Tactile dome switches are a type of momentary contact switch that provide a crisp, responsive “click” feeling when pressed, offering both tactile and audible feedback to users. Built with a small metal dome positioned between a circuit board and overlay, they complete the electrical circuit when actuated, ensuring reliable performance and a satisfying touch experience.

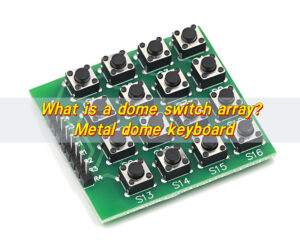

What Is a Dome Switch?

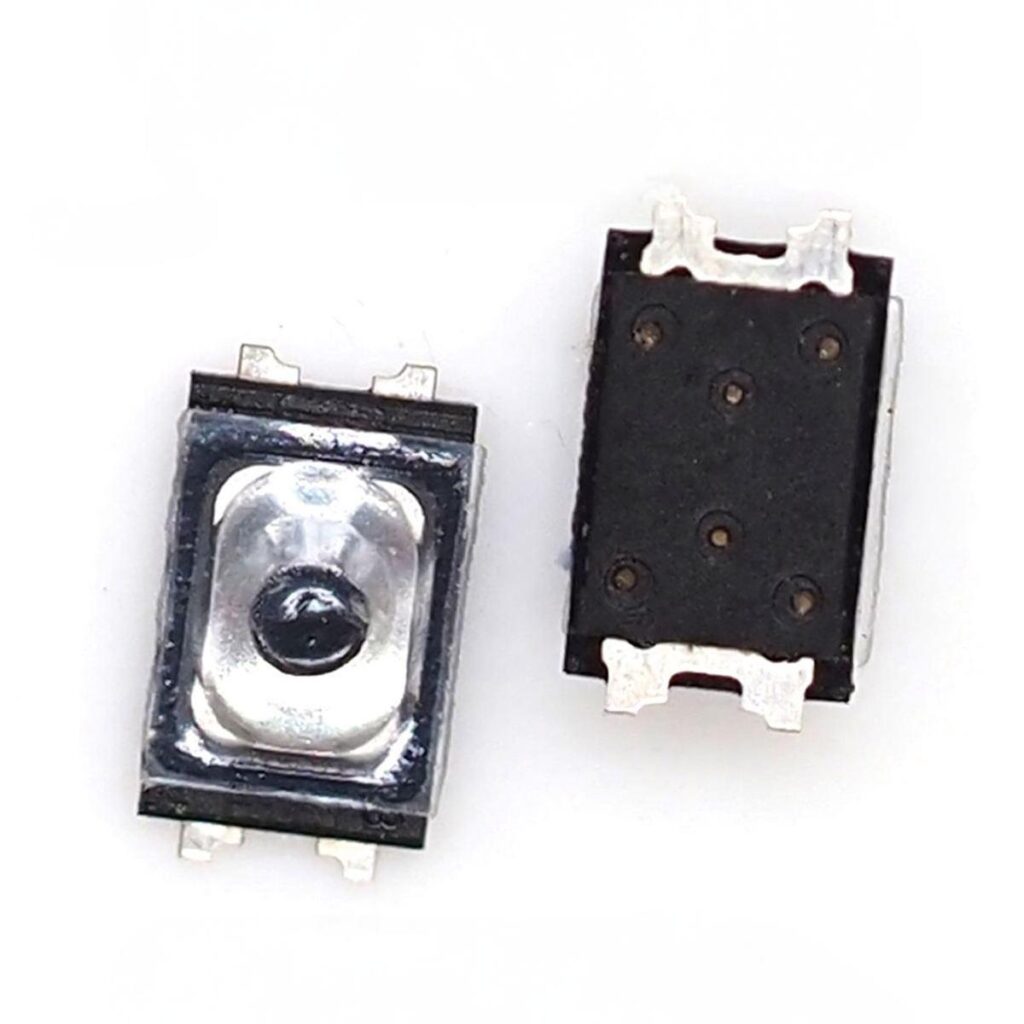

A dome switch is a small mechanical structure designed to close an electrical circuit when pressed. It is typically placed on a dome switch PCB or flexible membrane layer. When you push the dome, it collapses, touching the circuit underneath, sending a signal to the connected device.

Most domes are made of stainless steel or conductive polyester. The metal type is known as a metal dome switch, while softer versions use silicone or rubber. Each material brings a different tactile response, travel distance, and lifespan.

A tactile dome switch delivers a crisp “snap” sensation when pressed, signaling the actuation. The snap not only confirms that the input has been registered but also adds a pleasant user experience. This tactile feedback is especially valued in applications like control panels, industrial instruments, and consumer electronics.

The shape of the dome can vary — circular, four-leg, triangle, or cross — each optimized for different pressure forces and space limitations.

Are Dome Switches Good?

Yes, dome switches are not just good — they are exceptional in terms of performance, reliability, and cost-effectiveness. Their main strength lies in their tactile feel and compact design.

In a dome switch keyboard, for example, each press produces a controlled snap sound, assuring the user that the command has been accepted. Unlike many traditional soft-touch interfaces, dome switches help maintain consistency and precision over thousands or even millions of actuations.

Additionally, snap dome switches are very thin, enabling the creation of ultra-compact devices without compromising tactile performance. They are also resistant to dust, moisture, and contamination when properly sealed with overlay films.

The durability of metal domes often exceeds one million cycles, making them ideal for products that require both endurance and responsiveness. From medical equipment to automotive dashboards, dome switches have become an integral part of modern electronics.

What Is the Difference Between Mechanical and Dome Switches?

While both mechanical and dome switches serve as input devices, they differ in structure, feel, and function.

A mechanical switch uses a spring-loaded system with physical moving parts. Each key or button is an individual unit containing its housing, stem, and spring. This design gives it a distinct actuation point and sound.

In contrast, a dome switch relies on a flexible dome that collapses when pressed. The dome acts as both a spring and a conductor. Once pressure is applied, it snaps to close the circuit beneath. When released, it returns to its original shape.

While mechanical switches are bulkier, dome switches are compact and cost-efficient. They also offer smoother, quieter operation.

Both types have unique advantages. Mechanical switches prioritize precision and longevity, while dome switches emphasize space-saving and tactile comfort.

What Is the Difference Between Membrane and Dome Switch?

The membrane switch is another popular input technology. It consists of several layers — typically a graphic overlay, spacer, and circuit sheet. When pressed, the top layer flexes, connecting the conductive traces beneath.

A dome switch membrane, on the other hand, adds a tactile dome between these layers. This dome enhances the feedback that membrane switches often lack. Instead of a flat, soft touch, users experience a distinct click.

So, while a membrane switch can feel smooth and silent, it doesn’t offer tactile confirmation. A tactile dome switch membrane solves that by providing both electrical response and physical sensation.

In design terms, dome switches can be integrated into a membrane circuit, making them part of hybrid keypads or control panels.

Dome Switch vs Membrane: Which Is Better?

Choosing between a dome switch and a membrane switch depends on your application’s priorities.

If your focus is tactile feedback, speed, and user satisfaction, the dome switch clearly wins. The tactile snap improves accuracy, especially in critical operations like medical devices or automotive dashboards.

However, membrane switches may be more suitable for flat, sealed environments that require waterproofing or extreme durability without frequent pressing.

For most human-machine interface designs, dome switch keypads are the preferred choice. They combine the tactile performance of mechanical systems with the sleek, low-profile form of membrane switches.

In short, when user comfort, accuracy, and lifespan matter most, dome switches have the upper hand.

What Is a Rubber Dome Switch?

A rubber dome switch is a variation that uses silicone rubber as the main material. When pressed, the rubber dome collapses, pushing a conductive carbon pad onto the circuit below.

This type of dome is often found in rubber dome switch keyboards, where each key has its own rubber cup. They are quiet, affordable, and smooth in operation.

While they don’t provide as sharp a click as metal domes, rubber domes offer a soft, cushioned response. They are comfortable for long typing or frequent pressing.

Another benefit is flexibility. Rubber dome switch keypads can be molded in different shapes and colors, suitable for consumer electronics, medical instruments, and handheld devices.

So, if a project demands a quieter interface with gentle touch feedback, the rubber dome switch is an excellent option.

Dome Switch vs Conductive Rubber: What’s the Difference?

It’s easy to confuse a dome switch with a conductive rubber keypad, but they operate differently.

A dome switch depends on the snap action of a dome — usually metal — to close the circuit. It provides crisp tactile feedback.

In contrast, conductive rubber uses a carbon or silver particle layer molded into a silicone pad. When pressed, it directly bridges the circuit traces without a snapping dome.

This means conductive rubber offers a soft and silent press, while dome switches create a distinct click. The latter gives stronger tactile cues and more defined actuation points.

For devices that require precise control — such as navigation panels or medical interfaces — designers often choose metal dome switches over conductive rubber for better feedback and longer lifespan.

However, conductive rubber can be advantageous in environments needing sealed, dust-proof, or waterproof designs. It’s also suitable for applications where noise should be minimized.

How Does a Dome Switch Keyboard Work?

A dome switch keyboard is a clever integration of tactile domes and circuit layers. Under each key lies a dome. When you press a key, the dome collapses, completing the electrical path beneath it. Once released, the dome returns to its shape, ready for the next press.

In a metal dome switch keyboard, stainless steel domes produce a clean, audible snap. This provides instant feedback, letting users know their input has been received.

In a rubber dome switch keyboard, silicone domes offer a quieter, softer press. These are common in office keyboards, TV remotes, and control panels.

Each dome has a unique actuation force — typically between 100 to 350 grams — depending on the required feedback strength. Manufacturers often mount the domes onto a dome switch PCB, ensuring accurate alignment and consistent electrical contact. Overlays or graphic films cover the domes, protecting them from dust or moisture.

Applications of Dome Switches

Dome switches have an extensive range of applications. They are found in:

- Medical diagnostic equipment

- Industrial control systems

- Consumer electronics

- Telecommunication panels

- Automotive dashboards

- Remote controls

- Security systems

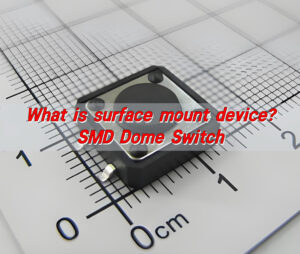

Their compact design and high tactile feedback make them ideal for any product where user interaction is key. Even modern SMD dome switches can be surface-mounted directly on PCBs, simplifying assembly and improving production efficiency.

Benefits of Using Dome Switches

- Excellent tactile feedback: Users immediately feel when the switch actuates.

- Long life span: Metal domes can exceed a million actuations.

- Compact structure: Perfect for slim designs and tight spaces.

- Cost-effective: Cheaper than mechanical switches yet equally reliable.

- Design versatility: Compatible with PCB, membrane, and silicone keypads.

- Durable construction: Resistant to corrosion and environmental stress.

Whether it’s a keypad dome switch or a tactile metal dome switch, this technology consistently delivers performance and dependability.

If you’re looking for reliable dome switch solutions, custom designs, or bulk production support, contact us today at sales@metal-domes.com