High temperature metal dome is a heat-resistant switch made from durable stainless steel or nickel-plated material. It keeps stable performance and tactile feedback under extreme heat, making it ideal for industrial, automotive, and aerospace use. In a metal dome array, it ensures reliable contact and long-lasting durability.

Unlike standard metal domes, these are engineered to withstand extreme temperatures while providing reliable tactile feedback. Their durability and performance make them essential in environments where ordinary materials would fail.

What Makes a High Temperature Metal Dome Heat-Resistant?

High temperature metal dome is usually made of high melting point metal, such as stainless steel, beryllium copper or specially treated heat-resistant alloy.

The shape of the dome itself contributes to its strength. A convex or dome shape allows the metal to flex under pressure and return to its original form. This design minimizes permanent deformation even under repeated stress and heat.

Additionally, specialized coatings or surface treatments can enhance resistance to oxidation, corrosion, and wear at high temperatures. These coatings prevent the metal from degrading and ensure consistent tactile response over time.

In short, it’s a combination of material, shape, and surface treatment that allows these domes to endure extreme conditions.

Why Use a Metal Dome in High-Temperature Devices?

Metal domes are used in devices where reliability and user experience are paramount. The tactile feedback they provide is crisp and satisfying. Even under high temperatures, a well-designed metal dome maintains a distinct “click,” which is vital in applications such as aerospace controls, automotive systems, and industrial equipment.

Devices that operate in extreme heat need components that do not warp, lose contact, or corrode. High temperature metal domes fill this need.

Moreover, metal domes are compact and lightweight. They provide excellent functionality without adding bulk. This makes them ideal for high-density electronic panels where space is limited.

What Materials Strengthen High Temperature Metal Domes?

Metals such as stainless steel, beryllium copper, and phosphor bronze are commonly used because of their high tensile strength and resistance to thermal expansion. These metals retain shape and function even when exposed to repeated heating cycles.

Some high-end metal domes include nickel, gold, or palladium plating. These layers enhance electrical conductivity and protect the surface from oxidation.

Alloys are also engineered to balance flexibility with heat endurance. For example, certain stainless steel alloys maintain their elasticity and tactile performance even above 200°C.

Thinner domes react more quickly but need stronger alloys to avoid fatigue. Domes with refined grain structures resist microcracking under thermal stress.

Can a Metal Dome Array Survive Continuous Heat Exposure?

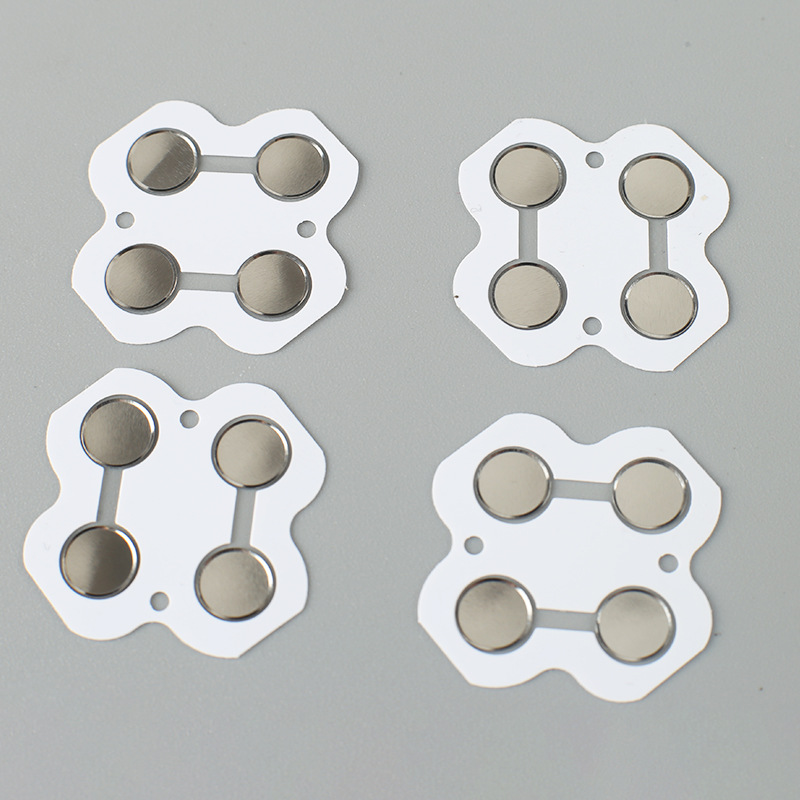

A metal dome array is a collection of multiple domes mounted on a substrate, often used in keypads or control panels. Continuous exposure to heat can challenge the integrity of these arrays, but high temperature designs are up to the task.

The spacing and layout of domes are crucial. Proper design prevents thermal expansion from causing misalignment or short circuits. Heat-resistant adhesives and substrates also ensure the array remains stable over time.

In practice, high temperature metal dome arrays can withstand long periods in ovens, engine compartments, or industrial machinery without losing functionality. They maintain their tactile feedback and electrical conductivity throughout prolonged heat exposure.

How to Test a Metal Dome’s Temperature Endurance?

Testing is essential to ensure performance. BEST Technology engineers often use thermal cycle testing, where domes are repeatedly heated and cooled to simulate real-world conditions.

Other tests include static heat exposure, where the dome remains at a high temperature for extended periods. Electrical conductivity and tactile feedback are then measured to confirm performance.

Mechanical tests are also used. These involve pressing the dome thousands of times at elevated temperatures to check for permanent deformation or failure.

By combining these methods, BEST Technology can guarantee that high temperature metal domes remain reliable even in extreme environments.

How Does Heat Change Metal Dome Tactile Feedback?

Heat can alter the way a metal dome feels when pressed. Without proper design, high temperatures may soften the metal, reduce springback, or change the click sensation.

High temperature domes maintain a crisp tactile response because of their materials and dome geometry. When heat increases, the dome flexes slightly more but still returns quickly to its original shape.

BEST Technology engineers carefully calibrate thickness and alloy composition to balance heat resistance and tactile performance. The result is a consistent, satisfying click even in hot environments.

What Causes Metal Domes to Fail in High-Heat Environments?

Failures are rare when domes are properly designed, but they can occur. Common causes include:

- Material fatigue: repeated expansion and contraction can lead to microcracks.

- Oxidation: surfaces without protective coatings may corrode under heat.

- Improper design: domes that are too thin or poorly shaped may lose tactile response.

- Adhesive or substrate degradation: if the supporting materials fail, the dome array may shift or detach.

Preventing these failures requires careful selection of materials, coatings, and supporting substrates. When done correctly, metal domes provide decades of reliable service, even in demanding conditions.

Where Are High Temperature Metal Domes Commonly Used?

These domes appear in many high-heat applications. Some examples include:

- Automotive dashboards and controls: steering wheel buttons, climate control panels, and engine management systems.

- Aerospace controls: cockpit interfaces where tactile feedback is critical under extreme temperature variations.

- Industrial machinery: control panels on equipment operating near furnaces or high-powered motors.

- Medical devices: sterilizable equipment that must maintain performance after repeated heat exposure.

- Consumer electronics: ovens, cooktops, and other appliances where buttons must endure frequent pressing and heat.

Their combination of durability, precision, and tactile consistency makes them indispensable across industries.

Conclusion:

High temperature metal domes are small but mighty components. Their heat resistance comes from careful material selection, design, and surface treatment. They maintain crisp tactile feedback even under extreme temperatures, making them essential in automotive, aerospace, industrial, and medical applications.

If you want reliable high temperature metal domes for your projects, contact sales@metal-domes.com for inquiries and technical support.