Need professional metal dome for aircraft cockpit control? We offer aviation-grade metal domes with excellent tactile feedback and durability.

What is a metal dome for aircraft cockpit control?

Metal dome for aircraft cockpit control is a precision-formed stainless steel dome used as a momentary switch contact. It sits between a printed circuit board and an overlay or keypad. When pressed, the dome collapses and completes an electrical circuit. When released, it returns to its original shape.

This action creates a clear tactile response. The user feels and hears a defined snap. That feedback confirms input without visual confirmation. In a cockpit, this is essential.

Unlike rubber contacts, metal domes offer stable force curves. They do not soften easily over time. They also handle environmental stress better.

Metal domes used in cockpit systems are not generic parts. They are engineered for aviation use. Shape, thickness, plating, and force are tightly controlled. The dome must actuate consistently for years.

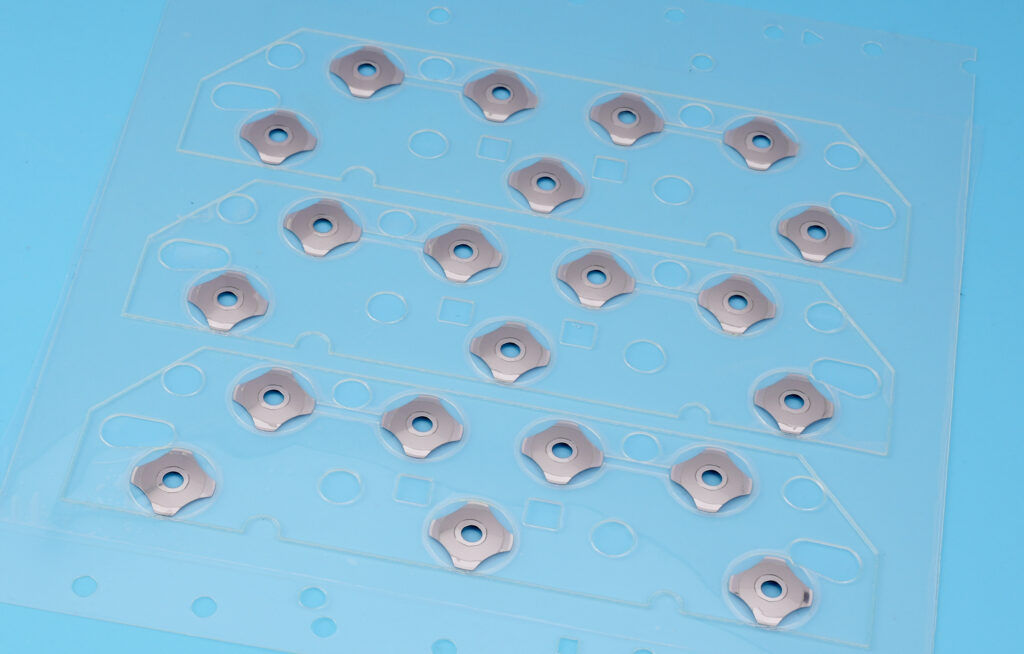

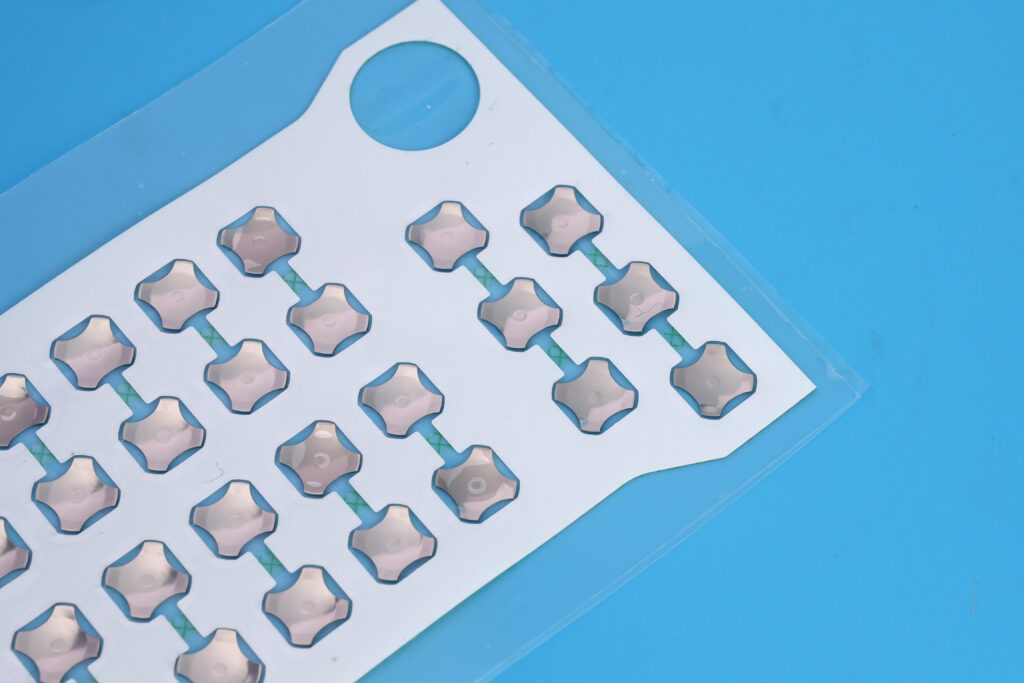

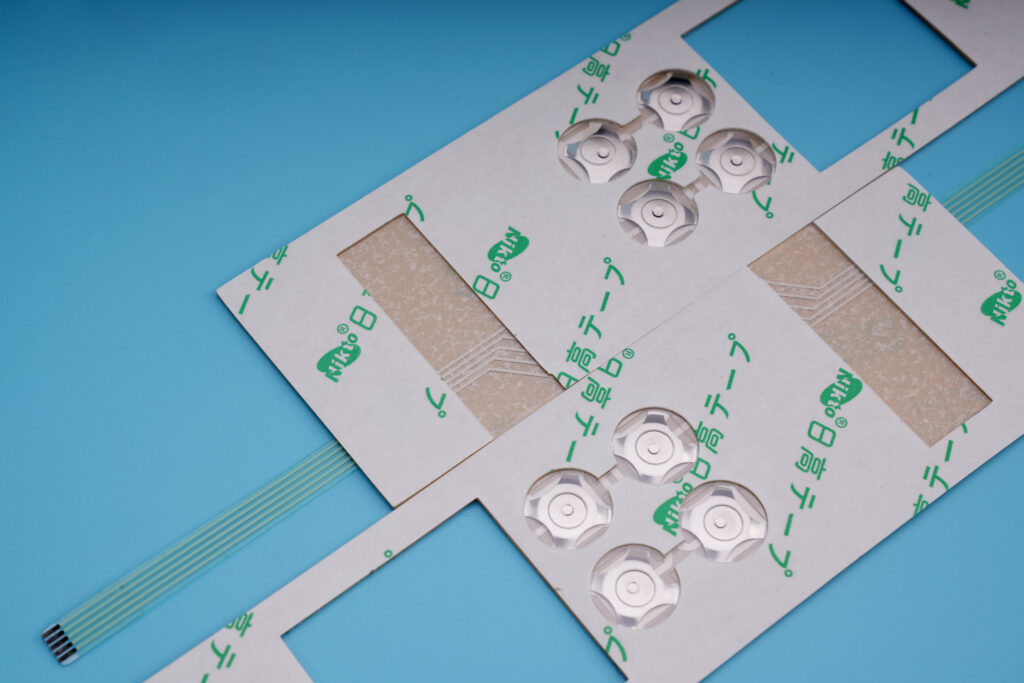

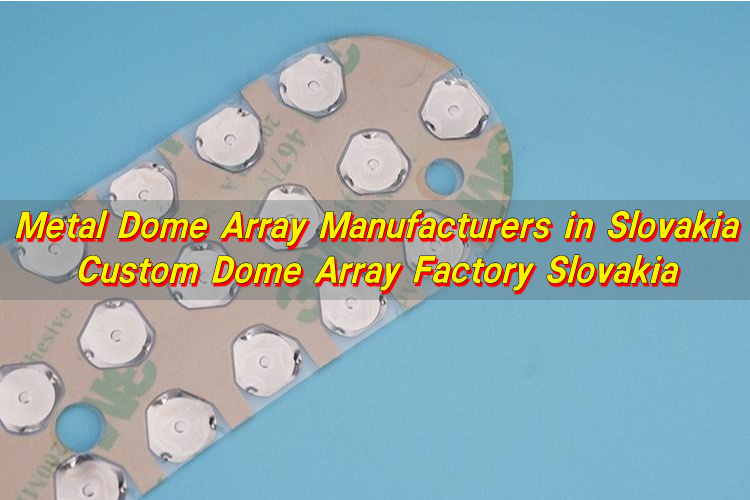

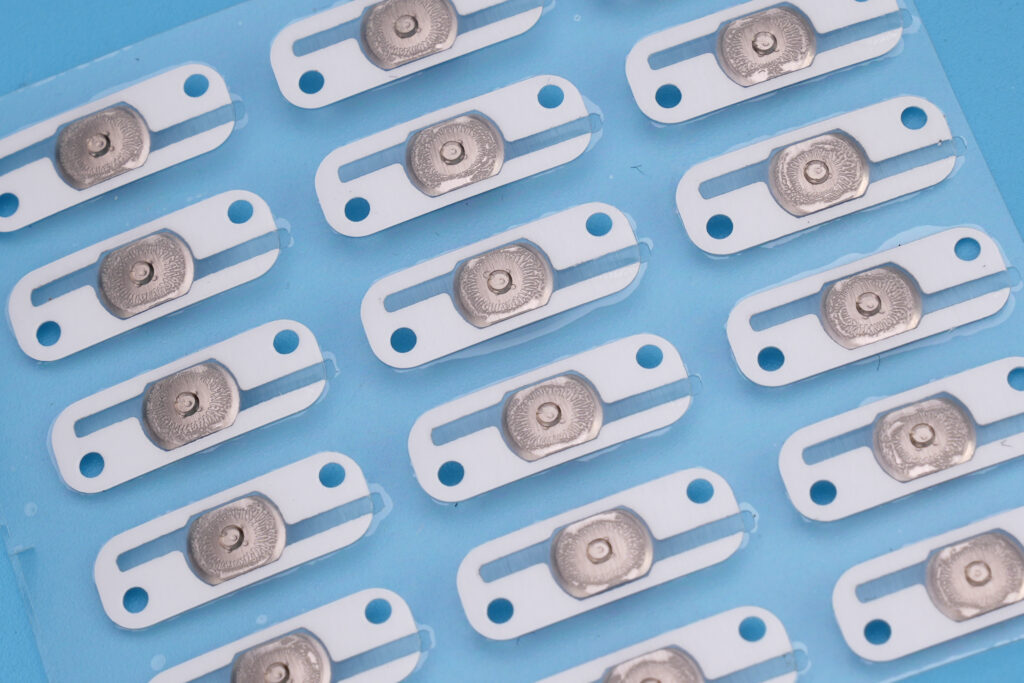

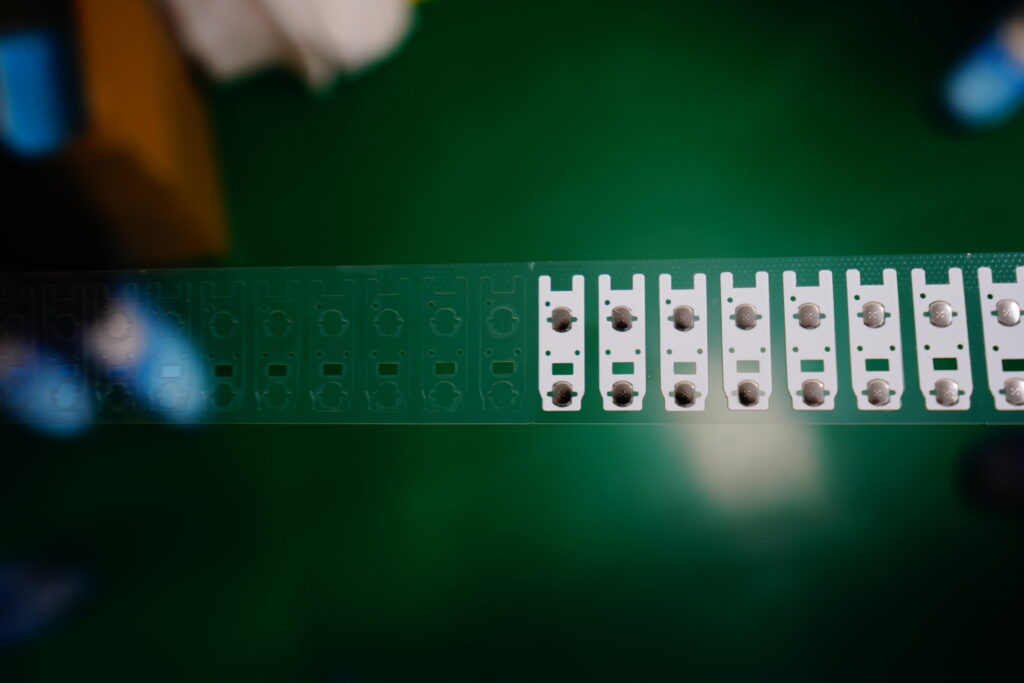

In aircraft applications, these domes are often part of a metal dome array. The array ensures precise alignment on the PCB. It also improves assembly accuracy and long-term stability.

At EBest Circuit (Best Technology), metal domes for aerospace projects are designed with strict dimensional control. Each dome is tested for force, rebound, and contact stability. This approach supports safe and repeatable cockpit operation.

How to choose a high-quality metal dome?

Choosing the right metal dome starts with understanding the cockpit environment. Aircraft controls face vibration, humidity changes, and temperature extremes. A dome that works in a factory panel may fail in flight conditions.

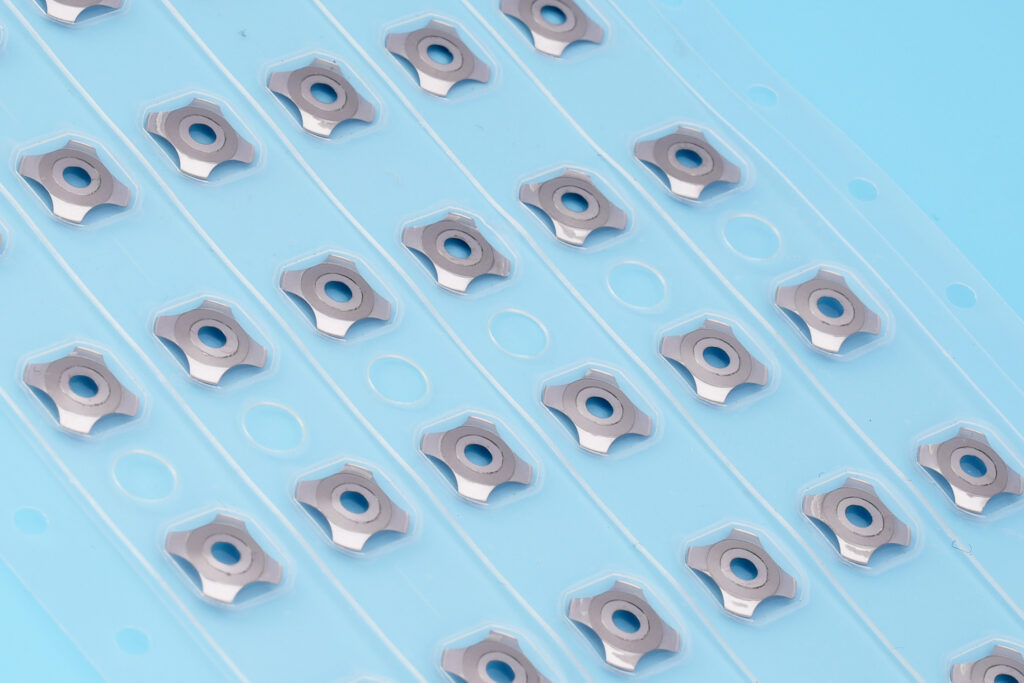

Material selection comes first. Aerospace domes usually use stainless steel. SUS301 and SUS304 are common. These materials balance elasticity and fatigue resistance. They maintain snap force after repeated cycles.

Next comes actuation force. The force must feel firm but not tiring. Too light, and false inputs occur. Too heavy, and pilot comfort suffers. Cockpit domes often fall in a mid to high force range for deliberate input.

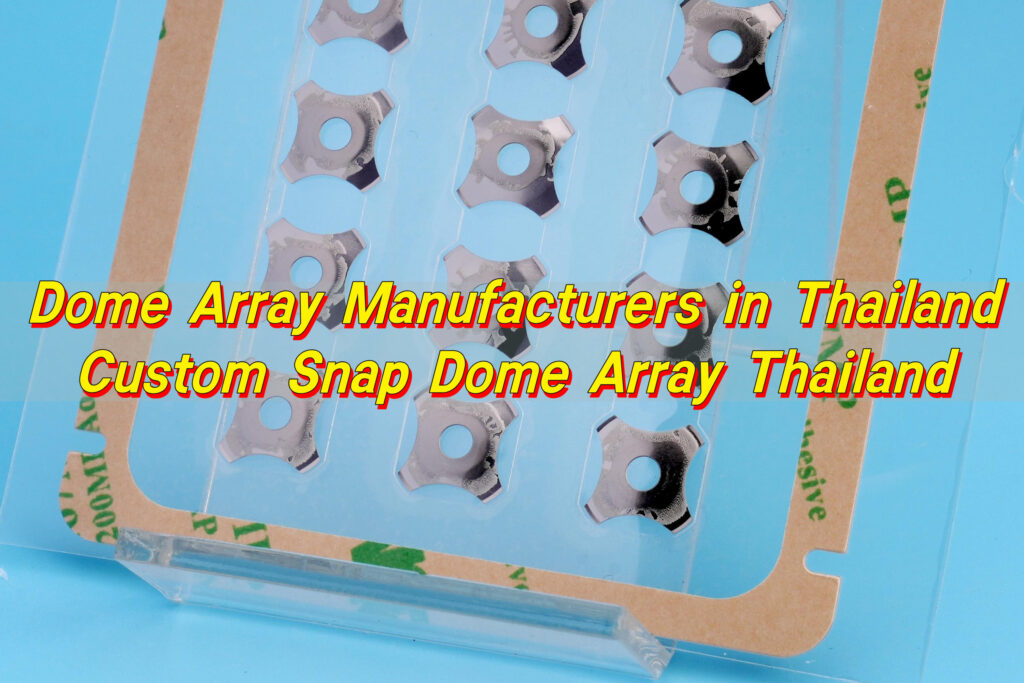

Dome shape also matters. Four-leg domes provide stable contact and low resistance. Round domes offer uniform response. Triangle domes save space but still deliver strong feedback. The choice depends on PCB layout and switch density.

Surface treatment affects signal quality. Gold plating improves contact resistance. Nickel layers add corrosion protection. For aircraft use, plating must remain stable over long service life.

Array accuracy is another key factor. Poor alignment causes uneven force and early failure. A high-quality supplier controls array tolerance tightly. At EBest Circuit (Best Technology), array positioning accuracy is controlled within ±0.05 mm.

Why use metal dome in aircraft cockpit control?

Metal domes offer clear advantages in cockpit systems. The most important benefit is tactile certainty. Pilots can confirm input by feel alone. This reduces visual workload during flight.

Durability is another reason. Metal domes withstand millions of actuations. They do not degrade like elastomer contacts. This suits long aircraft service intervals.

Environmental stability also stands out. Metal domes handle heat, cold, and vibration well. They maintain snap characteristics across wide temperature ranges.

Signal reliability improves as well. The metal-to-metal contact produces a clean electrical signal. This reduces bounce and misreads.

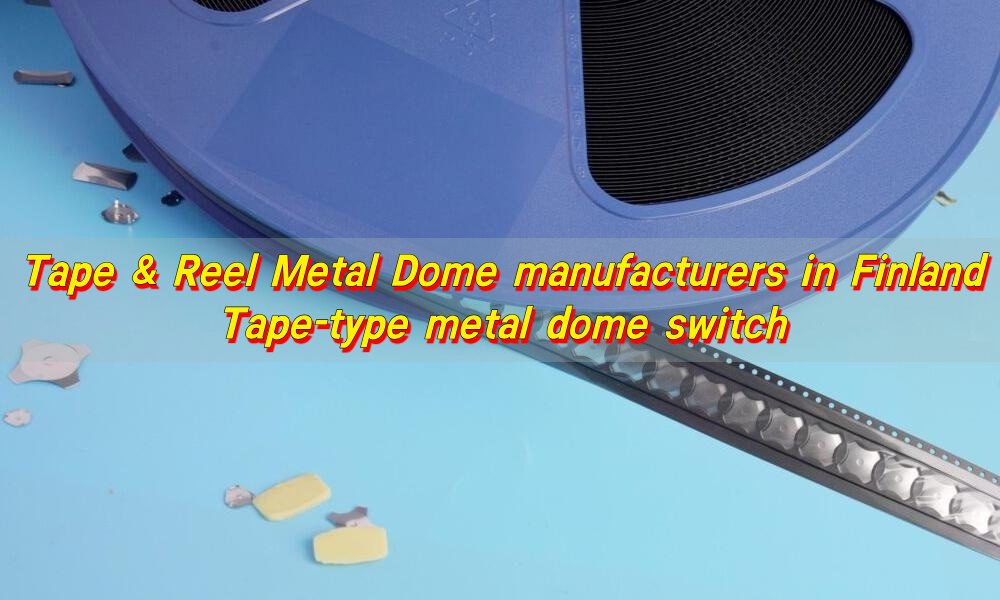

From a manufacturing view, metal domes integrate well with SMT processes. Tape and reel packaging enables automated placement. This improves consistency and lowers assembly error.

EBest Circuit (Best Technology) supports aerospace customers with dome solutions that match these needs. Our domes are designed for stable performance, not short-term use. This aligns with aircraft design philosophy.

What makes reliable aircraft cockpit control metal domes?

- Reliability comes from control at every stage. It starts with raw material inspection. Steel thickness must stay consistent.

- Forming accuracy is next. Dome height, radius, and leg geometry must match design data.

- Contact surface quality matters. Smooth contact points reduce wear. Plating must be even.

- Lifecycle testing confirms reliability. Aerospace domes often exceed one million cycles.

- Environmental testing adds confidence. Domes are exposed to heat, cold, and humidity. They are also tested under vibration.

- Packaging affects reliability too. Domes damaged during transport lose performance. Tape and reel packaging protects shape and orientation. It also supports automated assembly.

At EBest Circuit (Best Technology), reliability is built into the process. Each batch follows ISO9001 standards. Testing data is documented. This helps aerospace customers meet quality audits.

How to install metal dome correctly?

Correct installation ensures long service life. Even the best dome fails if placed poorly.

- The PCB pad design must match the dome. Contact pads should be clean and flat. Sharp edges increase wear.

- Alignment is critical. The dome must sit centered over the contact. Arrays simplify this step. They keep spacing consistent across the panel.

- Adhesive choice matters. The adhesive film must hold the dome without restricting movement. Too strong, and snap force changes. Too weak, and domes shift.

- Press-fit pressure during lamination should be even. Uneven pressure distorts dome shape. This affects tactile feel.

- ESD control is also important. Metal domes can carry charge. Grounding procedures protect sensitive circuits during assembly.

For high-volume production, automated placement is preferred. Tape and reel domes improve accuracy and speed. This reduces human error.

EBest Circuit (Best Technology) provides installation guidance with samples. Technical teams respond within 48 hours after sample delivery. This support helps customers avoid early design mistakes.

What standards apply to metal dome?

Aircraft components must meet strict standards. Metal domes used in cockpit controls often follow multiple guidelines.

ISO9001 governs quality management. It ensures process consistency and traceability.

RoHS and REACH address material safety. Even aerospace parts must comply with environmental rules.

In some projects, customer-specific aviation standards apply. These may reference DO-160 environmental conditions. While domes are passive parts, they must survive related tests.

Documentation is part of compliance. Material certificates, plating reports, and lifecycle data support approval.

A reliable supplier understands these needs. They prepare data in advance. This saves time during qualification.

EBest Circuit (Best Technology) includes compliance documents with samples. This supports smoother integration into aerospace programs.

How to test metal dome performance?

Testing verifies design assumptions. It also protects system reliability.

- Force testing measures actuation and return force. The curve should stay stable across cycles.

- Contact resistance testing checks signal quality. Low and consistent resistance is required.

- Lifecycle testing simulates long-term use. Domes are pressed repeatedly under controlled conditions.

- Environmental testing adds stress. Temperature cycling reveals material fatigue. Humidity tests expose corrosion risk.

- Visual inspection follows testing. Cracks, deformation, or plating wear indicate failure.

- Testing data guides improvement. It also reassures customers.

At EBest Circuit (Best Technology), testing is not optional. It is part of standard aerospace support. This builds trust with long-term partners.

Where is metal dome commonly applied?

Metal domes appear in many cockpit systems. They support both primary and secondary controls.

Common applications include:

- Flight management system keypads

- Autopilot control panels

- Radio and communication interfaces

- Environmental control panels

- Backup instrument inputs

They are also used in simulator panels. Training devices need the same tactile realism as real aircraft.

EBest Circuit (Best Technology) supplies domes for these uses worldwide. Their experience across industries supports reliable aerospace solutions.

Conclusion:

Metal dome for aircraft cockpit control is a small part with a large role. It delivers tactile certainty, signal reliability, and long service life. Choosing the right dome means focusing on material, force, and manufacturing control.

EBest Circuit (Best Technology) brings years of metal dome expertise to aerospace projects. With controlled manufacturing, fast technical support, and proven reliability, We support safe cockpit interaction.

For technical inquiries or project discussion, contact sales@metal-domes.com