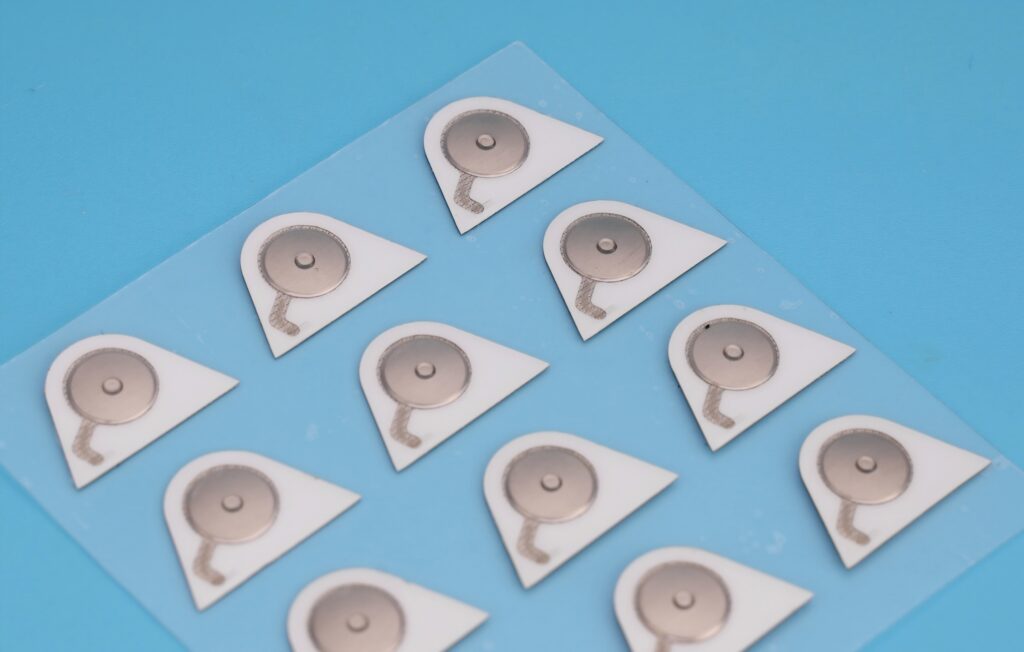

Metal dome conductive film (dome array) is a kind of glued PET array & sheet that carries metal dome, which will be peeled easy from the released paper and place sticky on circuit boards, as a switche of electronic device.

What is metal dome conductive film?

Metal dome conductive film is a thin, flexible layer placed over or under a metal dome in a switch structure. It carries an electrically conductive property, which allows current to flow when the dome is pressed.

This film acts as both a protective cover and a contact enhancer. It helps maintain stable performance by reducing oxidation, preventing dust intrusion, and ensuring that each press results in a clean, reliable signal.

In many cases, the conductive film comes as part of a dome array—where multiple domes are arranged and fixed on an adhesive sheet for easy installation. By combining both, manufacturers create switches that are not only responsive but also durable under repeated use.

Common metal domes for conductive films

Metal domes come in different shapes and sizes, and the conductive film must match their design for best results. Four common dome types are widely used:

- Four-leg domes have high stability and strong tactile feedback. They are often used in industrial equipment where consistent performance is critical.

- Triangle domes are compact and deliver sharp tactile response. They work well in handheld devices with small button spaces.

- Round domes offer a smooth and balanced click feel. They are common in consumer electronics and medical devices where comfort is important.

- Oblong domes fit narrow or elongated buttons. They are suited for control panels with limited space.

The conductive film must match the dome’s geometry. This ensures that every press is transmitted effectively, without delay or misalignment. Using the right pairing also reduces assembly errors and increases switch lifespan.

How does a conductive film sticker metal dome button work?

When you press a metal dome button with a conductive film sticker, the process is simple but precise. The metal dome, made of stainless steel, is slightly convex. It rests above two contact points on the PCB.

The conductive film covers the dome, holding it in place and protecting it from contamination. As you press, the dome collapses and makes contact with the PCB pads. The conductive film ensures that the contact area is stable and clean, which results in a quick and accurate electrical signal.

Once the pressure is released, the dome springs back to its original shape, breaking the contact. This quick action—combined with the tactile click—gives users a confident and satisfying feedback.

This quick action produces the familiar tactile click. The film also keeps the dome clean, which helps maintain signal reliability over time.

What is electrically conductive film made of?

Electrically conductive films are engineered from specialized materials that balance flexibility and conductivity. Common components include:

- Polyester (PET): Lightweight, flexible, and durable. Often used as the base material.

- Conductive coatings: Usually made from silver, carbon, or a conductive polymer. This layer enables the transfer of electrical signals.

- Adhesive backing: For easy application to dome arrays or PCBs.

The choice of coating depends on the application’s requirements. Silver coatings offer high conductivity and low resistance. Carbon coatings are cost-effective and have excellent wear resistance. Conductive polymers provide flexibility for more demanding designs.

Why use conductive films in dome arrays?

Conductive films add an important layer of reliability to dome arrays. Without them, domes are more exposed to dust, moisture, and oils from human touch. Over time, these contaminants can affect conductivity and cause inconsistent performance.

By integrating conductive films:

- Contact resistance stays stable for longer periods.

- Tactile feel remains consistent even after heavy use.

- The array becomes easier to handle during assembly.

- Durability improves, reducing the need for early replacements.

For manufacturers, this means fewer quality control issues and more satisfied customers. For end users, it means a smooth and dependable experience.

How to apply conductive film to a dome array?

Applying conductive film to a dome array requires precision. Here’s a simplified process:

- Clean the surface: The adhesive side of the dome array must be free of dust and oils.

- Align the film: The conductive film is cut to match the array’s layout, ensuring each dome is properly covered.

- Laminate carefully: Apply pressure evenly to avoid wrinkles or air bubbles.

- Inspect: Verify alignment and adhesion before packaging or assembly.

BEST Technology use automated machines for this process to achieve accuracy within ±0.05 mm. This ensures the film works effectively across all domes in the array.

Benefits of a metal dome array with conductive film

Using a metal dome array with conductive film offers clear advantages:

- Enhanced durability: Protects against wear, dust, and oxidation.

- Stable electrical performance: Keeps resistance low and consistent.

- Improved assembly efficiency: Pre-cut films align perfectly with dome arrays.

- Better tactile experience: Preserves the click feel for longer.

- Reduced maintenance costs: Longer lifespan means fewer replacements.

These benefits make conductive films a smart investment for projects where reliability and user experience are priorities.

How do conductive films improve metal domes?

Conductive films add extra value to metal domes by improving their electrical and physical performance. They protect the contact surface from oxidation, which can weaken signal strength over time.

They act as a barrier against dust and small debris that could block movement. They also help keep moisture away from the dome, preventing corrosion.

By maintaining a clean contact surface, the film ensures that every press delivers the intended tactile feedback and signal response.

Where is electrically conductive film used?

Electrically conductive films are versatile. They are found in:

- Consumer electronics: Remote controls, gaming devices, mobile phones.

- Industrial controls: Machine interfaces, control panels, measuring devices.

- Medical equipment: Diagnostic devices, handheld scanners.

- Automotive applications: Steering wheel controls, dashboard panels.

- Home appliances: Microwave ovens, washing machines, air conditioners.

In each of these applications, the combination of tactile domes and conductive films ensures a responsive and long-lasting button performance.

Conclusion:

Metal dome conductive films improve switch performance by protecting contacts, reducing resistance, and extending service life. When combined with a well-designed metal dome array, it creates a switch that is responsive, durable, and ready for heavy use.

Best Technology is the professional manufacturer of metal dome, snap dome, metal dome array, LGF (light guide film) in China, with different package: in PE bag, Tube, pick & place reel. We can also provide metal dome array assembled on PCB and flex circuits. Whatever type of trip force of metal dome or dome array you need, we will make it happen.

For more information or to discuss your project needs, contact us at: sales@metal-domes.com