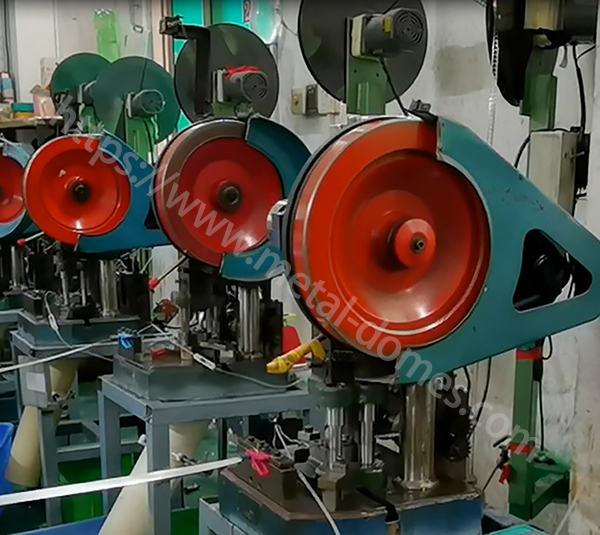

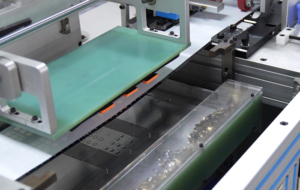

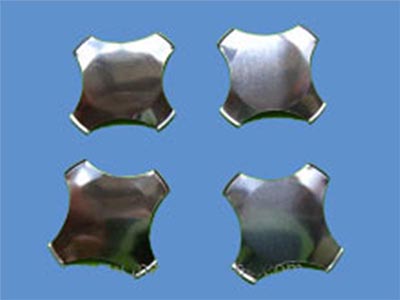

Normally we will use two types punching toolings to make metal dome: high speed tooling and low speed tooling, see below photos. Is there any difference in metal dome they produce? The answer is ” Yes”, there are many differences, please see below for more details.

- The stability of quality of dome switch is better with high speed tooling.

- The stamping speed is faster with high speed tooling, so lead time will be shorter. Normally 3-5 days for high speed tooling, 7-10 days for low speed tooling. Of course, we also need to depend on the production schedule and order quantity at that time.

- The life time is higher with high speed tooling. For example, for same diameter dome 12.2mm, 350g, the life times could be more than one million with high speed tooling, but only around 0.1 million times with low speed tooling.

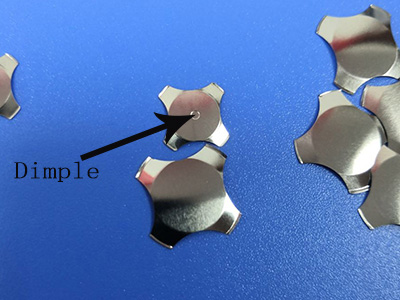

- The high-speed molding line is on the outside and the low-speed molding line is on the inside.

- The burr is smaller (around 0.3mm) with high speed tooling than low speed tooling (above 0.5mm).

- The cost of high speed tooling is around 10,000 USD-20,000USD, but the cost of low speed tooling is around 1,000 USD-5,000 USD

- The price of metal dome with high speed tooling is higher than low speed tooling, because of better quality.

In a word, when we choose a metal dome, we should not only pursue the price, but also look at other aspects, such as production technology, quality, delivery time and so on.

If you want to know more about metal dome, please don’t hesitate to contact us, Best Technology. We are always here, waiting for you.