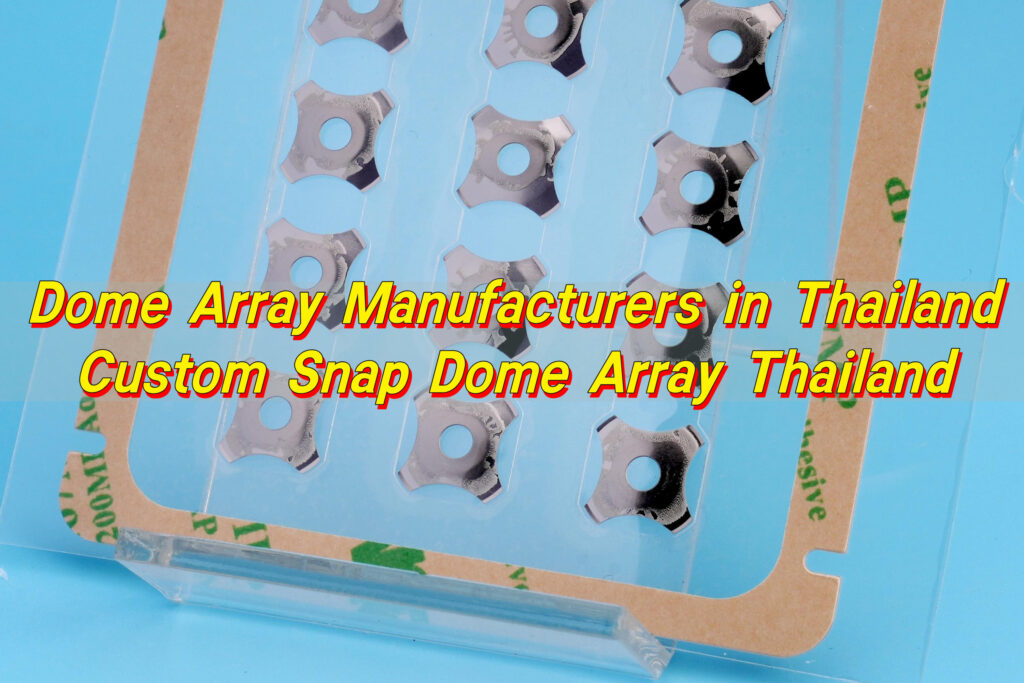

This article introduces trusted dome array manufacturers in Thailand, explains how buyers evaluate engineering depth and delivery reliability, and shows what truly differentiates professional suppliers from general EMS factories. It also outlines why global brands increasingly shortlist EBest Circuit (Best Technology) when benchmarking dome array manufacturers in Thailand for long-term projects.

Are you facing the following problems?

- Repeated sample modifications, inability to achieve stable mass production of the array structure

- Lack of data support for button feel design, relying solely on experience for adjustments

- Suppliers only provide assembly services, unable to offer material and spring structure optimization suggestions

- Increased failure rate after mass production, uncontrollable after-sales costs

- Low engineering communication efficiency, long problem identification cycle

End-to-End Solution: Our Solution

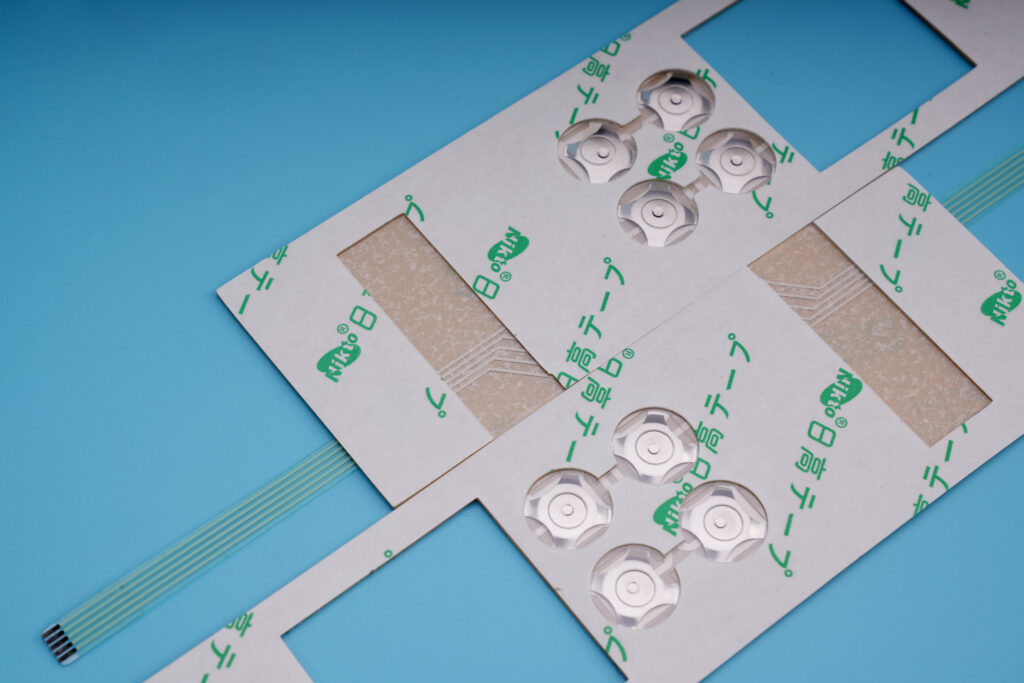

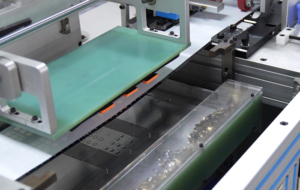

EBest Circuit (Best Technology) manages dome array projects in eight stages: “Requirements Confirmation -> Tactile Modeling -> Structural Design -> Small Batch Trial Production -> Reliability Verification -> Mass Manufacturing -> Standardized Packaging -> International Delivery,” with quantitative indicators and engineering review nodes set for each stage.

By establishing pressure curve models and array tolerance specifications in advance, we help customers lock in mass-producible solutions during the design phase, avoiding repeated modifications of PCBs and structural components later on. Simultaneously, combined with automated assembly and a traceable batch management system, we ensure consistent tactile and electrical performance across different order cycles.

Why Choose Us? EBest Circuit (Best Technology)’s Advantages

- Over 20 years of focus on the metal dome and array segment

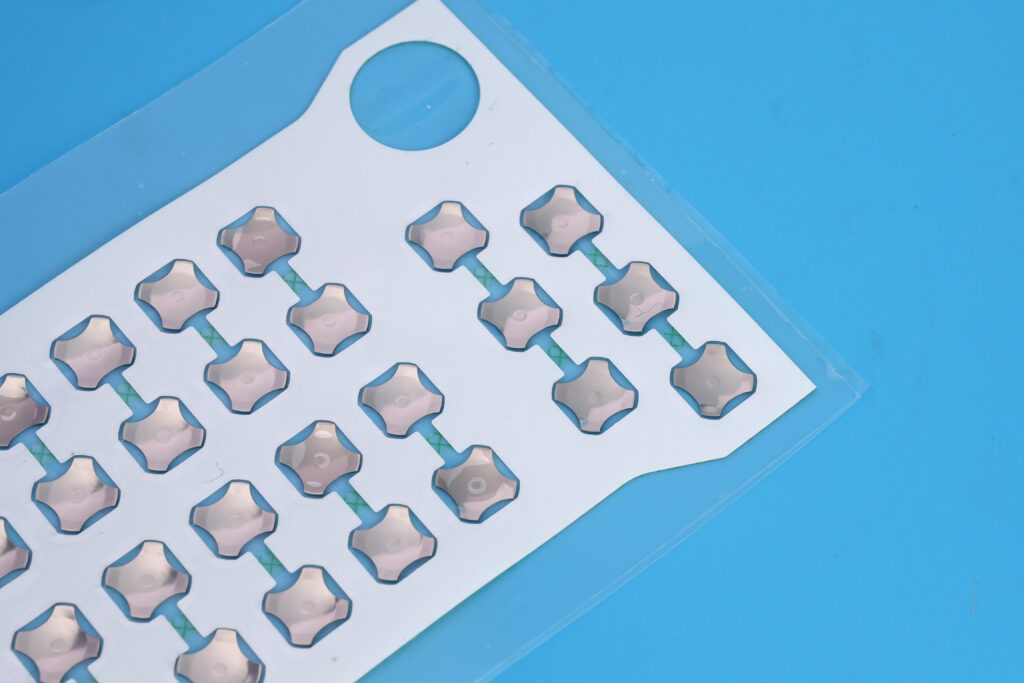

- Supports complex array structures and customized irregular layouts

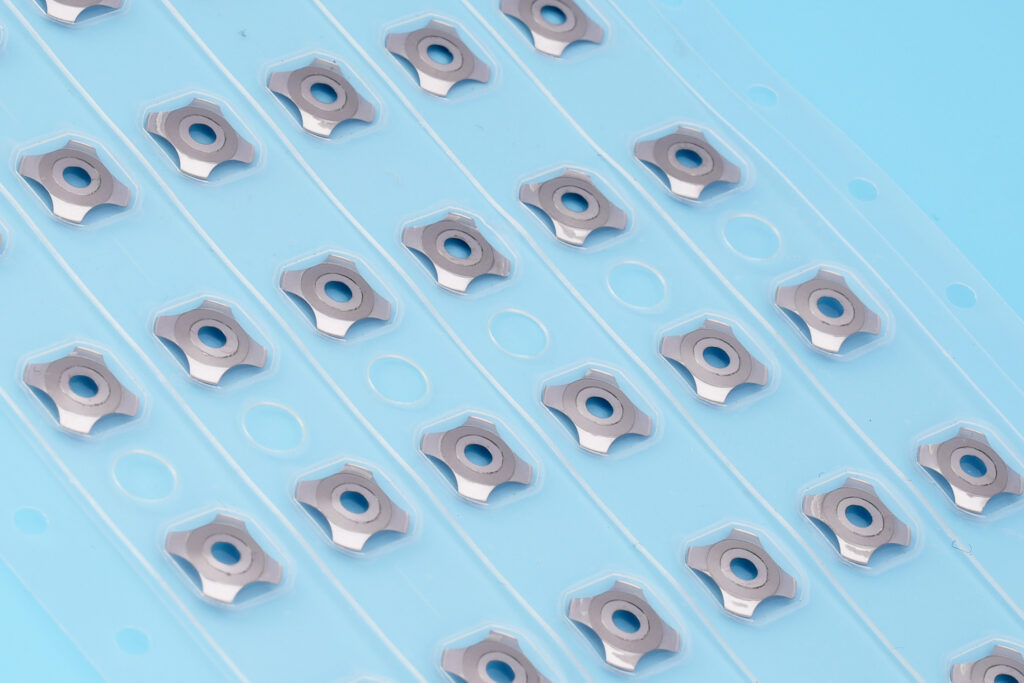

- Industry-leading batch force deviation control

- Automated assembly + Tape & Reel packaging, compatible with high-speed SMT

- Free engineering evaluation and initial sample production

- Dedicated project engineer for end-to-end support

Top 10 Dome array manufacturers in Thailand

| Company Name | Process Capability | Main Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Metal dome stamping, array lamination, automated inspection, Tape & Reel packaging | Focus on the dome array niche, strong engineering capability, stable delivery |

| Hana Microelectronics (Thailand) | PCBA, module assembly | Rich automotive electronics experience |

| Delta Electronics Thailand | Power supply and control system manufacturing | High level of automation |

| Cal-Comp Electronics Thailand | EMS, system assembly | Large-scale manufacturing capability |

| SVI Public Company Limited | Electronic Manufacturing Services (EMS) | Stable mid-to-high-end customer base |

| Sanmina Thailand | EMS, complex system assembly | Global supply chain support |

| Fabrinet Thailand | Optoelectronics and precision electronics manufacturing | High-reliability processes |

| Benchmark Electronics Thailand | Industrial and communication electronics manufacturing | Strong engineering support capability |

| MinebeaMitsumi Thailand | Electronic and electromechanical components | Precision machining capability |

| Sumida Electronics Thailand | Electronic component manufacturing | Mature quality system |

How to choose a Thailand Dome Array manufacturer?

- Do they have the capability for pressure force modeling and lifespan prediction?

- Can they provide array tolerance and alignment data?

- Do they support small-batch engineering verification?

- Do they have automated assembly equipment?

- Do they have experience with international customer projects?

- Do they provide complete test reports?

Why is EBest Circuit (Best Technology) a better choice for long-term cooperation?

EBest Circuit (Best Technology) doesn’t simply execute production based on drawings; instead, we participate in customer projects with a core model of “engineering co-creation.” We adjust the shrapnel material, thickness, and rebound structure according to the application scenario (automotive, medical, industrial, etc.), and quickly match mature solutions through our internal database, significantly shortening the design cycle.

During mass production, unified array design specifications and automated testing systems ensure minimal tactile differences between different batches, helping customers build a stable product reputation instead of frequently dealing with after-sales issues.

Core Pain Points of Thailand Dome Array Manufacturers

- Lack of standardized array design methods

- Non-quantifiable tactile tuning process

- High proportion of manual assembly, large yield fluctuations

- Slow feedback on engineering problems

- Disorganized project document management

EBest Circuit (Best Technology)’s Solutions:

- Establish a standard array structure library and material selection rules

- Use testing instruments to quantify pressure force and rebound curves

- Automated assembly and online inspection reduce human error

- Provide engineering improvement solutions within 48 hours

- Unified technical data and version management system

How to analyze the production capacity of a Thailand Dome Array manufacturer?

- Number of automated assembly lines

- Monthly stable output capacity

- Processing capabilities for irregularly shaped arrays

- Testing equipment configuration

- Ratio of engineering personnel

- Quality traceability system

- Multi-project parallel capability

EBest Circuit (Best Technology) has multiple dedicated array production lines and independent testing stations, serving multiple industry customers simultaneously and maintaining consistent delivery quality under high-volume orders.

How to evaluate the delivery time of a Thailand Dome Array manufacturer?

- Engineering sample confirmation cycle

- Mold development speed

- Raw material reserves

- Production line switching flexibility

- Does it support urgent orders?

- International logistics experience

EBest Circuit (Best Technology) can deliver samples and urgent projects within 2-3 days, and regular orders have a clear scheduling mechanism to avoid project delays due to unstable supply.

Thailand Dome Array Manufacturer Frequently Asked Questions (FAQ)

- Q1: Why do different suppliers have significantly different button feel?

A: The key lies in whether the contact spring material, heat treatment method, and structural design have undergone systematic modeling and testing.

- Q2: Is automatic assembly necessary for array products?

A: Yes, automation can significantly reduce the risk of misalignment and poor soldering.

- Q3: How to avoid quality degradation between batches?

A: Choose manufacturers with batch traceability and parameter locking mechanisms.

- Q4: What information should be included in the engineering documents?

A: It should include dimensions, tolerances, force curves, life cycle testing, and material specifications.

- Q5: Is it difficult to secure long-term supply for niche specifications?

A: If the supplier has its own molds and material channels, long-term stable support is possible.

From professional array structure design to rapid delivery and stable mass production, EBest Circuit (Best Technology) has become one of the key partners for many international customers when evaluating the top 10 dome array manufacturers in Thailand.