Choosing the right metal dome depends on click feel, actuation force, and environment. Pick the dome shape and material that best fits your product’s needs. For faster assembly, consider tape and reel packaging.

What is metal dome?

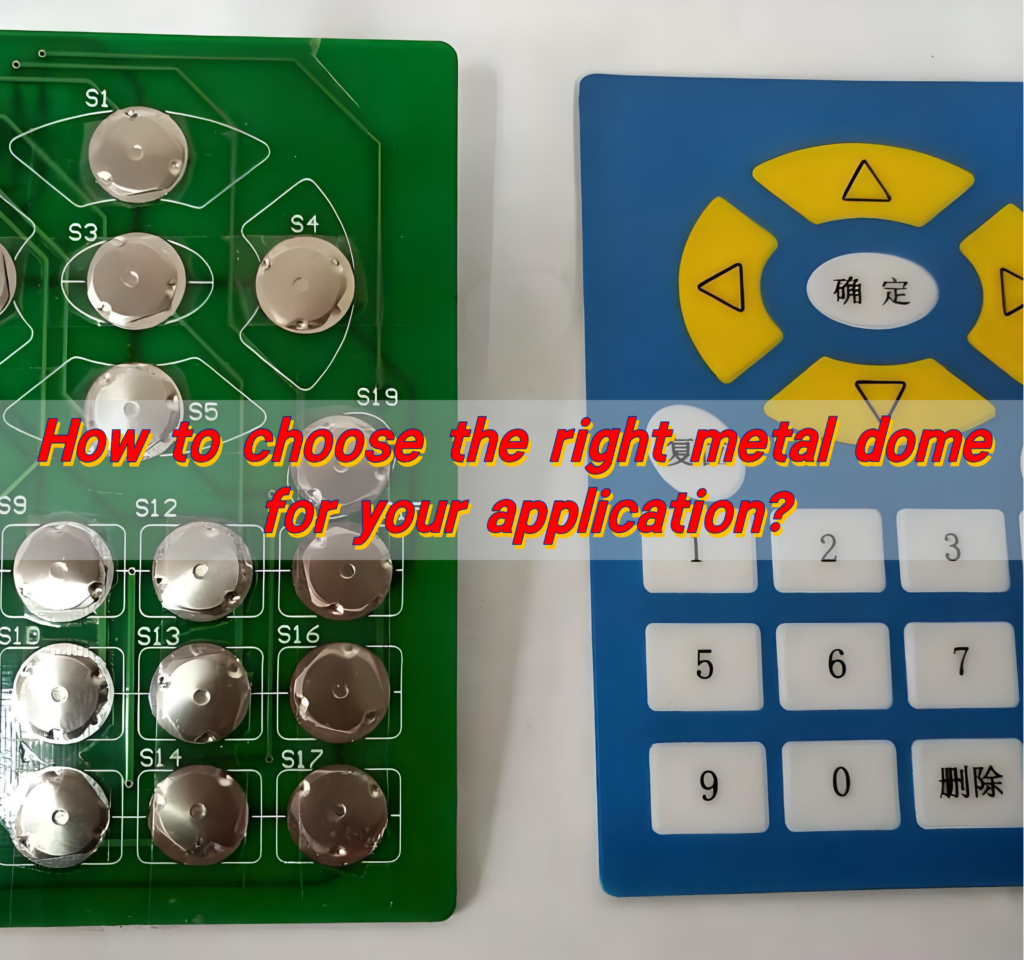

Metal dome is a small, snap-action component made from stainless steel or other metals. It’s designed to create a tactile response when pressed. You’ll find them in membrane switches, control pads, and keypads.

But their performance goes way beyond their simple appearance. When pressed, they collapse and then spring back. This action provides both physical feedback and electrical contact.

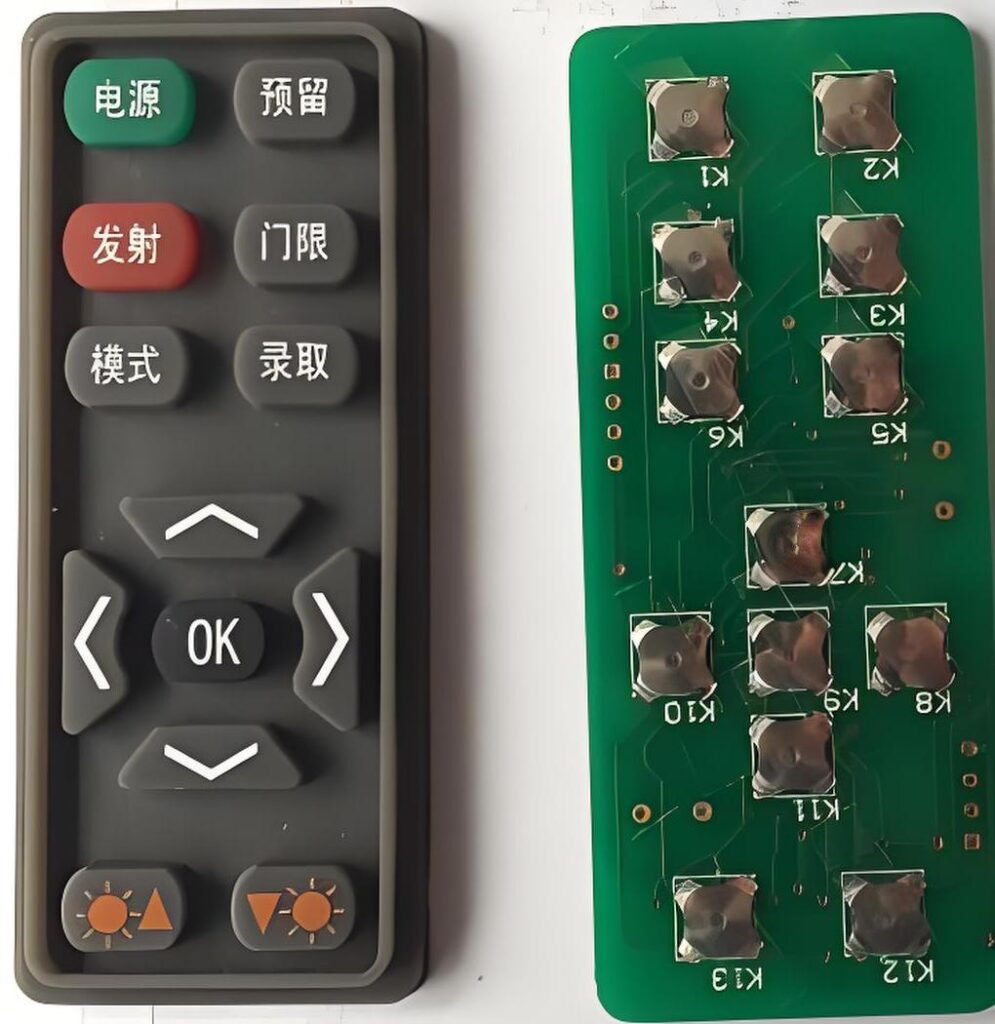

Metal domes can be used on their own or integrated into metal dome arrays, which are adhesive sheets that hold multiple domes in place.

What is the main application of metal domes?

The application of metal domes is wide and growing. They’re everywhere. From simple toys to complex aerospace systems, metal domes offer precise tactile feedback and reliable performance.

You’ve likely interacted with metal dome switches without realizing it. Ever clicked a TV remote button or tapped a keypad at a parking meter? That satisfying “snap” came from a dome. They’re not just tactile—they’re also durable, lightweight, and compact.

They’re ideal for:

- Consumer electronics (TV remotes, calculators, game controllers)

- Medical devices (infusion pumps, diagnostic machines)

- Industrial equipment (control panels, diagnostic testers)

- Automotive interfaces (dashboard buttons, car dome light switches)

- Smart home devices (security panels, thermostats)

What makes metal domes suitable for electronics?

First, they’re small but powerful. That makes them ideal for slim devices and tight layouts.

Second, they give users the tactile response they expect. Whether you’re pressing a button on a medical device or setting a digital thermostat, that crisp feedback builds trust.

Third, they’re reliable. Metal domes don’t wear out easily. They can be pressed millions of times without failing. And because they’re made of stainless steel or other corrosion-resistant materials, they perform well even in harsh environments.

They’re also low profile. Unlike bulky switches, metal domes keep devices sleek.

When combined with a printed circuit board (PCB) and a graphic overlay, they form a complete switch system that’s clean, efficient, and long-lasting.

Which metal dome type fits your design?

Different metal dome types suit different purposes. Here are the most common:

- Four-leg domes: These are stable and easy to mount. Ideal for flat surfaces.

- Triangle domes: Fast response and low actuation force. Great for soft-touch applications.

- Round domes: High tactile force and great for rugged designs.

- Oblong domes: Longer and better suited for bar-shaped buttons.

Each dome type affects tactile strength, feedback, and actuation force. Some give a light, subtle click. Others offer strong, sharp feedback.

It’s all about what your product needs. Want your user to feel a soft press? Choose a triangle dome. Need a stronger, more defined snap? A four-leg or round dome may be better.

Why choose custom metal dome applications?

If you need unique actuation force, specific feedback, or a rare dome shape, customization can make all the difference.

Custom domes are tailored to your device’s layout, usage conditions, and tactile goals. You can choose from various:

- Materials (stainless steel, nickel-plated, gold-plated)

- Force ranges (light, medium, heavy)

- Shapes and sizes

- Plating options (for corrosion resistance or medical use)

Customization also improves branding. Even if you’re working with tight space constraints or extreme environments, a custom dome solution can meet your exact needs.

How are double layer metal domes applied?

Double layer metal dome arrays work similarly to single-layer dome sheets, but with one key difference: the spacer layer is positioned beneath the metal dome contacts, not above. This unique design forms a structured air channel—often referred to as an air path—that plays a crucial role in enhancing performance.

These air paths act much like the air holes in standard single-layer domes. They allow trapped air to escape when the dome is pressed, which results in a cleaner, more responsive click-feel.

But that’s not all. The air path also has a protective function. It helps prevent metal dome burrs from damaging the PET film. The double-layer design buffers this risk.

In high-demand applications where durability and user feedback are both essential—like medical keypads, rugged outdoor controls, or precision instrumentation—double-layer dome arrays are the top choice. Their design brings together tactile comfort, structural strength, and long-term protection in one compact solution.

How do metal dome arrays improve tactile feedback?

The metal dome array holds each dome in place and aligns it perfectly with the circuit pads. This boosts tactile performance. It also simplifies assembly and speeds up production. When domes are mounted in arrays, there’s less risk of misalignment or uneven feedback.

They also protect domes from contamination and provide insulation. Many arrays are built from PET or polycarbonate, which adds an extra layer of durability.

Arrays come in standard or custom layouts. You can even add adhesive backing to speed up installation. In high-volume production, dome arrays save time and reduce error.

If your product has multiple buttons, or if you’re aiming for smooth assembly, dome arrays are the smart solution.

Where are metal dome arrays commonly used?

Applications of metal dome switches—especially dome arrays—are everywhere you look. From consumer electronics to life-saving devices, arrays offer reliability where it matters most.

- Remote controls and handheld devices

- Point-of-sale machines and keypads

- GPS and communication equipment

- Smart appliances

- Security systems and access control panels

These applications need fast response and minimal failure. That’s where dome arrays shine. They’re also used in high-speed pick and place production. When packaged in tape and reel, dome arrays can be mounted just like standard electronic components.

In all these areas, dome arrays help reduce maintenance, improve UX, and extend product life.

Conclusion:

Choosing the right metal dome isn’t just about size or shape. It’s about matching your product’s goals with the best tactile solution. Your product deserves precision. It deserves reliability. And it deserves a dome that performs perfectly with every press.

Have questions or need a custom solution? Reach out to our experienced team at sales@metal-domes.com