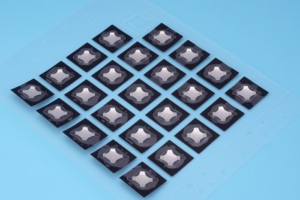

Recently, we got feedback fron one of our customers that found Plastic of Dome Switch bulge and peel off as below photo when production after assembly dome array on PCB, we could see the place from the red arrow. Why will have such issue happened? See the following analysis.

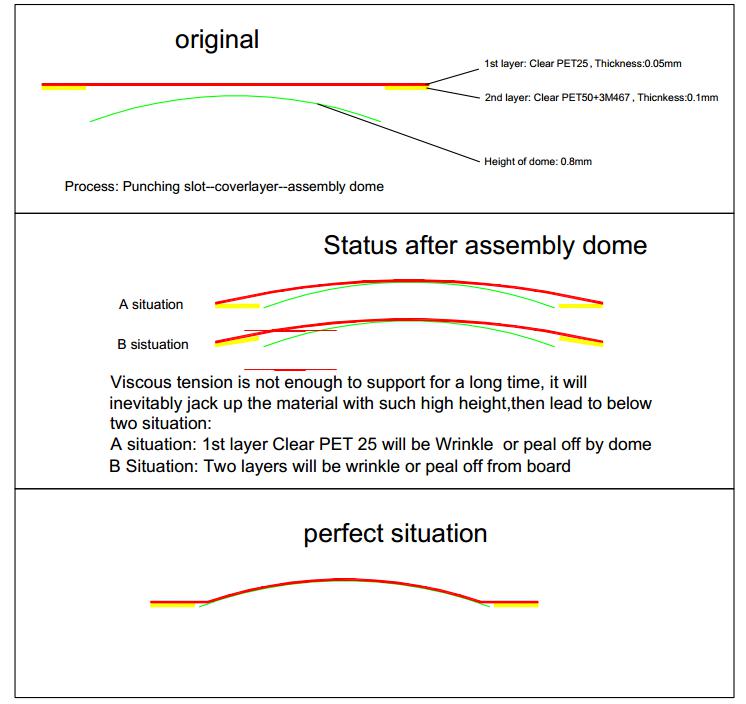

This is due to the product design flaws, it’s not the problem of the PET adhesive, two reasons below that lead to this issue:

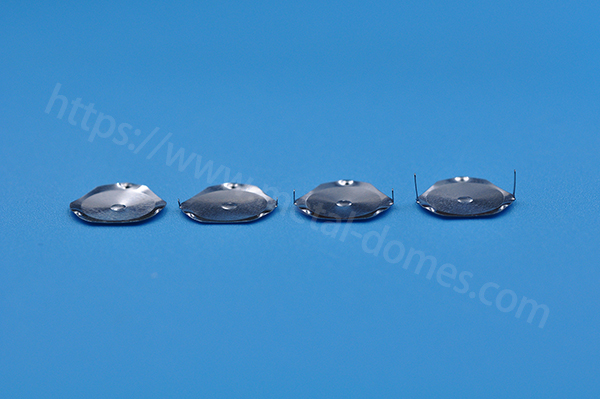

- The height of dome switch that used is around 0.75-0.80mm, it’s very high height.

- The adhesive tape area from metal dome to edge is only 0.40-0.60mm, you could see from above photo, and only cover a layer of PET with 0.05mm glue, viscous tension is not enough to support for a long time; It will inevitably jack up the material with such high dome height.

We can use the schematic diagram below to understand above issue. If we want to achieve the ideal, we need to use the right height of snap domel and the suitable adhesive tape size. If we want to solve this issue above, we could do below based on the actual situation:

- Drecease the height of metal dome, keep original adhesive tape size.

- Increase the adhesive tape size, keep the original height of metal dome

- Drecease the height of metal dome and Increase the adhesive tape size.