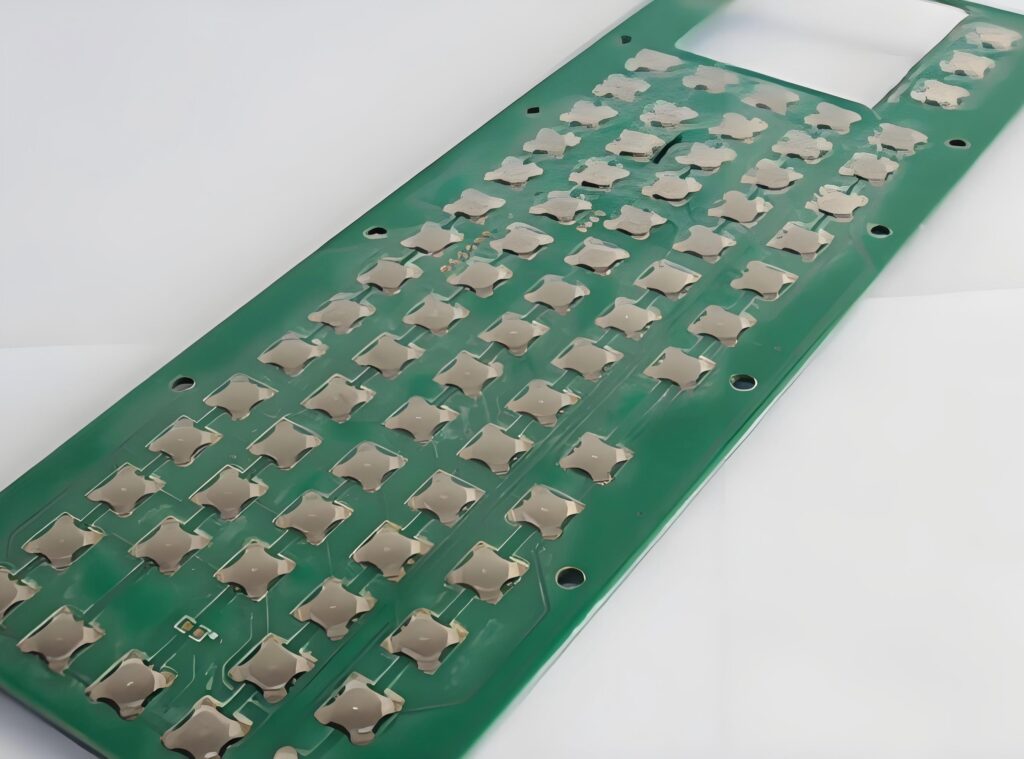

Industrial touch panels are vital in modern manufacturing and automation. They deliver precise control and smooth operation. A key part of their reliability is the Stainless Steel Metal Dome for Industrial Touch Panel, which provides strong tactile feedback and consistent response even in harsh environments.

What is an Industrial Touch Panel?

An industrial touch panel is a specialized interface used to operate machinery, monitor processes, and interact with automated systems. Unlike consumer touchscreens, industrial panels endure harsh conditions, including extreme temperatures, dust, moisture, and frequent heavy use.

These panels come in different formats, from simple resistive screens to advanced capacitive touchscreens. Regardless of the technology, industrial panels rely on components that provide tactile feedback, durability, and precise actuation.

Metal domes act as switches beneath the touch surface. When pressed, they provide a satisfying “snap” feeling. This feedback ensures operators know their input is registered without needing to look at the screen constantly.

Transitioning from traditional mechanical buttons to metal domes also helps reduce panel size, increase durability, and maintain consistent operation over millions of cycles.

Why Does the Industrial Touch Panel Use Metal Dome?

Metal domes, often called snap domes, are preferred in industrial touch panels for several reasons:

- Reliable Feedback: Every press produces a crisp tactile response, which is crucial for accurate operation in noisy or visually demanding environments.

- Longevity: Snap domes can withstand millions of presses without performance degradation, making them ideal for high-use industrial equipment.

- Low Actuation Force: They require minimal pressure to register a command. This reduces operator fatigue during extended use.

- Compact Design: Metal domes occupy less space than traditional mechanical buttons, allowing for sleeker panel designs.

- Moisture Resistance: Unlike mechanical switches, metal domes can function reliably even when the panel is exposed to dust, oil, or moisture.

The combination of tactile feedback, durability, and compactness makes metal domes the top choice for industrial panels.

Why is Stainless Steel Used for Metal Dome?

Stainless steel is the go-to material for high-quality metal domes. But why is it so widely preferred?

- Corrosion Resistance: Industrial environments often expose equipment to humidity, chemicals, and other corrosive elements. Stainless steel resists rust and maintains functionality.

- High Strength: Despite being thin and flexible, stainless steel withstands repeated pressing without deforming or breaking.

- Stable Electrical Properties: Stainless steel ensures consistent electrical conductivity, providing accurate signal registration every time.

- Temperature Tolerance: It performs reliably under extreme temperatures, whether in freezing warehouses or hot manufacturing lines.

- Hygienic and Cleanable: Stainless steel is easy to clean, making it suitable for medical, food processing, or laboratory applications where hygiene is critical.

Because of these qualities, stainless steel metal domes outperform many other materials, combining tactile excellence with long-term reliability.

What Are the Types of Metal Dome?

Metal domes come in various designs, each offering unique features tailored to industrial applications.

- 1. Round Domes

Round domes are the most common. They provide even tactile feedback across the entire surface and are suitable for standard industrial panels.

- 2. Square Domes

Square domes are excellent for panels that require precise alignment or larger button areas. They ensure consistent snap force across corners.

- 3. Triangle Domes

Triangle domes are ideal for small, high-precision buttons. Their shape allows for stable contact even with limited pressing surface.

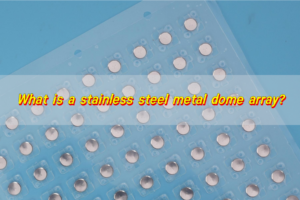

- 4. Array Domes

Array domes come in sheets or tapes and can be mounted as a complete unit. They are ideal for keypads or panels with multiple buttons in a compact layout.

- 5. High-Force Domes

Some industrial applications require a stronger actuation force to prevent accidental presses. High-force domes are designed for such environments.

- 6. Low-Force Domes

For touch panels used in delicate operations, low-force domes reduce strain and improve ease of use.

Selecting the correct type depends on your panel layout, required feedback, and environmental conditions.

Which Metal Dome Suits High-Precision Industrial Panels?

For panels with tight spacing or multiple inputs, consider array domes. These come pre-aligned on a tape or sheet, ensuring precise placement and uniform feedback across all buttons.

Snap domes with low or medium actuation force are ideal for control panels that require frequent pressing without operator fatigue.

Transitioning from individual domes to an array solution also speeds up assembly and reduces errors.

What Are the Benefits of Using Metal Dome?

Investing in quality metal domes brings multiple advantages:

- Consistent Tactile Feedback: Operators feel a sharp, reliable “snap” every time.

- High Durability: Millions of actuation cycles without performance loss.

- Space Efficiency: Smaller footprint compared to mechanical switches.

- Environmental Resistance: Functionality is unaffected by dust, moisture, or oil.

- Easy Maintenance: Stainless steel surfaces are simple to clean and sterilize.

- Customizable: Dome shapes, sizes, and forces can be tailored to your panel.

- Cost-Effective: Reduced maintenance and longer lifespan lower overall operational costs.

Overall, metal domes enhance the user experience while ensuring industrial touch panels remain robust and reliable.

How to Select the Right Metal Dome for Your Touch Panel?

Choosing the right dome requires careful consideration of several factors:

- Actuation Force: Decide if your panel needs low, medium, or high-force feedback.

- Dome Shape: Round, square, or triangular shapes can affect tactile precision.

- Material: Stainless steel is the best for corrosion resistance and durability.

- Size and Layout: Ensure the dome fits within your panel’s design and button spacing.

- Environmental Conditions: High temperature, humidity, or chemical exposure should guide material and coating choices.

- Mounting Method: Tape & reel or sheet arrays provide easier assembly and precise alignment.

Consulting with an experienced manufacturer can help you match dome specifications to your panel requirements.

Why Trust Best Technology’s Stainless Steel Domes for Industrial Panels?

Best Technology has over 18 years of experience in designing and producing metal domes and arrays. We understand the unique demands of industrial touch panels.

Why Choose Us?

- Precision Engineering: Contact accuracy within ±0.05mm ensures perfect tactile response.

- High Durability: Domes can withstand over 1 million actuations.

- Labor & Cost Savings: Our tape & reel packaging increases assembly efficiency up to four times.

- Fast Delivery: Industry-leading 7-day turnaround for most orders.

- Certifications & Standards: All products meet ROHS/REACH and ISO9001:2015 standards.

- Full Technical Support: Free first sample with complete technical documentation and 48-hour response.

With Best Technology, you gain trustworthy, high-performance stainless steel domes tailored for industrial applications.

Conclusion:

Industrial touch panels using stainless steel metal domes ensures tactile accuracy, longevity, and resistance to harsh environments. From different shapes to custom arrays, these tiny components enhance every interaction while keeping maintenance low and efficiency high.

By partnering with Best Technology, you access superior domes that meet exacting industrial standards, deliver consistent feedback, and provide a smooth user experience.

For high-quality stainless steel metal domes for your industrial touch panels, contact us today at sales@metal-domes.com