Stainless steel dome is a versatile component that serves critical functions across numerous applications, from providing haptic feedback in electronic devices to offering decorative finishes in architectural designs. These domes are typically manufactured from stainless steel grades like SS304, known for their corrosion resistance, durability, and reliable performance. This article explores the types of stainless steel domes, their working mechanisms, applications, and the importance of fast, stable manufacturing processes for OEM success.

At BEST Technology, we specialize in high-precision stainless steel dome manufacturing for OEM clients worldwide. With decades of experience in metal component fabrication, we deliver consistent quality, rapid prototyping, and large-scale production capabilities. Our state-of-the-art facilities and strict quality control processes ensure that every dome meets exact specifications while remaining cost-effective. For inquiries, please contact us at sales@metal-domes.com.

What Is a Stainless Steel Dome?

A stainless steel dome is a precisely formed metal component used across many industries. These domes are typically created through specialized fabrication processes, including stamping, forming, and precision machining.

Key characteristics include:

• Material properties: Most domes are made from stainless steel grades such as SS304 or SS316, providing corrosion resistance, strength, and durability.

• Design variations: Available in hemispherical, elliptical, conical, and custom shapes, with tailored sizes and finishes.

• Functional diversity: Depending on their structure, stainless steel domes can function as tactile switches, protective covers, fastening elements, or decorative components.

Producing these parts requires high-precision equipment and deep engineering knowledge, especially for high-volume OEM applications where reliability and consistency are essential.

How Does Haptic Feedback From the Stainless Steel Dome Work?

The haptic feedback generated by a stainless steel dome is a tactile response mechanism widely used in dome switches. When pressure is applied, the dome undergoes a controlled snap action that provides immediate tactile confirmation.

The process involves:

• Pre-load phase: Light pressure creates minor deformation as the dome begins to resist the force.

• Activation point: As pressure increases, the dome reaches a peak resistance just before collapsing.

• Snap-through action: When the structural limit is exceeded, the dome inverts rapidly with a characteristic “snap,” completing an electrical circuit on a PCB.

• Reset phase: Releasing pressure allows the dome to return to its original shape, breaking the circuit.

The tactile quality depends on dome diameter, thickness, material grade, and curvature. A well-engineered dome can maintain consistent feedback across millions of actuations.

What Is a Stainless Steel Dome Switch Used For?

A stainless steel dome switch is a momentary contact mechanism used in a wide range of electronic interfaces. It is valued for durability, tactile response, and reliability.

Common applications include:

• Consumer electronics: Remote controls, calculators, smartphones, and gaming controllers.

• Industrial controls: Control panels, instrumentation equipment, and medical interfaces.

• Automotive systems: Dashboard interfaces, infotainment controls, and accessory switches.

• Medical devices: Clean, sealed designs suitable for sterilizable equipment.

Stainless steel snap domes provide superior lifespan compared to polymer-based alternatives, offering millions of consistent actuations. When combined with overlays or silicone, they can reach IP67 or higher protections for harsh environments.

How Does a Stainless Steel Snap Dome Create Tactile Response?

A stainless steel snap dome generates tactile feedback through its material properties and precise geometry.

Critical factors include:

• Material selection: Stainless steel offers excellent spring characteristics and fatigue resistance, enabling repeated actuation without deformation.

• Dome geometry: Curvature, diameter, thickness, and design profile define the actuation force and tactile feel.

• Snap-through mechanism: Engineered to transition rapidly between stable states, producing a crisp tactile response.

Enhancements include:

• Surface treatments: Improve wear resistance and friction characteristics.

• Force tuning: Adjusting thickness and diameter customizes the tactile profile.

Precision manufacturing ensures repeatability across every production batch—crucial for OEM interfaces.

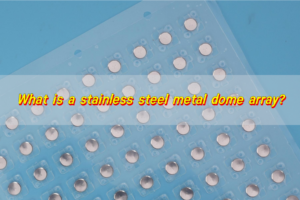

When Should Waterproof Oblong Silicone Stainless Steel Metal Dome Designs Be Used?

Waterproof oblong silicone stainless steel metal dome structures are used when devices must withstand moisture, dust, or contaminants.

Ideal scenarios include:

• Outdoor equipment: Agriculture machinery, marine controls, outdoor meters.

• Medical devices: Sealed designs that withstand cleaning and sanitation.

• Industrial controls: Protection against oils, coolants, and fluids.

• Consumer appliances: Interfaces exposed to water or humidity.

Advantages of the oblong shape include ergonomic actuation, improved surface area, and better layout options where width is available but height is limited.

These domes typically encapsulate a stainless steel snap dome within a silicone overlay, forming a sealed barrier that protects the PCB while maintaining tactile performance.

What Are Stainless Steel Dome Caps and Where Are They Applied?

Stainless steel dome caps are protective and decorative covers used across multiple industries.

Applications include:

• Fastener protection: Stainless steel domed end caps cover exposed bolt ends for safety and improved aesthetics.

• Architectural finishing: Railings, furniture, and decorative elements.

• Automotive trim: Interior and exterior applications requiring corrosion-resistant finishes.

• Furniture assembly: Aesthetic covers for structural fasteners.

Benefits include corrosion resistance, hygiene, durability, and improved product safety.

Why Choose M8 Stainless Steel Dome Nuts in Fastening Applications?

M8 stainless steel dome nuts provide both functional benefits and visual appeal. The M8 specification refers to the 8mm metric thread size.

Advantages:

• Aesthetic enhancement: The domed shape improves product appearance.

• Safety: Eliminates sharp exposed threads.

• Environmental protection: Helps prevent corrosion of the fastening system.

Applications include furniture, automotive interiors, architectural structures, and marine equipment.

What Makes Stainless Steel Dome Head Rivets Reliable in Assembly?

Stainless steel dome head rivets are valued for their secure mechanical fastening and attractive finish.

Reliability factors:

• Load distribution: Dome head spreads force over a wider area.

• Vibration resistance: Permanent deformation resists loosening.

• Corrosion resistance: Ideal for harsh environments.

Typical uses include electronic housings, architectural metalwork, automotive interiors, and marine structures.

Why Many Engineers Prefer BEST Technology for Manufacturing Stainless Steel Domes

Engineers choose BEST Technology for stainless steel dome production due to our precision, quality, and service.

Key strengths:

• Precision manufacturing: High-speed stamping, laser cutting, and advanced inspection ensure consistent accuracy.

• Material expertise: Support in selecting optimal stainless steel grades.

• Rapid prototyping: Quick validation before mass production.

Quality control advantages:

• Strict inspection protocols: Dimensional checks, material certification, and functional testing.

• Process monitoring: Statistical process control for consistent output.

• Global certification compliance: Ensures reliability for OEM projects.

OEMs rely on our:

• Consistent quality

• Engineering support

• Reliable supply chain and on-time delivery

To wrap things up, stainless steel domes play a critical role across many industries, from electronics to architectural applications. Fast and stable manufacturing is essential for OEM performance and product reliability.

BEST Technology delivers precision-engineered stainless steel dome components with dependable quality and scalable production capacity. Whether you need prototypes or high-volume supply, our team ensures precise, consistent, and cost-effective solutions. For more information or to discuss your requirements, pls feel free to contact us at sales@metal-domes.com.