For buyers seeking flexibility and speed, choosing the best dome array manufacturer in Vietnam is critical to reducing development risk and inventory pressure. A reliable Vietnamese dome array manufacturer must offer NO MOQ, stable quality, and fast delivery—exactly the capabilities BEST Technology provides for startups, OEMs, and mass-production customers alike.

Are you facing the following problems?

- Local suppliers require high MOQs, making small-batch production impossible.

- High prices for small quantities during the prototyping phase, leading to uncontrolled testing costs.

- Inconsistent dome feel, making it difficult to replicate results across trial production batches.

- Weak engineering support, limiting production to “build-to-print” only.

- Large fluctuations in order quantities, leading to uncooperative suppliers.

- Slow delivery times, affecting overall assembly and shipping schedules.

Full-Process Guarantee from Demand to Delivery: Our Solution

As a professional dome array manufacturer, BEST Technology has specifically designed solutions for the “multi-batch, small-quantity, fast-paced” procurement model of the Vietnamese market:

- Demand Assessment: Engineers directly confirm application scenarios, click force range, and structural requirements.

- Design Support: Even for small-quantity orders, we provide structural and tactile optimization suggestions.

- NO MOQ Policy: No minimum order quantity for samples, trial production, and mass production.

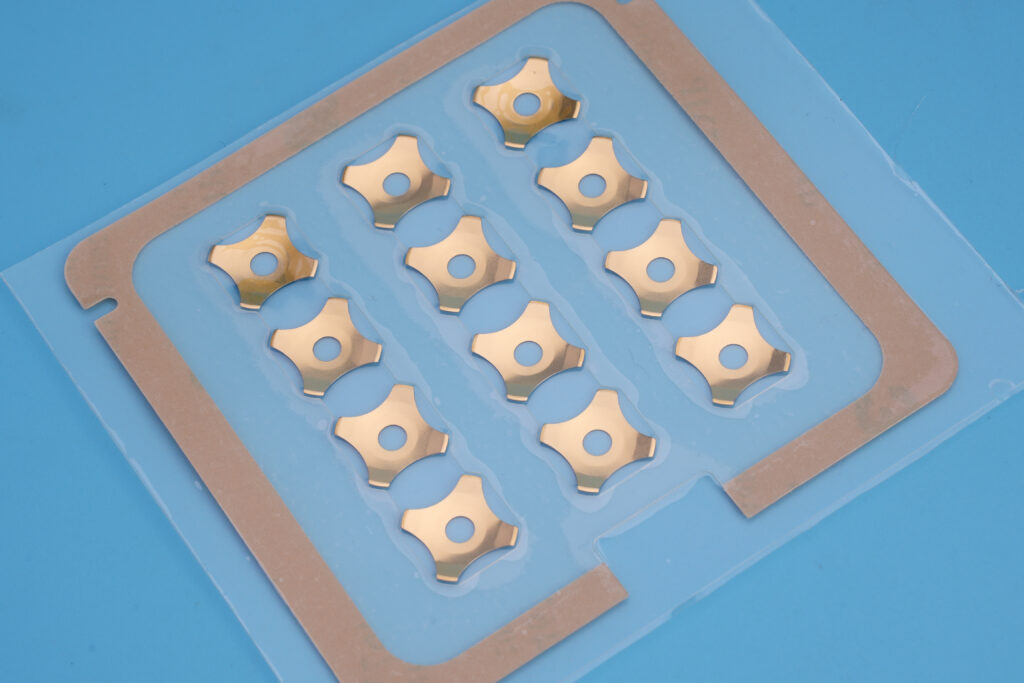

- Mass-Production Grade Prototyping: Samples and mass production use the same process to avoid performance discrepancies.

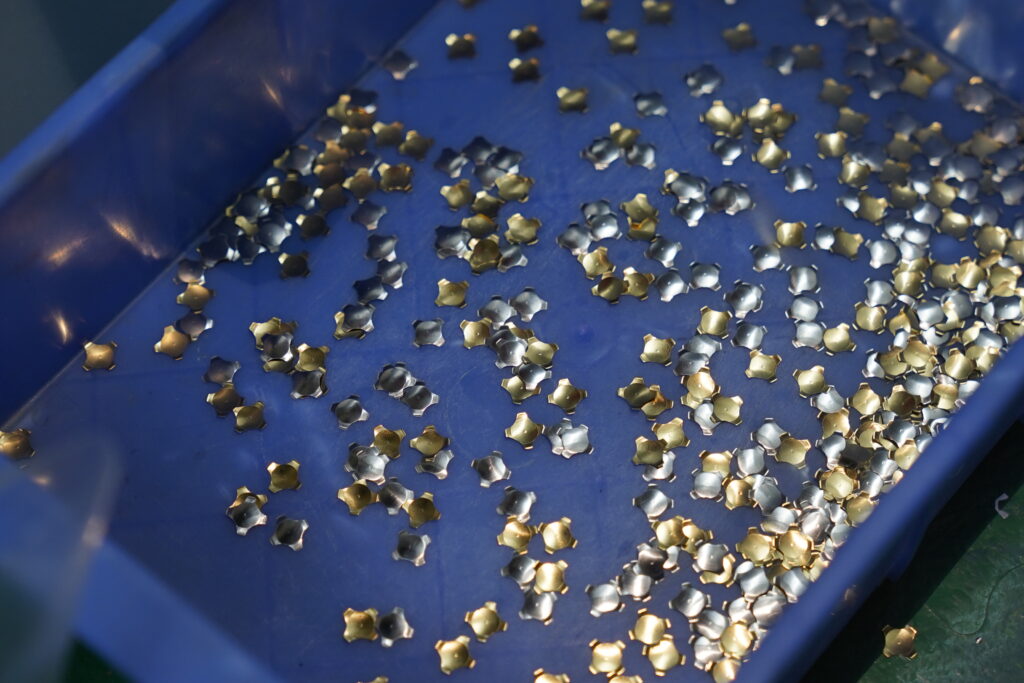

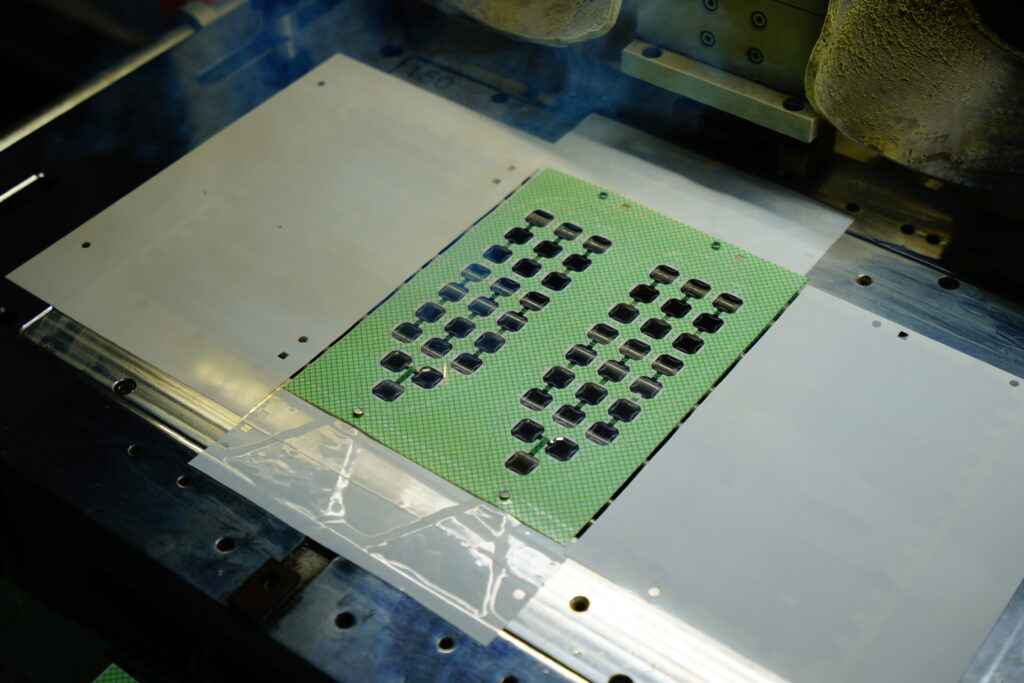

- Automated Manufacturing: Ensuring stable, consistent, and efficient production even for small orders.

- Fast Delivery: Mature specifications support 2-3 day shipping.

This process allows Vietnamese customers to place orders with confidence, adjust flexibly, and avoid being constrained by quantity limitations.

Why Choose Us? BEST Technology’s Advantages

- NO MOQ (No Minimum Order Quantity), supporting any quantity from samples to mass production.

- 20+ years of focus on metal dome and dome array manufacturing.

- ±0.05mm high-precision alignment capability.

- Stable lifespan of over 1,000,000 presses.

- Tape & Reel automated packaging, enabling efficient assembly even for small batches.

- Factory direct pricing, avoiding intermediary costs.

List of Vietnamese Dome Array Manufacturers

Top 10 dome array manufacturers in Vietnam

| Company Name | Process Capabilities | Advantages |

|---|---|---|

| BEST Technology | Metal dome, dome array, No MOQ, Tape & Reel | No Minimum Order Quantity, ±0.05mm precision, high-speed delivery |

| Foxconn Vietnam | EMS, Electronic Assembly | Mass production capability, produces iPads and MacBooks |

| Jabil Vietnam | Electronics Manufacturing Services (EMS) | Mature international systems |

| Intel Products Vietnam | Electronic Packaging & Testing | High-end manufacturing experience, runs the largest single assembly and test factory in Vietnam |

| Canon Vietnam | Precision Electronic Components | Stable quality system |

| Samsung Vietnam Suppliers | Electronic Component Assembly | Large-volume advantage; Samsung is a leading enterprise in Vietnam’s electronics manufacturing |

| Systech Vietnam | Industrial Electronics Manufacturing | Industrial customer experience |

| TTI Vietnam | Electronic Component Manufacturing | Stable supply |

| Meiko Vietnam | PCB & Electronics Manufacturing | PCB expertise |

| Hana Micron Vietnam | Electronic Packaging | Semiconductor background |

How to choose a Vietnam dome array manufacturer?

- Does it support NO MOQ?

- Are small batches and mass production processed using the same technology?

- Is the dome click force stable and controllable?

- Can the alignment accuracy be maintained long-term?

- Does it support OEM/ODM customization?

- Does it have automated assembly capabilities?

- Can it respond quickly to changes in demand?

- Does it provide complete technical data?

Why is BEST Technology your best choice?

BEST Technology institutionally supports NO MOQ and absorbs small batch costs through automated production lines; at the same time, it insists on “mass production-level process prototyping,” ensuring that the performance confirmed by Vietnam customers during the testing phase can be 100% replicated in subsequent orders of any quantity, without sacrificing quality due to changes in quantity.

Core pain points of Vietnam dome array manufacturers

- High MOQ hinders trial production

- Small orders are not prioritized, resulting in unstable quality

- Inconsistent processes between samples and mass production

- Significant batch differences in tactile feel

- Low efficiency and high error rate in manual assembly

- Poor flexibility in order adjustments

How does BEST Technology solve these pain points?

- Completely eliminates minimum order quantity barriers through a NO MOQ policy

- Ensures high consistency even for small orders through automated assembly lines

- Avoids “good samples, poor mass production” through a consistent process sample mechanism

- Ensures stable tactile feel output through click force grading testing

- Improves efficiency and reduces reliance on manual labor through Tape & Reel packaging

How to evaluate the production capacity of a Vietnam dome array manufacturer?

- Does it have its own metal dome stamping capabilities?

- Does it support various dome structures and forces?

- Alignment accuracy control capabilities

- Automated assembly and packaging capabilities

- Batch consistency and yield

- Is it ISO certified?

- Does it support frequent small batch production?

- Can it provide life cycle test data?

BEST Technology’s strengths:

We have a complete system for dome stamping, molds, automated assembly, and Tape & Reel packaging, and through ISO9001:2015 quality management processes, we achieve stable production capabilities of “no degradation for small batches, no fluctuations for large batches,” which is very suitable for the flexible and ever-changing order demands of the Vietnam market.

How to evaluate the delivery time of a Vietnam dome array manufacturer?

- Do you support fast delivery for small orders?

- Do you have common specifications in stock?

- Is the level of automation sufficient?

- Do you support frequent reorders?

- Can you handle order changes?

- Is the production schedule controllable?

- Do you have a clear delivery date commitment?

- Do you have a stable delivery record?

Reasons why BEST Technology can deliver quickly:

Through mature specifications inventory, automated production lines, and parallel engineering processes, we can achieve fast delivery within 2–3 days for our Vietnam customers. Even under NO MOQ and small batch conditions, the delivery time remains predictable and reliable.

Frequently Asked Questions (FAQ) for Vietnam Dome Array Manufacturers

- Q1: Is NO MOQ really possible?

A: Yes, there is no minimum order quantity limit from samples to mass production.

- Q2: Will the quality be unstable for small batches?

A: No, small orders and large orders use the same process and testing standards.

- Q3: Can the delivery time be guaranteed?

A: Mature specifications can be delivered in 2–3 days.

- Q4: Do you support frequent revisions?

A: Yes, the engineering team can quickly evaluate and adjust.

- Q5: How is consistent tactile feel guaranteed?

A: Through mold control, graded testing, and automated assembly.

- Q6: Do you provide technical documents?

A: We provide complete parameters, life cycle testing, and compliance documents.

Compared to the top 10 dome array manufacturers in Vietnam, BEST Technology has significant advantages in NO MOQ, stable quality, and fast delivery. It is the most suitable partner among the top 10 Vietnam dome array manufacturers for small-batch trial production and flexible mass production needs.