Haptic feedback technology is a technology that enhances user experience through physical feedback and is widely used in electronic devices. It provides users with a real tactile response through vibration, resistance or deformation, making the interaction more intuitive and natural.

Among the many implementation methods, the tactile metal dome switch stands out. This switch uses the elastic deformation of the metal dome to provide users with easy-to-perceive tactile feedback. When the user presses the button, the deformation of the metal dome is converted into a clear touch, ensuring a sense of confirmation of the operation.

What is tactile feedback?

Tactile feedback, also known as touch feedback, is a physical response that your body feels when interacting with a surface or control. It’s a signal — usually a tiny vibration, a press, or a snap — that lets you know an action has been completed.

For example, when you click a pen, that noticeable “click” is tactile. It’s feedback through touch. You don’t need to look. You simply feel it.

What does tactile feedback mean?

The meaning of tactile feedback goes beyond just sensation. It’s about confirmation. It ensures that a user knows their input was registered.

Think about turning the volume knob in a car. With each click or bump, you feel the adjustment. That’s tactile technology feedback in action.

Without tactile feedback, you might press a button and second-guess if anything happened. But with that physical response, there’s no confusion.

What is tactile feedback technology?

Tactile feedback technology involves the use of mechanical or electronic elements that generate physical responses when triggered. These responses can be a sharp snap, a subtle vibration, or a spring-like movement.

In the tech world, it’s often paired with haptic feedback technology — especially in touchscreens or gaming controllers. While haptics often focus on vibrations, tactile feedback focuses more on crisp, mechanical responses you can feel through your fingers.

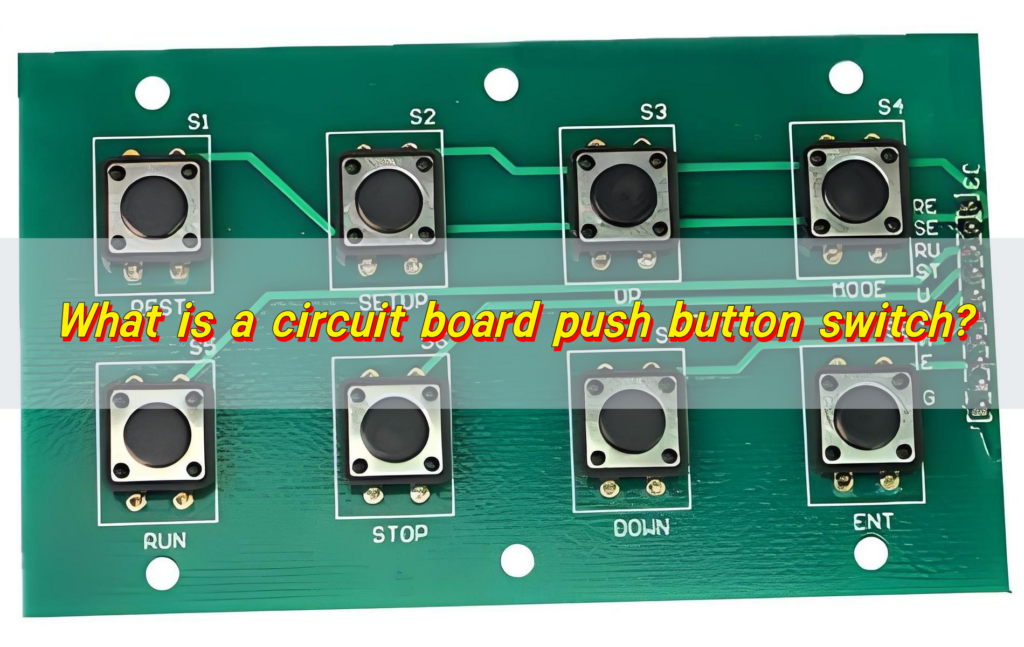

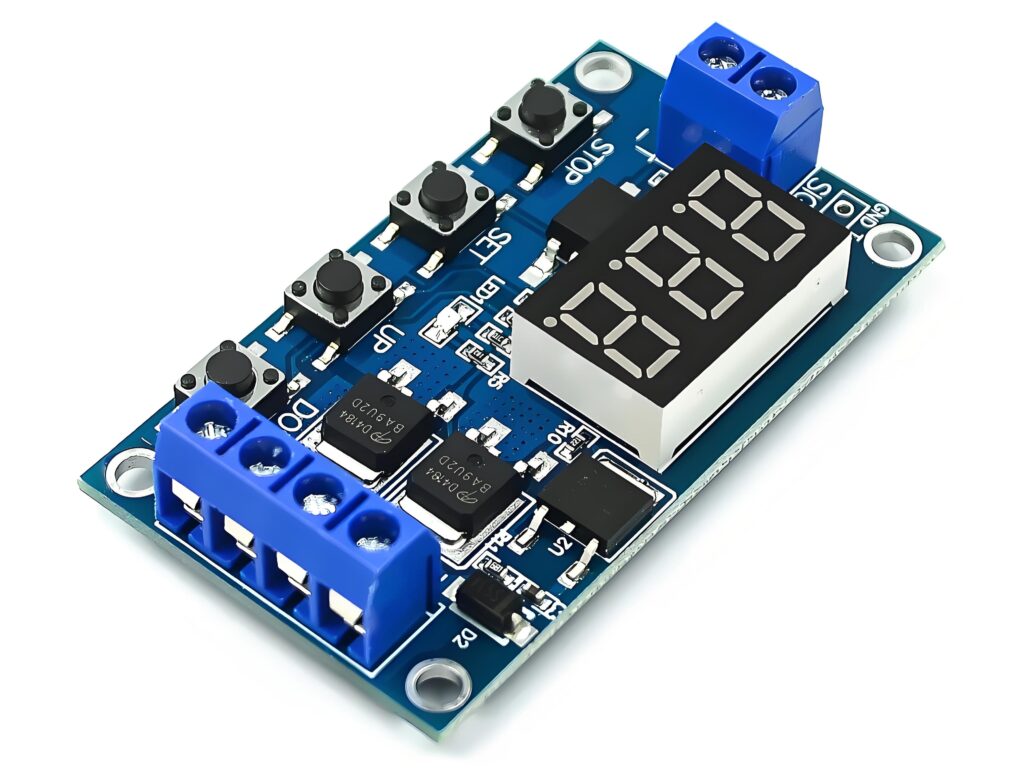

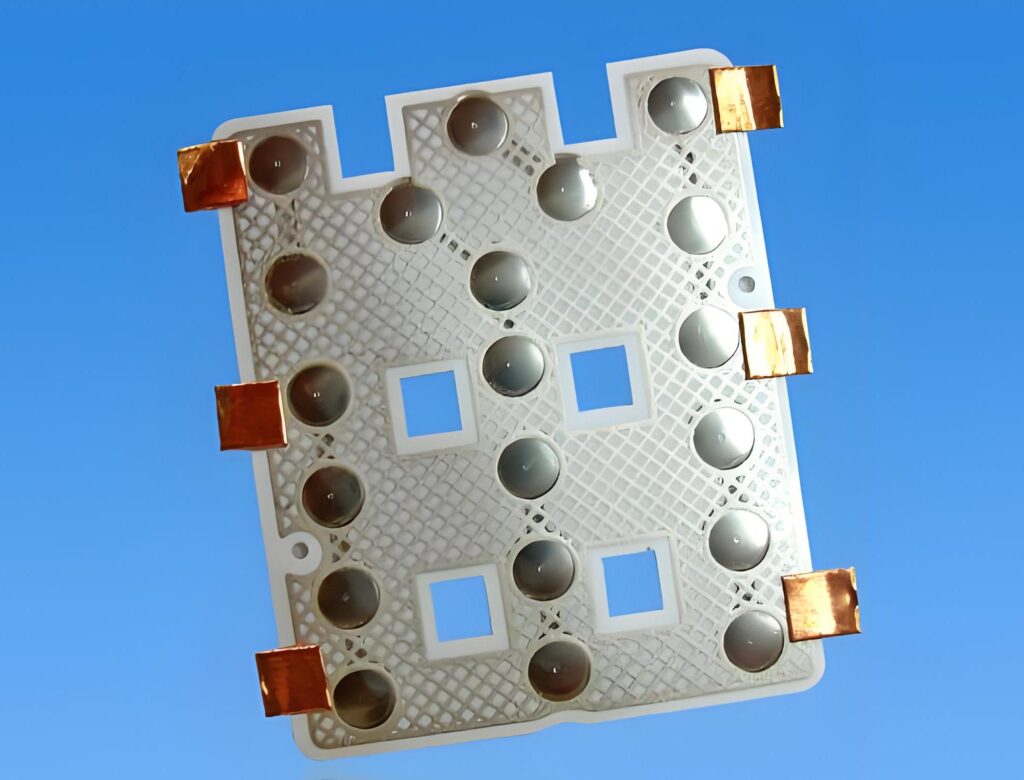

Tactile metal domes, mechanical switches, and smart actuators. These components are designed to create that precise and immediate response when pressed.

What is an example of tactile feedback?

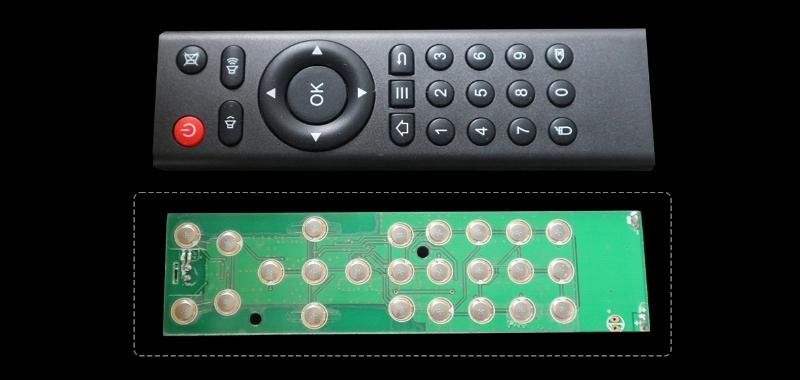

Metal dome switches in microwave panels or elevator buttons. They create a sharp “snap” when pressed.

- Mechanical keyboards with distinct keys that respond with every stroke.

- Touchscreens with slight pulses when you tap an icon.

- Car dome light switches with firm, tactile push buttons.

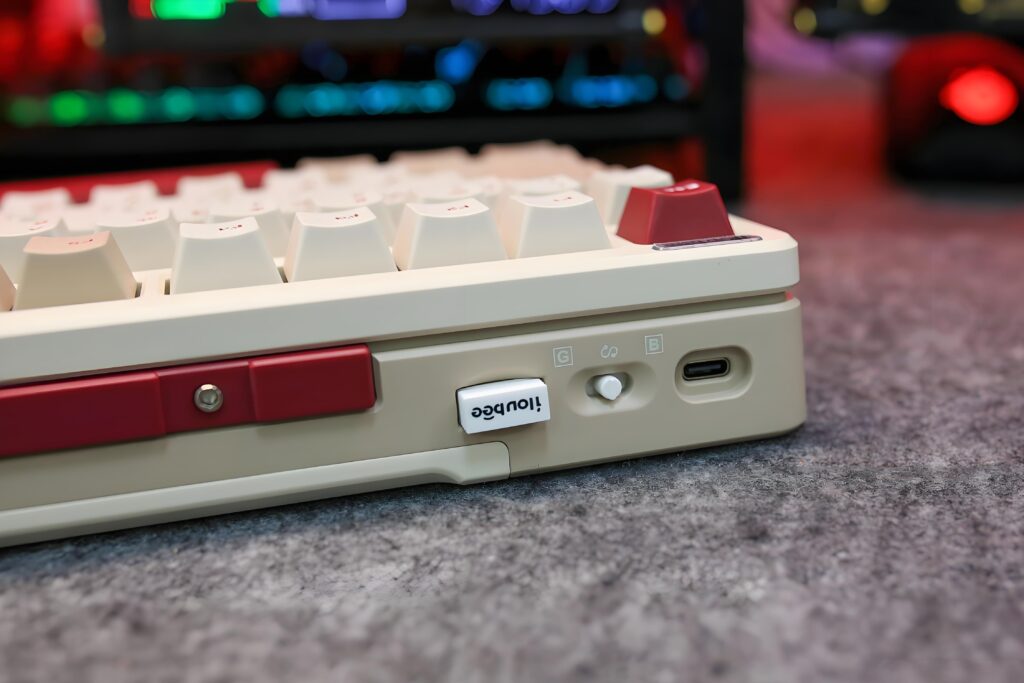

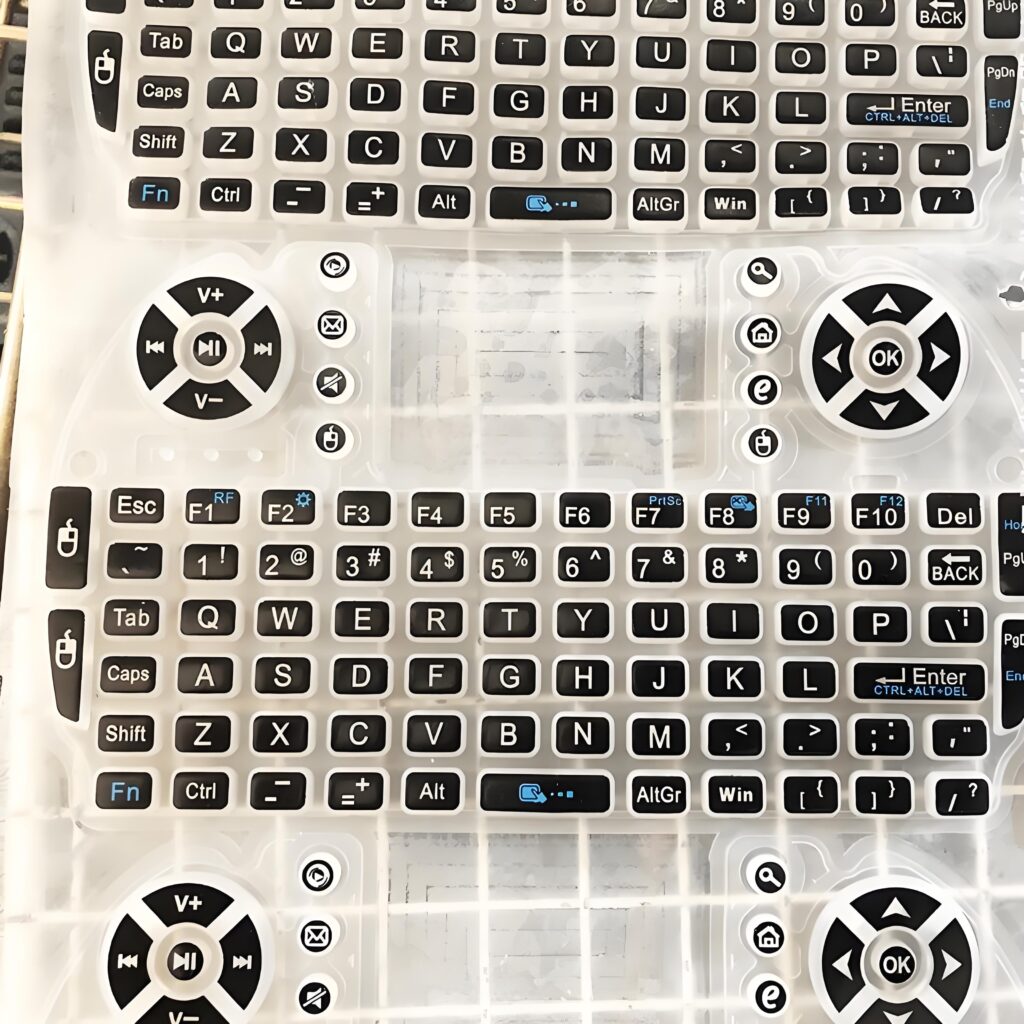

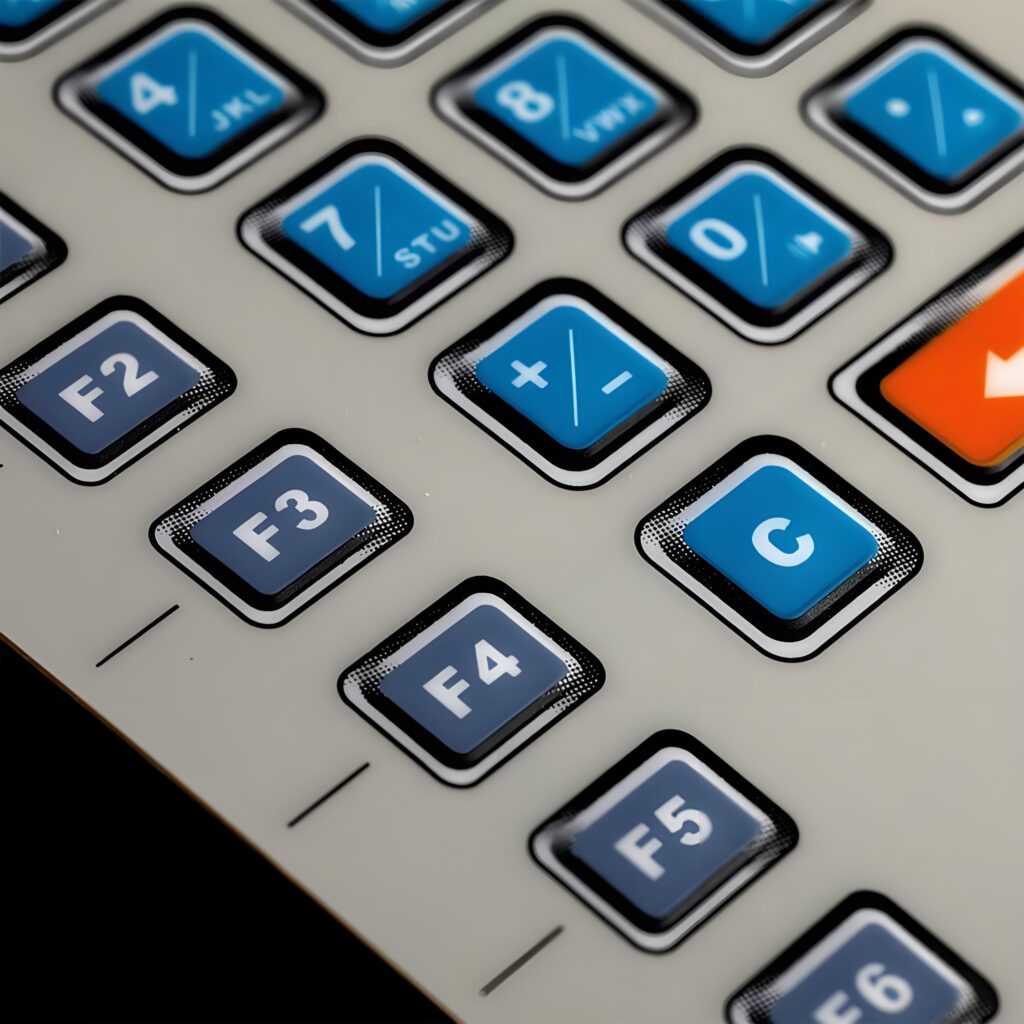

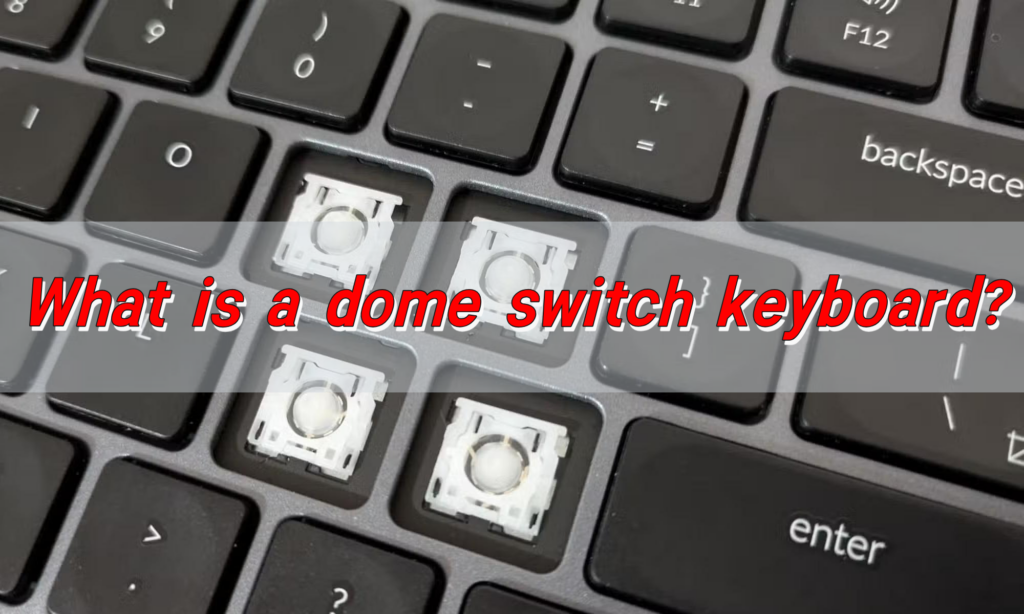

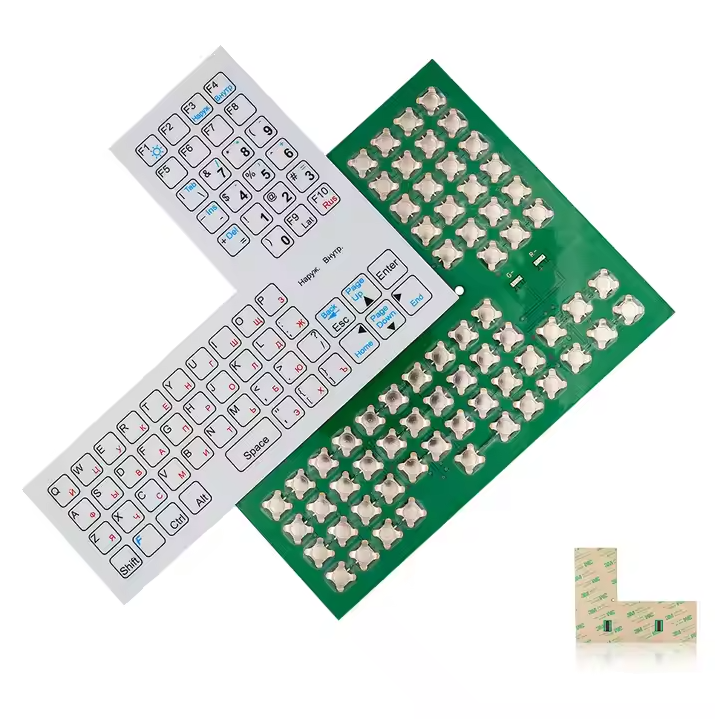

What is tactile feedback keyboard?

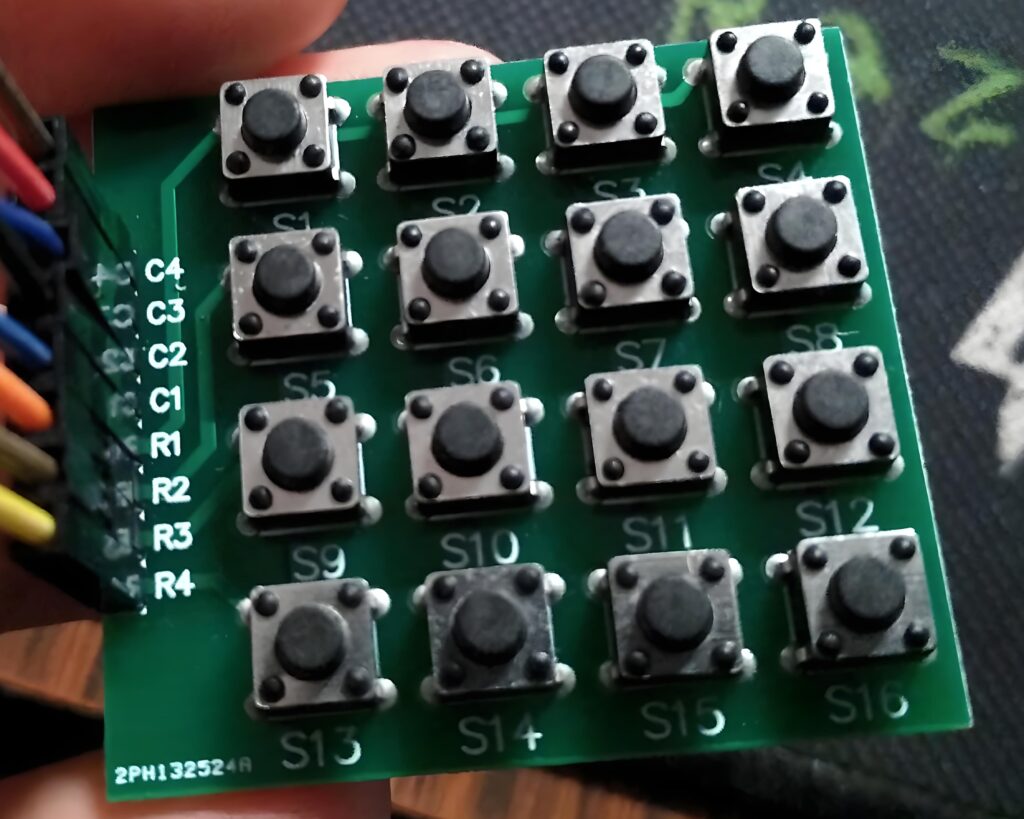

Tactile feedback keyboard is a keyboard that gives a noticeable response with each key press. It’s often found in professional settings where typing speed and accuracy are important.

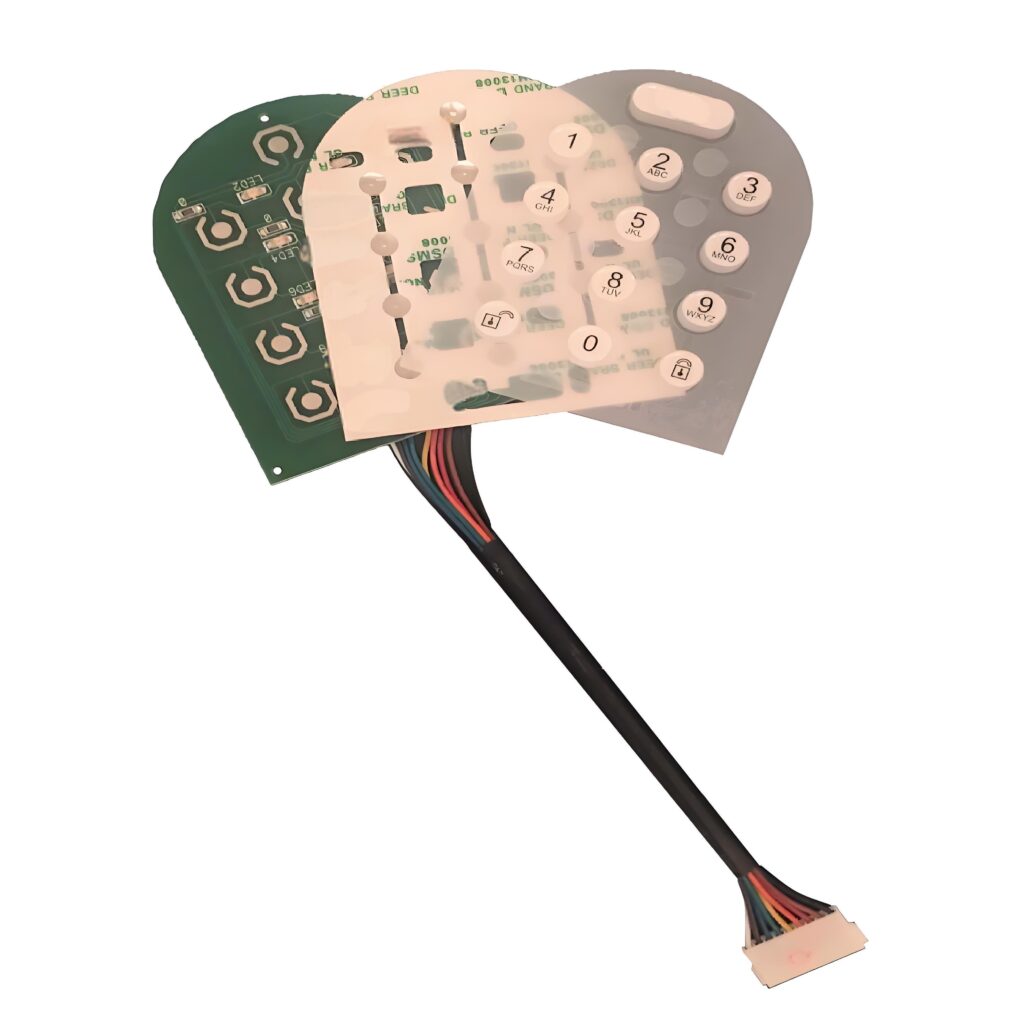

These keyboards may use rubber dome, mechanical, or metal dome switch mechanisms. Metal dome keypads, in particular, provide a strong, crisp feel. Each press delivers a clear confirmation that a key was successfully hit.

If you’ve ever used a soft-touch keyboard and felt unsure whether your input registered, you’ll immediately appreciate the difference tactile feedback makes.

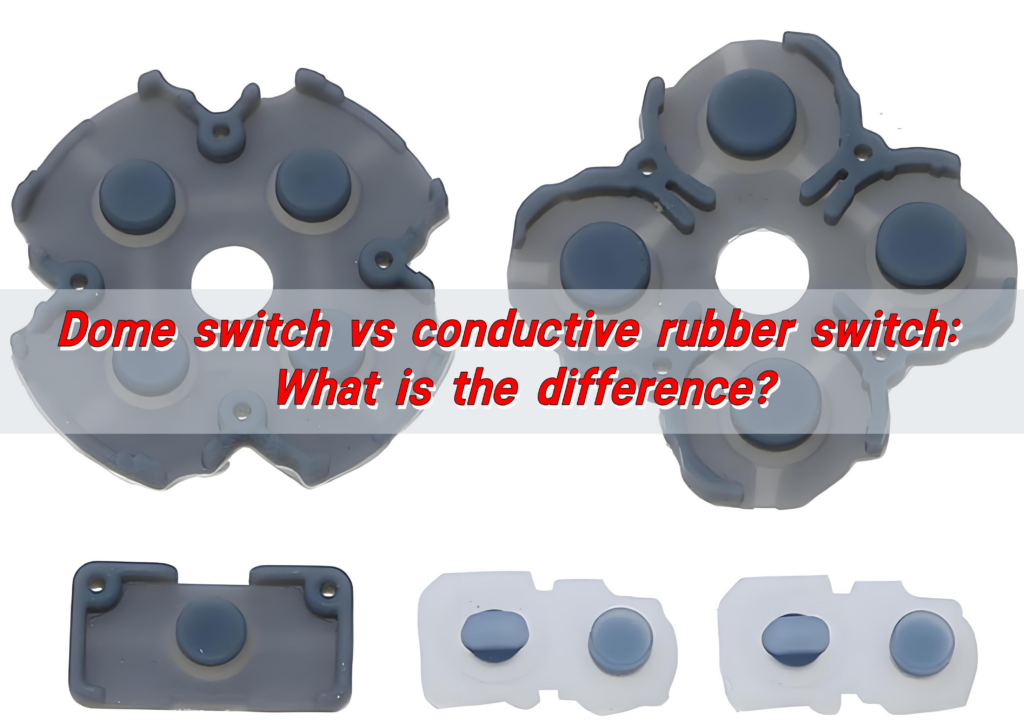

What is the difference between haptic feedback and tactile feedback?

These two terms — haptic feedback and tactile feedback — are often used interchangeably. But they’re not quite the same.

- Tactile feedback is physical. It’s what you feel when you press a button or switch. It can be a click, a snap, or resistance.

- Haptic feedback is often digital. It uses vibrations or pulses to mimic the sensation of touch, especially in touchscreens and handheld devices.

Haptics try to simulate touch using electronic signals. Tactile feedback creates real, mechanical sensations.

For example, tapping a virtual button on your phone that vibrates uses haptics. Pressing a real button on a remote control that clicks is tactile feedback.

In many devices today, these technologies work together to create a seamless experience. But tactile feedback stands out for its accuracy and reliability.

What are the disadvantages of haptic feedback?

While haptic feedback has many benefits, it’s not perfect.

- Lack of precision: Vibrations can feel vague. It’s sometimes unclear if an action was accepted.

- Limited in harsh environments: Vibrations may go unnoticed if the user is wearing gloves or working in a noisy place.

- Not as satisfying: Haptics simulate feel. But for many, it lacks the sharp certainty of real tactile feedback.

That’s where tactile feedback technology shines. It provides a mechanical response you can trust — no batteries required.

How to improve the tactile feedback of metal dome switches?

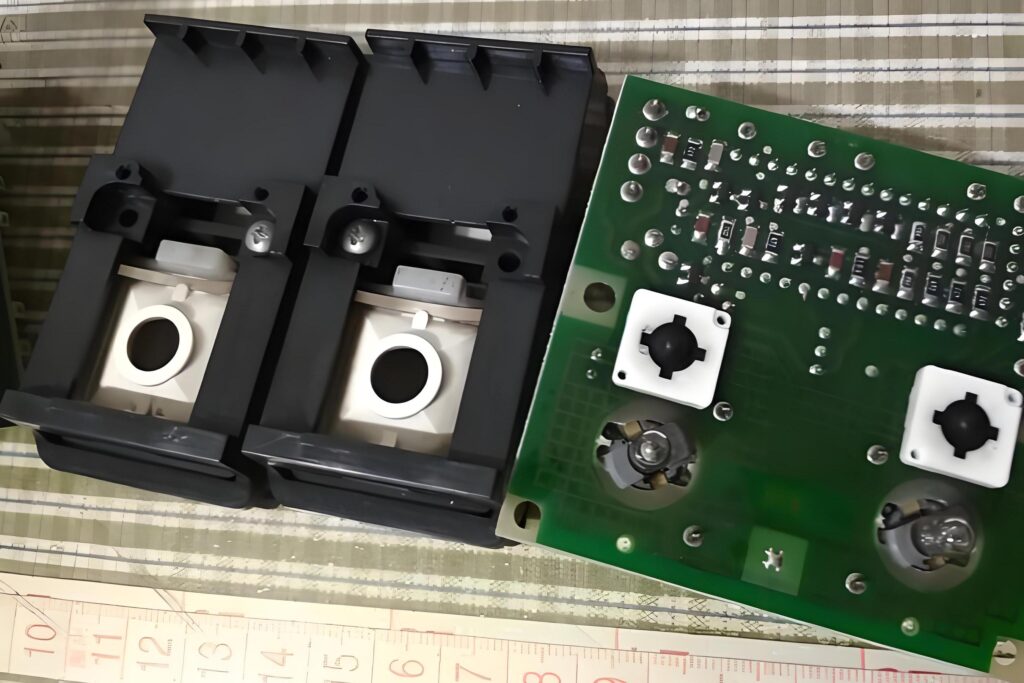

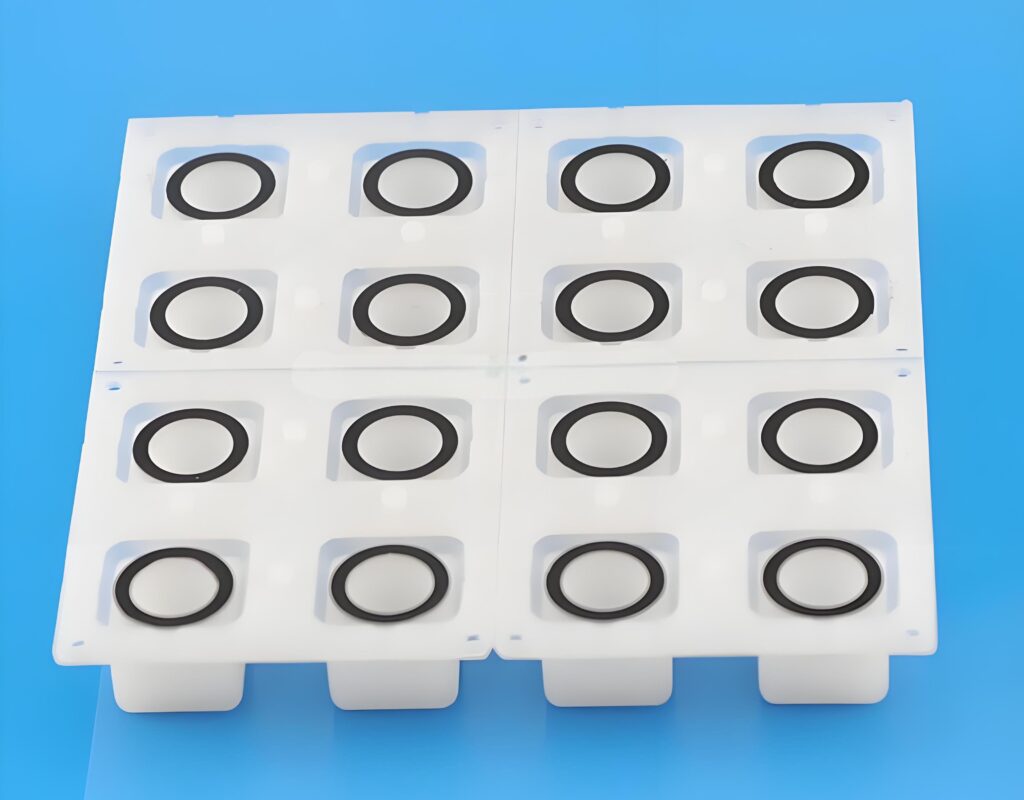

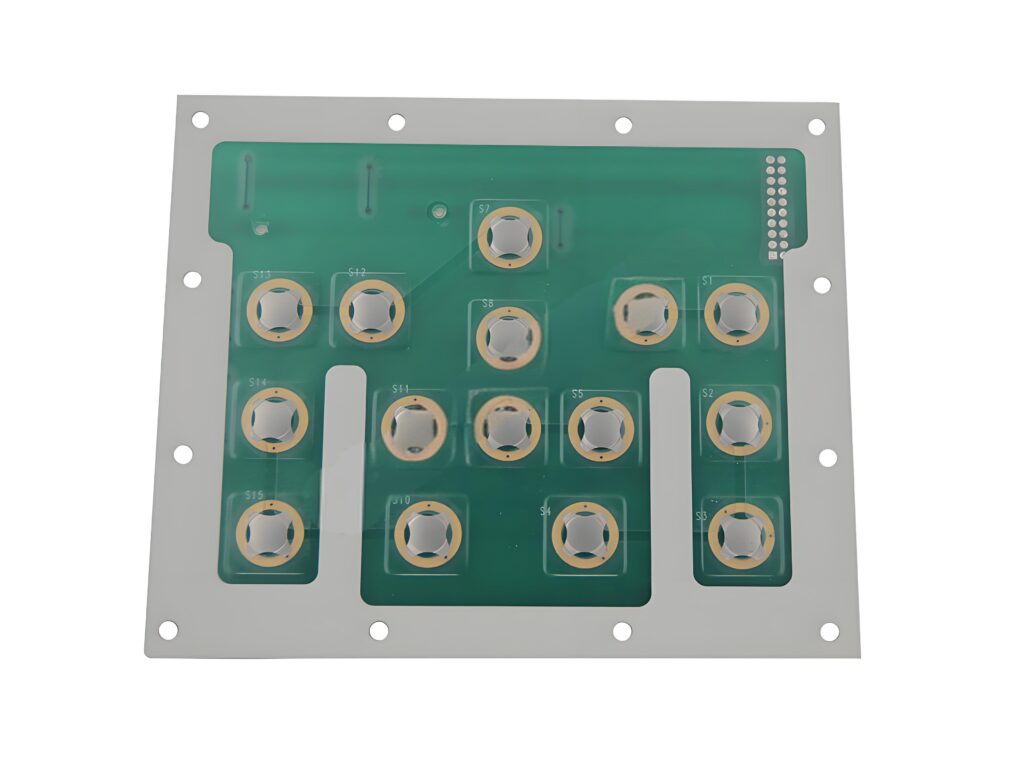

Tactile metal dome switches are widely used in control panels, keypads, and handheld devices.

1. Choose the Right Dome Force

The actuation force (measured in grams) should match the user’s needs. A lighter force is better for fast inputs. Heavier domes give stronger feedback for more confident operation.

2. Select High-Quality Materials

Stainless steel domes retain shape and performance longer. They offer more consistent feedback across millions of presses.

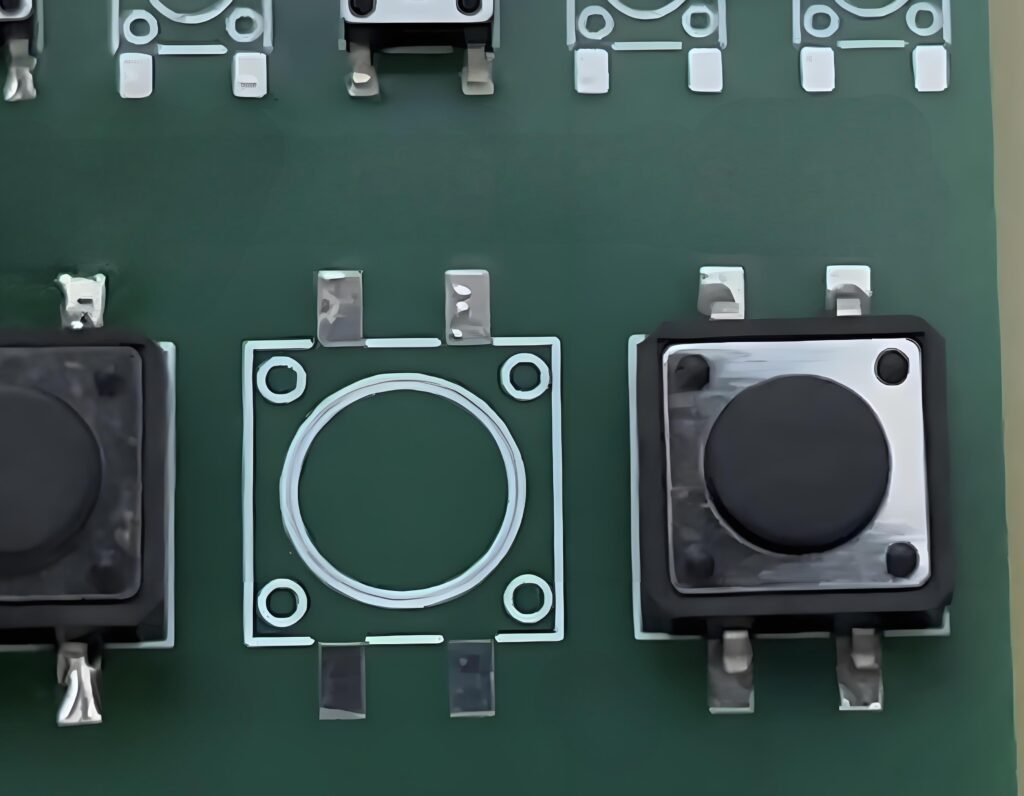

3. Optimize the Dome Shape

Different dome shapes create different sensations. Four-leg domes offer high click feel. Triangle domes are compact. Matching the dome shape with application matters.

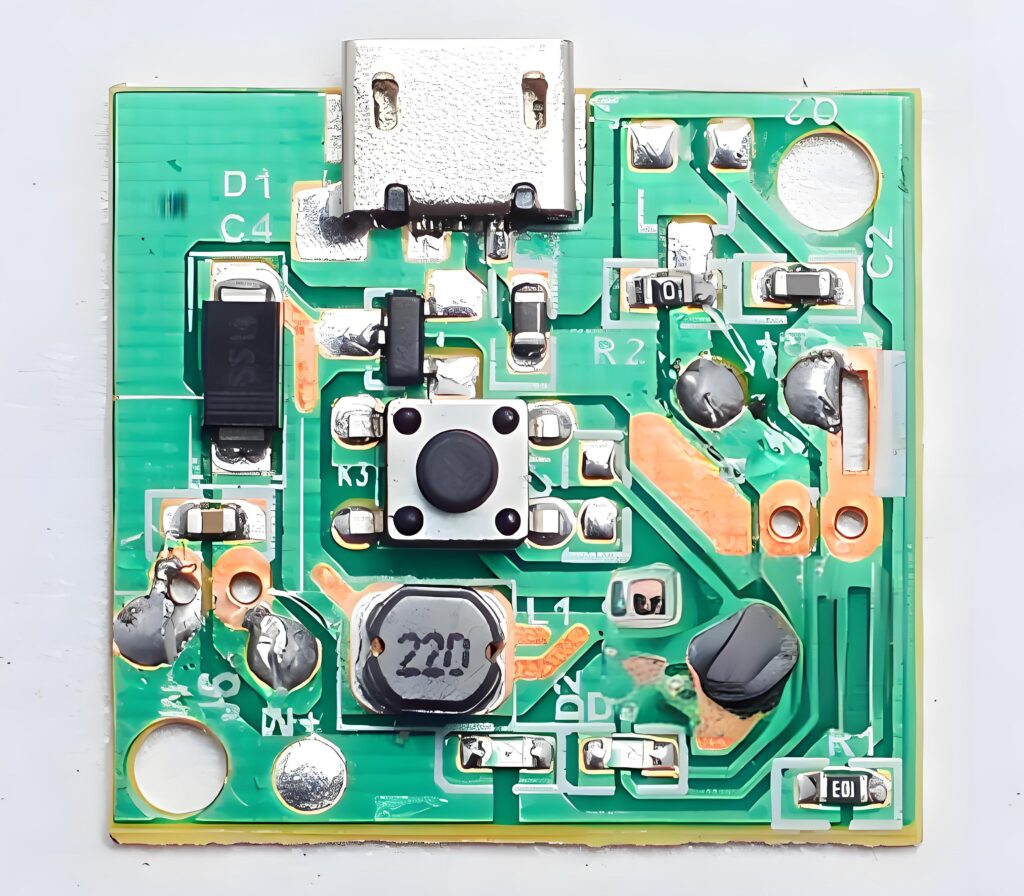

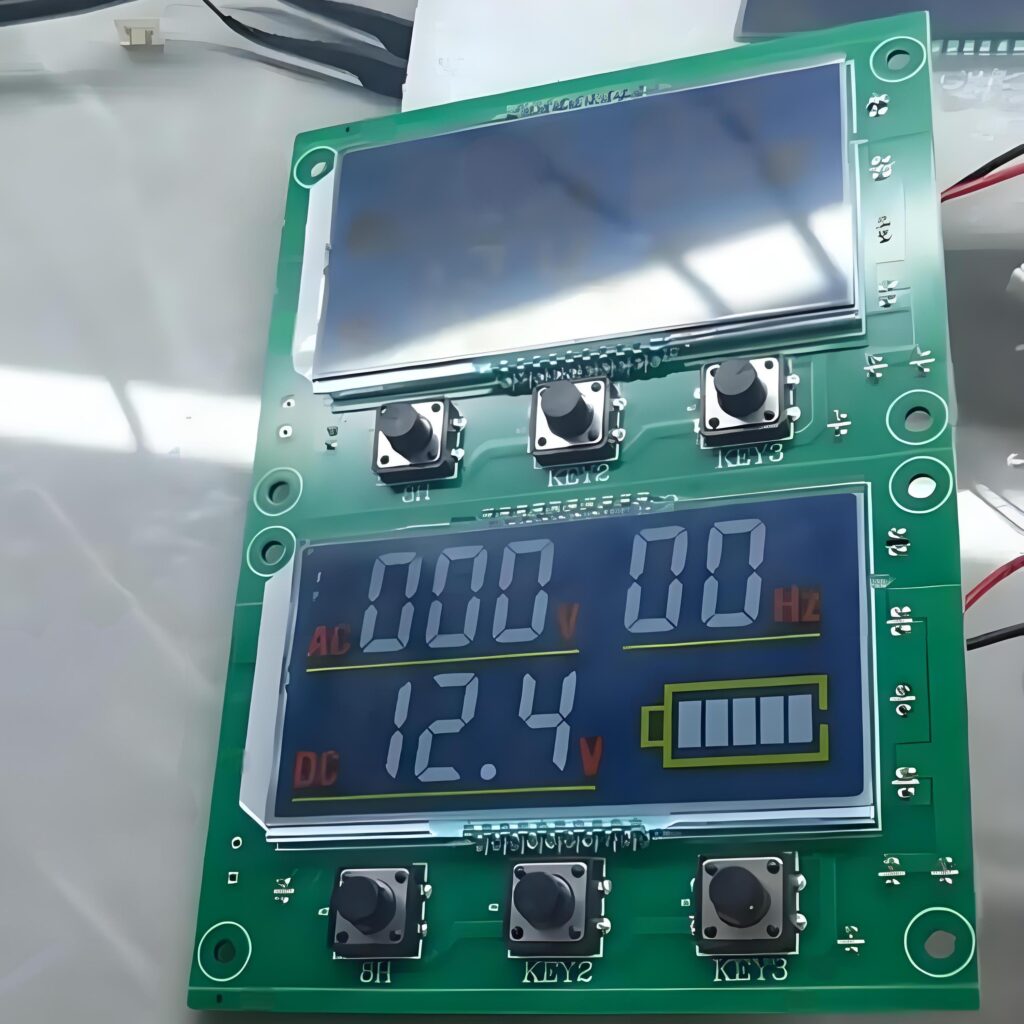

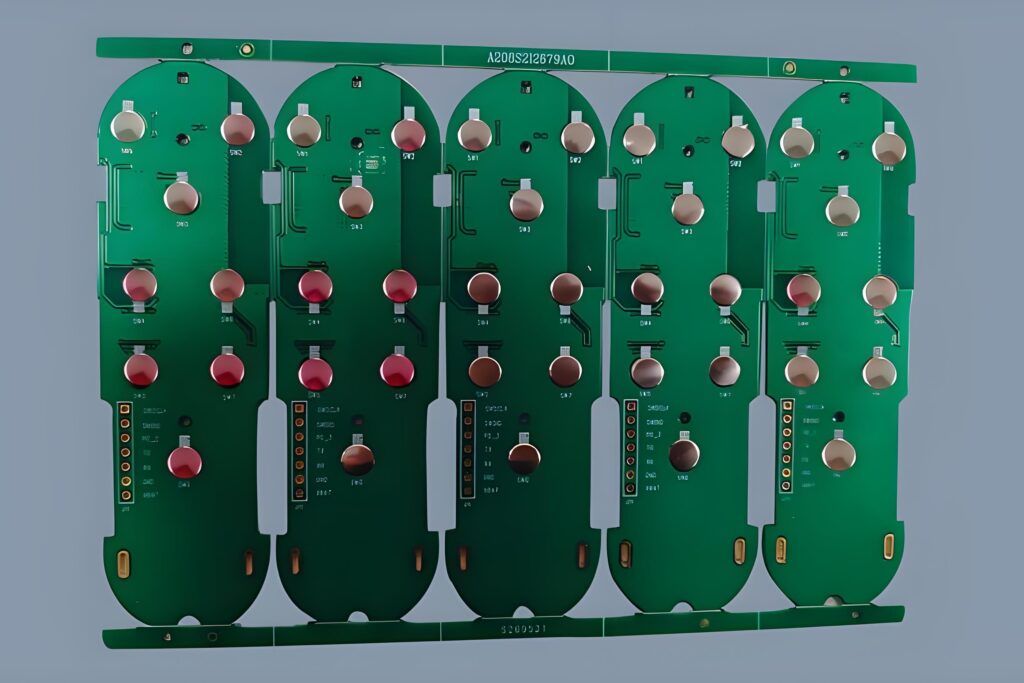

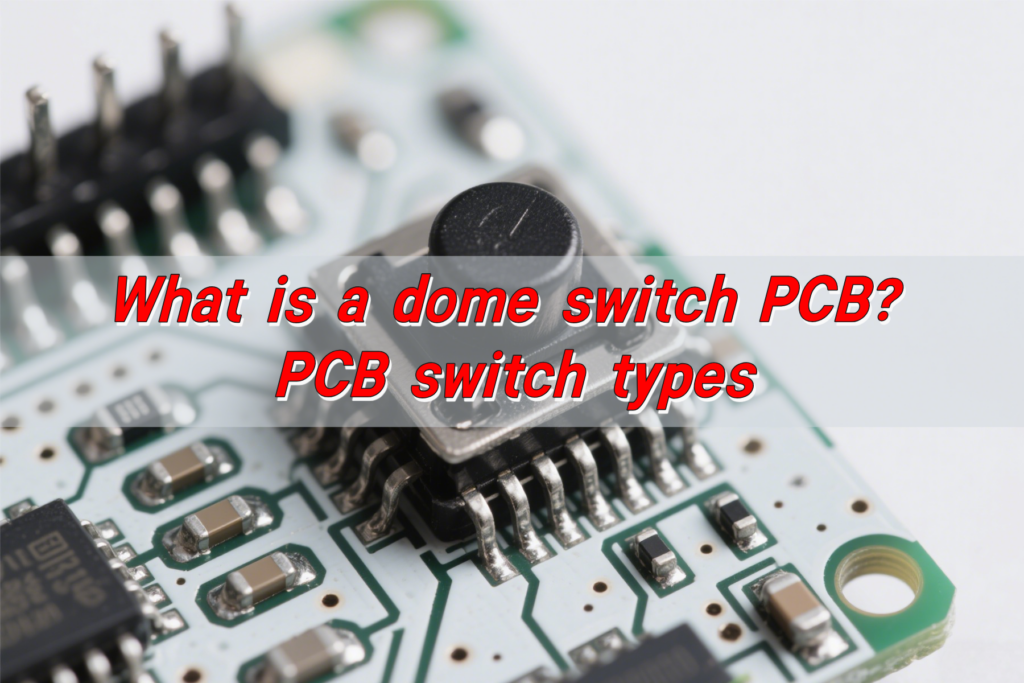

4. Use Proper Circuit Board Design

A smooth and flat contact surface ensures better conductivity and a more accurate response. Precision is key.

5. Add Spacer Layers or Embossing

Layers can improve feel and protection. Embossed overlays create a better press area. These layers help direct finger force and increase tactile clarity.

6. Protect Against Wear

Over time, repeated use can wear down feedback. Using protective coatings and durable overlays extends the life of tactile switches.

7. Regular Testing

Routine quality testing helps maintain consistent performance. It’s essential for safety-critical applications like medical devices or military gear.

When done right, tactile metal domes offer unmatched reliability, clarity, and satisfaction.

Conclusion:

Tactile feedback is more than just a snap or a click. It’s a critical part of how we interact with machines. It brings confidence, clarity, and comfort. From tactile feedback keyboards to advanced metal dome switches.

While haptics offer a digital feel, tactile feedback provides something real. And when optimized — especially through tactile metal domes — it offers unbeatable performance in almost any application.

Want to upgrade your devices with world-class tactile performance? Contact us at sales@metal-domes.com