When exploring Dome array manufacturers in Norway, it’s important to clarify that there aren’t many specialized dome array producers located directly in Norway (unlike in major electronics hubs in Asia or central Europe).

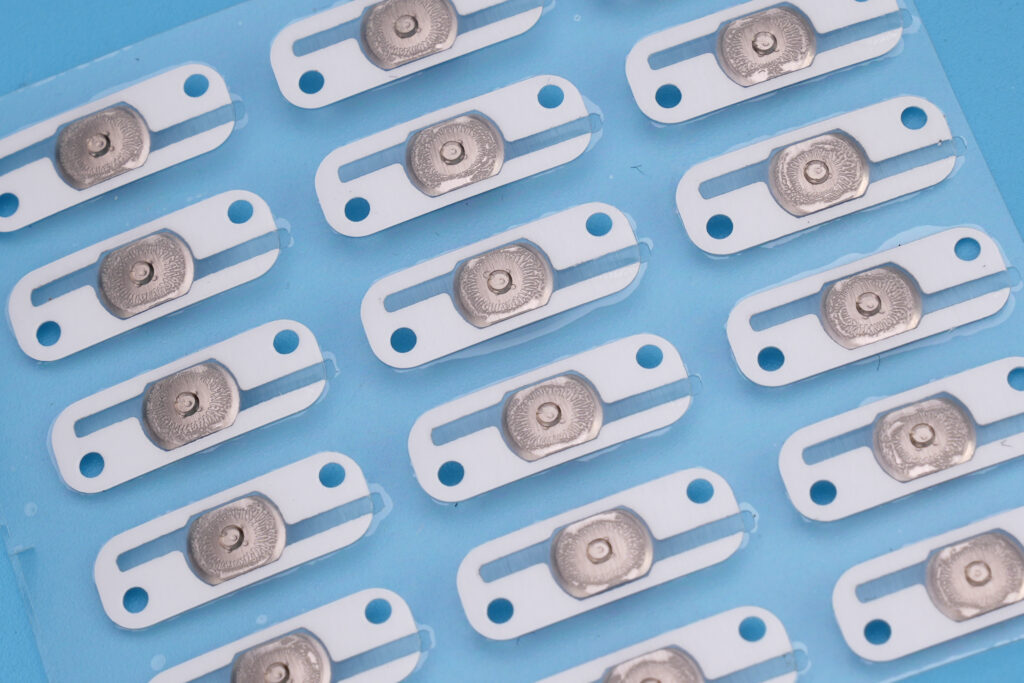

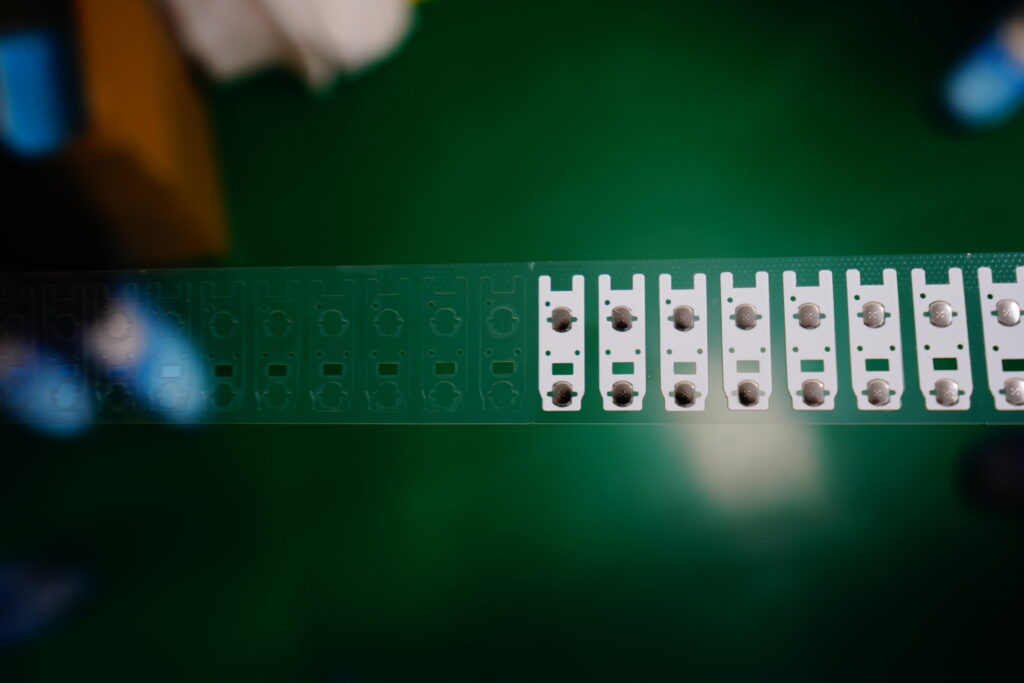

And EBest Circuit (Best Technology) is your best choice. As a professional metal dome and dome array manufacturer, EBest Circuit (Best Technology) offers full in-house capabilities covering dome forming, array layout design, adhesive lamination, and electrical performance testing.

Are you facing the following problems?

- Long prototyping cycles, repeated structural modifications without achieving a perfect design in one go

- Inconsistent metal dome tactile feel, significant variations in touch feel across batches

- Small batch orders are neglected, resulting in low communication efficiency and slow response times

- Large positioning deviations in high-precision arrays, affecting assembly yield

- Lack of complete material and reliability test reports, leading to high verification costs

End-to-end process guarantee from requirements to delivery – EBest Circuit (Best Technology)’s solution

As a manufacturer specializing in metal domes and dome arrays, we divide the project into five stages: requirements confirmation —> engineering evaluation —> sample verification —> mass production —> shipment tracking:

- Our engineering team directly interfaces with customer design files to proactively eliminate structural and assembly risks.

- We provide free initial samples and a complete technical parameter package (including RoHS/REACH).

- We use high-precision molds and automated assembly processes to ensure array consistency.

- Full SPC control throughout the mass production phase to avoid batch variations.

- Appearance, lifespan, rebound force, and packaging integrity testing are performed before shipment.

This process not only reduces the probability of project failure but also significantly shortens the product’s time to market, allowing customers to confidently entrust us with the production of their critical input devices.

Why choose us? EBest Circuit (Best Technology)’s core advantages

- 20+ years of experience in metal dome and array manufacturing, focusing on a single niche market with mature processes

- Array positioning accuracy of ±0.05mm, suitable for high-density assembly and automated production

- Lifespan exceeding 1 million presses, suitable for industrial and medical applications

- Supports OEM/ODM, customizable from structural design to packaging methods

- Tape & Reel high-speed packaging solution, increasing assembly efficiency by more than 4 times

- 48-hour technical response mechanism, ensuring rapid resolution of engineering issues

- These capabilities make us not just a supplier, but a long-term technical partner.

Top 10 dome array manufacturers in Norway

| Company Name | Process Capability | Main Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Metal dome stamping, array lamination, Tape & Reel packaging, automated inspection | High precision, fast delivery, supports large volume and customization |

| Norbit EMS | Electronic assembly, simple input modules | Local delivery convenience |

| Kitron ASA | Industrial electronics manufacturing | Complete quality system |

| NOTE Norway | Electronic manufacturing services (EMS) | Standardized project management |

| Westcontrol | Industrial control electronics | Small batch flexibility |

| Datek Smart Home | Electronic product integration | Strong design capability |

| Inission Norway | EMS manufacturing | Covers multiple industries |

| Elmatica | PCB and component supply | Supply chain integration |

| Scanmatic | Automation systems | Industrial background |

| Norautron | Aviation and industrial electronics | Experience in high-reliability fields |

How to choose a Norway dome array manufacturer?

- Does the manufacturer have specialized equipment for metal dome array production?

- Is the array bonding accuracy quantifiable?

- Does the manufacturer provide reliability and lifespan test data?

- Can they support automatic pick-and-place packaging (Tape & Reel)?

- Is engineering support directly available?

- Is the prototyping cycle controllable?

- Do they have stable international shipping experience?

Why is EBest Circuit (Best Technology) the best choice?

We have a mature system in each of the above areas: dedicated stamping dies, high-precision array fixtures, automated packaging lines, complete test reports, and years of experience working with European and American customers, enabling us to meet the core needs of both engineering and procurement.

Core Pain Points of Norway Dome Array Manufacturers

- High local production costs —> Reduce costs by 30-40% through large-scale manufacturing in China

- Insufficient process specialization —> Focus on the niche field of metal dome arrays

- Unstable batch consistency —> Automated bonding + SPC control

- Outdated packaging methods —> Provide Tape & Reel high-speed placement solutions

- Long technical communication cycles —> 48-hour engineering feedback mechanism

EBest Circuit (Best Technology) systematically solves these problems through vertically integrated manufacturing and automated processes.

How to analyze the production capacity of a Norway dome array manufacturer?

- Stamping equipment tonnage and precision

- Mold development capabilities

- Array bonding tolerance control

- Level of automation

- Daily and monthly production capacity

- Quality inspection process

- Raw material traceability

- Yield rate statistics method

Our capabilities:

EBest Circuit (Best Technology) has multiple dedicated stamping and array production lines, with a daily capacity of millions of domes, supporting simultaneous production of multiple specifications, and is under long-term control of the ISO9001 quality system.

How to evaluate the delivery time of a Norway dome array manufacturer?

- Is the prototyping cycle ? 5 days?

- Mold development time

- Batch production flexibility

- Raw material inventory strategy

- Do they support urgent orders?

- Does the packaging method affect delivery time?

- Is the shipping process standardized?

Our delivery capabilities:

Prototyping for regular projects can be completed in 2-3 days, batch orders can be quickly scheduled, and Tape & Reel products are always in stock, significantly shortening customer waiting times.

Frequently Asked Questions (FAQ) about Norway Dome Array Manufacturers

- Q1: What to do if the array edges curl after bonding?

A: The adhesive selection and bonding pressure parameters need to be optimized, and a flatness testing fixture should be used.

- Q2: Why do batch products have inconsistent tactile feel?

A: This is usually caused by stamping die wear or material batch variations. A die life management mechanism should be established.

- Q3: Is it worthwhile to outsource small-batch orders to overseas factories?

A: As long as engineering support is in place, small batches can also achieve stable quality and lower costs.

- Q4: How to ensure correct automatic placement direction?

A: Use Tape & Reel and design with polarity marking.

- Q5: What is the lifespan test standard for contact springs?

A: Industrial grade recommends ?500,000 cycles, and high-reliability applications recommend ?1,000,000 cycles.

Choosing the right partner is key to ensuring stable mass production. A systematic analysis of the Norwegian market shows that engineering capabilities, automation levels, and delivery time management are far more important than geographical location.

For companies seeking long-term stable supply, collaborating with dome array manufacturers in Norway with mature systems, or choosing equivalent international suppliers, will significantly reduce overall costs and project risks; and in the global supply chain environment, the evaluation standards for professional dome array manufacturers in Norway are gradually becoming more unified and transparent.