As a professional stainless steel dome manufacturer in Japan, customers across various industries, when choosing a Japanese stainless steel dome manufacturer, often focus not only on the product itself but also on manufacturing stability, delivery reliability, and long-term partnership capabilities. The Japanese market has particularly stringent requirements for stainless steel metal domes; from tactile consistency to lifespan reliability, every detail determines the quality and market competitiveness of the final product.

Are you facing the following problems?

- Long prototyping cycles, repeated design revisions, and slow project progress

- Small batch orders rejected or priced too high, making trial production costs difficult to control

- Inconsistent metal dome feel and poor batch consistency, affecting the overall user experience

- Rapid fatigue degradation and uncontrollable failure rates under high lifespan requirements

- Conservative manufacturing processes of local manufacturers, making it difficult to support new structures or customized needs

- High communication costs, slow engineering response, and inability to quickly resolve issues

Full-Process Guarantee from Demand to Delivery

We are not simply a metal dome supplier, but a provider of full-process solutions, from demand definition, structural design, material selection, and process control to delivery management.

Starting with the initial pressure, rebound curve, and lifespan targets, our engineering team is involved in design optimization from the outset. Through a standardized mold system and automated molding process, we ensure that every batch of stainless steel domes has a stable tactile feel, predictable lifespan, and high consistency.

For our Japanese customers, we reduce procurement risks with faster response times and more stable delivery schedules, making ordering simple and worry-free.

Why Choose Us? EBest Circuit (Best Technology)’s Core Advantages

- 20+ years of experience in metal dome manufacturing, serving industrial, medical, automotive, and high-end consumer electronics industries

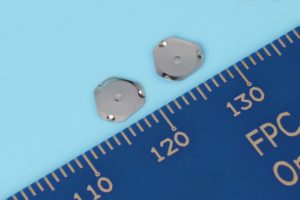

- Mature stainless steel material system, with controllable performance of 304/301/SUS series domes

- ±0.05mm contact precision control, ensuring button consistency and reliable conductivity

- Lifespan exceeding 1,000,000 cycles, suitable for high-frequency use scenarios

- Supports OEM/ODM customization, providing a one-stop solution from structure to packaging

- Fast engineering response mechanism, with samples and issue resolution completed within 48 hours

These advantages are not just slogans, but manufacturing capabilities that have been repeatedly verified by our international customers over the long term.

Top 10 metal dome manufacturers in Japan

| Company Name | Process Capability | Core Advantage |

|---|---|---|

| EBest Circuit (Best Technology) | Stainless steel dome forming, array lamination, Tape & Reel | High consistency, rapid delivery, full-process support |

| Panasonic Industry | Metal contact stamping | High brand recognition |

| Alps Alpine | Precision switch components | Strong structural integration capability |

| Nidec Components | Micro metal dome | Rich experience in miniaturization |

| TDK | Functional material processing | Strong material R&D capability |

| MinebeaMitsumi | Precision stamping | Large-scale mass production |

| Hosiden | Input component manufacturing | Consumer electronics experience |

| JAE | Connectors and metal domes | Solid industrial customer base |

| Sumida | Metal components | High degree of automation |

| Tokai Rika | Automotive components | Automotive-grade quality system |

How to Choose a Japan Metal Dome Manufacturer?

In the Japanese market, choosing a metal dome manufacturer shouldn’t be based solely on price or reputation, but rather on a systematic evaluation of the following key dimensions:

- Does the manufacturer have long-term mass production experience with stainless steel spring contacts, not just sample production?

- Can they precisely control actuation force, tolerances, and rebound curves?

- Do they support small-batch prototyping and rapid iteration, rather than just providing a one-time quote?

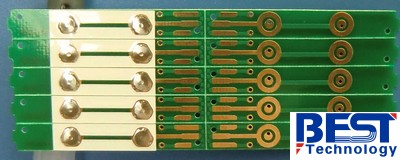

- Do they possess array assembly and automatic placement (SMT) capabilities?

- Can they provide data on lifespan, tactile feel, and consistency testing?

- Do they have experience working with international clients and strong engineering communication skills?

Why EBest Circuit (Best Technology) is a better choice:

We are involved in parameter definition from the initial stages of the project, precisely controlling the diameter, arch height, and contact structure of the stainless steel spring contacts through our proprietary mold system, ensuring controllable actuation force deviation.

At the same time, we support small-batch rapid prototyping and consider mass production feasibility during the prototyping phase, avoiding the problem of “prototype feasible, mass production uncontrollable.” With array design and Tape & Reel packaging, EBest Circuit (Best Technology) can directly meet Japanese customers’ dual requirements for automation and stability.

Core Pain Points of Japan Metal Dome Manufacturers

In actual cooperation, Japanese customers often encounter the following core manufacturing problems:

- Lack of manufacturing input during the design phase, leading to repeated modifications later.

- Spring contact lifespan meets laboratory standards, but degrades quickly in actual use.

- Significant differences in tactile feel between batches, affecting overall product consistency.

- Positioning offset or incorrect orientation during automatic placement.

- Delivery time is constrained by molds or production scheduling, making planning unpredictable.

EBest Circuit (Best Technology)’s solution is not just a “promise,” but process design:

We evaluate structural manufacturability at the initial design stage, controlling parameters within a limited range to avoid later risks; regarding lifespan issues, we optimize material thickness, tempering process, and stress distribution to ensure stable rebound even under high-frequency use.

For placement problems, we use array and Tape & Reel solutions to ensure consistent direction and position; in terms of delivery time, standardized molds and multi-line parallel production capabilities ensure that production scheduling does not depend on a single piece of equipment, resulting in more stable delivery.

How to analyze the production capacity of a Japanese metal dome manufacturer?

To assess the true production capacity of a Japanese metal dome manufacturer, the following aspects should be considered:

- Does the manufacturer have its own mold design and maintenance capabilities?

- Is the proportion of automated molding sufficiently high?

- Is there a complete life cycle and consistency testing process?

- Is multi-specification parallel production stable?

- What is the array bonding precision control capability?

- Is quality management implemented throughout the entire process?

- What is the response speed to engineering anomalies?

EBest Circuit (Best Technology)’s specific performance in these capabilities:

We have an independent mold development and maintenance system, avoiding precision fluctuations caused by outsourcing; through automated stamping and molding equipment, we reduce human intervention and improve batch consistency; each stainless steel dome has a corresponding life cycle and tactile testing standard; array bonding precision can be controlled within ±0.05mm; we also have dedicated engineering support, allowing for analysis and adjustment of abnormal problems in a short time, rather than simply rework.

How to evaluate the delivery time of a Japanese metal dome manufacturer?

Delivery time is not just about “speed,” but about long-term predictability. It should be judged from the following aspects:

- Is there a safety stock of commonly used specifications?

- Is mold development standardized, and is the cycle fixed?

- Can sampling and mass production proceed in parallel?

- Does it support urgent projects or rush orders?

- Is production scheduling transparent and communicative?

- Are packaging and logistics mature and stable?

EBest Circuit (Best Technology)’s delivery advantage lies in its systematic approach, not just temporary acceleration:

Through standard molds and material reserves, we can complete sample delivery within 2-3 days; mass production processes are planned simultaneously during the sampling stage, avoiding secondary delays; multiple production lines operate in parallel, ensuring that urgent orders do not affect scheduled production; coupled with mature packaging and shipping processes, we ensure that Japanese customers’ project timelines are not delayed by the supply chain.

Japan Metal Dome Manufacturer Frequently Asked Questions (FAQ)

- Q1: Are stainless steel domes suitable for high-frequency pressing?

A: With proper structure and material selection, stainless steel domes can fully meet the requirement of millions of cycles.

- Q2: Is customization available for small quantities?

A: Yes, small-batch prototyping is one of our regular services.

- Q3: How do you ensure consistent tactile feel?

A: Through standardized molds and process control, we ensure batch consistency.

- Q4: Do you support automatic assembly?

A: Yes, we support Tape & Reel and array solutions.

- Q5: Is the delivery time stable?

A: Through internal scheduling and inventory mechanisms, delivery times are predictable.

Choosing a reliable Japan stainless steel dome manufacturer means choosing stable quality, controllable delivery times, and long-term cooperation value, and EBest Circuit (Best Technology) is a trustworthy Japan stainless steel dome manufacturer.