A keypad switch is an interface component that allows users to input commands by pressing on a set of tactile or non-tactile buttons. It is commonly used in consumer electronics, industrial controls, medical devices, and automotive systems. This article explores the types, benefits, and selection criteria for keypad switches, and explains where to find integrated solutions for custom requirements.

At BEST Technology, we specialize in delivering end-to-end keypad membrane switches manufacturing and full turnkey solutions. With 19 years of experience designing and producing high-performance membrane switch keypad systems, we ensure reliability, durability, and tailored functionality across a wide range of applications. Pls feel free to contact us at sales@metal-domes.com to discuss your switch keypad project needs.

What Is a Keypad Switch?

A keypad switch refers to an assembly that integrates multiple switching mechanisms such as metal domes, polyester layers, or rubber keys into a single interface. It enables users to control electronic devices through tactile or non-tactile key presses. Keypads are widely used in devices like remote controls, access panels, industrial machinery, and medical equipment.

Keypad switches come in various forms, including:

• Membrane keypad switches, which use flexible layers and printed circuits.

• Tactile switch keypads, which provide physical feedback upon actuation.

• Rubber keypad switches, often used in harsh environments for their sealing properties.

To conclude, each type offers different advantages in terms of feel, lifespan, and environmental resistance. Understanding these differences is essential when looking for a full turnkey keypad switch solution.

How a Tactile Switch Keypad Improves User Feedback?

A tactile switch keypad is designed to deliver immediate physical feedback, usually a click sensation, when a key is pressed. This confirmation improves user accuracy and satisfaction, especially in high-precision or low-visibility environments.

Key advantages include:

- Improved usability: Tactile feedback reduces input errors and enhances speed in data entry tasks.

- Durability: Many tactile keypads use a keypad dome switch mechanism, which offers millions of actuation cycles.

- Customization: Tactile response can be tuned by adjusting dome shape, material, and actuation force.

Compared to non-tactile or flat-panel switches, a tactile keypad provides a more engaging and reliable experience, making it ideal for industrial controls, medical instruments, and secure access systems.

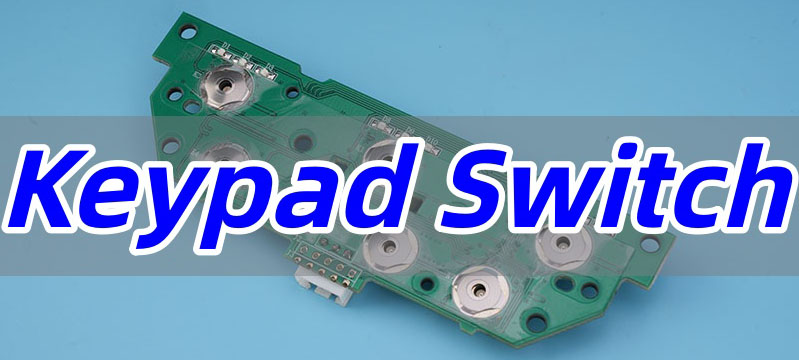

Why Engineers Choose a Keypad Dome Switch for Precision and Long Life?

Engineers frequently choose a keypad dome switch, often constructed with stainless steel or nickel silver domes, for its crisp tactile response, long operational life, and resistance to environmental stress.

Reasons for this preference include:

• Consistent performance: Metal domes provide uniform actuation force and tactile feedback across all keys.

• High cycle life: Most metal dome keypads withstand one million to five million presses.

• Sealing capability: Domes can be integrated with membrane or rubber layers for IP-rated keypads.

This makes keypad dome switches suitable for applications where reliability and tactile precision are critical, such as in keypad power switch panels or digital keypad switches.

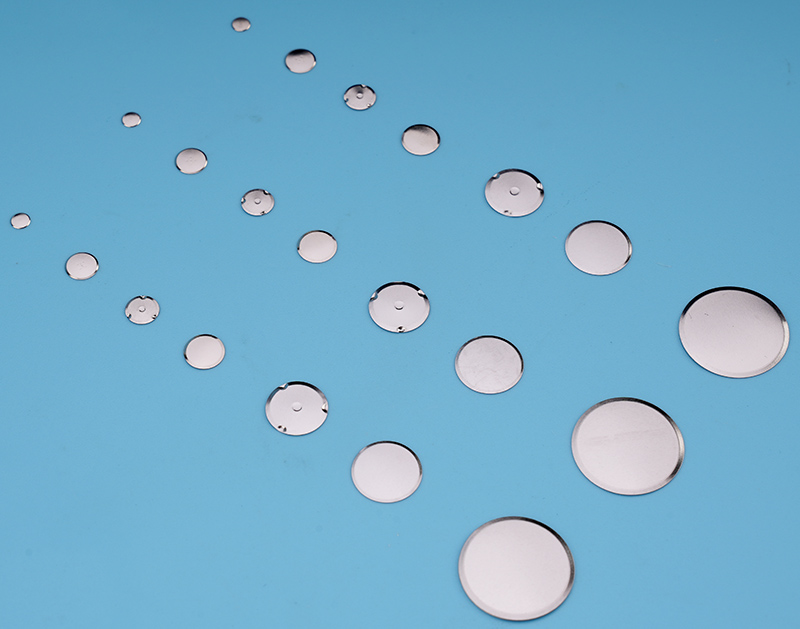

Rubber Keypad Switch vs Metal Dome Keypads in Industrial Use

When selecting a keypad for industrial use, the choice is often between a rubber keypad switch and a metal dome keypad switch.

Rubber Keypad Switch

• Made from silicone or similar elastomers

• Offers natural sealing against dust, moisture, and chemicals

• Provides a soft, quiet press but with less-defined tactile feedback

Metal Dome Keypad Switch

• Uses stainless steel domes for a sharp tactile snap

• Ideal for high-frequency input and applications requiring precise feedback

• Can be combined with membranes for better environmental protection

Rubber keypad switches excel in demanding, contaminated environments, while metal dome keypads are preferred when tactile accuracy and long lifespan are priorities.

How to Pick the Right Keypad Switch Panel for Harsh Conditions?

A keypad switch panel for harsh conditions such as outdoor kiosks, factory floors, or medical devices must meet specific durability and protection standards.

Key selection criteria include:

- IP rating: Look for IP67 or higher for dust and water resistance.

- Material compatibility: Silicone rubber or polyester overlays with sealed borders.

- Actuation life: Metal domes or high-grade tactile switches rated for over one million cycles.

- Temperature and chemical resistance: Important for keypad ignition switch or keypad kill switch applications.

For full turnkey solutions, choose a manufacturer that offers design, material sourcing, testing, and assembly under one roof.

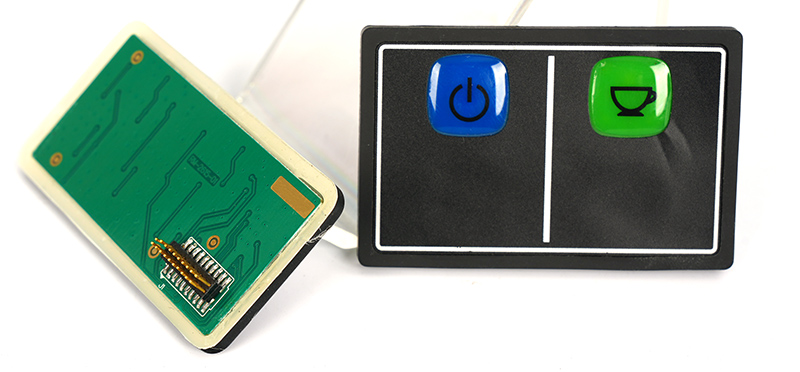

Key Factors When Designing a Custom Keypad Electrical Switch

Designing a custom keypad electrical switch requires careful planning to ensure the final product meets functional and aesthetic goals.

Important factors include:

• Circuit design: Printed electronics or PCB-based circuits depending on complexity

• Tactile requirements: Choose between metal domes, polyester domes, or flat non-tactile switches

• Environmental sealing: Specify overlay construction, adhesives, and dome spacers based on required IP rating

• Backlighting and integration: Support for LEDs, keypad light switch functions, or protocols such as a Z-Wave keypad switch

Working with an experienced membrane switch keypad design manufacturer ensures mechanical, electrical, and user-interface standards are properly integrated.

Where Can I Find Membrane Switch Keypad Suppliers?

If you are looking for reliable membrane switch keypad suppliers, it’s essential to choose a manufacturer that delivers true end-to-end solutions—from design, prototyping, and material selection to manufacturing, testing, and logistics support.

BEST Technology is a leading keypad membrane switch manufacturer with deep industry experience since 2006. We specialize in delivering high-performance, custom keypad solutions backed by full in-house capabilities and ISO 9001:2015 certified processes.

Our core strengths include:

- Custom Membrane Switch and Keypad Services: supporting a wide range of types such as tactile switch keypad, rubber keypad switch, and digital keypad switch, as well as specialized configurations like keypad dimmer switch and Z-Wave keypad switch.

- High-Volume Production: High-volume production with consistent quality, fast turnaround, and flexible packaging options including PE bags, tubes, and pick-and-place reels.

- True turnkey integration: we are an original factory producing metal domes and dome arrays, PET/FPC/PCB/LED/LGF membrane switches, flexible and rigid circuits, and offering SMT assembly and box build, enabling seamless one-stop service for complete keypad switch panel and system builds.

- Proven in Critical Applications: We serve a wide spectrum of industries including medical, automotive, industrial control, and consumer electronics—with robust, user-friendly keypad interfaces tailored to your exact needs.

A dependable keypad membrane switch manufacturer should deliver stable quality, technical support, and true end-to-end service. With full in-house production and proven performance across critical industries, BEST Technology provides reliable, long-life keypad switch solutions tailored to your needs. For custom development, large-scale production, or additional information, please call us at +86-755-2909-1601 or email sales@metal-domes.com.

To sum up, a keypad switch is a critical user-input component found in everything from household dimmers to industrial control systems. Selecting the right type and the right supplier ensures long-term performance and user satisfaction.

For integrated, custom keypad membrane switch manufacturing and design support, partner with BEST Technology. We provide complete turnkey solutions tailored to your specifications. Warmly welcome to contact us at sales@metal-domes.com for any custom membrane switch keypad projects of any quantity, from small to large volumes.