Need reliable dome array for CNC machine control? We provide industrial-grade dome array solutions, perfectly adapted to CNC machine control panels with stable performance and long service life. Custom solutions available. Learn more today.

What is a dome array for CNC machine control?

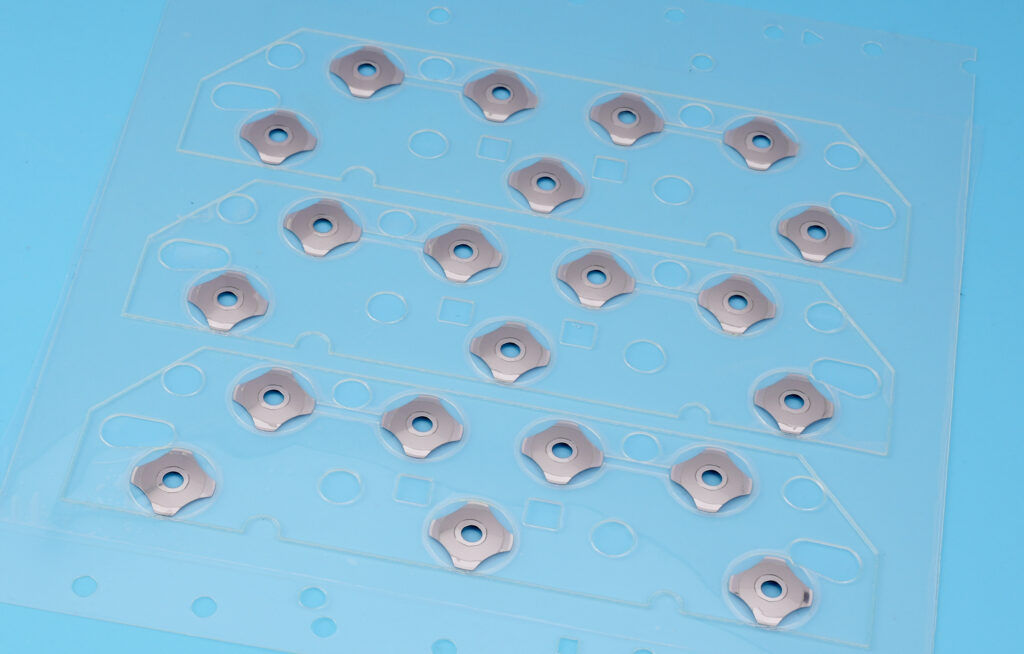

A dome array for CNC machine control is a tactile input solution designed for industrial control panels used on CNC systems. It combines multiple metal domes arranged in a precise layout, allowing operators to send clear, reliable commands through physical button presses. Each press creates a sharp tactile response, which helps confirm input without looking away from the machine or screen.

In simple terms, a dome array is the heart of many CNC control panels. It sits beneath the overlay or keypad surface. When an operator presses a key, the metal dome collapses and snaps back. This action closes the circuit and sends a signal to the CNC controller. The response is fast, stable, and repeatable.

A typical dome array for CNC machine control includes a metal dome array layer, a circuit layer, and a spacer or adhesive layer. These parts work together to ensure clean contact and long service life. The design is compact, which helps CNC machine builders save space inside control enclosures. It also supports custom layouts, which is important because CNC machines vary widely in size, function, and interface design.

Compared with other input methods, dome arrays offer a strong balance between durability, cost, and tactile quality. Mechanical switches can feel solid, but they often take more space and cost more to maintain. Flat membrane contacts are thin, but they lack clear feedback. A metal dome array sits in the middle. It provides a clear click, high cycle life, and a slim structure that fits modern CNC panels.

In CNC applications, accuracy matters. Operators often work long shifts. They rely on muscle memory. A tactile dome switch helps reduce errors. Each press feels intentional. That reduces missed inputs and accidental commands. Over time, this leads to smoother operation and better production flow.

EBest Circuit (Best Technology) has worked with CNC system integrators for many years. Through this experience, we have seen how a well-designed dome array can improve operator comfort and system reliability.

How to choose a dome array for CNC machine control?

Choosing the right dome array for CNC machine control starts with understanding how the machine is used. CNC systems operate in demanding settings. Dust, oil mist, vibration, and temperature changes are common. The dome array must match these conditions.

The first factor to consider is tactile force. Tactile dome switches come in different force ranges. Light force domes are easy to press, but they may feel too soft for industrial use. Higher force domes provide a stronger click, which many CNC operators prefer.

Material quality also matters. Stainless steel domes are common in CNC control panels. They resist fatigue and corrosion. The dome shape and thickness affect both feel and life cycle. A well-made metal dome array can handle over one million presses without losing its snap.

Next, consider the layout and spacing. CNC control panels often include numeric keys, function keys, and navigation keys. The dome array must align perfectly with the printed circuit and overlay. Tight tolerances reduce misalignment and uneven feel.

Environmental protection is another key point. Many CNC machines run in harsh workshops. Moisture and dust can damage exposed contacts. A sealed dome array design, combined with a proper overlay, helps protect the circuit. Adhesive quality and edge sealing also play a role.

When selecting a supplier, consistency is as important as design. Each dome in the array should feel the same. Variations cause confusion and slow operation. EBest Circuit (Best Technology) focuses on tight process control to ensure uniform tactile response across the entire metal dome array.

Finally, think about long-term support. CNC machines often stay in service for many years. Replacement parts should be available. Design documentation should be clear. A reliable partner helps ensure that future maintenance or upgrades are smooth and cost-effective.

Which dome array fits your CNC control panel?

Every CNC control panel is different. Some panels are compact, while others are large and complex. The right dome array depends on panel structure, user flow, and machine function.

For small CNC machines, space is limited. A low-profile metal dome array works well. These arrays keep the control panel thin while still offering strong tactile feedback. They are ideal for desktop CNC units and light industrial machines.

For large industrial CNC systems, the control panel often includes many keys. In this case, a custom dome array layout is usually the best choice. Custom spacing and dome force allow the panel to match the operator’s workflow.

Different CNC tasks may also require different dome responses. Emergency stop or critical function keys often use higher force domes. This reduces the risk of accidental activation. Standard operation keys may use medium force domes for comfort.

Here are common dome array options used in CNC control panels:

- Single-layer metal dome array for compact panels

- Multi-layer dome array for complex key layouts

- Mixed-force dome arrays for safety and function balance

- Sealed dome arrays for harsh environments

Overlay design also affects the choice. Thick overlays may dampen tactile feel. In such cases, a stronger tactile dome switch is needed. Thin overlays allow lighter domes to perform well.

EBest Circuit (Best Technology) often works closely with CNC panel designers during early development. This approach helps match the dome array to the real use case. The result is a control panel that feels natural from the first press.

Why use a dome array for CNC machine control?

A dome array for CNC machine control offers clear advantages over many other input methods. One of the biggest benefits is tactile clarity. Operators can feel each press.

Durability is another strong reason. CNC machines run for long hours. Control panels see heavy use. A quality metal dome array withstands repeated presses without losing performance.

Dome arrays also support compact design. CNC panels often need to include screens, knobs, and indicators. A thin dome array leaves more room for other components.

Cost control is important in machine manufacturing. Compared with mechanical switches, dome switches are often more cost-efficient when used in arrays. They reduce assembly time and part count.

Another benefit is design flexibility. Dome arrays can be customized in shape, size, and force. This allows CNC builders to create unique panels without complex tooling.

From a user perspective, dome arrays support faster learning. Consistent tactile feedback helps new operators build muscle memory. Over time, this improves productivity and reduces errors.

How to install a dome array on CNC machines?

Installing a dome array on CNC machines requires care and precision. Proper installation ensures consistent feel and long service life. While the process is not complex, attention to detail is essential.

Before installation, the surface must be clean. Dust or oil can affect adhesion. The printed circuit board should be flat and free from defects. Alignment marks help ensure the dome array sits in the correct position.

Most dome arrays use pressure-sensitive adhesive. Once aligned, firm and even pressure is applied. This secures the array without deforming the domes. Avoid excessive force, as it may affect dome shape.

After placement, the overlay is applied. The overlay should align with the dome centers. Misalignment can cause uneven feel or poor contact. A test press on each key helps confirm proper installation.

Typical installation steps include:

- Clean the PCB and work area

- Align the metal dome array carefully

- Apply even pressure to secure adhesive

- Place and align the overlay

- Test all dome switches for response

In production settings, fixtures are often used to improve accuracy and speed. For prototypes or small batches, manual installation is common. Both methods can deliver good results when done correctly.

EBest Circuit (Best Technology) provides clear installation guidance with every dome array shipment. This helps CNC manufacturers reduce errors and speed up assembly.

How to maintain CNC machine control dome arrays?

Maintenance of CNC machine control dome arrays is usually simple. One of the advantages of dome switches is their low maintenance needs. Still, regular checks help extend service life and ensure consistent performance.

Routine inspection is a good starting point. Operators or technicians should check for changes in tactile feel. A dome that feels soft or uneven may be nearing the end of its life. Early detection prevents unexpected downtime.

Cleaning the control panel surface also matters. Dust and oil buildup can affect overlay performance. A clean surface helps maintain clear tactile response. Use gentle cleaning methods that do not damage the overlay or adhesive.

In harsh environments, sealing integrity should be checked. If moisture enters the panel, it can affect the circuit. Proper sealing during installation reduces this risk, but periodic checks add extra safety.

When replacement is needed, modular design helps. Many CNC panels allow dome array replacement without full disassembly. This saves time and cost.

EBest Circuit (Best Technology) designs dome arrays with long life in mind. Many CNC clients report years of stable performance with minimal intervention.

What makes a durable CNC dome array?

Durability in a CNC dome array comes from design, materials, and process control. Each factor plays a role in how the array performs over time. In CNC environments, durability is not optional. It is expected.

Material choice is the foundation. High-quality stainless steel domes resist fatigue. They maintain their snap even after repeated presses.

Dome geometry also matters. The height, diameter, and leg design affect both force and life. A well-balanced design spreads stress evenly. This reduces metal fatigue and extends cycle life.

Adhesive quality is another key factor. The adhesive holds the dome array in place. It must resist heat, humidity, and vibration.

Manufacturing precision ties everything together. Tight tolerances ensure each dome behaves the same. Process control reduces variation.

EBest Circuit (Best Technology) invests heavily in quality control. From raw material inspection to final testing, each step is monitored.

How to test a CNC machine control dome array?

Testing a CNC machine control dome array is essential before final assembly and shipment. Proper testing ensures that each dome performs as expected and meets design requirements.

Functional testing is the first step. Each dome switch is pressed to confirm electrical response. This verifies that the circuit closes and opens correctly.

Tactile testing follows. Operators or test fixtures check the feel of each dome. The snap should be clear and consistent.

Life cycle testing is also common, especially for critical CNC systems. Automated equipment presses the domes repeatedly. This simulates long-term use.

Environmental testing may be used for demanding applications. Heat, humidity, and vibration tests reveal how the dome array performs under stress. This is important for CNC machines used in harsh workshops.

Typical test methods include:

- Electrical continuity testing

- Tactile force measurement

- Repeated actuation testing

- Environmental stress testing

EBest Circuit (Best Technology) performs comprehensive testing on dome arrays for CNC applications. Test data is documented and shared when needed. This transparency helps CNC manufacturers trust the product.

In summary, a dome array for CNC machine control plays a vital role in accuracy, safety, and user comfort. The right design improves operator confidence and system reliability.

If you are exploring dome array solutions for CNC control panels, EBest Circuit (Best Technology) is ready to support your project. For technical discussions or quotations, contact us at sales@metal-domes.com