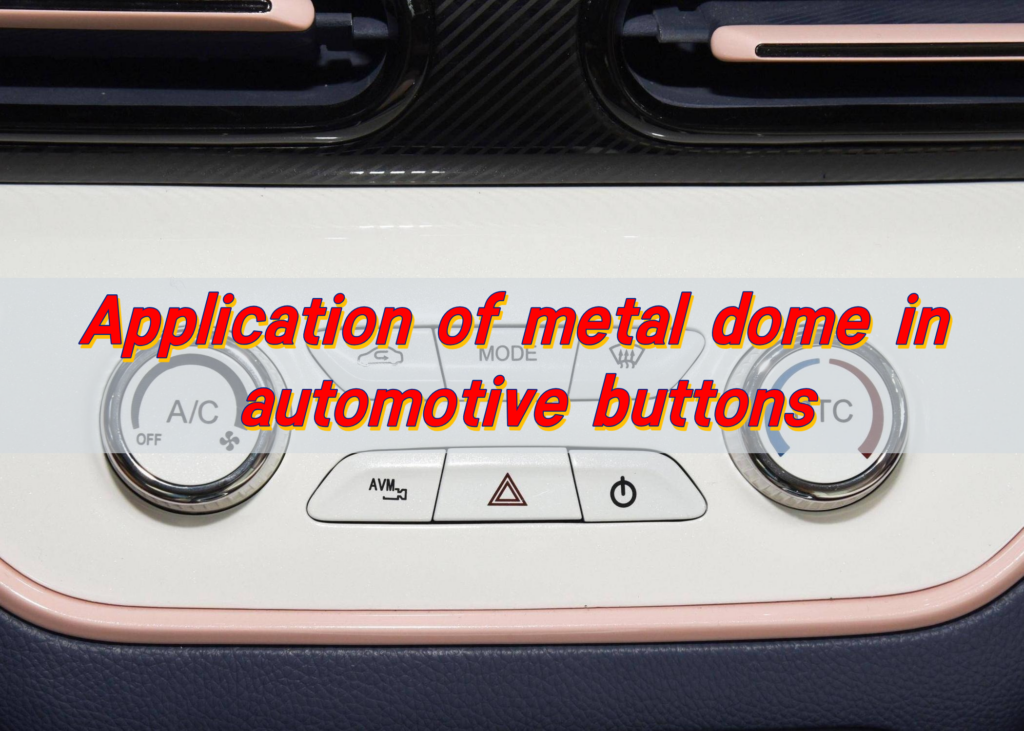

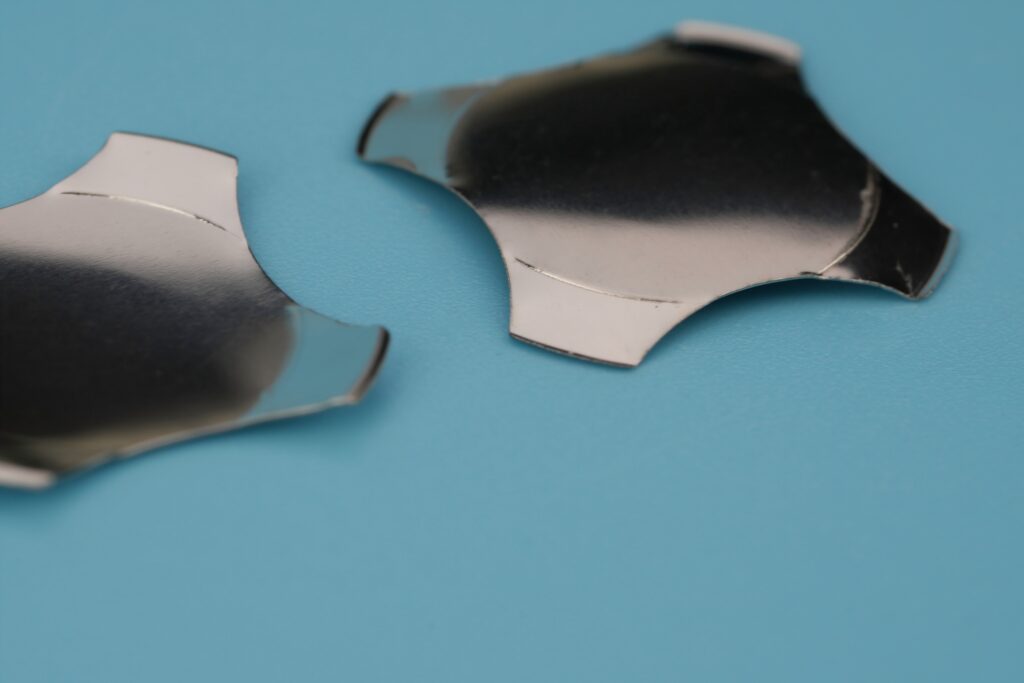

Metal domes are widely used in automotive button systems, including steering wheel multi-function buttons, central control panels, window lifts, and air conditioning controls. Their stainless steel structure maintains stability and elasticity, capable of withstanding more than one million presses, ensuring that every command is accurately and quickly transmitted during driving.

What is an automotive button?

An automotive button is a small but critical interface in your vehicle. It’s what you press to start your engine, adjust the air conditioning, roll down windows, or activate emergency lights. Some buttons are mechanical. Others are touch-sensitive. Yet, the core function remains the same—providing quick access to vital car features.

In newer cars, buttons are designed with aesthetics, durability, and ease of use in mind. They’re made to respond instantly and feel satisfying to touch. This is where metal dome switches step in.

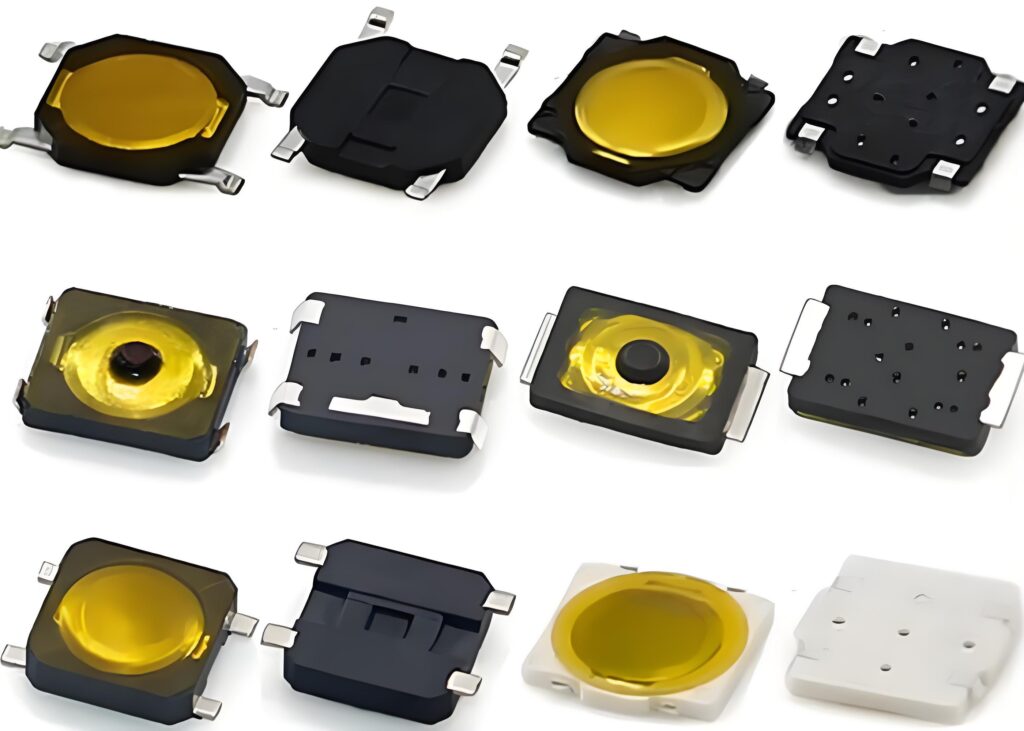

Why use a metal dome in car buttons?

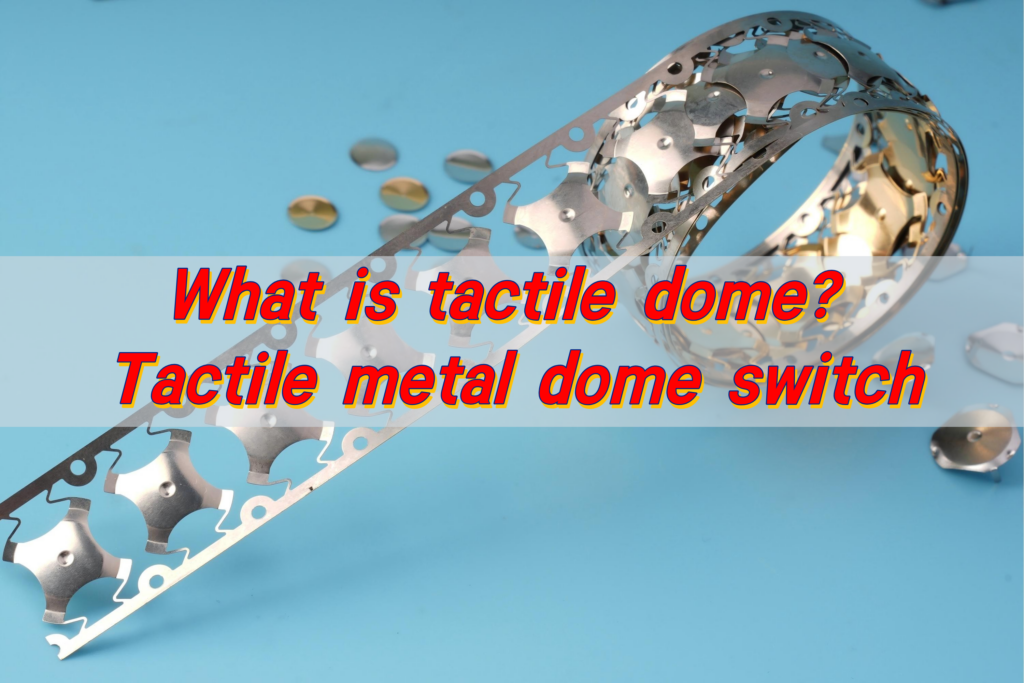

Not all buttons feel the same. You might have noticed how satisfying it feels when you press some buttons—they offer a crisp, tactile response. That feedback often comes from a metal dome hidden underneath the button surface.

Metal domes are thin, stainless-steel discs placed beneath the button’s surface. When pressed, the dome collapses and makes contact with a circuit board. This completes the circuit and sends a signal.

What makes metal domes ideal for automotive buttons?

- Fast response time

- Reliable tactile feedback

- Consistent electrical performance

- Long lifespan under frequent use

- Slim structure ideal for modern dashboards

Drivers need fast, accurate, and consistent input. A metal dome button ensures that each press is properly registered. That means fewer mistakes and a better driving experience.

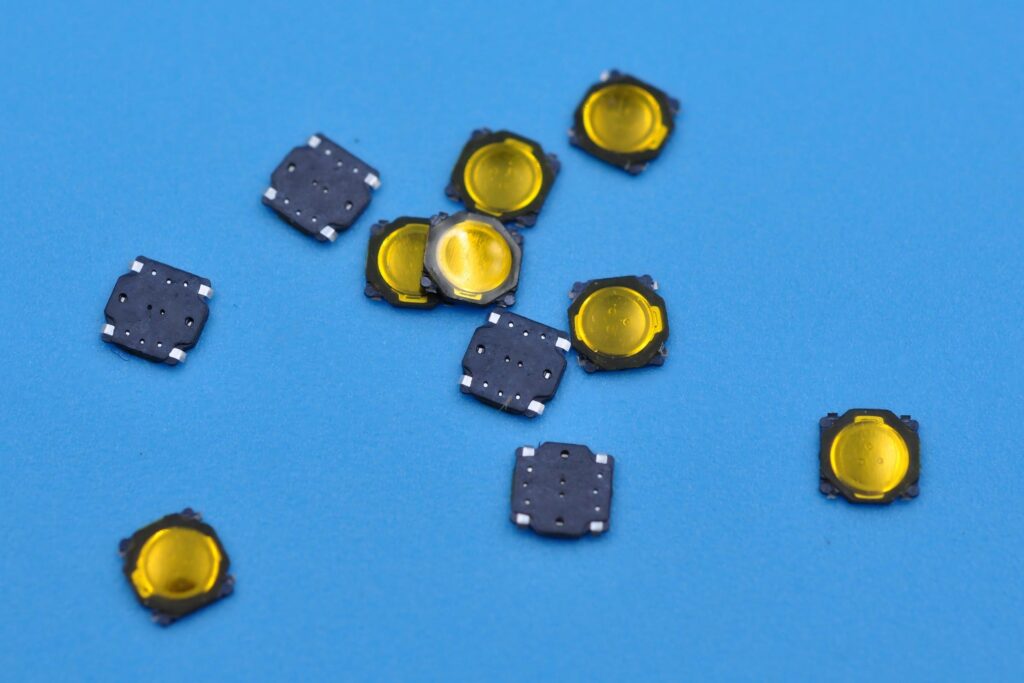

Is a metal dome button reliable for vehicles?

Absolutely. In fact, metal dome switches are preferred in automotive settings for their exceptional reliability. They’re built to handle millions of cycles without failure.

That’s critical in a car where buttons are used daily. Think about how many times you tap the automotive push button start or toggle the radio controls. Without a robust system, these buttons would fail quickly.

Here’s what makes metal domes a trustworthy choice:

- Durability: They withstand up to 1 million presses.

- Precision: The feedback ensures each action is felt and completed.

- Compact size: They allow sleek button designs.

- Minimal wear and tear: Thanks to quality stainless-steel construction.

So yes, if your car has a metal dome button, you can count on it for years.

Can dome buttons handle harsh automotive conditions?

Automotive environments are tough. Buttons are exposed to heat, cold, moisture, and dust. That’s where dome buttons shine.

They function under extreme temperatures, from frigid winters to scorching summers. Moisture, dirt, or vibrations don’t stop them.

Key strengths of dome buttons in harsh settings:

- Sealed designs protect against dust and moisture

- High-temperature resistance up to 125°C

- Anti-corrosion metal domes for longevity

- Vibration tolerance, ideal for bumpy roads

All these make metal dome buttons the smart choice for vehicle dashboards, steering wheels, and central consoles.

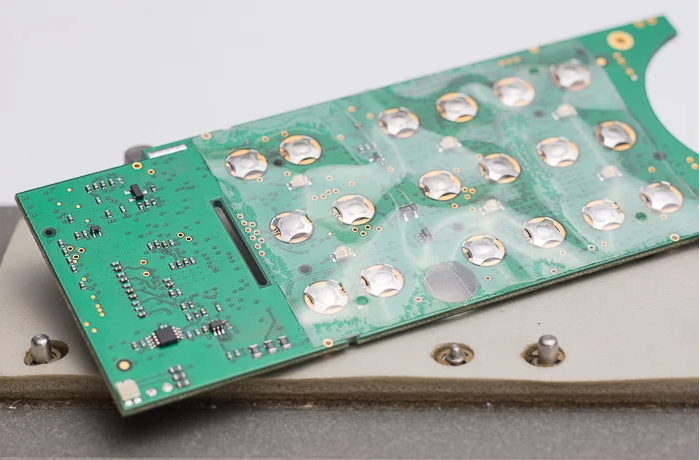

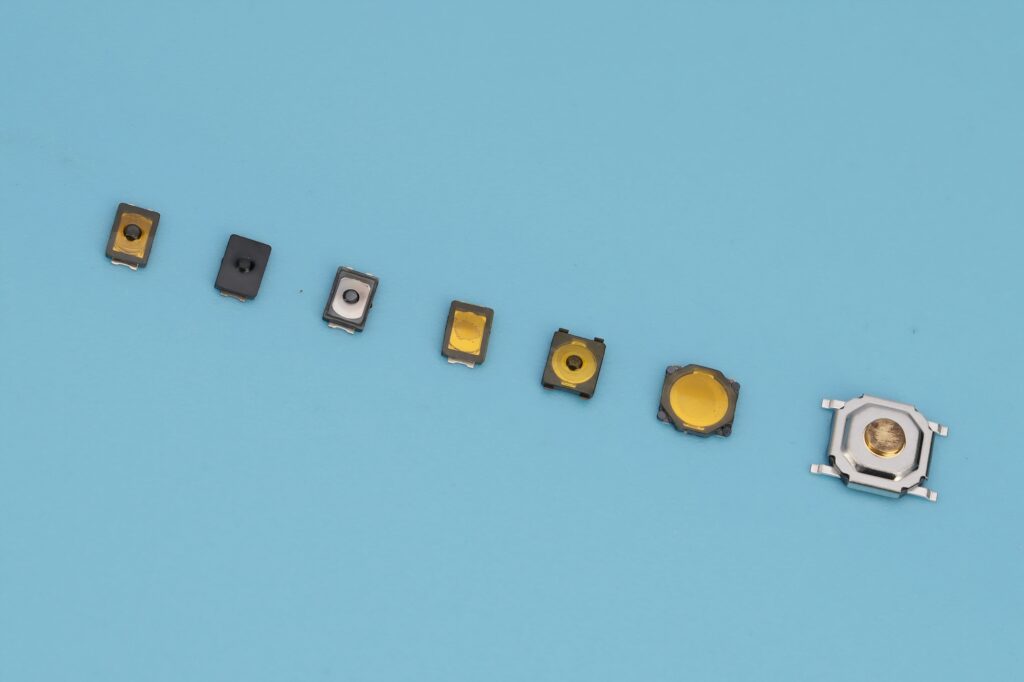

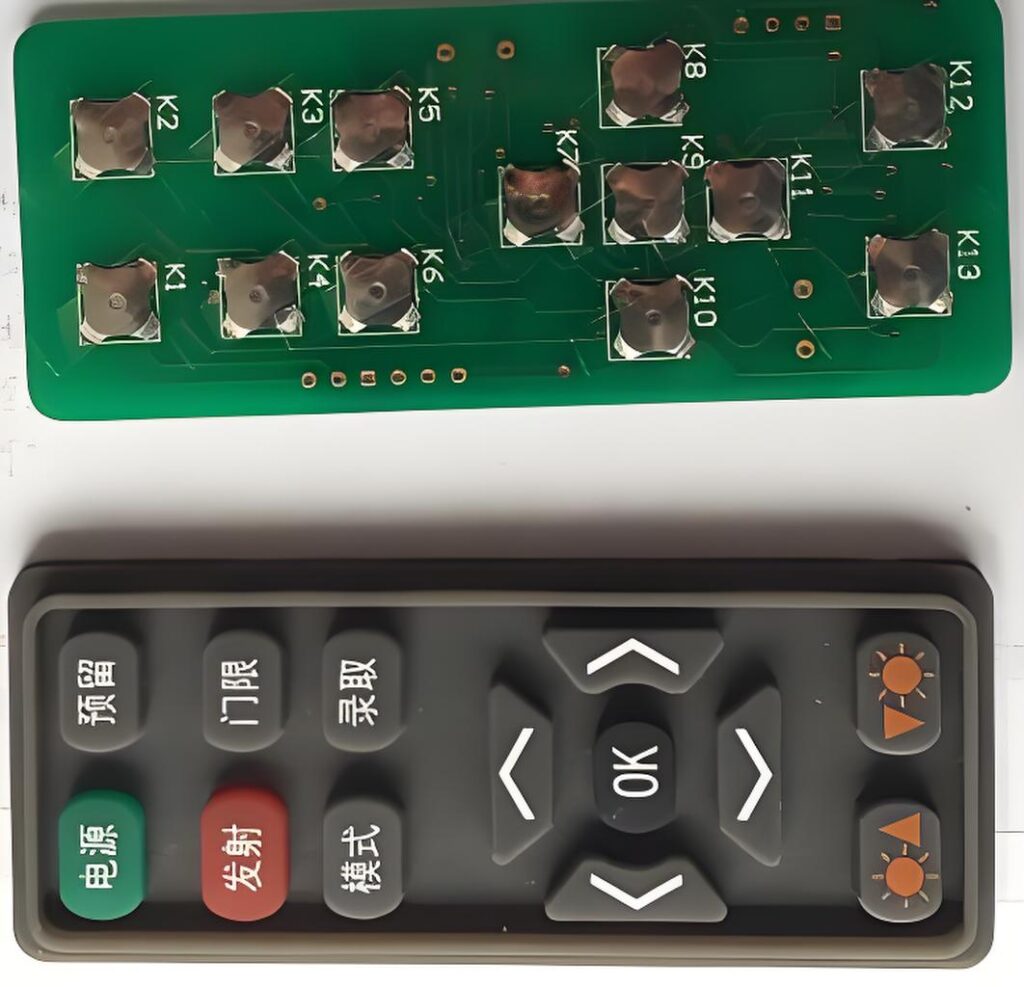

What’s inside a metal dome automotive button?

The heart of a dome button lies in its layered construction. Here’s a simplified look:

- Graphic overlay: The visible part of the button

- Spacer layer: Separates the circuit and dome

- Metal dome: Provides tactile feedback

- Bottom circuit: Where the signal is sent

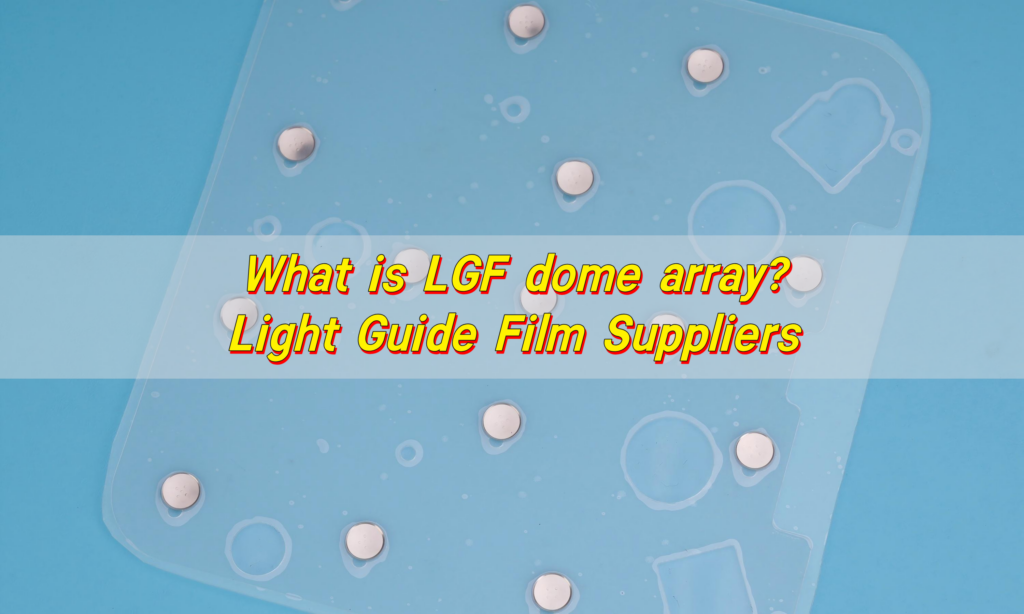

Some advanced designs also include:

- LEDs for backlighting

- Light guide films for even brightness

- Conductive adhesives to improve connection

This simple yet effective design makes automotive buttons reliable and versatile across many functions.

How does an automotive push button switch work?

Press the button. Hear the click. That click is not just a sound—it confirms your action was successful. In a metal dome automotive push button switch, here’s what happens:

- Your finger presses the button.

- The dome flexes and makes contact with the circuit.

- The electric signal is triggered.

- The dome springs back.

It takes less than a second, but this tactile feedback means the driver doesn’t need to look away from the road. It’s efficient and safe.

That’s why automotive starter buttons often use metal domes. You get instant feedback and precise response.

What are common automotive switches and buttons?

Cars today have dozens of buttons, each designed for specific needs. Here are some of the most common:

- Automotive push button start

- Steering wheel control buttons

- Window control switches

- Climate control buttons

- Infotainment system buttons

- Emergency flasher switches

- Seat heater toggles

Each of these uses different switch types, but many of them—especially those that require tactile feedback—use metal dome switches.

What is an automotive button used for?

Beyond just starting the engine, automotive buttons serve many roles:

- Convenience: Easy control of vehicle functions

- Safety: Immediate access to critical features

- Comfort: Customize the cabin environment

- Communication: Control calls and audio hands-free

Metal domes make these interactions more enjoyable. The satisfying click, the speed, and the response.

Conclusion:

Metal domes are the preferred choice for automotive buttons due to their excellent tactile feel, reliability, and durability. Whether you’re starting the engine, adjusting the air conditioning, or controlling the music, these small components can make a big difference.

They survive tough environments, offer instant feedback, and improve user satisfaction. As vehicle technology evolves, automotive buttons with metal domes will remain essential.

Want to upgrade your automotive buttons with high-quality dome switches? Contact us at sales@metal-domes.com