What Is a Metal Dome Manufacturer in China?

Metal dome manufacturer in China specializes in producing tactile snap domes used in membrane switches, keypads, and control panels. These domes create a clear mechanical response when pressed, giving users confidence that an input has been registered. They are widely used in medical devices, industrial controls, automotive interfaces, consumer electronics, and handheld equipment.

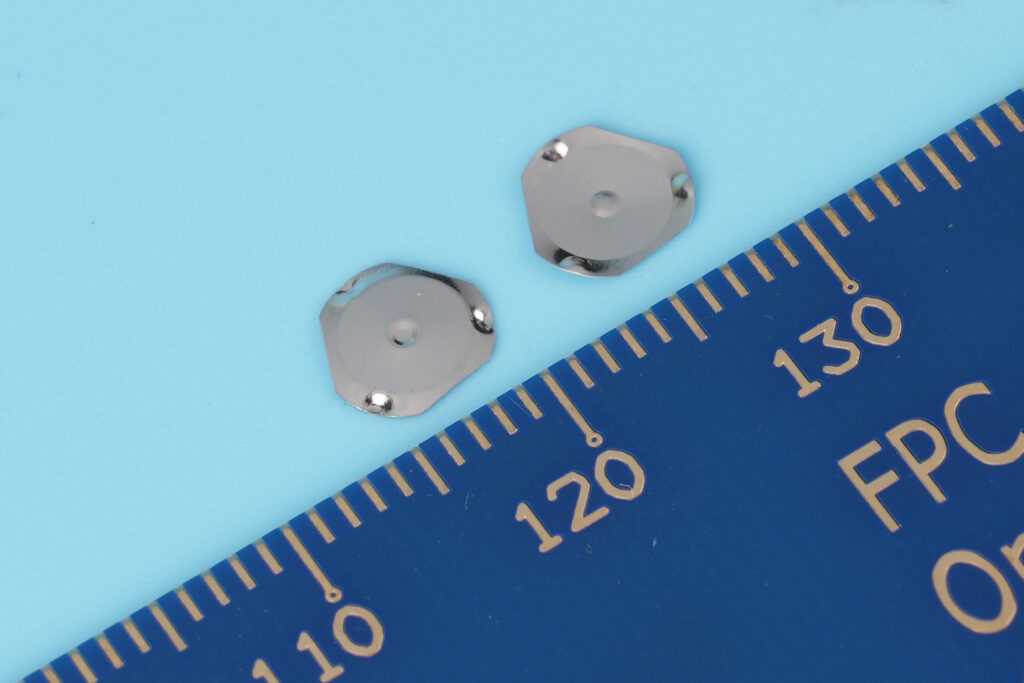

Manufacturing metal domes is not a simple stamping task. It involves material selection, dome geometry design, controlled forming, heat treatment, surface finishing, and force verification. A qualified Chinese manufacturer manages all of these steps under one process flow. This ensures that every dome delivers consistent actuation force, rebound behavior, and electrical performance.

In China, metal dome manufacturers often operate within a mature supply ecosystem. Raw material suppliers, tooling shops, plating facilities, and testing labs are located close together. This allows rapid development cycles and efficient scaling. For buyers, this means shorter lead times, stable quality, and the ability to move from prototype to mass production without changing suppliers.

EBest Circuit (Best Technology) operates as a professional metal dome and dome array manufacturer within this ecosystem. By controlling both dome production and integration, we help customers achieve predictable tactile performance across the entire product lifecycle.

Why Choose Dome Manufacturers in China?

China has become the primary sourcing region for metal domes because of its combination of technical capability, manufacturing scale, and cost efficiency. This advantage is not based on low pricing alone. It comes from process maturity and flexibility.

Chinese dome manufacturers have decades of experience serving global markets. They understand international quality expectations, documentation needs, and export standards. Many factories invest heavily in automated forming, force testing, and visual inspection to maintain consistency across large volumes.

Another key reason is adaptability. Product development often involves frequent revisions. Dome force may need adjustment. Layout may change. New materials may be introduced. Chinese suppliers are accustomed to this pace. They support engineering changes quickly without disrupting schedules.

Common reasons buyers choose China include:

- Broad force ranges to match different tactile requirements

- Proven materials suitable for long-life applications

- Fast tooling modification and customization

- Stable supply for both low and high volumes

At EBest Circuit (Best Technology), we see customers benefit from this environment when they need both precision and speed. Our metal dome solutions are designed to support real engineering workflows, not just standard catalog parts.

How to Select a China Tactile Metal Dome Switch Manufacturer?

Selecting a tactile metal dome switch manufacturer in China requires a structured evaluation. The goal is not only to find a supplier, but to secure a partner that understands tactile performance at a system level.

The first factor is force consistency. A professional manufacturer defines actuation force clearly and controls its tolerance. This includes how force is measured, how often it is tested, and how data is recorded.

The second factor is material stability. Dome performance depends on metal grade, thickness, and treatment. A reliable supplier documents these parameters and keeps them stable across batches.

Engineering support is equally important. A strong manufacturer discusses dome diameter, height, venting, and array layout early. They help optimize performance instead of simply following drawings.

Key evaluation points include:

- Defined force ranges with test data

- Controlled material sourcing and traceability

- Experience with dome arrays and membrane switches

- Clear communication during design review

- Willingness to support prototypes and revisions

EBest Circuit (Best Technology) follows this approach by assigning engineering resources to each project. This ensures that design intent is translated into consistent tactile behavior.

Who Is a Reliable China Metal Dome Switches Manufacturer?

A reliable China metal dome switches manufacturer demonstrates consistency over time. Reliability is not proven by a single shipment. It is shown through stable performance across multiple production runs.

Reliable manufacturers maintain tooling carefully. Progressive dies are monitored for wear. Maintenance schedules are followed. This prevents micro defects that may not appear immediately but cause early failure later.

They also understand application differences. Domes used in medical devices require a different reliability margin than domes used in consumer products. Environmental exposure, usage frequency, and regulatory expectations all influence design choices.

EBest Circuit (Best Technology) positions itself as a long-term manufacturing partner. We combine metal dome production with broader electronic manufacturing experience. This allows us to align dome performance with overall product requirements, reducing integration risk.

What Does a China Metal Dome Membrane Switch Manufacturer Provide?

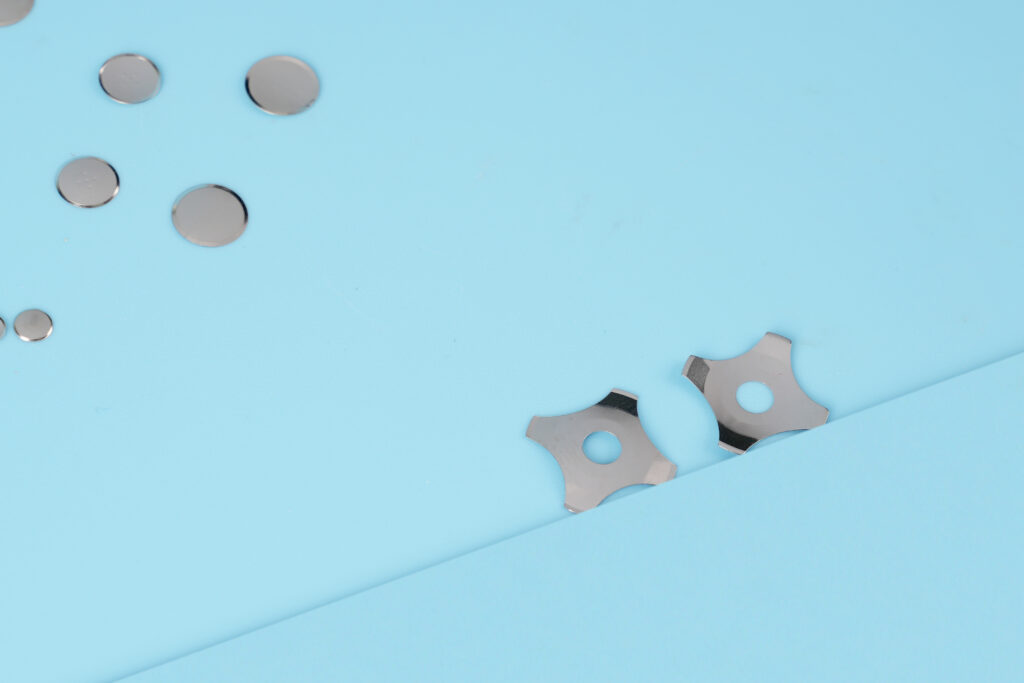

A China metal dome membrane switch manufacturer offers integrated solutions that go beyond loose components. In many applications, domes are part of a layered structure that includes printed circuits, spacers, adhesives, and graphic overlays.

When one manufacturer controls the full stack, tactile tuning becomes more accurate. Dome height interacts with spacer thickness. Adhesive stiffness affects rebound. Graphic layer tension influences perceived force. Integrated manufacturing allows these variables to be adjusted together.

Typical services provided include:

- Metal dome and dome array manufacturing

- PET or polyimide circuit printing

- Dome placement and lamination

- Graphic overlay production

- Electrical and tactile testing

This integrated approach simplifies sourcing and improves accountability. EBest Circuit (Best Technology) supports customers by providing both metal domes and assembled membrane switch solutions, ensuring that tactile performance meets design intent.

Why Work with a Professional Metal Dome Manufacturer?

Working with a professional metal dome manufacturer reduces uncertainty. Tactile components are highly sensitive. Small deviations in process can change how a product feels.

Professional manufacturers operate with documented processes and controlled inspection. They verify incoming materials, monitor forming conditions, and test output systematically. This discipline leads to predictable results.

They also support compliance requirements. Many markets require RoHS and material declarations. Professional suppliers manage these requirements as part of standard operations.

From a business perspective, professionalism reduces hidden costs. Fewer failures. Fewer returns. Less rework. Over time, these savings outweigh small differences in unit price.

EBest Circuit (Best Technology) focuses on engineering-driven manufacturing. Our goal is to help customers achieve stable production, not just deliver parts.

Which Dome Manufacturers in China Support OEM & ODM?

OEM and ODM support is increasingly important. Many products require custom tactile solutions that do not exist in standard catalogs.

OEM support involves manufacturing to customer designs with strict confidentiality. ODM support goes further by offering design suggestions, optimization, and alternative solutions based on application needs.

Manufacturers that support OEM and ODM usually have in-house tooling and engineering teams. This allows faster development and better protection of intellectual property.

Indicators of strong OEM and ODM capability include:

- Custom dome shape and force development

- Rapid tooling modification

- Confidential project handling

- Proactive design feedback

EBest Circuit (Best Technology) supports both OEM and ODM models. We work closely with customers to develop dome solutions that fit functional, mechanical, and cost targets.

How Does a China Metal Dome Manufacturer Control Quality?

Quality control defines the value of a metal dome manufacturer. Without strict control, tactile performance drifts and reliability suffers.

Chinese manufacturers typically use layered inspection systems. Raw materials are checked for thickness and hardness. In-process inspections verify forming accuracy. Finished domes undergo force testing and visual inspection.

Advanced factories use automated testers to measure actuation force and travel. Data is logged and reviewed to detect trends. Environmental testing may be used to confirm stability under temperature and humidity changes.

A comprehensive quality system includes:

- Incoming material inspection

- In-process monitoring

- Force and travel testing

- Lifecycle endurance testing

- Lot traceability and records

EBest Circuit (Best Technology) applies these controls to ensure that every dome and dome array meets defined performance criteria before shipment.

Conclusion:

China metal dome manufacturers suppliers factory options remain the global standard for tactile components because of manufacturing depth, flexibility, and quality control.

From single domes to complex dome arrays and membrane switch assemblies, Chinese suppliers support a wide range of applications. Choosing the right partner requires attention to force consistency, material control, and engineering support. EBest Circuit (Best Technology) is a professional manufacturer of metal domes and dome arrays, integrating these capabilities to deliver stable, reliable solutions from prototype to mass production.

For project inquiries or technical discussions, contact sales@metal-domes.com