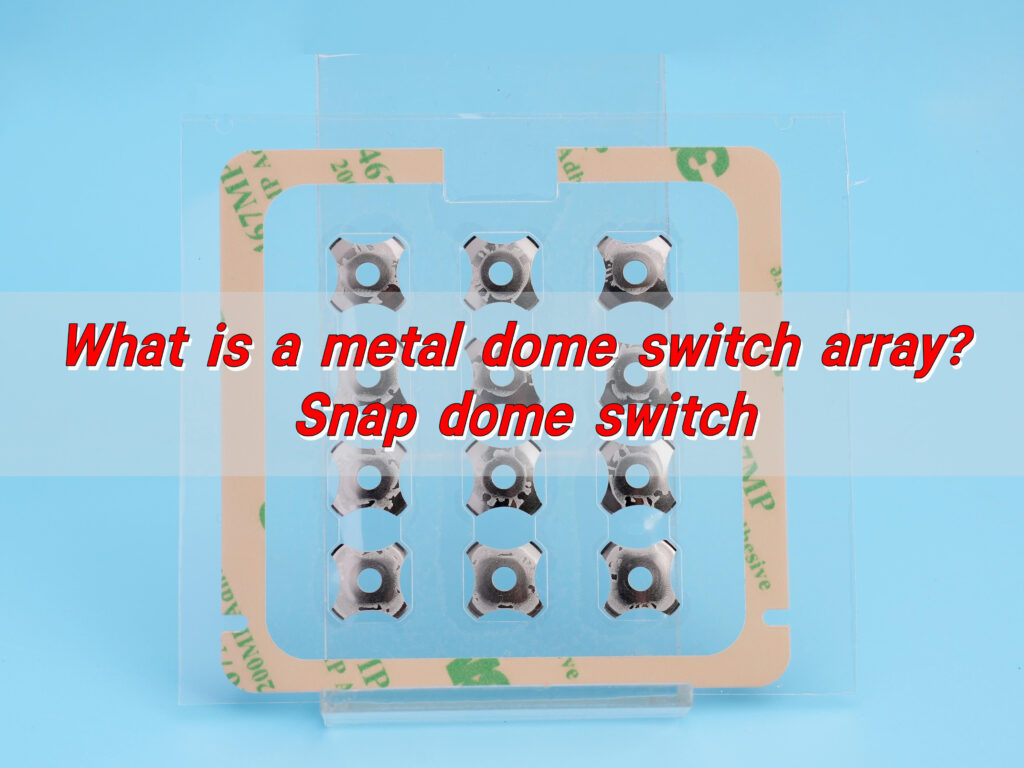

- 1. Multi-Button Layout

A dome switch keyboard can hold many domes on a single flexible circuit. This makes it easier to create custom layouts for different games.

- 2. Faster Assembly

Instead of installing many separate buttons, manufacturers mount one dome switch array. This saves time and ensures perfect alignment.

- 3. Cost Efficiency

Using a single keyboard with multiple domes reduces labor costs. It also makes repairs simple because the entire sheet can be replaced at once.

- 4. Better Sealing and Protection

A dome keyboard often comes with overlays that protect domes from dust and liquids. This keeps performance steady even in tough conditions.

- 5. Smooth and Responsive Controls

When a player hits the button, the dome reacts instantly. This makes gameplay fast, accurate, and enjoyable.

How does a dome switch improve game controls?

Game controls need to be quick and reliable. Dome switches help in multiple ways:

- Immediate Response: When pressed, the dome completes the circuit instantly. No lag.

- Accurate Inputs: Each dome is designed for a specific force, so every press feels the same.

- Less Player Fatigue: The actuation force is light but firm. Players can enjoy long sessions without finger strain.

- Smooth Gameplay: Consistent response means no missed moves during critical moments.

Arcade gaming is all about speed and precision. Dome switches provide both.

Dome switch vs mechanical switch: Which is better?

Many wonder whether dome switches or mechanical switches are better for arcade machines.

| Feature | Dome Switch | Mechanical Switch |

| Tactile Feedback | Crisp, noticeable snap | Strong click feel |

| Durability | Up to 10 million presses | Around 50 million presses |

| Cost | Lower | Higher |

| Size | Compact, slim | Bulkier |

| Maintenance | Low | Requires cleaning, repairs |

| Assembly | Easy with dome arrays | Requires individual mounting |

While mechanical switches last longer in some cases, they are expensive and bulky. Dome switches offer the perfect balance of performance, cost, and compactness. For arcade gaming, dome switches are often the preferred choice.

Conclusion:

Dome switches are the heart of arcade machine controls. They provide quick response, great tactile feedback, and long-lasting performance. Dome switch keyboards make assembly simple and improve the gaming experience. Compared to mechanical switches, they are lighter, cheaper, and easier to maintain.

If you need high-quality dome switches or dome switch keyboards for arcade machines, we can help. Contact us today: sales@metal-domes.com