Russian dome array manufacturer are becoming reliable suppliers in the fields of electronic products and human-machine interface applications. We focus on stable actuation, durable metal domes, and customized array layouts to meet industrial and consumer device needs.

Are you facing the following problems?

- Excessively long prototyping cycles (more than 7 working days), causing project launch delays?

- Lagging response to customized design requirements, preventing accurate implementation of core functions?

- Low yield rates during manufacturing (below 95%), resulting in excessively high loss rates in mass production?

- Insufficient material compatibility, unable to meet special usage scenarios such as low temperatures and high humidity?

- Large fluctuations in delivery times, lack of flexible solutions for urgent orders?

- Weak after-sales technical support, unable to quickly troubleshoot and resolve product malfunctions?

Why Choose Us? (BEST Technology Core Advantages)

- Dual Guarantee of Local Manufacturing + International Standards: With 12 years of experience in the Russian market, our factory is certified by international standards such as ISO9001 and IPC-A-610. Our core processes meet Russian industrial-grade quality standards, balancing the stability of the local supply chain with global technical specifications.

- Rapid Prototyping Service: An industry-first 48-hour rapid prototyping service (standard specifications), with customized solutions delivered within 72 hours, shortening the cycle time by 50% compared to the industry average, facilitating rapid project validation.

- Full-Process Customization Capability: Our professional R&D team provides one-stop customized services for various fields, including medical, industrial control, and consumer electronics, from design optimization and material selection to process adaptation.

- Ultra-High Standard Quality Inspection System: Equipped with 3D optical inspection equipment (AOI) and an environmental reliability testing laboratory, we implement triple quality control: incoming material inspection, process inspection, and finished product inspection, ensuring a stable mass production yield of over 99.2%.

- Flexible Supply Chain and Delivery Guarantee: We have established a strong local supply chain with Russia. We have signed long-term agreements with key material suppliers and established an international backup supply chain, reducing delivery time for regular orders to 5-7 business days and providing 24-hour response for urgent orders.

- Lifetime technical after-sales support: We have a bilingual (Russian/English) technical team providing 7×12-hour online consultation and solutions for product malfunctions within 48 hours.

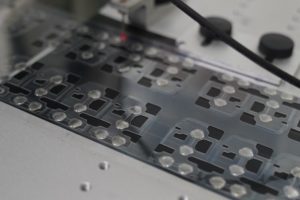

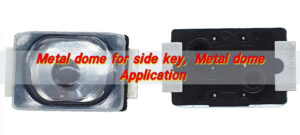

Russian Dome Array Manufacturer Examples

| Company Name | Process Capability | Core Advantages |

|---|---|---|

| BEST Technology | Supports 0.1mm-1.0mm travel Dome design; compatible with stainless steel/copper alloy materials; SMT placement accuracy ┬▒0.02mm; monthly mass production capacity of 5 million pieces. | Comprehensive international certifications; rapid prototyping and high customizability; strong supply chain flexibility; responsive after-sales service. |

| TechDome Russia | Focuses on 0.3mm-0.8mm standard travel products; supports conventional stainless steel materials; SMT placement accuracy ┬▒0.05mm; monthly mass production capacity of 3 million pieces. | Mature local supply chain; significant price advantage for standard products; stable delivery period (7-10 working days). |

| DomePro Manufacturing | Supports 0.2mm-0.9mm travel; compatible with copper alloy materials; capable of simple customization; monthly mass production capacity of 2 million pieces. | Cost-effective for small-batch orders; specializes in industrial control field products; high cost-performance ratio. |

| RusDome Solutions | Focuses on 0.4mm-1.0mm travel; supports stainless steel materials; SMT placement accuracy ┬▒0.04mm; monthly mass production capacity of 2.5 million pieces. | Close collaboration with local Russian electronics companies; fast localized service response; ample inventory of conventional products. |

| EuroDome Rus | Supports 0.3mm-0.7mm travel; compatible with various materials; holds ISO certification; monthly mass production capacity of 3.5 million pieces. | Extensive experience serving international clients; strict quality control; suitable for mid-to-high-end standard product requirements. |

How to Choose a Russian Dome Array Manufacturer?

Verify the manufacturer’s industrial-grade quality certifications, such as ISO9001 and IPC-A-610, and their compliance with Russian domestic industrial product regulations.

Confirm that the manufacturer’s process capabilities match your needs (e.g., stroke range, material compatibility, SMT placement accuracy, and other core parameters).

Evaluate the prototyping cycle and sample quality (prioritize manufacturers that can deliver samples within 72 hours with a sample yield of ?98%).

Examine the quality control system (whether the manufacturer has AOI inspection equipment, a reliability testing laboratory, and provides quality inspection reports).

Verify historical delivery time data (whether regular orders are ?10 working days, and whether there is a clear response mechanism for urgent orders).

Assess customization capabilities (whether the manufacturer has a professional R&D team and can provide design optimization suggestions).

Understand the level of after-sales support (response time, troubleshooting efficiency, and whether on-site service is provided).

Assess supply chain stability (whether there are backup material suppliers and contingency plans for raw material shortages).

Confirm cost transparency (whether a detailed quotation is provided, with no hidden fees, and whether there are tiered discounts for bulk orders). Refer to past client case studies (experience working with others in the same industry, client reputation, and repurchase rate).

Core Pain Points for Russian Dome Array Manufacturers

- Shortage of High-End Materials: Reliance on imports for core materials such as special-specification stainless steel and copper alloys, resulting in long procurement cycles and significant cost fluctuations.

- Low Yield in Precision Manufacturing: Processing micro-stroke products below 0.1mm is difficult, and insufficient SMT placement precision control leads to high loss rates in mass production.

- Lagging Customization Response: Lack of a professional R&D team hinders rapid adaptation to customized needs in complex scenarios (such as extreme environments or special sizes).

- Insufficient International Standard Certification: Some domestic manufacturers have not passed internationally recognized standard certifications such as IPC, making it difficult for their products to enter the supply chains of multinational corporations.

- High Costs for Small-Batch Orders: Insufficient production line flexibility leads to excessively high equipment setup costs for small-batch orders (below 1000 pieces), resulting in uncompetitive pricing.

- Limited Investment in Technological R&D: Insufficient investment in R&D for new material applications and process optimization results in product iteration speeds lagging behind international standards.

- Inefficient Cross-Border Logistics: Reliance on a single logistics channel makes international transportation prone to customs clearance delays and cargo damage. Outdated quality inspection equipment: Some manufacturers still use traditional testing equipment, which cannot meet the full inspection requirements of high-precision products, resulting in higher quality risks;

- Weak design collaboration capabilities: Lack of standardized processes for design collaboration with customers easily leads to incompatibility between design solutions and production processes;

- Inadequate handling of urgent orders: Rigid production scheduling and a lack of emergency production plans make it impossible to meet customers’ urgent replenishment needs.

How to assess the production capacity of Russian dome array manufacturers?

- Equipment Accuracy Level: Verify the brand and parameters of core equipment such as SMT placement machines and punch presses (e.g., whether the placement accuracy is ? ┬▒0.03mm);

- Material Supply Chain Stability: Understand the number of core material suppliers (at least 2 backup suppliers) and procurement cycle (general materials ? 3 working days);

- Yield Data Verification: Require the provision of batch production yield reports for the past 6 months, with core product yield needing ? 98%;

- Capacity Flexibility: Confirm the minimum order quantity (MOQ), maximum monthly capacity, and the ability to handle order volume fluctuations (┬▒50%);

- Process Engineering Documentation: Check for the existence of standardized process operation instructions (SOPs), design compatibility specifications, and other technical documents;

- Quality Control Process: Verify the specific processes and testing items for incoming quality control (IQC), in-process quality control (IPQC), and final quality control (FQC);

- R&D Team Configuration: Understand the number of R&D personnel, their industry experience, and whether they possess design optimization and new product development capabilities;

- Compliance Certifications: Confirm whether they have passed ISO9001 and IPC-A-610 certifications. Certifications and Russian domestic industrial product access qualifications are required.

- Production environment control: Inspection of the workshop’s temperature and humidity control (temperature 20┬▒2?, humidity 40%-60%), anti-static measures, and other production environment conditions is required.

- Sample testing capabilities: Reliability test reports for samples are required (e.g., button life ? 1 million cycles, temperature resistance range -40?~85?).

How to assess the delivery time of Russian Dome array manufacturers?

- Request historical delivery data: Require the average delivery time for regular orders over the past 12 months, and the late delivery rate (?3%);

- Understand order priority management: Confirm whether there is a priority mechanism for different customers and order types to avoid scheduling conflicts;

- Verify supply chain redundancy design: Confirm whether there is safety stock of core materials (enough to meet at least 15 days of production needs) and whether there are backup suppliers;

- Assess production scheduling transparency: Require the provision of order scheduling visualization tools (such as an online progress query system) to track production status in real time;

- Evaluate logistics partners: Understand the brand, transportation methods (such as air freight, land freight), and customs clearance experience of the logistics partners;

- Emergency order handling capability: Confirm the response time (?24 hours) and production cycle (50% of regular orders) for emergency orders;

- Inventory management strategy: Understand whether there is finished goods inventory of regular specifications and the inventory turnover rate (?12 times/year);

- Cross-border transportation contingency plan: Verify whether there are contingency plans to deal with logistics delays and customs clearance obstacles (such as alternative transportation routes and expedited customs clearance services); Delivery and Acceptance Process: Confirm whether product certificates of conformity, quality inspection reports, and other documents are provided upon delivery, and whether acceptance standards are clearly defined;

- Delay Compensation Mechanism: Verify whether there are clear clauses for compensation for delayed delivery (e.g., 1%-3% of the order amount for each working day of delay).

Frequently Asked Questions (FAQ + Solutions) for Russian Dome Array Manufacturers

- Q: Long prototyping cycles cause project verification delays?

A: Choose manufacturers that support rapid prototyping (such as BEST Technology’s 48-hour rapid prototyping service), provide detailed design drawings and requirements in advance, and prioritize manufacturers with spare material inventory.

- Q: Customized designs are incompatible with production processes, requiring repeated modifications?

A: Request design compatibility specifications from manufacturers before cooperation and conduct design reviews in advance; choose manufacturers with design optimization capabilities, and have a professional R&D team assist in adjusting design parameters to ensure compatibility with production processes.

- Q: Low yield and high loss rate in mass production?

A: Prioritize manufacturers equipped with AOI inspection equipment and a full-process quality inspection system; clearly define yield standards (e.g., ?98%) and loss compensation clauses in the contract; request manufacturers to provide process optimization solutions to reduce losses.

- Q: Frequent delivery delays affect downstream production plans?

A: Choose manufacturers with redundant supply chain designs and backup logistics channels; sign clear delivery date agreements and late payment compensation clauses; track order production progress in real time and reserve a 10%-15% buffer period in advance.

- Q: What if the product experiences performance failures in low temperature/high humidity environments?

A: Clarify the usage environment requirements before cooperation; choose manufacturers that support special materials (such as low-temperature resistant stainless steel) and have environmental reliability testing capabilities; request product temperature and humidity resistance test reports to ensure they meet the needs of the usage scenario.

- Q: What if after-sales technical support is slow to respond and faults cannot be resolved in a timely manner?

A: Choose manufacturers with professional technical teams that provide 7├Ś12-hour online consultation; confirm after-sales response time (?4 hours) and fault resolution cycle (?48 hours); for bulk orders, request manufacturers to provide free on-site debugging services.

- Q: What if small-batch orders are quoted too high, making cost control difficult?

A: Choose manufacturers with flexible production lines and low minimum order quantities (MOQ); negotiate with manufacturers to consolidate small batch orders for production and share equipment setup costs; for long-term cooperation, a framework agreement can be signed to lock in tiered pricing.