Dome array manufacturer in Netherlands selection plays a critical role in whether your product can pass validation smoothly and enter mass production without repeated rework. From early design validation to long-term supply, BEST Technology helps Netherlands customers reduce engineering risk, maintain tactile consistency, and accelerate time to market.

Are you facing the following problems?

- Unable to obtain dome array structure suggestions during the design phase, resulting in trial and error.

- Samples are available, but the tactile feel or positioning changes after mass production.

- Insufficient matching between the dome array and PCB/FPC assembly.

- Each design modification requires re-validation of the entire structure.

- Limited support during the small-batch production phase, slowing down project progress.

- Unstable delivery times, affecting product validation and market launch schedule.

End-to-end process guarantee from requirements to delivery: Our Solution

BEST Technology does not treat dome arrays as “passive components,” but rather as part of the human-machine interaction system. Our process aims to reduce validation cycles and lower structural risks:

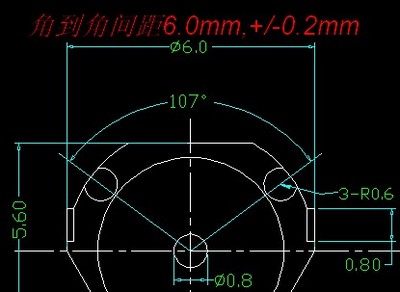

- Evaluating click force, lifespan, and structural limitations based on application scenarios.

- Providing suggestions on array spacing and positioning methods during the dome array design phase.

- Using the same materials and processes as mass production to complete samples.

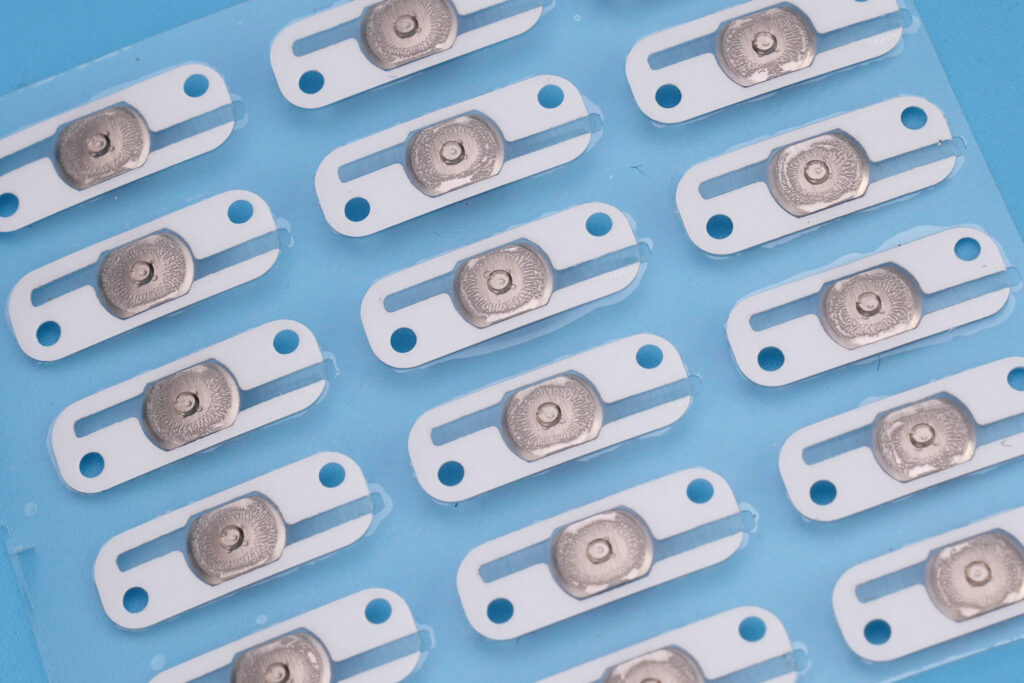

- Controlling tolerances during the array attachment phase to avoid assembly deviations later.

- Enabling dome arrays to directly enter the SMT process through automated packaging.

- Establishing a fast delivery channel for mature solutions to shorten project cycles.

This mechanism allows Netherlands customers to lock in mass production feasibility during the design phase, rather than waiting until problems arise before rework.

Why choose us? BEST Technology’s Core Advantages

- Focus on dome arrays, not general electronic manufacturing.

- Involvement from the design phase, not just accepting drawings.

- Long-term stable array accuracy, suitable for automated assembly.

- Quantifiable and reproducible click force and lifespan parameters.

- Smooth transition from small-batch verification to mass production.

- Engineering and manufacturing are handled by the same team, ensuring seamless communication.

List of Netherlands Dome Array Manufacturers

Top 10 dome array manufacturers in the Netherlands

| Company Name | Process Capability | Advantage |

|---|---|---|

| BEST Technology | Dome array design and manufacturing, Tape & Reel | Strong customization capability, stable consistency |

| Philips Innovation Services | Electronics and medical equipment | Rich R&D resources |

| ASML (NL) | Precision system manufacturing | Ultra-high-end equipment experience |

| VDL Group | Electromechanical and electronic manufacturing | Scaling capability |

| Prodrive Technologies | Industrial electronics | High-reliability systems |

| Neways Electronics | EMS (Electronic Manufacturing Services) | European manufacturing network |

| Benchmark Electronics NL | EMS (Electronic Manufacturing Services) | International project experience |

| TKH Group | Industrial technology | Industrial customer base |

| Jabil Netherlands | EMS (Electronic Manufacturing Services) | Global supply chain |

| NXP Ecosystem Partners | System integration | Semiconductor support |

How to Choose a Netherlands Dome Array Manufacturer?

- Do you understand the role of dome arrays in human-machine interfaces?

- Can they participate in designing the dome array, rather than just receiving finished drawings?

- Can the array accuracy be maintained long-term?

- Is there batch-to-batch variation in click force?

- Do they support SMT automatic placement?

- Are the samples representative of mass production processes?

- Will engineering modifications trigger cascading risks?

- Are they suitable for long-term product line collaboration?

Why is BEST Technology a better fit for you?

Compared to suppliers who treat dome arrays as “replaceable parts,” BEST Technology helps Netherlands customers mitigate structural and assembly risks during the design phase, allowing a single confirmed solution to be replicated long-term, avoiding the time and cost losses associated with repeated verification.

Core Pain Points of Netherlands Dome Array Manufacturers

- Separation of design and manufacturing makes problem identification difficult

- Insufficient customization depth for dome arrays

- Array alignment gradually loses control during mass production

- Tactile consistency relies on manual experience

- Limited support for automated packaging

- Project cycles are extended by multiple rework cycles

BEST Technology’s Solution

- Design and manufacturing are completed by the same engineering system

- Customization is achieved at the mold and material level, not just simple adjustments

- Standardized array attachment process reduces cumulative errors

- Click force is managed parametrically, not subjectively

- Provides Tape & Reel, allowing direct integration into SMT

- Risks are addressed in the early stages, not postponed until mass production

How to Evaluate the Production Capabilities of a Netherlands Dome Array Manufacturer?

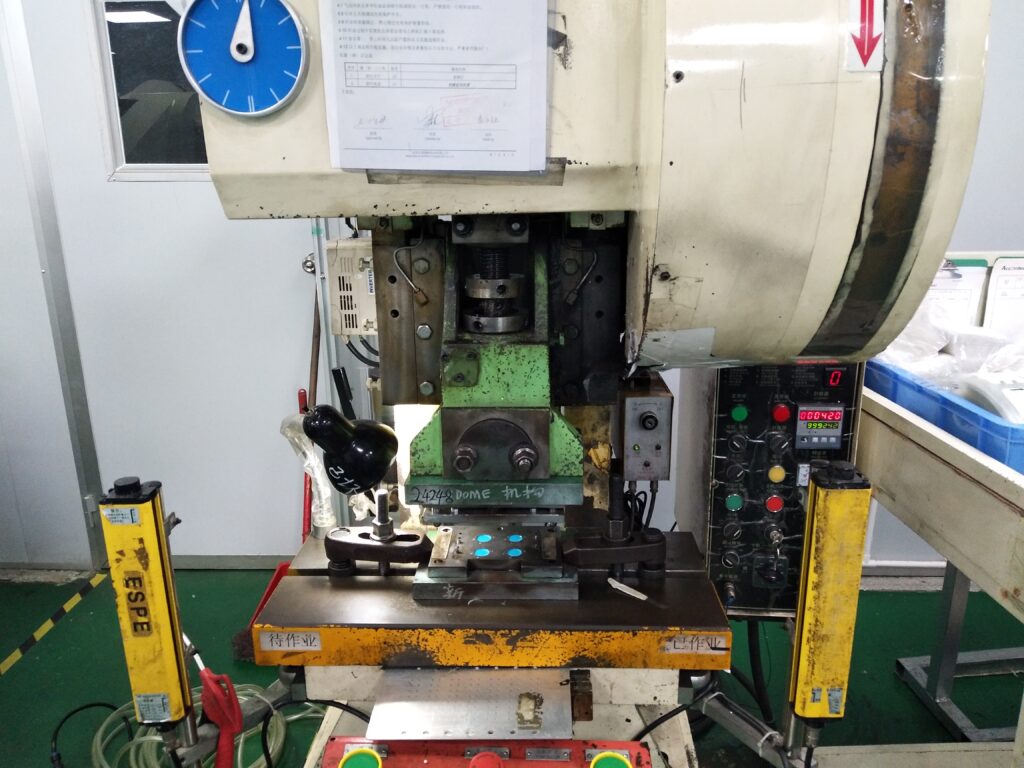

- Do they have their own dome stamping capabilities?

- Can they stably control array attachment tolerances?

- Automation ratio and yield level

- Click force and lifespan testing system

- Multi-specification parallel production capabilities

- Batch consistency control methods

- Engineering change execution efficiency

- Are they suitable for long-term supply?

BEST Technology’s Capabilities

We have complete dome stamping, array attachment, and automated packaging production lines. Through systematic testing and process control, every batch of dome arrays shipped to the Netherlands maintains high consistency in structure, feel, and assembly performance.

How to evaluate the delivery time of Netherlands dome array manufacturers?

- Do samples require separate production scheduling?

- Can repeat orders be processed quickly?

- Do they have a mature solution library?

- How much does automation support delivery time?

- What is the response speed after design modifications?

- Can they provide clear time commitments?

- Is actual delivery stable?

- Do they support expedited projects?

BEST Technology’s Delivery Capabilities

For verified dome array solutions, BEST Technology can achieve fast delivery within 2-3 days, helping Netherlands customers accelerate verification at critical junctures or meet urgent production needs.

Frequently Asked Questions for Netherlands Dome Array Manufacturers

- Q1: Can you participate in the dome array design phase?

A: Yes, we provide dome array design support.

- Q2: Are samples and mass-produced products completely identical?

A: Yes, using the same materials and processes.

- Q3: How do you control click force consistency?

A: Through dual control of molds and test parameters.

- Q4: Do you support SMT assembly?

A: Yes, we support Tape & Reel packaging.

- Q5: Can the delivery time be shortened?

A: Mature solutions can be completed within 2-3 days.

- Q6: Is it suitable for long-term product lines?

A: Yes, we support long-term stable supply.

After comparing the top 10 Netherlands dome array manufacturers, it can be seen that BEST Technology has advantages in design collaboration, manufacturing stability, and delivery efficiency, making it a more suitable choice for long-term cooperation among the top 10 Netherlands dome array manufacturers.