When searching for conductive film manufacturers in Hungary, customers typically focus not only on price but also on prototyping speed, conductivity stability, structural reliability, and the ability to handle long-term mass production. Truly professional conductive film manufacturers in Hungary must possess a deep understanding of materials, structural design capabilities, and large-scale manufacturing experience to ensure stable long-term delivery in applications suchs as industrial control, medical equipment, and consumer electronics.

Are you facing these problems?

- Long prototyping cycles, and multiple rounds of communication still fail to meet tactile and conductivity requirements.

- Poor consistency in dome array structure, with inconsistent quality between small batches and mass production.

- Unstable conductive film conductivity, failing life cycle testing.

- Insufficient design support; manufacturers can only “produce according to drawings,” unable to optimize the structure.

- Limited capacity of local manufacturers, making delivery times difficult to guarantee.

- Incomplete quality documents and certification materials, affecting end-customer audits.

End-to-End Process Guarantee from Requirements to Delivery

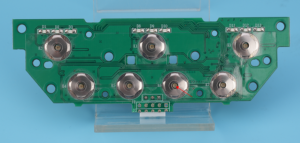

As a professional manufacturer specializing in dome arrays and conductive films for many years, EBest Circuit (Best Technology) focuses on “engineering-driven manufacturing,” forming a complete closed loop from requirements assessment, structural design, material selection, sample verification, to mass production and delivery.

We don’t simply take orders and produce; we get involved in customer design early on, proactively mitigating failure risks and ensuring conductivity consistency, button lifespan, and assembly compatibility.

This is why more and more Hungarian customers choose to cooperate with us long-term – for greater stability, peace of mind, and control.

Why Choose Us? EBest Circuit (Best Technology)’s Core Advantages

- 20+ years of experience in dome array and conductive film manufacturing, serving high-demand fields such as industrial, medical, and telecommunications.

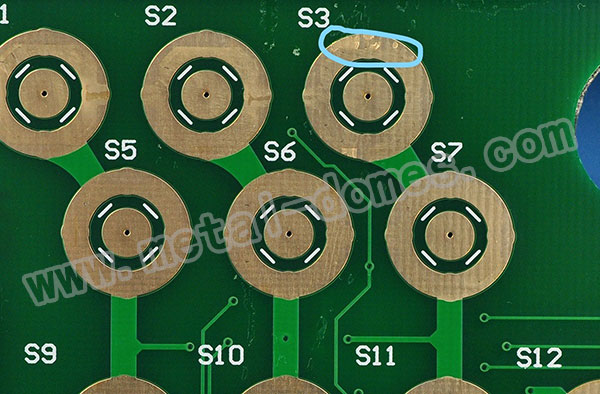

- ±0.05mm structural precision control, ensuring high consistency in conductivity and tactile feel.

- Stable lifespan of ?1 million presses, far exceeding conventional market standards.

- Fast prototyping and engineering response, providing technical feedback within 48 hours.

- Full OEM/ODM support, from design to mass production, all in one place.

- ISO9001 system control, ensuring strong batch stability and traceability.

Top 10 dome array manufacturers in Hungary

| Company Name | Process Capability | Core Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Dome array and Conductive film design, prototyping, and mass production (Overseas collaboration prototyping/manufacturing center) | Provides optimization solutions for product electrical characteristics and key lifespan; Fast sample feedback; Engineering support |

| Videoton EAS Kft. | Electronic Manufacturing Services (PCBA, box build, EMS) | One of Hungary’s largest EMS providers; Large production line scale; Covers industrial electronics manufacturing services |

| TI-Electronic Company | PCB assembly and precision SMT/THT | 30+ years of PCB assembly and circuit manufacturing experience, supports assembly of various components |

| Elektromont Kft. | PCB assembly and electronic module assembly | Provides PCB assembly, cable assembly, and unit assembly services |

| Gémosz Elektronikai Kft. | EMS & SMD assembly | Supports small/medium batch production; Can handle rapid prototyping and sample production |

| Albacomp EA Kft. | PCB assembly & circuit manufacturing | Provides PCB assembly, testing, and wiring harness services |

| Z Elektronika Kft. | EMS, prototype development, process development | Supports integrated process from design to manufacturing |

| ECO-Elektronik | SMT/PCB assembly | Supports small/medium/large volume SMT production |

| SMTplus Kft. | SMT production services | Flexible production lines support small/medium batch orders |

| Kontron Electronics Kft. | EMS & electronic system assembly | Provides modern electronic assembly and system manufacturing services |

How to choose a Hungary dome array manufacturer?

- Do they have integrated conductive film capabilities?

- Can they provide engineering advice instead of just executing drawings?

- Are there quantifiable standards for structural accuracy and consistency?

- Do they have life cycle and conductivity testing capabilities?

- Is the quality consistent between small batches and mass production?

- Do they support OEM/ODM?

- Can they respond quickly to design changes?

EBest Circuit (Best Technology)’s advantages: We are involved from the design stage, and through structural optimization and material matching, we help customers achieve near-mass production standards with just one prototype, significantly reducing repeated modifications and time costs, making us the most worry-free choice for Hungarian customers.

Core pain points of Hungary dome array manufacturers

- Slow prototyping and long verification cycles

- Unstable conductivity and rapid life cycle degradation

- Lack of structural optimization capabilities

- Poor batch consistency

- Narrow process window and low yield

- Uncontrollable delivery schedule

EBest Circuit (Best Technology)’s solution:

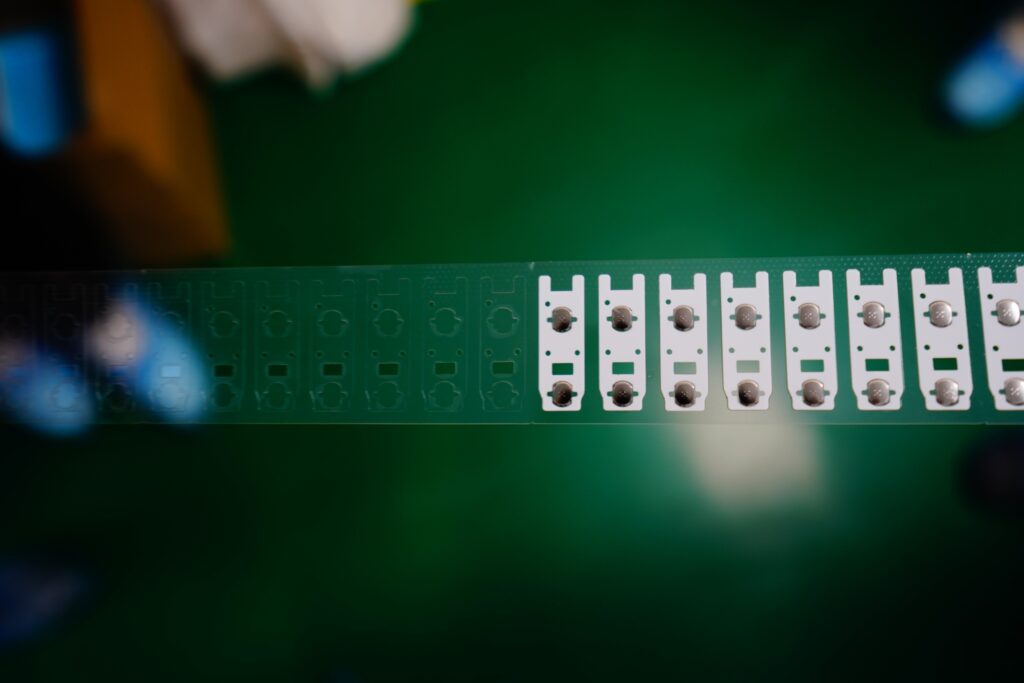

Through a mature mold system, standardized process parameters, and life cycle verification mechanisms, we lock in mass production processes at the sample stage, ensuring consistent performance from the first piece to the 100,000th piece.

How to analyze the production capacity of a Hungary dome array manufacturer?

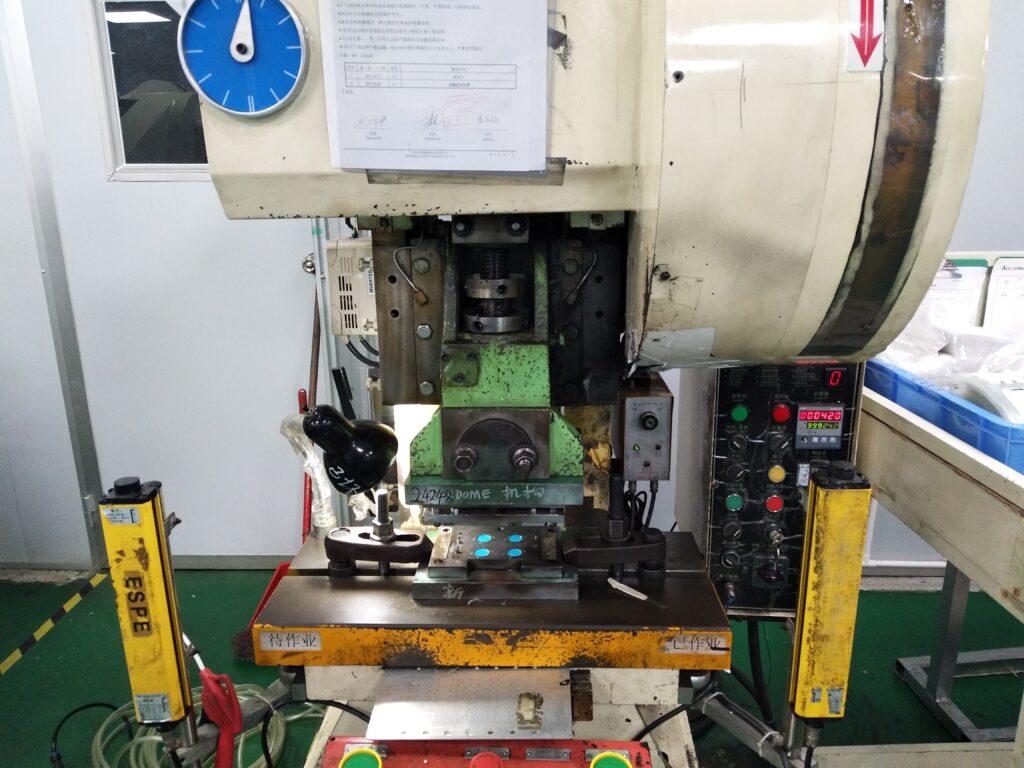

- Do they have dedicated dome forming and bonding equipment?

- Do they have conductive film material control capabilities?

- Do they have life cycle and environmental testing?

- Do they support multi-specification parallel production?

- Are yield and rework rates controllable?

- Do they have batch traceability capabilities?

EBest Circuit (Best Technology) fully meets the above conditions and has SMT and dome-related production lines in China and Vietnam, possessing stable and scalable delivery capabilities.

How to evaluate the delivery time of a Hungary dome array manufacturer?

- Is prototyping standardized?

- Are the molds owned in-house?

- Is the engineering response timely?

- Is the production line flexible?

- What are the material preparation and inventory mechanisms?

- Do they support urgent orders?

EBest Circuit (Best Technology) can achieve fast sample delivery in 2-3 days, and the mass production cycle is significantly shorter than the industry average, helping customers seize project milestones.

Common questions about Hungary dome array manufacturers

- Q1: Why is the feel of the sample and mass-produced product inconsistent?

A: This is often because the sample was not made according to the mass production process. EBest Circuit (Best Technology) uses mass production parameters at the prototyping stage.

- Q2: How to solve unstable conductivity?

A: Through material matching and structural optimization, rather than simply replacing the conductive layer.

- Q3: What if the life cycle test fails?

A: Both the dome shape and the conductive film thickness need to be adjusted simultaneously, and we can complete the optimization during the design phase.

- Q4: Do you support customization?

A: We support full OEM/ODM customization, including size, feel, and lifespan requirements.

If you are looking for truly reliable conductive film manufacturers in Hungary that can not only provide samples but also ensure stable mass production and fast delivery, then EBest Circuit (Best Technology) is the conductive film manufacturer in Hungary worth partnering with for the long term.