What is a tactile dome?

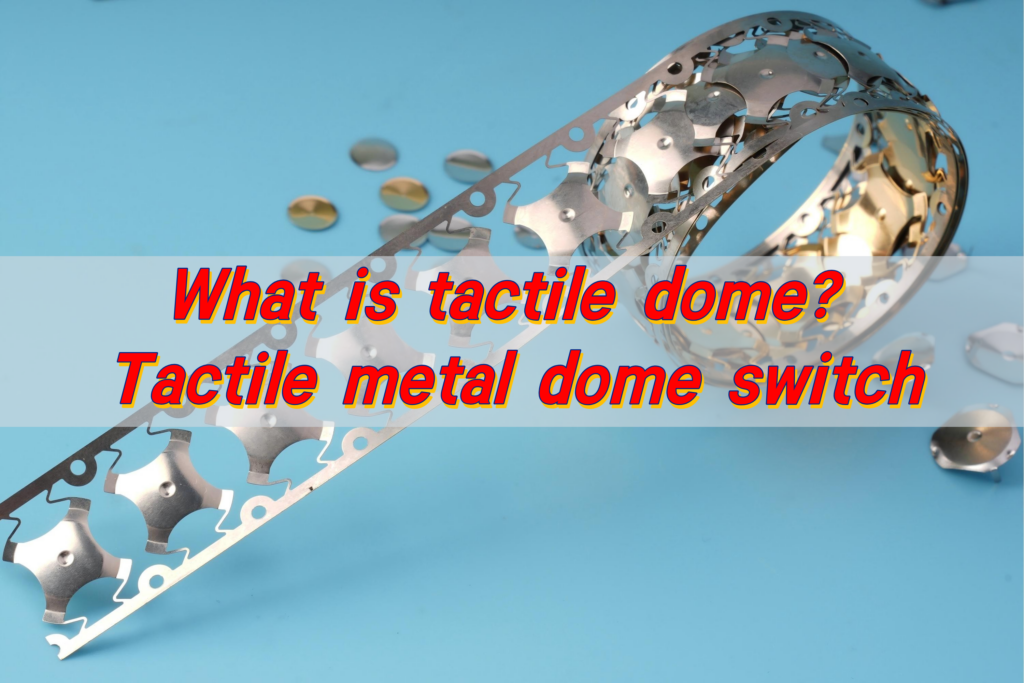

Tactile dome is a small yet essential component used in electronic switches. Its purpose is to give users tactile tactile feedback, a physical response that feels like a soft snap or click when pressed. Most tactile domes are made from stainless steel and are designed to collapse and rebound when activated. This motion creates a signal by bridging the contact points on the PCB underneath.

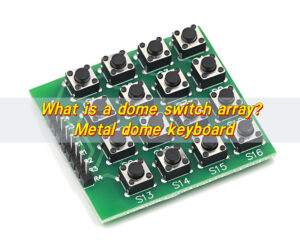

In a tactile dome switch, the dome acts as the mechanical spring. When force is applied, the dome collapses and connects with the circuitry below. When released, it pops back into shape, ready for the next press.

Tactile domes can be round, triangle-shaped, four-leg, or oblong. They vary in force, size, and response. Their design influences how the button feels and behaves. Despite their size, they play a big role in how responsive a device feels to the user.

Is the tactile dome worth it?

If you value precision, the tactile dome is absolutely worth it. It brings reliable tactile tactile feedback without bulky mechanical parts. They make sure every touch counts.

Their thin profile allows them to fit into compact spaces. They’re ideal for handheld devices, control panels, and wearable electronics.

What makes them even more worthwhile is durability. A quality metal dome can last millions of presses without losing performance. That saves money and time over the long run.

Is the tactile switch loud?

No, a tactile dome switch isn’t loud. It produces a gentle, satisfying snap. This is different from the loud clack of mechanical keyboards. The sound comes from the dome’s movement as it collapses and rebounds.

It confirms that the switch has registered the input. In quiet environments like hospitals or control rooms, this gentle sound is quiet enough to be unobtrusive.

There’s a balance between silence and response. Tactile domes hit the sweet spot. They give feedback without becoming distracting. And if total silence is needed, dome styles with lower force and reduced noise are available.

How does a tactile dome switch work?

Tactile dome switch works by collapsing the metal dome onto a conductive trace or pad on a circuit. This action creates an electrical connection. When released, the dome returns to its original shape, breaking the connection.

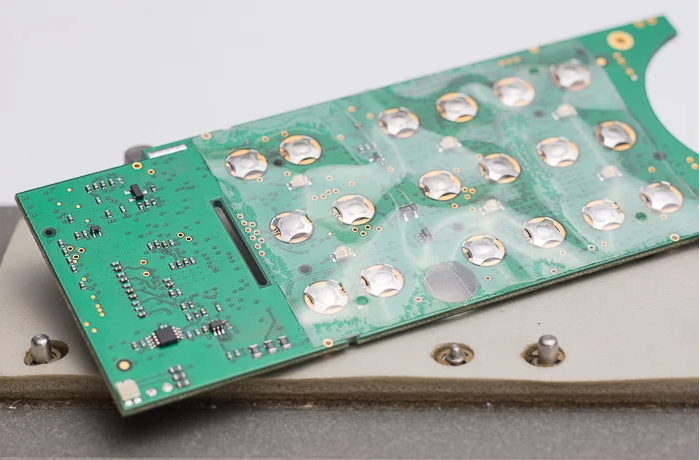

The dome sits between an overlay and the PCB. When the user presses the top layer, the pressure travels to the dome. Once the force passes a certain point, the dome snaps downward. That snap closes the circuit below. When released, the dome rebounds instantly.

The result is fast, accurate input. Each press is clean and controlled. That’s why industries like automotive, telecom, and medical prefer tactile metal dome switches.

Are rubber dome keyboards tactile?

Rubber dome keyboards have a softer feel and are less responsive. Rubber domes rely on a flexible membrane that deforms when pressed. But it lacks that sharp feedback.

In contrast, metal tactile domes offer a clear click. The difference is like tapping on sponge versus snapping a spring. The rubber dome compresses, but the response is slow. Metal domes rebound with precision.

For low-cost consumer devices, rubber domes might be acceptable. But for professional-grade electronics, they don’t hold up. They wear out faster and can become inconsistent over time. If tactile response is essential, metal domes are the only real choice.

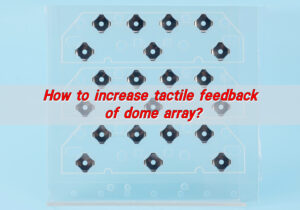

How do tactile metal domes make contact with PCB?

Tactile metal domes connect with the PCB through pressure. When pressed, the center of the dome touches the conductive pads on the PCB. This completes the circuit and sends a signal to the device.

The dome’s shape is crucial here. It’s engineered to collapse in a controlled way. Some designs include dimples or legs to improve stability and response. The pressure required for contact can be adjusted by changing the material thickness or dome shape.

When the force is removed, the dome’s tension restores it to its original shape. It’s a fast, precise method that doesn’t rely on complex mechanics.

Because of this contact system, metal domes are used in devices that demand high reliability and minimal maintenance. They’re sealed, clean, and efficient.

Are tactile mech dome keyswitches reliable?

Yes, they are extremely reliable. Tactile mech dome keyswitches can handle millions of cycles without failure. Their structure is simple yet strong.

Each dome is made from stainless steel. It resists rust, temperature, and pressure damage. Even in tough environments, tactile domes stay consistent. Whether used in outdoor equipment or sensitive lab gear, they deliver the same feel every time.

What makes them even more dependable is their simplicity. Fewer components mean fewer points of failure. In industrial and medical equipment, this reliability is priceless.

How to wire silicone dome tactile switch?

Wiring a silicone dome tactile switch involves placing the silicone sheet over the PCB, aligning it so that each dome covers a set of conductive traces.

When a dome is pressed, a carbon pad on the underside touches the traces, closing the circuit. The wiring is done by designing the traces on the PCB in such a way that each dome has a dedicated circuit.

Keep in mind that silicone domes aren’t the same as metal tactile domes. They provide softer feedback. The tactile tactile response isn’t as sharp. But they still serve well in low-cost or flexible applications. Wiring must be clean and accurate, as any misalignment can cause performance issues.

Tactile dome inside: what should you know?

Inside every tactile dome is thoughtful design. The shape, material, and structure all affect performance. Most tactile domes are made from 301 or 304 stainless steel.

The center might have a dimple. That dimple helps guide the press force and improve the return snap. Some domes have four legs for stability. Others have triangle or oblong shapes for different force profiles.

Under the dome is usually adhesive tape or a spacer layer. This keeps the dome centered and prevents false presses. It also helps manage travel and resistance.

What you should know most: not all domes are created equal. Small changes inside the dome can make a big difference in feel and durability.

How long do tactile domes last?

A good tactile dome lasts between 1 million and 5 million presses. Some high-end domes go even further. That lifespan depends on usage, pressure, and environmental factors.

Metal tactile domes from trusted manufacturers, like Best Technology, go through strict testing. Their performance stays consistent across their entire lifespan. Even after thousands of presses, the snap remains crisp.

This long life makes tactile domes ideal for devices used every day. Keypads, medical instruments, industrial controls. You save time, reduce errors, and avoid costly replacements.

Where are tactile domes used?

Tactile domes are everywhere. You’ll find them in:

- Remote controls

- Car dashboards

- Medical instruments

- Security systems

- Military equipment

- Industrial control panels

- Telecommunication devices

- POS systems and ATMs

They’re perfect for any device that needs durable, responsive switches. Designers use them because they fit tight spaces and still deliver strong feedback.

From daily gadgets to mission-critical tools, tactile domes deliver. Their flexibility, performance, and lifespan make them essential in modern electronics.

Conclusion:

Tactile domes may be small, but they offer a big advantage in electronic switch design. Whether you need precision control in a medical device or a reliable input for a consumer gadget, tactile dome switches deliver performance you can feel.

Want help choosing the best tactile dome for your project? Reach out to our team at sales@metal-domes.com