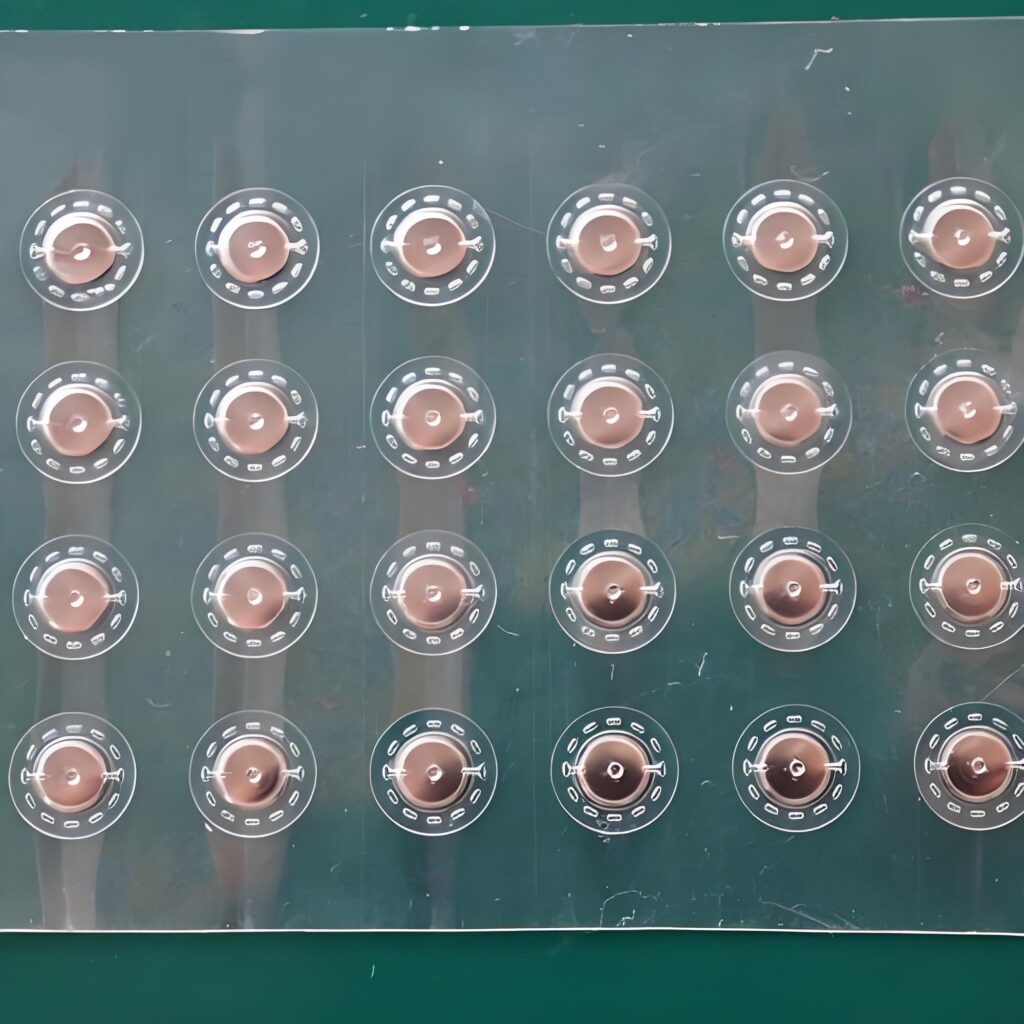

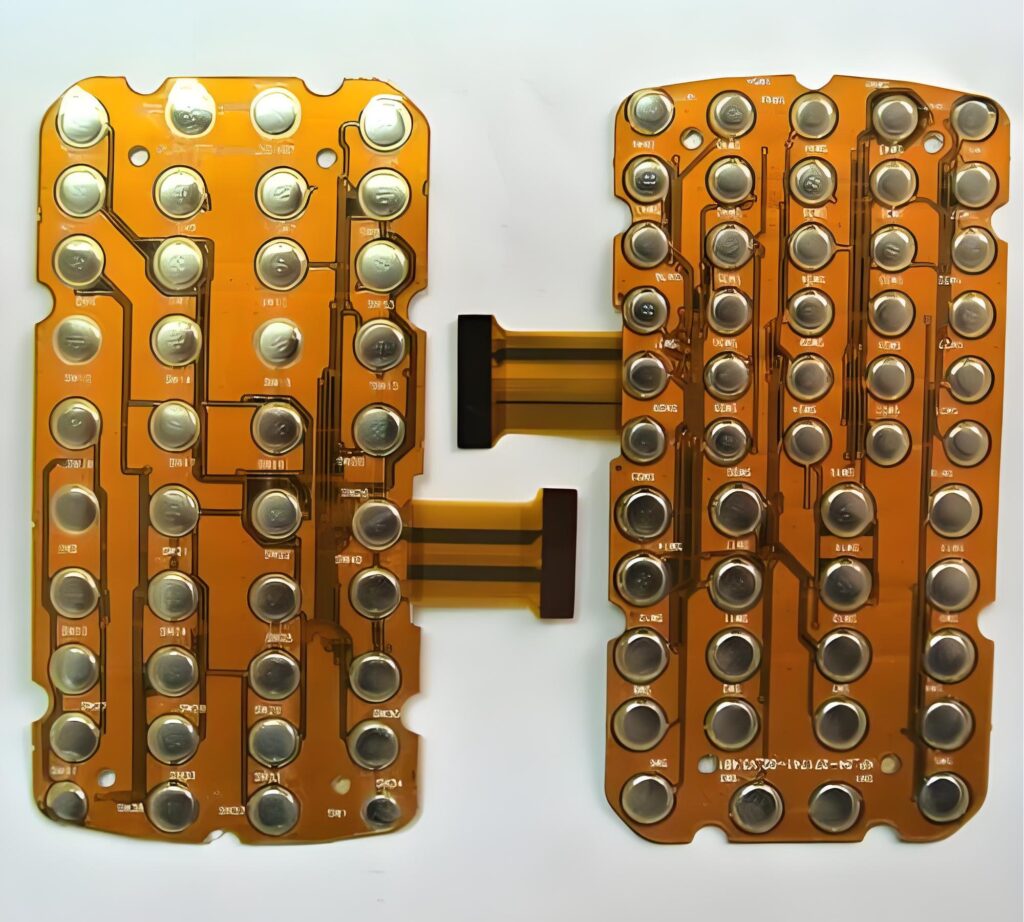

Standard tactile metal domes is a precision stamped stainless steel dome with a slightly convex center to form a “dome”. When pressed, it instantly concave and contacts the circuit, and elastically rebounds after release, giving crisp tactile feedback and ensuring reliable switching for millions of times. It is a key component of keyboards, remote controls and car panels.

What is a tactile dome?

Tactile dome is a small, metal component used in switches to provide tactile feedback. It sits beneath a surface like a plastic overlay or keypad. When pressed, it collapses slightly and then returns to its shape, sending a signal and delivering that crisp click sensation.

It confirms the input and gives the user immediate physical feedback—without any guesswork. That moment of tactile feedback is why it’s often preferred in high-precision industries.

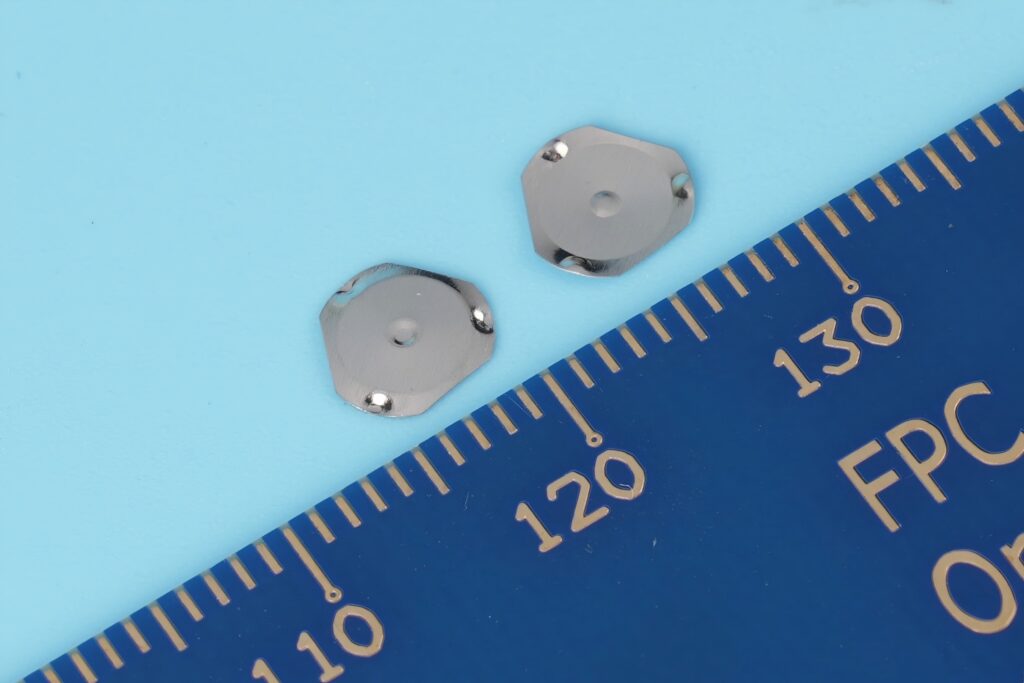

Made from stainless steel, tactile metal domes come in various sizes and actuation forces. They’re built to last and respond consistently across thousands—sometimes millions—of presses.

What is the difference between tactile and haptic?

You’ve probably heard both terms: tactile and haptic. Though people use them interchangeably, they are not the same. Tactile feedback is physical. It’s the “click” or the “snap” you physically feel. It’s real, mechanical movement.

Haptic feedback, on the other hand, is more general. It can include vibrations, electric signals, or force feedback. It’s often generated through software. A smartphone’s buzz when typing? That’s haptic, not tactile.

So, in short:

- Tactile = physical, real switch movement

- Haptic = simulated feedback, often digital

Tactile metal dome switches provide true tactile feedback, not a digital imitation. This realness makes them reliable and trusted.

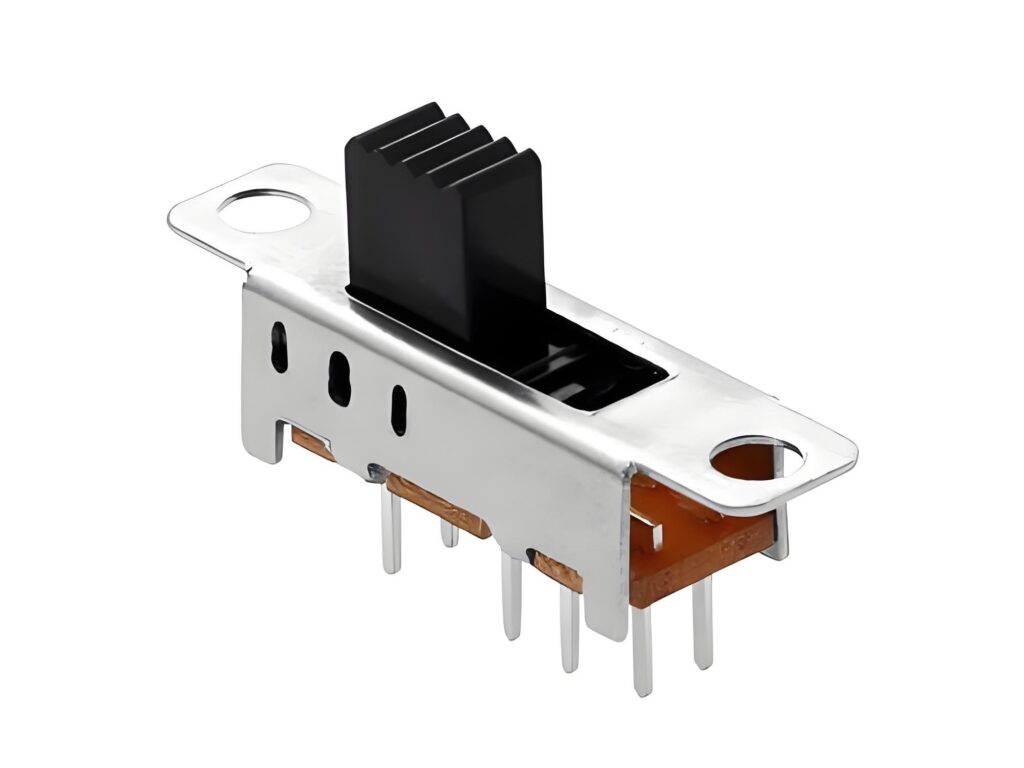

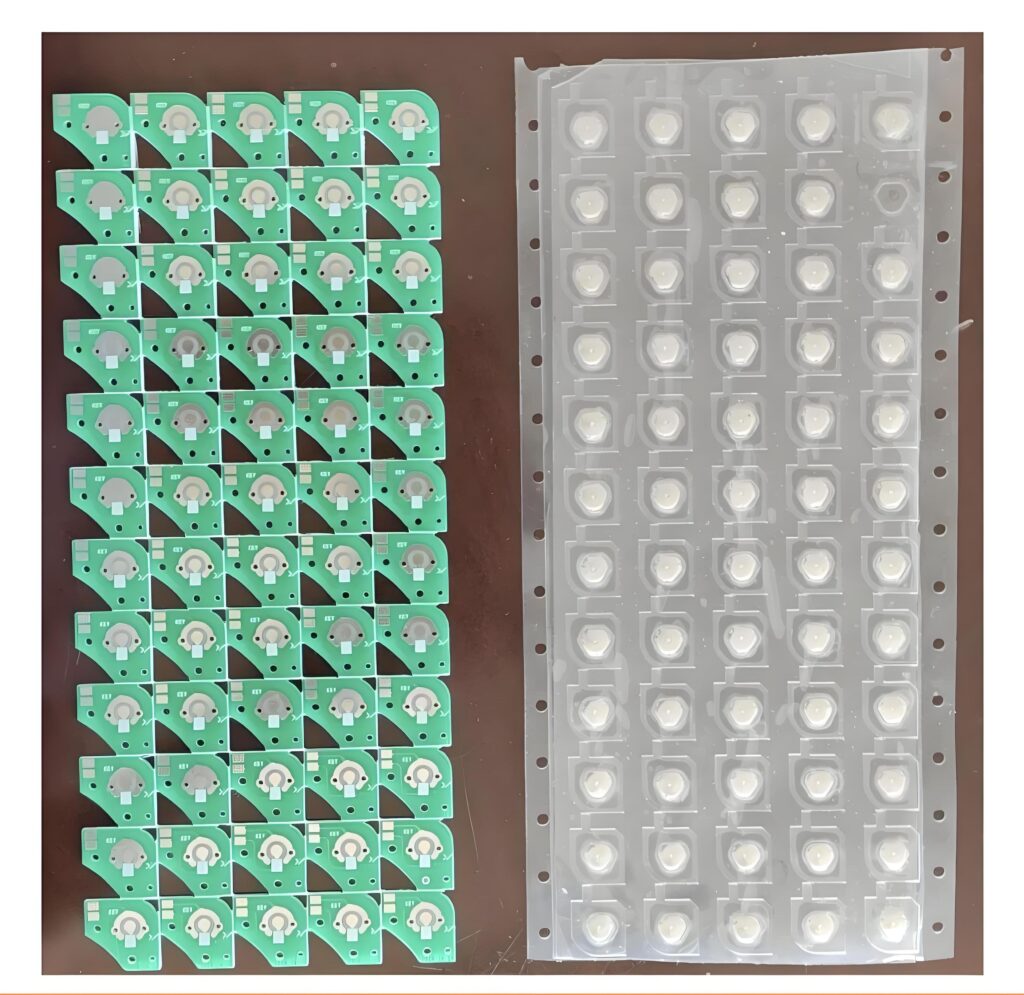

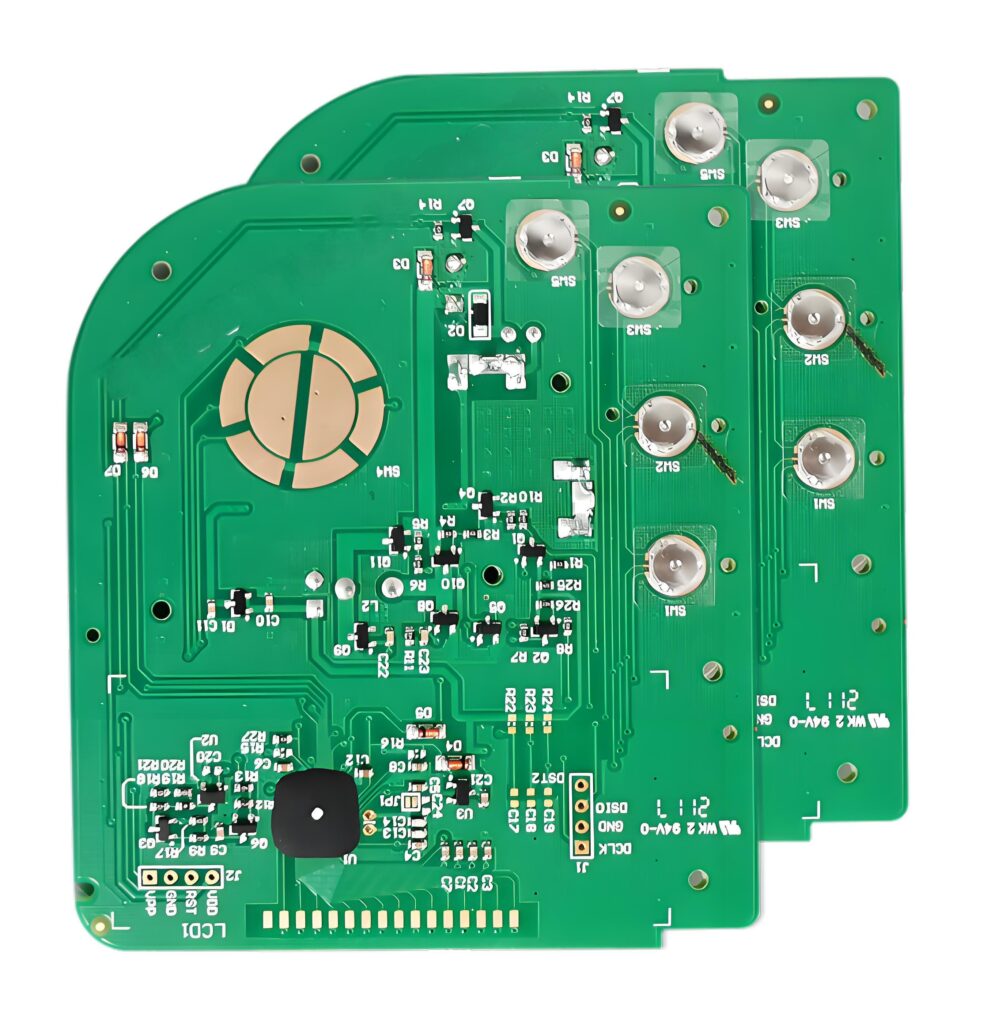

How does a tactile metal dome switch work?

Here’s the simple magic: When you press down on a tactile dome, it collapses. This mechanical movement closes an electrical circuit below. As the dome pops back into place, it opens the circuit again.

The snap action is key. It eliminates confusion and increases accuracy, especially in blind or rapid operations. This is why snap dome switches are popular in industrial and medical equipment.

Some domes even feature four-leg designs, ensuring solid balance and reliable centering. Others use triangle or round shapes, depending on the needs of the application.

What is the click ratio for metal dome?

The click ratio is the difference between the peak force needed to collapse the dome and the force felt at the snap point. It’s a technical way to measure how satisfying or responsive a switch feels.

Higher click ratio means:

- More noticeable tactile feedback

- A more distinct snap

- Less accidental activation

Most standard tactile metal domes have click ratios ranging from 40% to 70%. That tactile snap builds user trust.

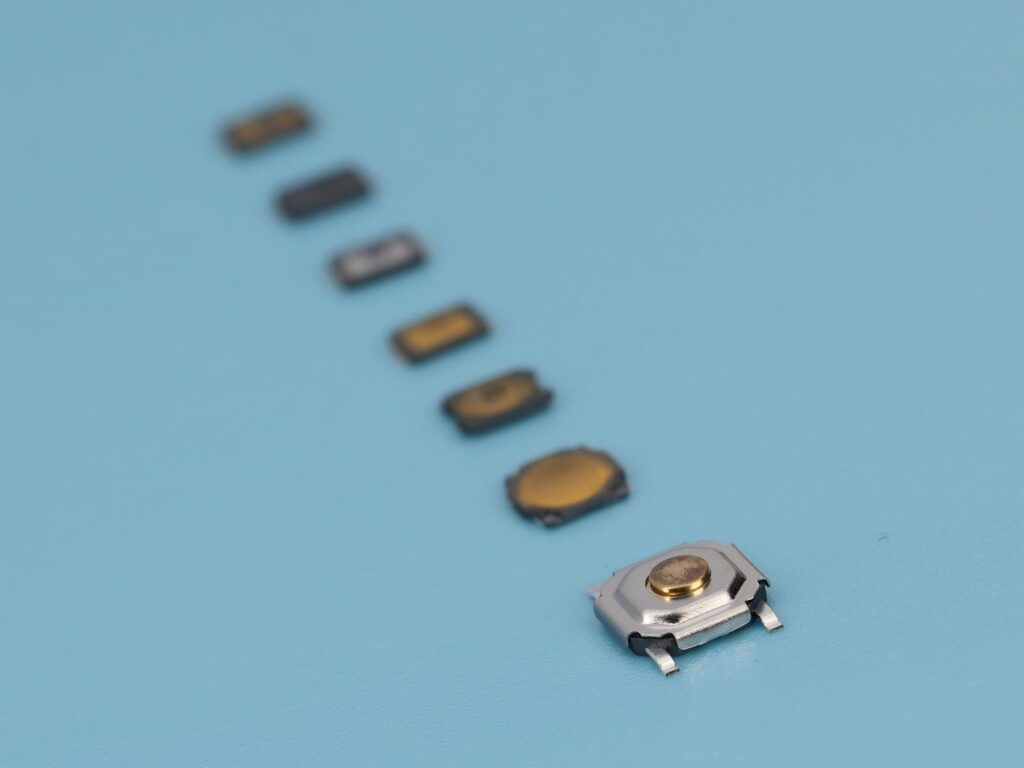

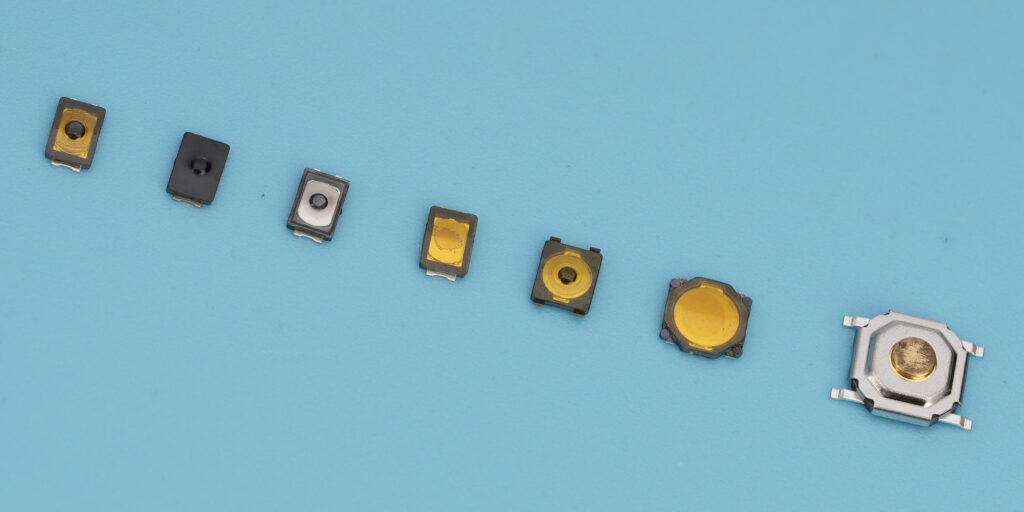

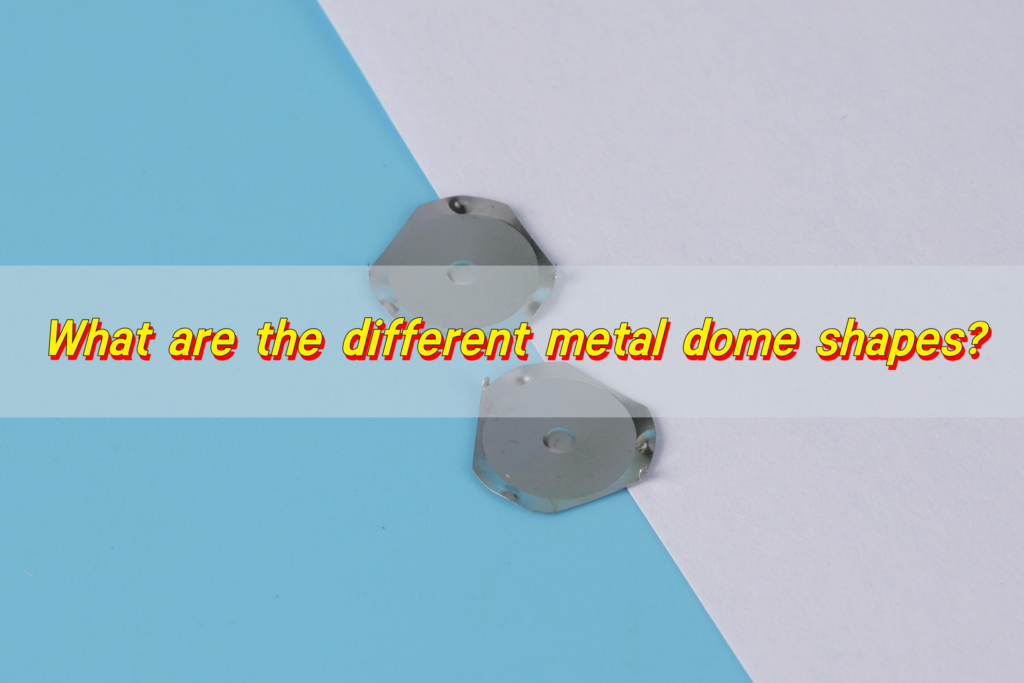

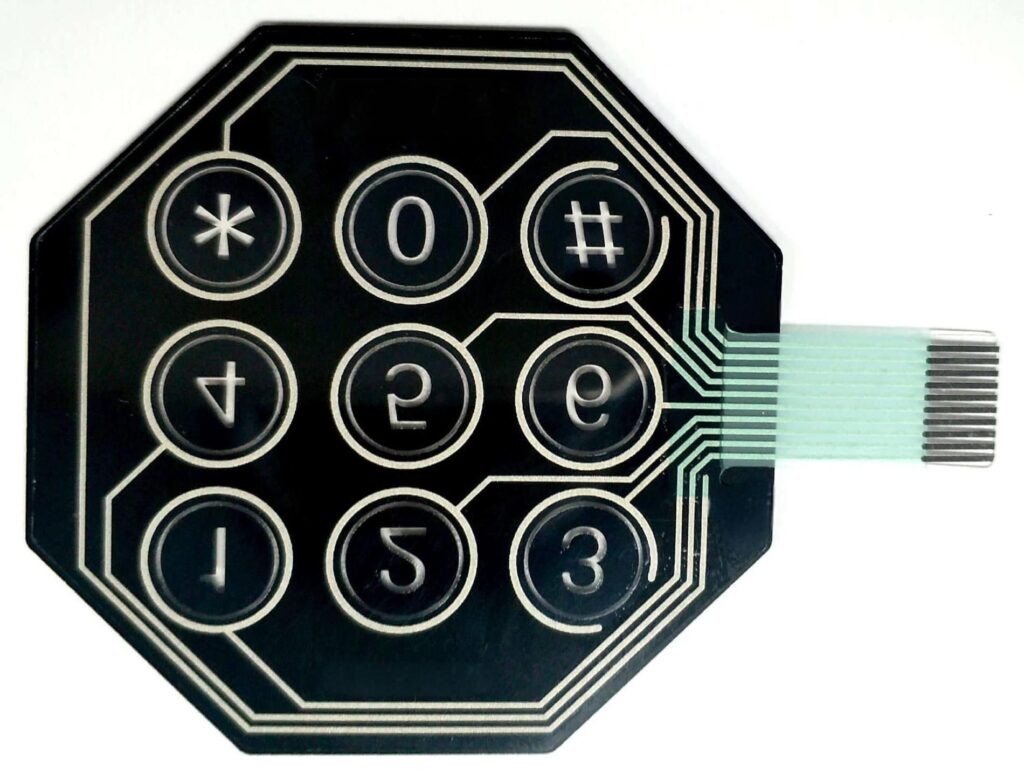

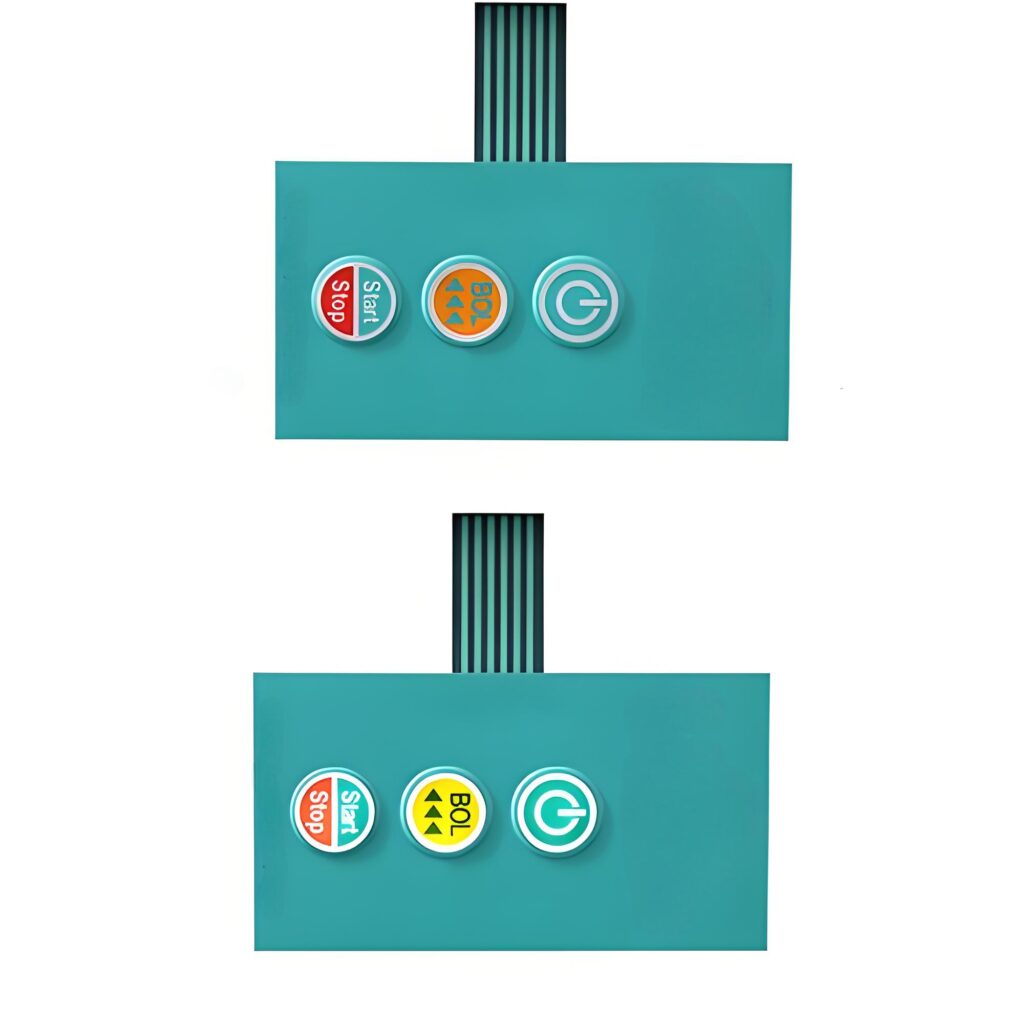

What are the different metal dome shapes?

The design of the dome changes how it feels and performs. The most common shapes include:

- Four-leg domes: Excellent balance, ideal for larger keypads or where uniform actuation is critical.

- Round domes: Smooth press, commonly used in handheld devices.

- Triangle domes: Great for smaller footprints and tighter areas.

- Oblong domes: Custom-fit for long keys or bars.

Each shape creates a unique tactile experience. Depending on the device type, BEST Technology choose the best tactile metal dome switch shape to balance feel, durability, and cost.

What are the benefits of using a dome tactile switch?

Here are some powerful benefits:

- Durability: Most standard tactile metal domes are rated for over 1 million actuations. Some go far beyond that.

- Consistency: Each press delivers the same crisp response. No surprises.

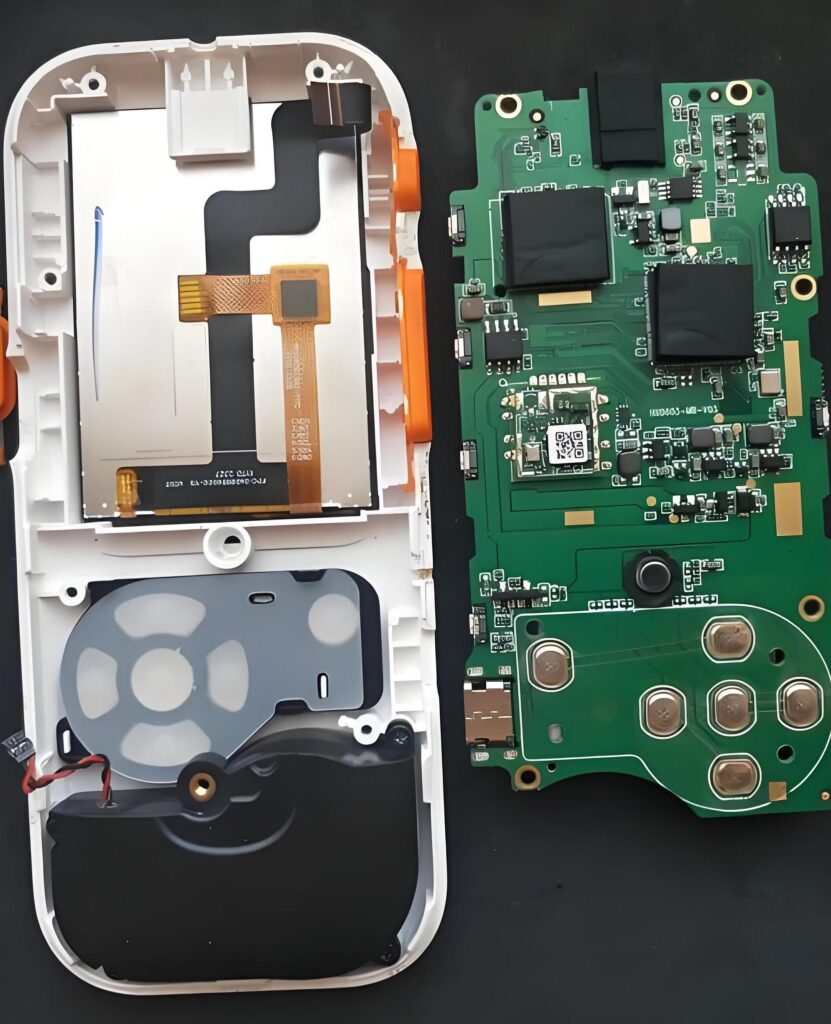

- Thin Design: Dome switches take up minimal space, perfect for compact devices.

- Moisture Resistant: With proper sealing, they can resist dust and liquids—great for outdoor or industrial use.

- Customization: Actuation force, size, shape, and click feel can all be customized.

- Cost-Effective: They offer high performance without high costs, especially in bulk.

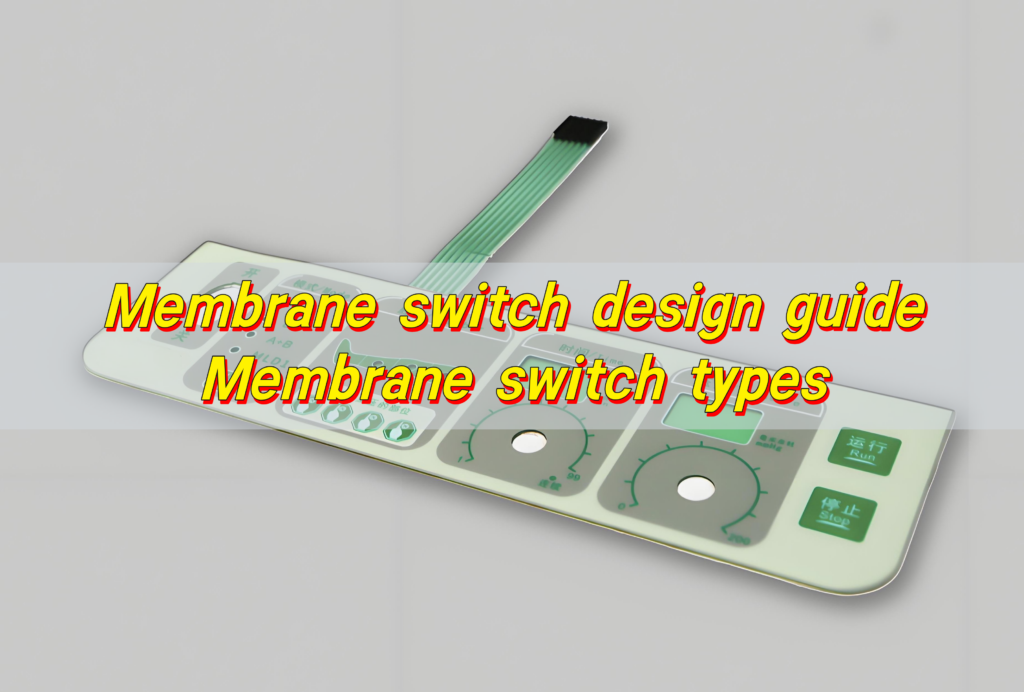

When integrated into a dome switch keyboard, they provide seamless user interaction. No lag. No noise. Just precision.

How long do standard tactile metal domes last?

On average, standard tactile metal domes last between 1 to 5 million actuations, depending on use and environment.

Factors like material quality, environmental sealing, and actuation force all impact lifespan. But with proper design, dome switches offer long-term reliability.

They’re built to endure repetitive pressing without losing snap or signal. That’s why they’re trusted in life-saving tools, automotive controls, and factory machines.

What factors affect tactile metal dome performance?

Several key factors influence how a tactile dome performs:

- Material Quality: Stainless steel domes resist fatigue better than lower-grade metals.

- Click Ratio: As mentioned earlier, this affects feedback clarity. A poor click ratio leads to mushy presses.

- Dome Shape: Different shapes distribute force differently.

- Environmental Protection: Moisture, dust, or extreme heat can reduce life expectancy. Proper sealing is essential.

- Overlay Thickness: The layer above the dome can dull or enhance the tactile response. It must be optimized.

- Mounting Method: Whether it’s part of a dome array or assembled individually, alignment and placement impact the press accuracy.

Conclusion:

Standard tactile metal domes offer more than just a snap. They bring confidence, clarity, and control. From the satisfying feedback of a snap dome switch to the tailored feel of a dome switch keyboard, these little components shape the way we interact with machines.

If you need expert guidance, custom specifications, or just want to find the perfect dome for your design, our team at Best Technology is here to help.

Contact us at sales@metal-domes.com and discover how the right dome can change everything.