What Are Printed Circuit Board Switches?

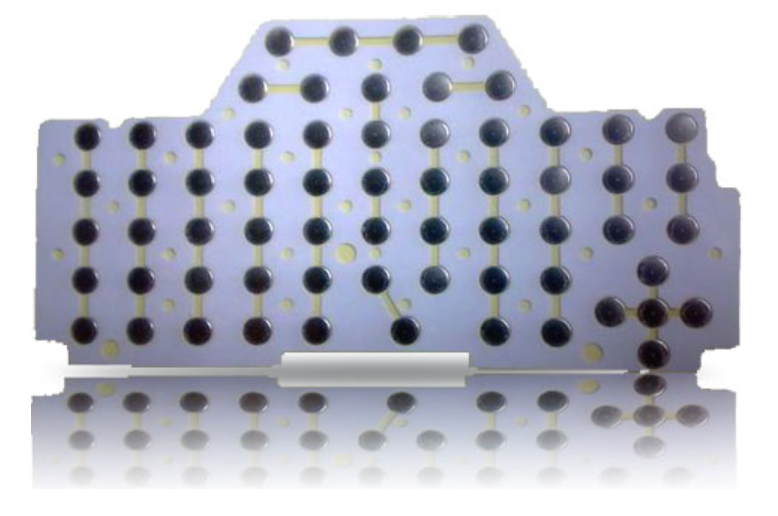

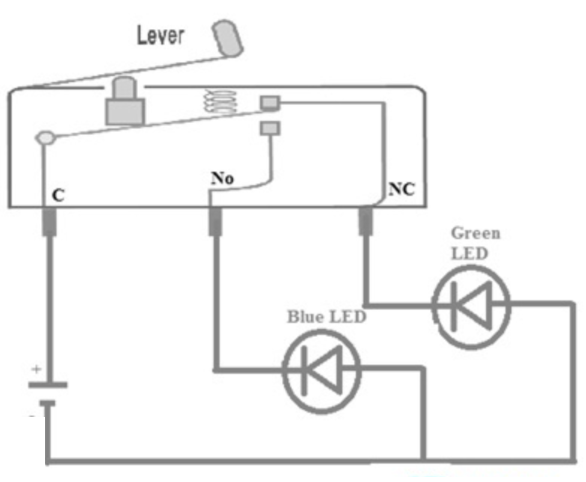

PCB switch refers to the switch installed on the printed circuit board (PCB), used to achieve the on-off function of the circuit. PCB switch is connected with the spring through the metal contact piece, when the user presses the switch, the contact piece produces elastic deflection, and other contact pieces contact or separation, so as to achieve the purpose of opening and closing the circuit.

PCB switches have the advantages of small size, high integration, low power consumption and long life, and are widely used in various electronic devices, such as mobile phones, optical drives, computer internal hard disks, etc. ?. With the development of intelligence and automation, PCB switches are also widely used in intelligent appliances, automotive electronic products, medical equipment and other fields.

Types of Printed Circuit Board Switches

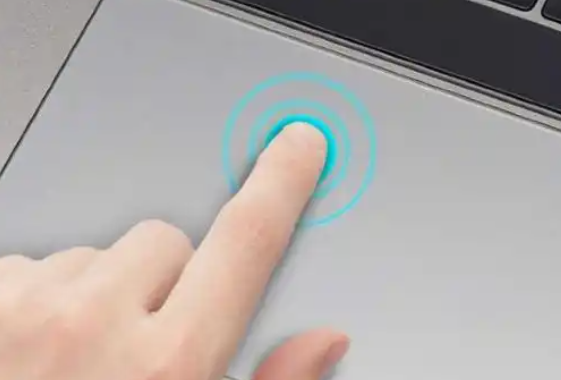

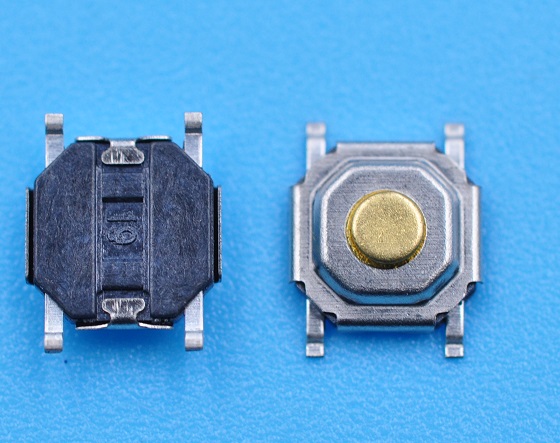

- Tactile Switches

Tactile switches are small, responsive components that provide a distinctive click when pressed. They are widely used in compact devices like keyboards, remote controls, and medical equipment. Their tactile feedback ensures precise operation, making them a favorite in applications requiring accuracy.

- Slide Switches

Slide switches allow users to toggle between options by moving a small slider. They are durable and versatile, making them ideal for audio equipment, control panels, and toys. Their simple mechanism ensures longevity even in high-use scenarios.

- Push-Button Switches

Push-button switches operate when a button is pressed and released. Known for their reliability, they are commonly found in household appliances, consumer electronics, and industrial control systems. Their straightforward design ensures consistent performance.

- Rotary Switches

Rotary switches feature multiple positions, allowing users to select from various options. These switches are used in audio mixers, instrumentation panels, and older telecommunication devices. Their robust construction ensures a long operational life.

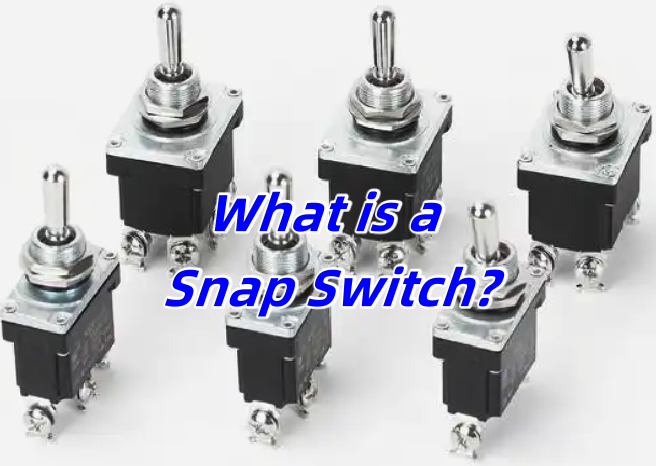

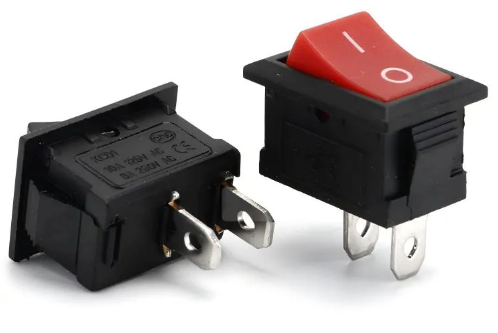

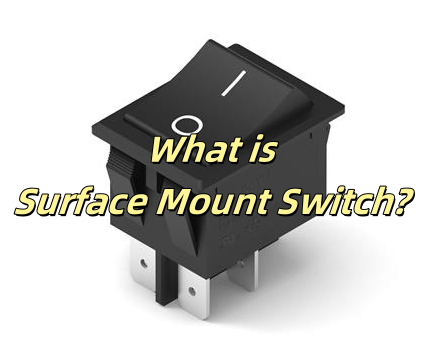

- Toggle Switches

Toggle switches have a simple lever mechanism, allowing users to switch between on and off states. They are widely used in automotive controls, aerospace systems, and heavy machinery. Their reliability under extreme conditions makes them a trusted choice.

How Do PCB Switches Work?

The working principle of the PCB switch is based on transistor on-off and cutoff control. When the transistor base is high current level, the transistor saturates, the inductor stores energy, and the capacitor charges. When the transistor base is low current, the transistor shuts off, the inductor releases energy, and the capacitor discharges. The duty cycle is regulated by the sampling circuit and feedback circuit to achieve the purpose of voltage regulation.

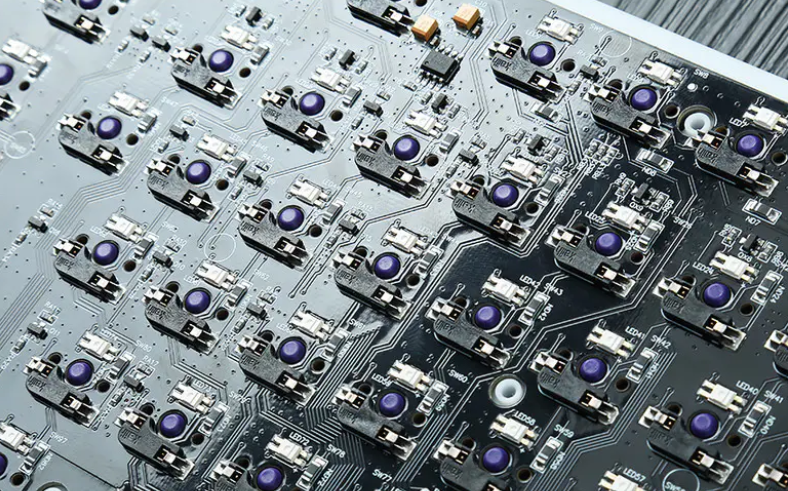

Key Part in PCB Switches

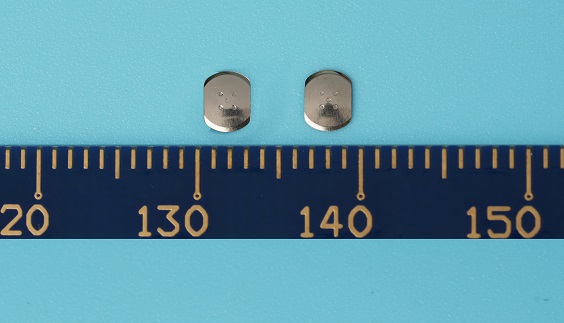

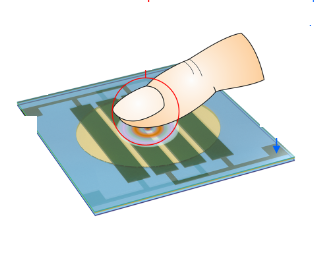

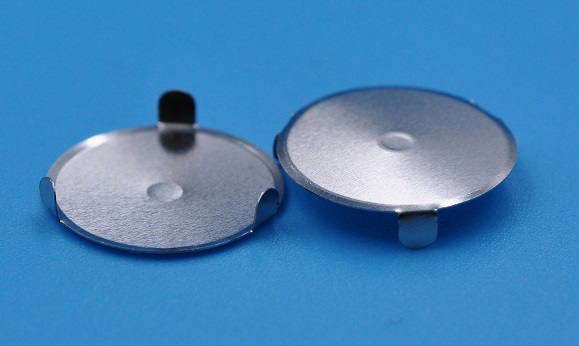

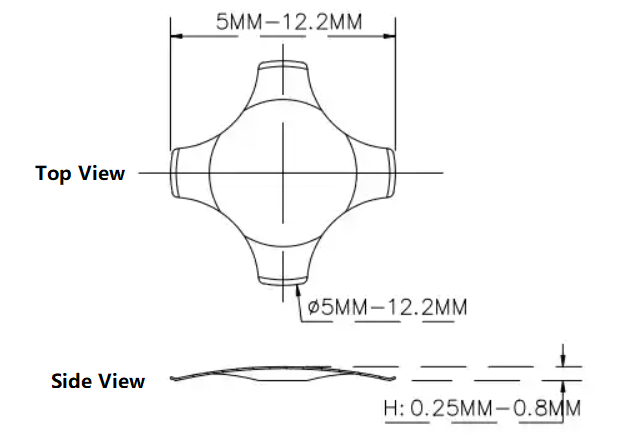

Metal domes play a significant role in PCB switches. They are small, dome-shaped metallic components that act as contact points. Specifically, when the user presses the switch, the center point of the metal dome is concave, which contacts the conductive part on the PCB board, forming a loop, thus allowing the current to pass through and complete the switching operation. This mechanism provides a tactile “click,” ensuring user satisfaction and accurate input. Metal domes are commonly used in applications like medical devices, mobile phones, and remote controls due to their durability and responsiveness.

In addition to this, SMD metal domes, a variation of traditional domes, are designed for PCB surface mounting. They are ideal for compact devices where space is at a premium. Their integration enhances design flexibility, allowing engineers to create smaller and more efficient circuits.

Key Advantages of PCB Switches

- Small size, light weight: PCB switch can be directly installed on the printed circuit board, so it has the characteristics of small size and light weight, convenient for the layout and installation of the equipment.

- Highly integrated: PCB switches can be integrated into the circuit board to provide high-density wiring, making product design more flexible.

- Good mechanical properties: PCB switch mechanical properties are stable, can provide long life and high reliability, contact using special processing, with good electrical contact performance, can maintain the stability of electrical performance.

- ?Good electrical conductivity: PCB switch has strong electrical conductivity, can meet the needs of various circuits.

- Customizable: PCB switches can be customized designed and manufactured according to customer needs to meet the needs of specific application scenarios.

- Strong environmental adaptability: PCB switch can adapt to different working environments, such as temperature, humidity, dust and other conditions.

Applications of PCB Switches

PCB switches, including those with SMD metal domes, are essential in various industries:

- Consumer Electronics: Found in remote controls, gaming devices, and smart appliances.

- Medical Equipment: Utilized in diagnostic tools and monitoring devices requiring precision.

- Automotive Industry: Used for dashboard controls and infotainment systems.

- Industrial Automation: Implemented in control panels, machinery, and monitoring systems.

- Telecommunications: Essential in devices like routers, modems, and communication equipment.

How to Select the Right PCB Switches?

Choosing the right PCB switch depends on several factors:

- Application Requirements: Consider the environment and use case, such as industrial or consumer applications.

- Tactile Feedback Needs: Determine if the application requires tactile switches with metal domes for user interaction.

- Space Constraints: Evaluate the size and placement of the switch on the PCB.

- Durability and Lifespan: Choose switches built to withstand the intended operating conditions.

- Customization Options: Look for switches, such as SMD metal domes, that can be tailored to specific design needs.

Printed circuit board switches are vital components in today’s electronics. From tactile switches to advanced SMD metal domes, they offer unmatched reliability, functionality, and adaptability. Their role in creating compact, efficient designs cannot be overstated. Whether you’re designing consumer electronics, medical equipment, or industrial systems, PCB switches provide a dependable solution. For high-quality PCB switches, including custom options with metal domes, trust Best Technology. Our expertise ensures you get the best solutions for your projects. Contact us today at sales@metal-domes.com to learn more about our offerings and how we can support your designs.