What is a metal dome for microwave control panel?

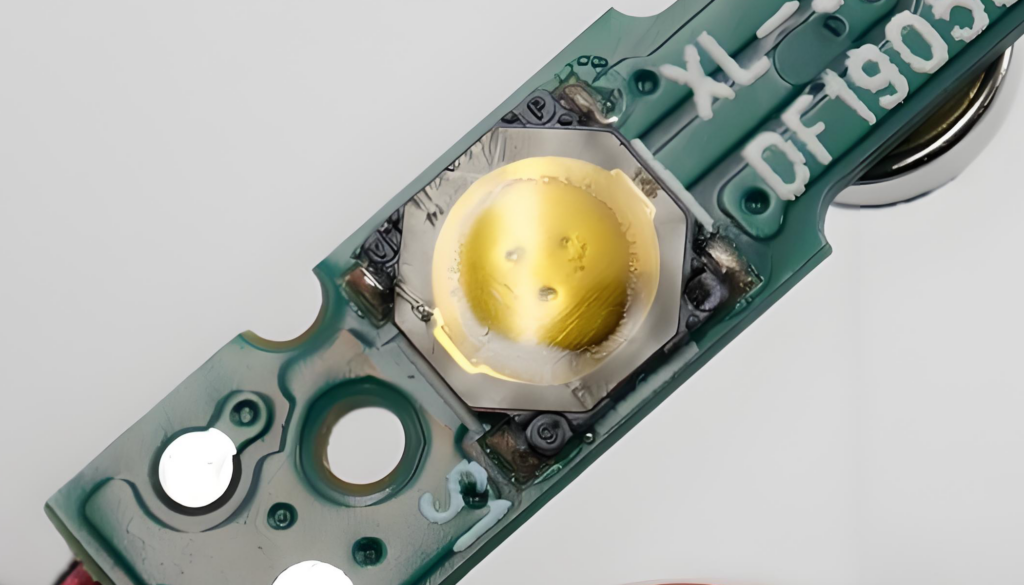

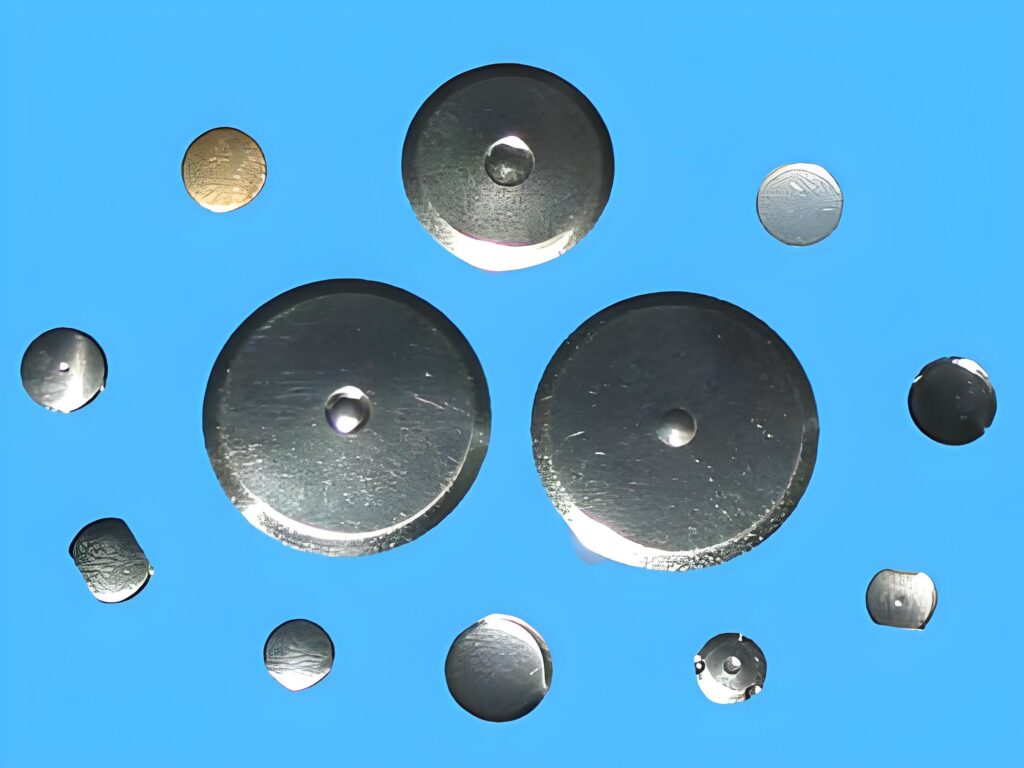

Metal dome for microwave control panel is a tiny switch made from stainless steel. When you press a button on a microwave, you feel a crisp snap. That snap comes from this dome. Its job is simple. It connects the circuit when pressed and disconnects it when released.

Each dome is shaped to store energy. When pressure is applied, the dome flexes down. When you remove pressure, it springs back to its original shape.

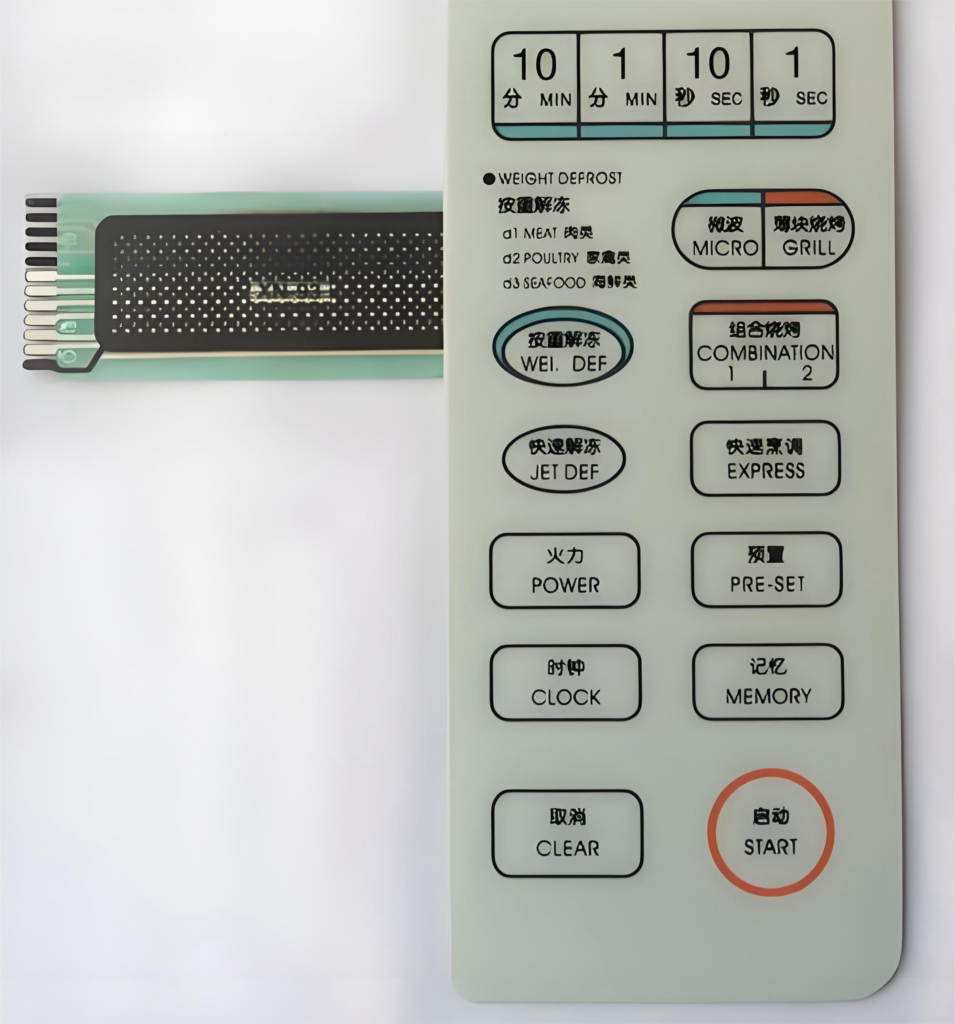

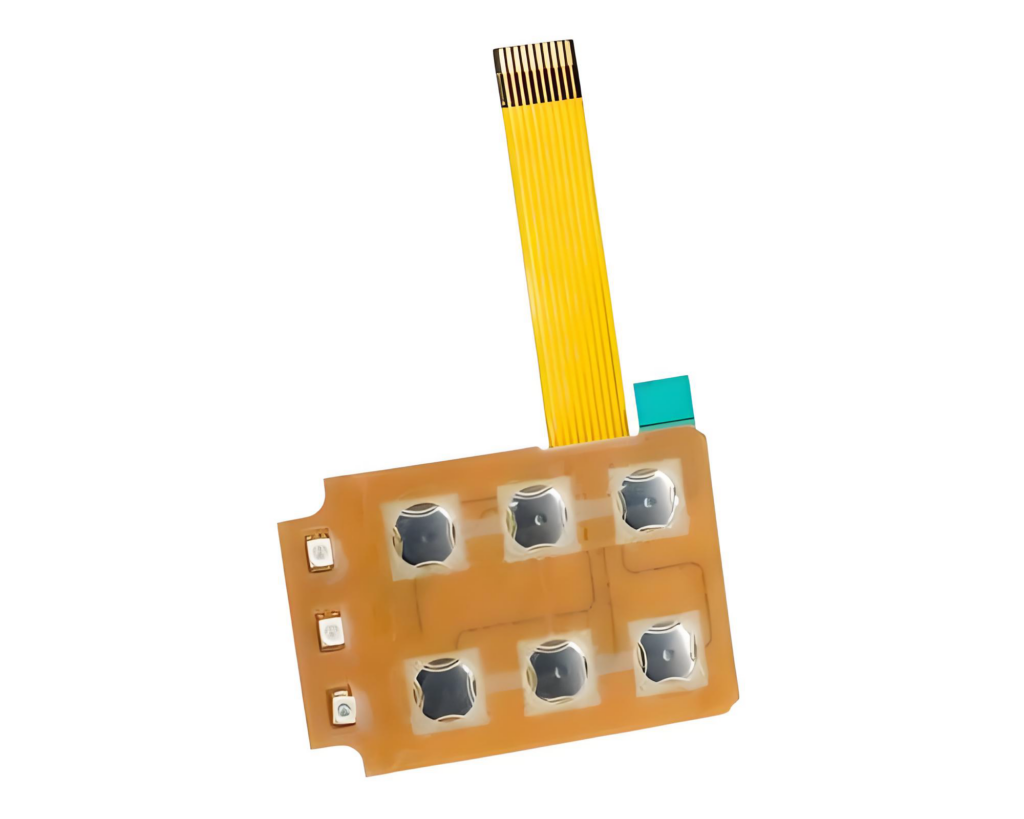

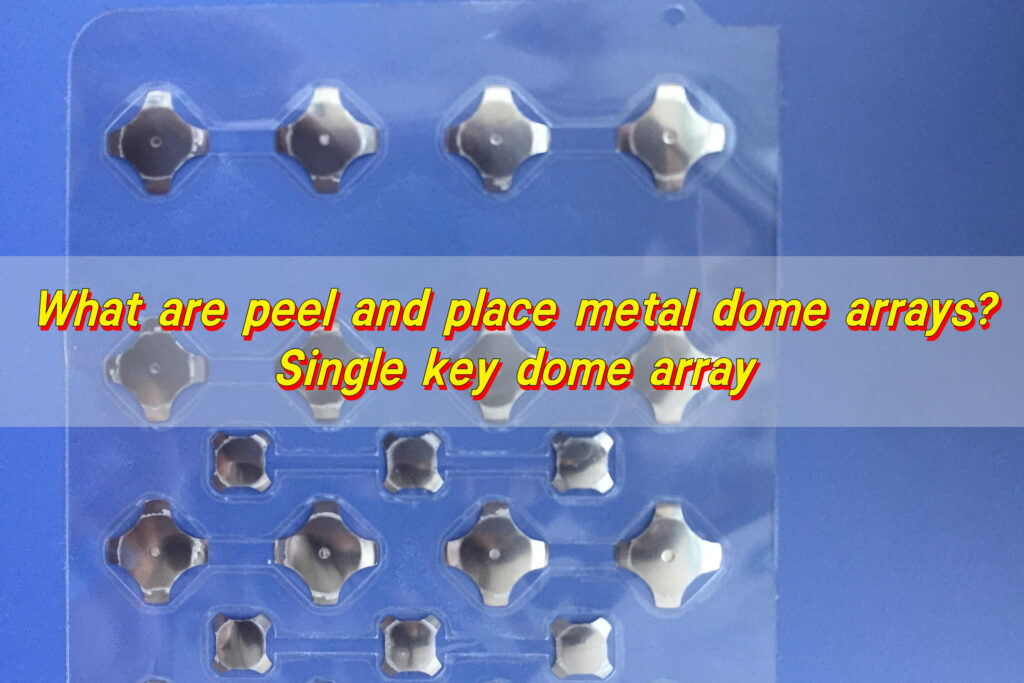

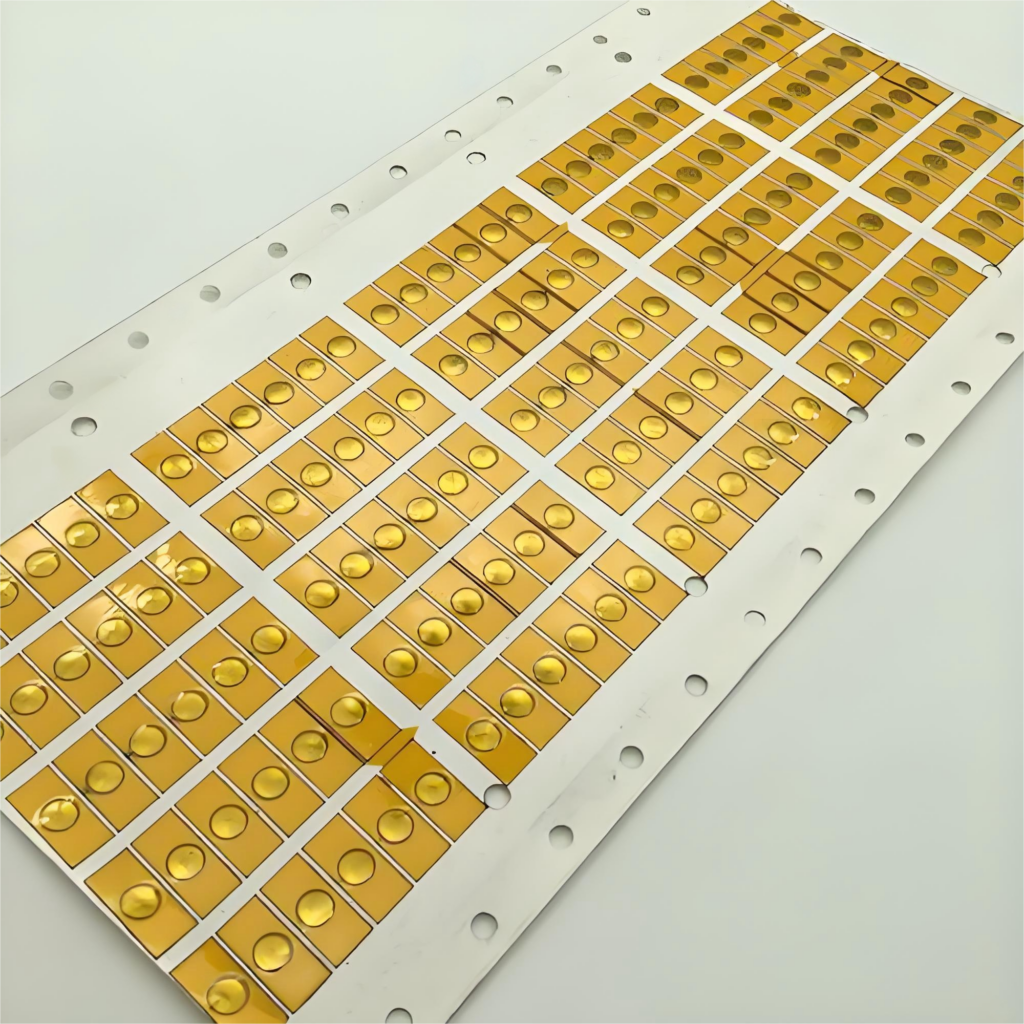

Inside the microwave panel, domes sit under the printed layer. They may be placed individually or arranged in an organized metal dome array. The array helps position the domes exactly where the keys need them.

The dome also controls the tactile response. This includes:

- How strong the click feels.

- How loud the click sounds.

- How much force the user must apply.

Why use a metal dome array in microwave keypads?

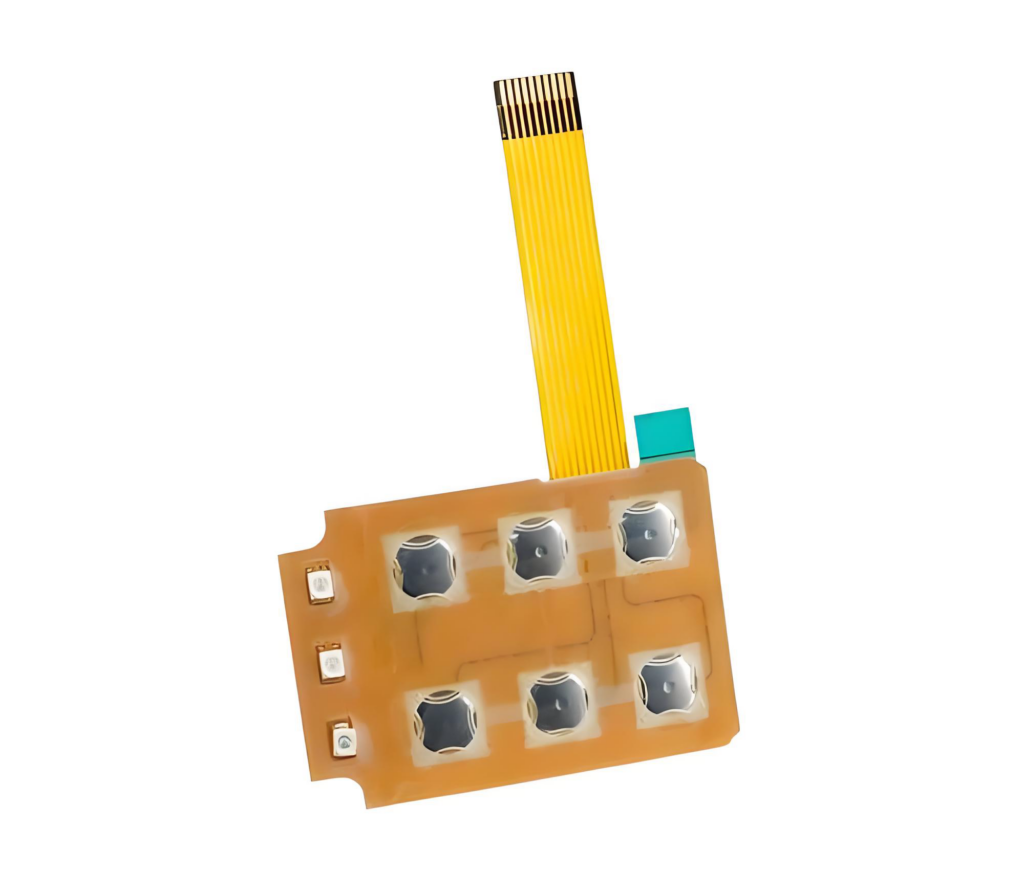

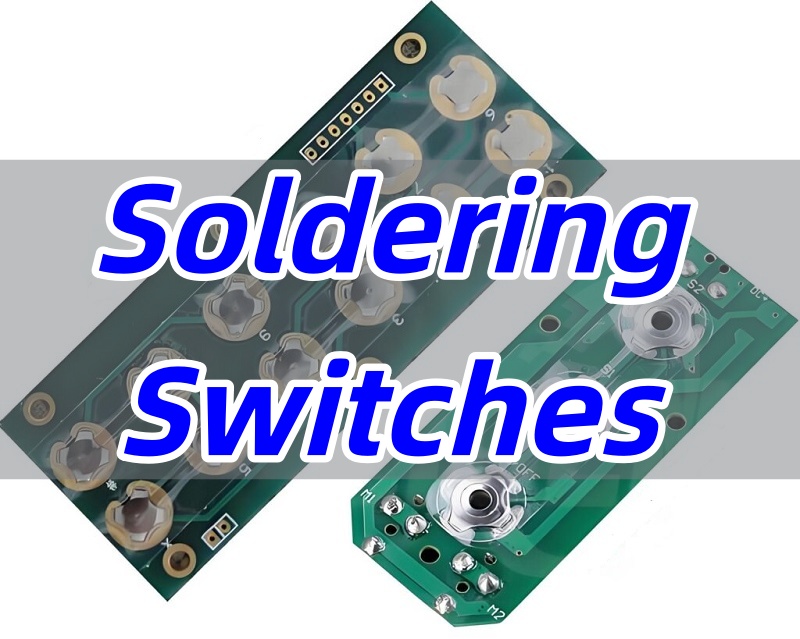

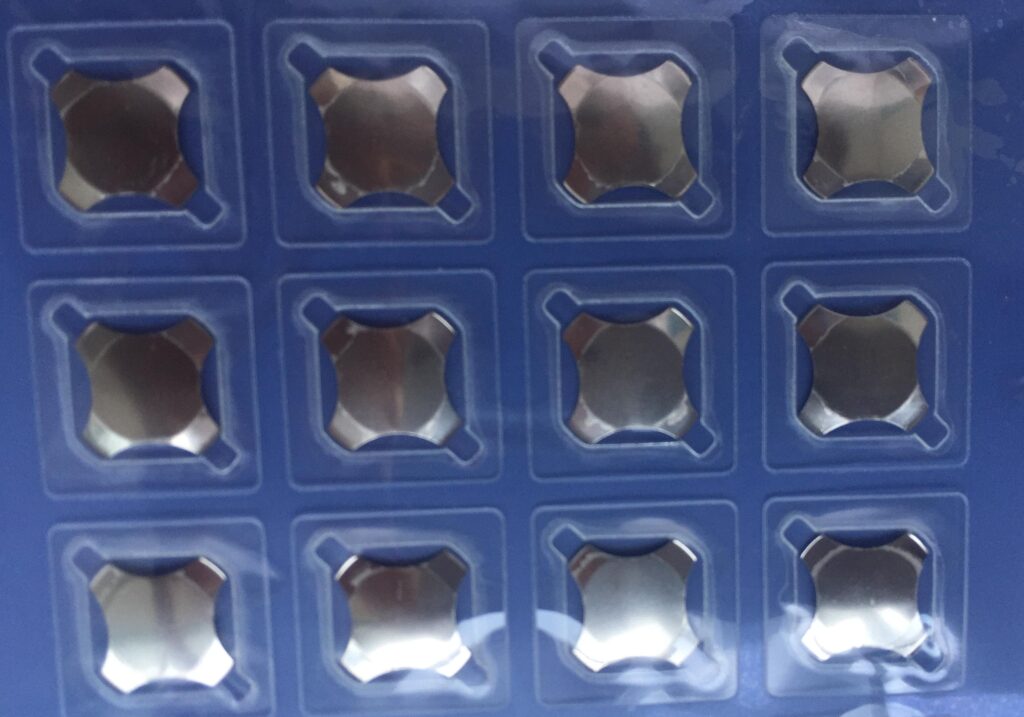

A dome array is a sheet with many domes pre-placed on an adhesive or PET layer. It creates a structured, stable layout. Instead of placing domes one by one, the array places them all at once. This keeps alignment perfect and boosts manufacturing efficiency.

Microwave brands use dome arrays for several reasons.

- First, arrays simplify production. Instead of handling small parts individually, the entire sheet is mounted onto the keypad in one step.

- Second, dome arrays improve accuracy. Each dome stays locked in the correct position. That means the keys line up cleanly with the printed icons.

- Third, arrays enhance reliability. The thin PET film on the array protects the domes. It shields them from dust and moisture inside the keypad.

- Fourth, arrays boost long-term performance. The perfectly balanced structure reduces stress. The domes sit flat and remain stable through years of use.

Overall, the metal dome array offers a clean, organized, and high-quality approach to building microwave keypads. It also supports a faster production flow.

Where is a metal dome tactile membrane switch used in microwaves?

You can find the metal dome tactile membrane switch in the front control panel. It sits behind the decorative overlay. This area includes all the user buttons:

- Start

- Stop

- Timer

- Mode settings

- Power level

- Numeric pads (0–9)

- Quick-cook shortcuts

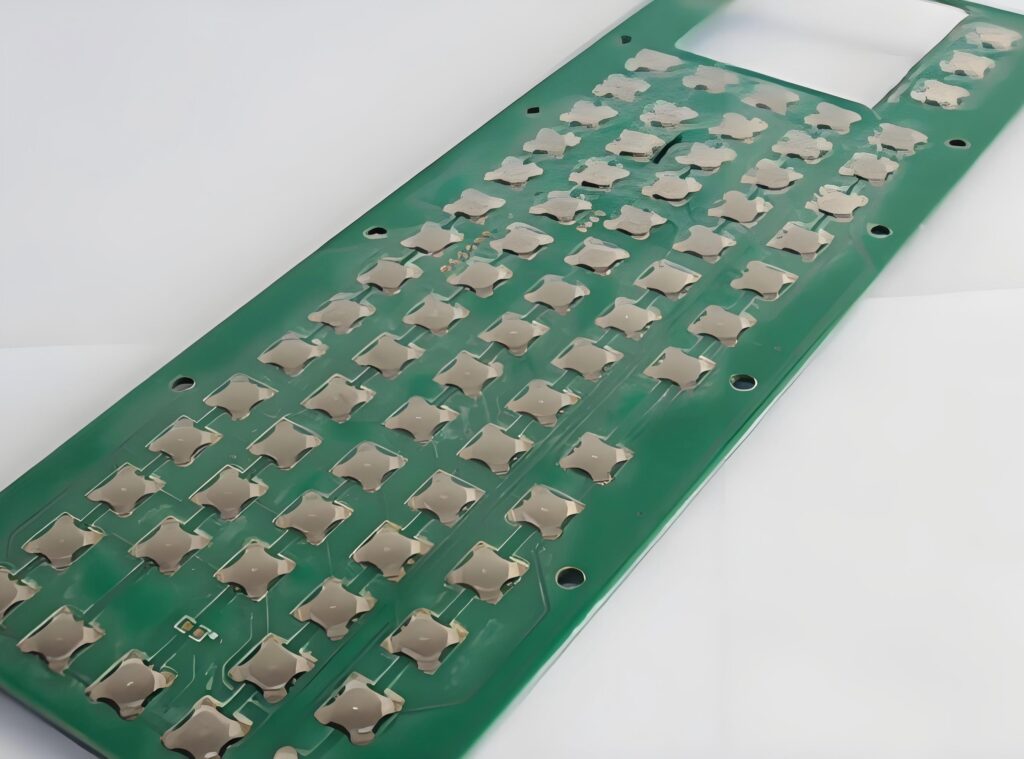

Every time a user interacts with the microwave, they press on a key connected to a metal dome. These domes hide inside a tactile membrane switch structure. The layers include:

- Graphic overlay

- Spacer

- Circuit

- Dome array

- Rear adhesive

This stack works together to create fast and stable button behavior. The switch is flat, slim, and durable. It offers a smooth interface while protecting the internal system.

How does a dome array boost control panel durability?

Durability matters in home appliances. A microwave control panel must endure thousands of presses. It must remain responsive.

Here is how it boosts durability.

- First, the dome uses stainless steel. This material resists wear, heat, and fatigue stress. It maintains elasticity even after heavy use.

- Second, the array helps distribute pressure. Each dome sits on a PET sheet that supports its structure. This helps prevent bending or warping. The dome stays stable, even after long use.

- Third, the array seals the dome environment. It protects the domes from dust and moisture. This keeps the contact surface clean. A clean surface means stable electrical performance.

- Fourth, the array reduces metal fatigue. When domes are positioned correctly, they flex evenly. That balanced motion reduces strains that could weaken the material over time.

- Fifth, the array reduces key failure risk. Misalignment is one of the main causes of button failure. A dome array prevents that. Everything stays where it should be.

Another benefit is the consistent tactile response. A long-lasting dome keeps its snap for years. That makes the microwave feel new even after thousands of uses.

A good dome array can maintain performance for more than 1,000,000 cycles. That level of durability creates value for brands and confidence for users.

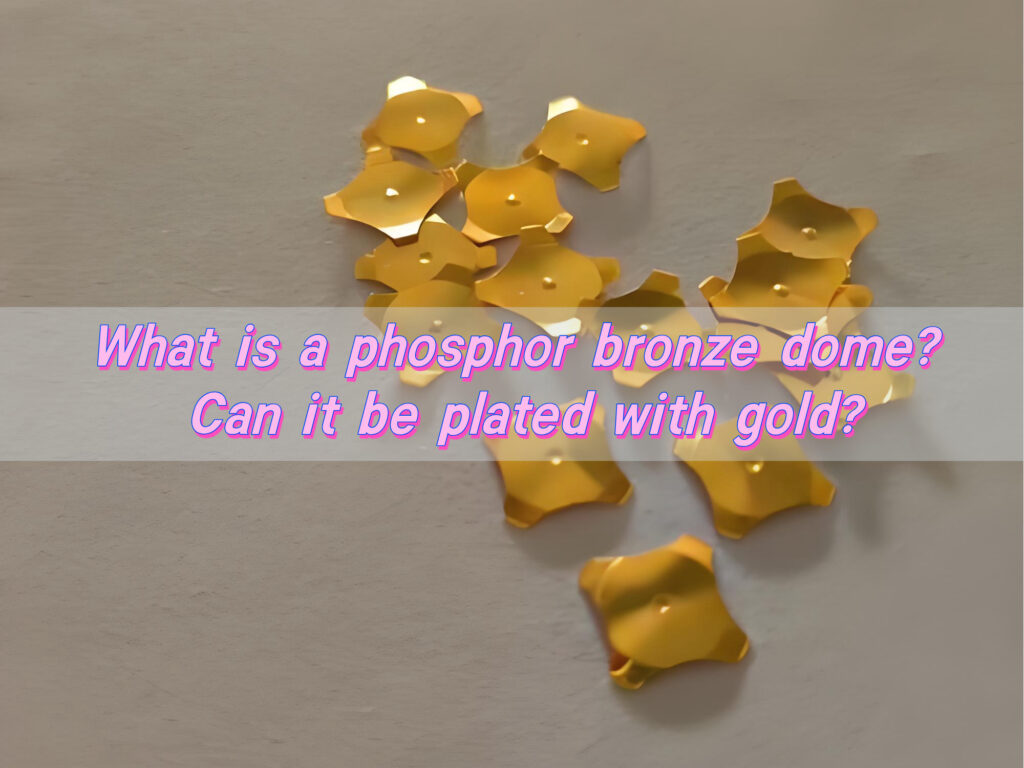

Which metal dome offers the best tactile feel?

The “best” tactile feel depends on the experience the brand wants to deliver. Some users love a soft click. Others want a sharper snap.

Here are the main factors that shape the tactile feel:

- Dome size: Larger domes often give a softer but broader click. Smaller domes deliver a sharp and focused snap.

- Actuation force: Force values range widely. Soft domes feel gentle and require little pressure. High-force domes feel firm and precise.

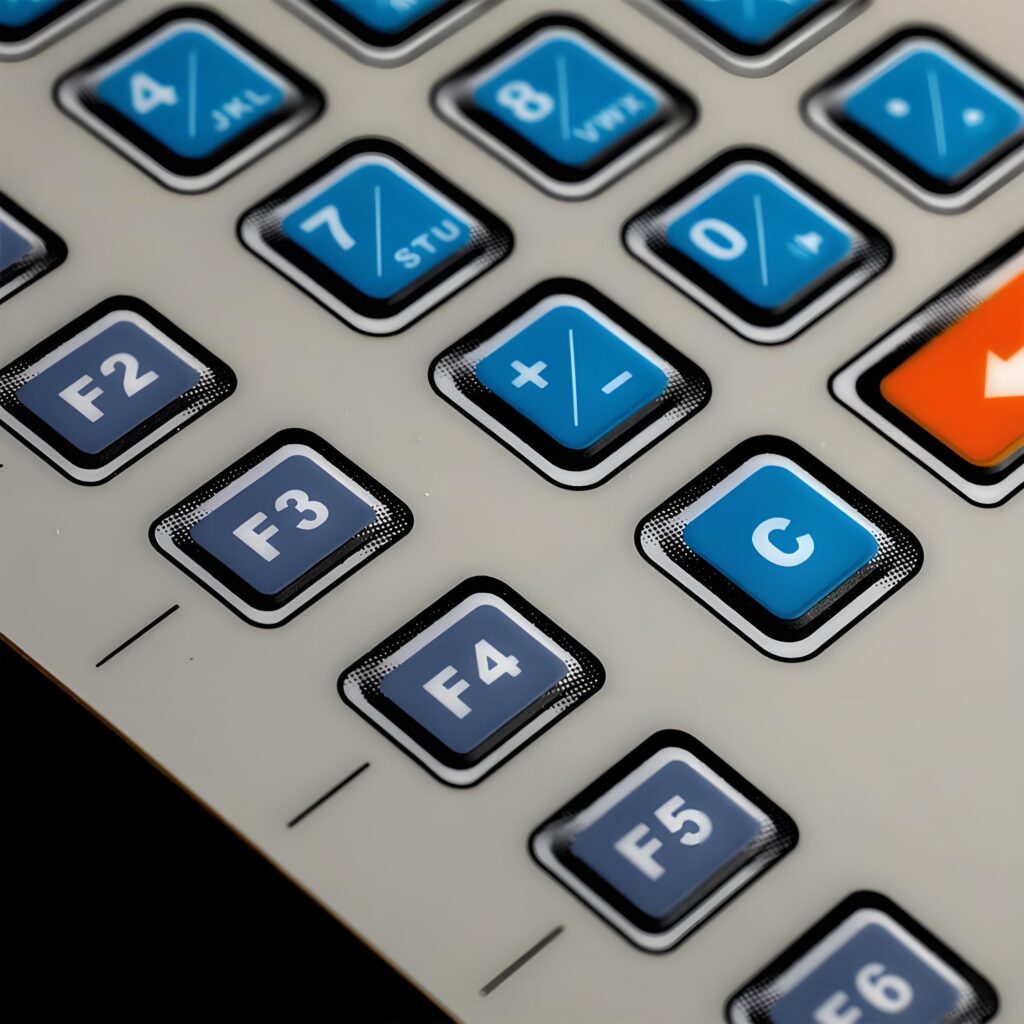

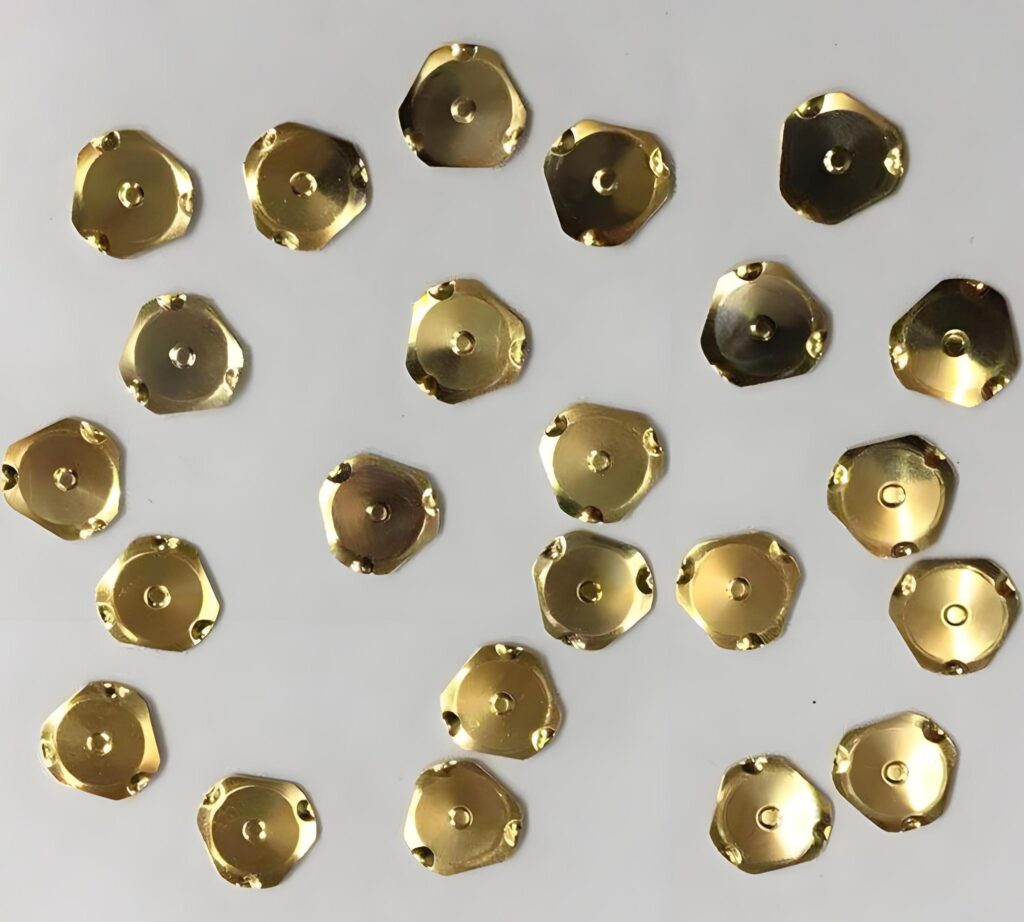

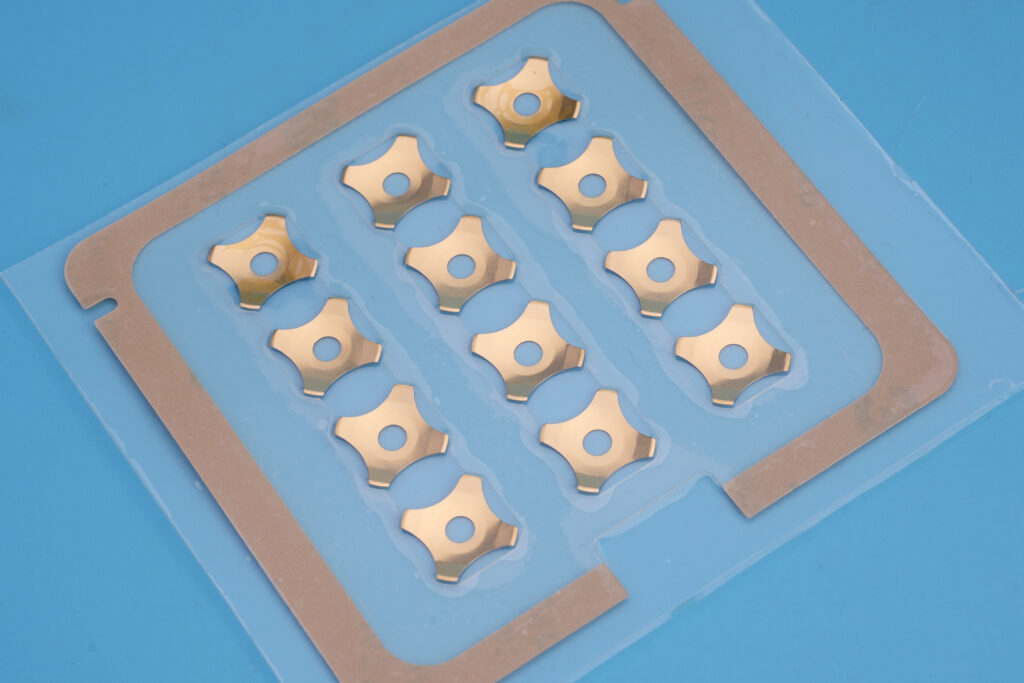

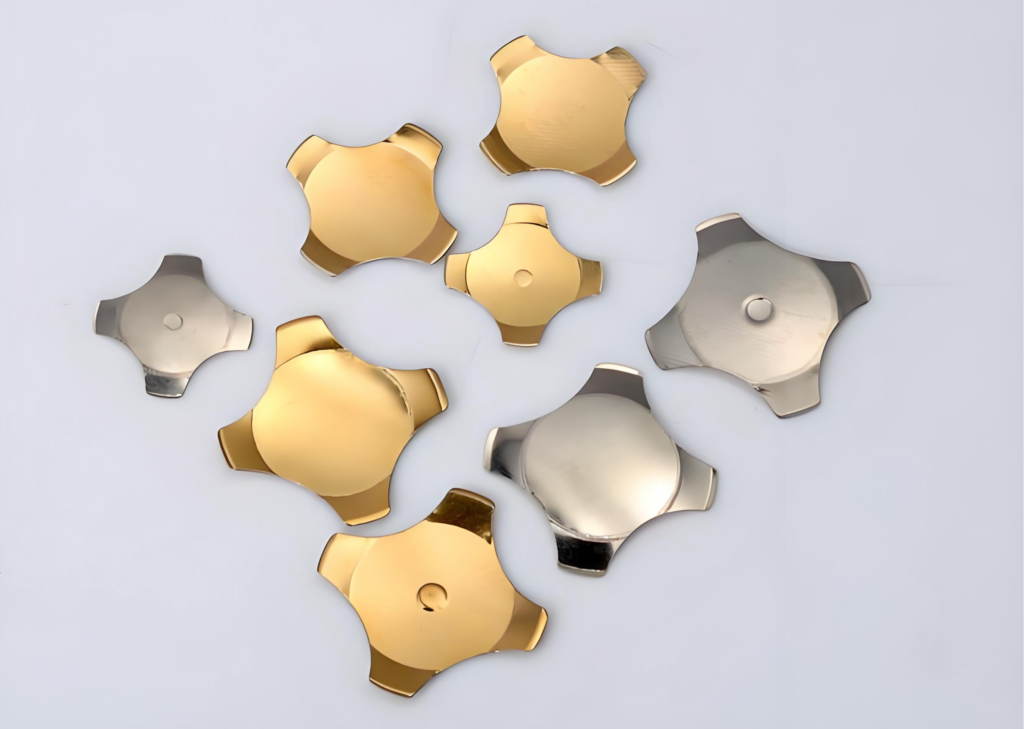

- Dome shape: The most common shapes include: Four-leg domes?Triangle domes?Round domes. Four-leg domes often create the strongest tactile snap. Round domes can feel smoother. Triangle domes offer a mix of stability and speed.

- Surface finish: A clean stainless steel finish supports consistent motion.

- Consistency over time: The best tactile feel is one that remains stable. Stainless steel domes with high-precision stamping perform well in long-term use.

For microwaves, customers usually prefer a clean, clear, and reliable click. Four-leg stainless steel domes with mid-range actuation force often deliver that experience.

How to choose a metal dome for microwave control panel?

Choosing the right metal dome requires careful thought. Microwaves involve fast daily use, so the dome must meet high standards.

Here are the key points to consider.

- Actuation force: Choose a force level that feels comfortable but clear.

- Dome size: Size affects responsiveness.

- Tactile ratio: This refers to how strong the snap feels. A higher tactile ratio delivers a sharper response.

- Lifespan requirements: Always choose domes that support at least 1,000,000 cycles.

- Material quality: Pick domes made from high-precision stainless steel.

- Panel thickness: The dome must match the total stack height of the membrane switch.

- Operating environment: Microwaves may face humidity, heat, and daily impact.

- Dome array vs. loose domes: Dome arrays are the better choice for large panels. They improve placement accuracy. They also boost efficiency and reduce failure risks.

When selecting a dome, always test samples. Feel the response. Listen to the click. Check the rebound. The right dome should feel steady, responsive, and comfortable.

Why is a metal dome array better than rubber switches?

Rubber switches used to be the mainstream on home appliance panels. Today, many have been upgraded to metal dome switches because they perform better.

Here is why metal dome arrays outperform rubber switches.

- 1. Stronger tactile response

Metal domes give a sharp and crisp click. Rubber switches feel soft and less precise.

- 2. Longer lifespan

A metal dome can last more than a million cycles. Rubber may degrade faster under daily use. Steel resists fatigue. Rubber can weaken with age.

- 3. Better rebound speed

Metal domes spring back instantly. Rubber slows down over time.

- 4. Steady performance

Metal domes maintain consistent force. Rubber becomes inconsistent when exposed to heat or pressure.

- 5. Higher sensitivity

The metal dome’s electrical contact is fast and clean. Rubber domes rely on carbon pills, which may wear out.

- 6. Slimmer design

Metal dome arrays allow ultra-thin key structures. Modern microwaves use sleek, flat panels. Rubber designs are thicker.

- 7. Cleaner interface

The dome array stays sealed. It avoids dust issues more effectively. Rubber material can attract particles.

- 8. Better production efficiency

Dome arrays speed up assembly. Rubber keypads require more complex molding.

For these reasons, the metal dome array has become a preferred choice. It raises the overall quality of the microwave panel. It creates better tactile feedback and longer service life.

If you need high-quality metal domes or dome arrays, feel free to reach out. Email: sales@metal-domes.com