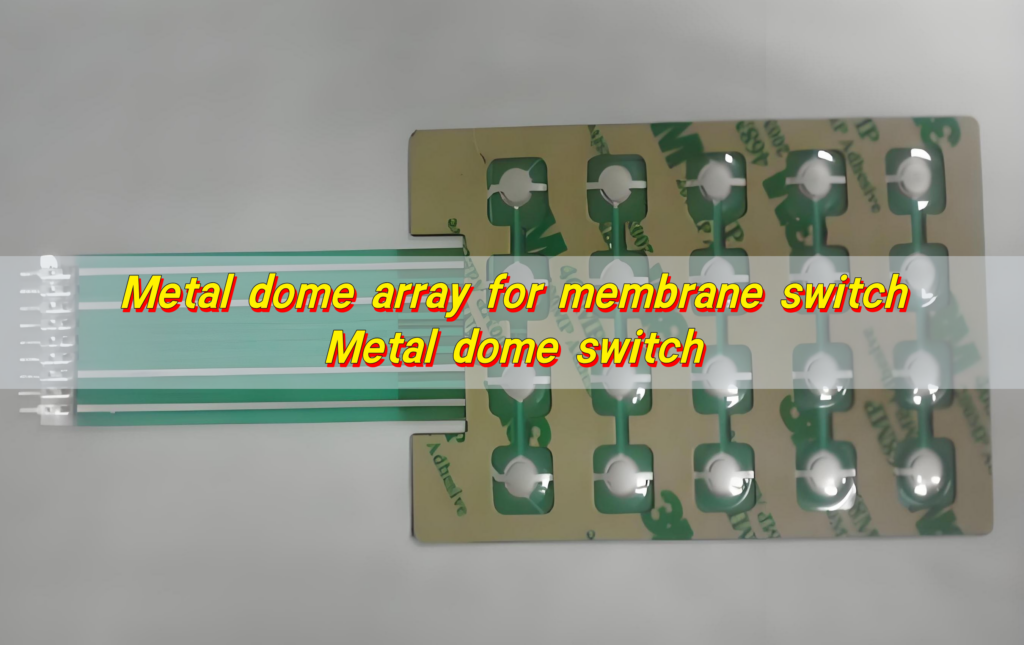

Metal dome array for membrane switch is a key electronic component. It consists of multiple small metal domes arranged in a specific array, each of which has good elasticity and conductivity. When used in combination with a membrane switch, these metal domes can provide instant circuit connection when the key is pressed, ensuring fast signal transmission.

What is a metal dome array?

Metal dome array is a set of tactile domes mounted onto a flexible adhesive sheet. Each dome is placed at a specific location aligned with a circuit beneath. When pressure is applied, the dome collapses downward and completes the circuit, then quickly returns to its original shape once the pressure is released.

This array is layered between the graphic overlay and the circuit layer in a membrane switch. It acts as the tactile feedback system while maintaining electrical performance. Arrays can be custom designed to fit the shape and size of each button on a switch panel, making them ideal for various industries.

Metal dome arrays are most commonly found in medical devices, handheld controls, industrial equipment, and consumer electronics.

What materials are used in dome arrays?

The domes themselves are typically made from stainless steel. This metal is chosen because it’s strong, corrosion-resistant, and flexible. The steel can also be nickel-plated, which improves conductivity and resistance to wear. Dome material must hold its shape under millions of actuations without fatigue. That’s why quality stainless steel is non-negotiable in long-life applications.

The adhesive sheet that carries the domes is usually made from PET (polyester) film. PET is stable, flexible, and can withstand repeated use without distortion. The film must be clear, durable, and dimensionally stable. The adhesive used between the dome array and circuit layer must also be clean and strong.

Each material used in the dome array must be tested for durability, accuracy, and compatibility.

What is a metal dome sheet?

Metal dome sheet is a flexible layer containing a group of metal domes pre-positioned in exact locations. This sheet can be a single dome format or a complete dome array depending on the application. It simplifies assembly, increases dome placement accuracy, and helps maintain consistency across every device.

There are two types of dome sheets: loose dome sheets and pre-assembled dome arrays. Loose sheets provide single domes that are manually positioned, which increases labor. In contrast, dome arrays are factory-assembled to exact specifications. They speed up production and reduce errors.

Metal dome sheets offer another important benefit. They protect domes during storage and transportation. Sheets also prevent contamination and help ensure every dome stays in perfect working condition until final installation.

Which dome shape offers the best feel?

Dome shape directly affects how the switch feels when pressed. The choice depends on how strong or soft the tactile feedback needs to be.

Four-leg domes are the most common and widely preferred. Their shape allows for even pressure distribution, strong tactile feedback, and excellent rebound.

Triangle domes have a slightly lighter actuation force, offering faster feedback. These are useful for applications where users need a gentle press or frequent tapping.

Round domes provide a softer, smoother feel. These are ideal for devices operated with minimal pressure, such as medical touchpads or portable devices.

Oblong domes are shaped for directional or long-button interfaces. They’re used when the button layout is narrow or linear.

Each shape has a specific response curve. However, if strong tactile response and long life are required, four-leg domes consistently deliver the best experience.

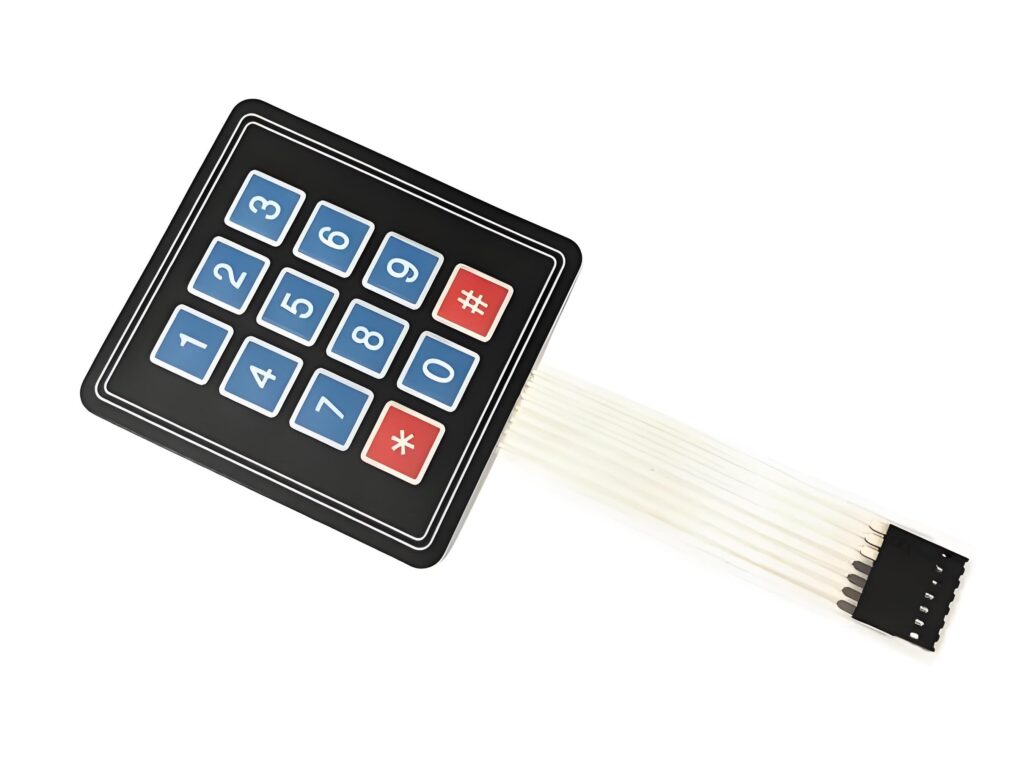

How is metal dome array installed in membrane switch?

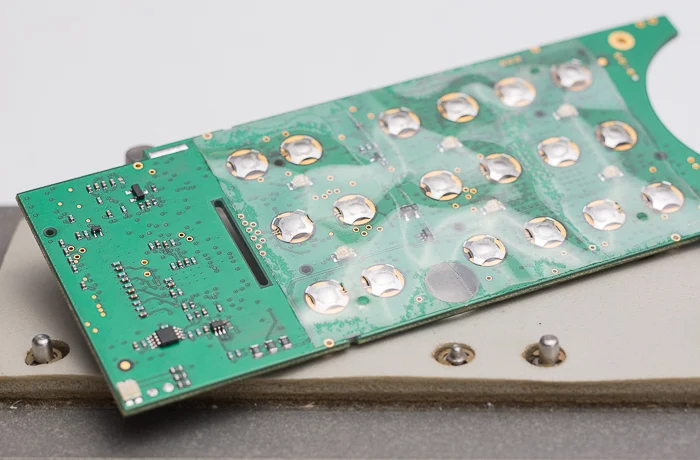

Installation begins with the printed circuit layer. Once this layer is complete, the dome array is carefully aligned on top. The domes must match exactly with the underlying contacts. This precision determines how reliably each press will register.

Once aligned, the dome array is laminated using a pressure-sensitive adhesive. This ensures each dome stays in place and maintains the right distance from the circuit layer.

Spacer layer is often added between the dome array and the lower circuit to prevent accidental contact. Above the dome array, a graphic overlay is attached.

In high-speed manufacturing, especially with Tape & Reel packaging, dome arrays are installed using automated pick-and-place machines. This process improves speed, consistency, and accuracy, especially for large-volume production.

Every layer must be flat, clean, and properly bonded. Even a small misalignment can reduce tactile feedback or cause response issues. That’s why precise engineering and experienced assembly teams are essential.

Why use metal domes in membrane switches?

First, the tactile response is unmatched. Metal domes provide a crisp, clean click that tells users the press was successful.

Second, domes are incredibly durable. Many high-quality domes are tested to 1 million presses or more. This extends the life of the entire device and reduces failure rates.

Third, metal domes offer low electrical resistance. This ensures that the signal is clean and accurate, with minimal power loss. They also maintain consistent actuation force, meaning each press feels the same every time.

Fourth, metal domes are compact and light. They fit into thin interfaces without needing springs or large mechanisms. This allows for sleek, modern designs without sacrificing function.

Finally, they are versatile. Force values, shapes, sizes, and materials can all be customized to suit any interface. From rugged outdoor equipment to delicate medical devices, metal domes meet the challenge.

How does a dome switch work?

When you press down on the button, you’re applying force to the top of a metal dome. As the pressure increases, the dome collapses downward and connects the top and bottom layers of the circuit.

This instant contact closes the circuit and sends an electronic signal. As soon as you release the button, the dome springs back into shape, breaking the circuit again. This snap action not only provides electrical function but also tactile feedback.

Its shape and material allow it to flex and recover millions of times without deformation. It requires no lubrication, springs, or external components. This structure is reliable, repeatable, and efficient

How long do metal dome switches last?

High-quality domes can last between 1 million to 5 million cycles, depending on the material and usage environment.

Factors that influence dome life include dome thickness, actuation force, environmental exposure, and frequency of use. Stainless steel domes typically offer the longest life. Nickel-plated domes provide additional corrosion resistance, especially in humid or harsh environments.

Domes designed and manufactured with precision—like those offered by Best Technology—undergo extensive quality checks and life testing. These tests simulate years of use in real-world conditions.

Long-lasting dome means fewer replacements, lower costs, and happier users. When durability matters, metal domes deliver—press after press.

Conclusion:

The metal dome array for membrane switch is more than a layer—it’s the foundation of a responsive, durable interface. Dome shape influences feel, dome material determines life, and proper installation ensures performance.

Four-leg domes offer the best feel for most applications. Stainless steel ensures strength. And dome sheets simplify manufacturing and improve reliability.

Do you need a metal dome array? Contact us at sales@metal-domes.com and request a free sample.