When evaluating Tape & Reel Metal Dome manufacturers in Austria, many customers find that local Austrian companies are more proficient in system integration, industrial electronics, and EMS, while there are few manufacturers truly familiar with the structure, orientation control, and high-speed placement requirements of Tape & Reel Metal Domes.

Are you facing the following problems?

- Unstable Tape & Reel alignment: Domes are misaligned during placement, leading to high pick-and-place failure rates.

- Samples are placeable, but mass production experiences feeding or placement errors: Initial samples pass verification, but high-speed placement results in feeding issues and unstable vacuum pickup.

- Placement parameters require repeated adjustments for different batches: Dome height or positioning accuracy fluctuates, increasing production line setup time.

- Local suppliers are unfamiliar with actual SMT working conditions: They only focus on “putting the domes into the Tape & Reel” but don’t understand the real needs of the placement machine.

- Slow delivery times affect the overall machine trial production schedule: Tape & Reel Metal Domes are critical auxiliary materials, and delays directly slow down the entire machine project.

End-to-End Process Guarantee from Requirements to Delivery

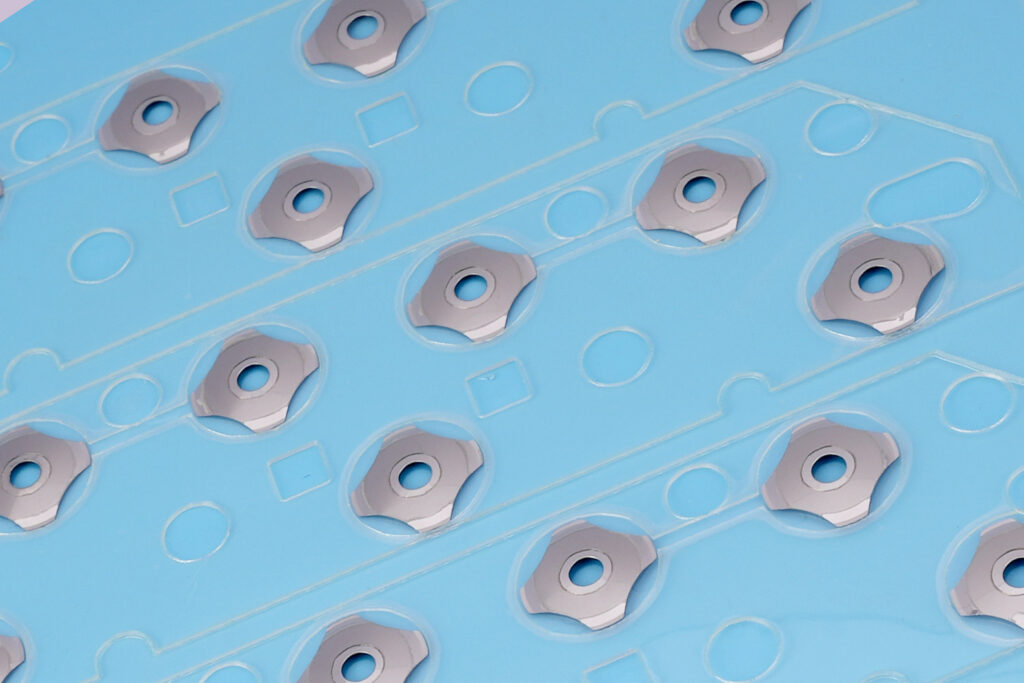

A truly reliable Tape & Reel Metal Dome is not simply “putting the domes into the carrier tape,” but rather designing and manufacturing the process from the perspective of the SMT application scenario.

We confirm the customer’s placement machine type, nozzle specifications, placement speed, and cycle time at the early stages of the project; during the design phase, we control the dome shape, height, and center of gravity to ensure stable pickup; during the Tape & Reel stage, we strictly control the pocket size and positioning accuracy; and before delivery, we verify feeding stability through placement simulation.

This manufacturing logic, focused on placement success rate, is the core reason why EBest Circuit (Best Technology) has been able to serve European industrial and electronic customers for a long time.

Why Choose Us? EBest Circuit (Best Technology)’s Core Advantages

- We truly understand the purpose of Tape & Reel; we design Tape & Reel Metal Domes from the perspective of SMT placement.

- High-precision array and positioning control: Array design accuracy can be controlled within ±0.05mm, significantly improving placement success rate.

- Compatible with high-speed placement equipment: Verified for use in high-speed SMT production lines with speeds of 20,000–100,000 pcs/hour.

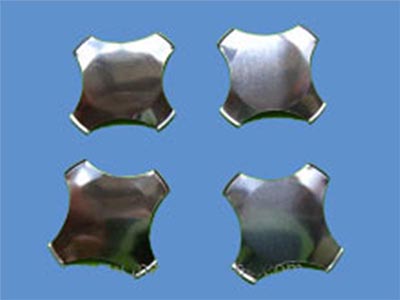

- Long lifespan and stable rebound force: Dome lifespan exceeds 1,000,000 cycles, suitable for industrial and automotive applications.

- The engineering team communicates directly, focusing on “how to ensure a secure attachment,” not “whether it’s possible to do it.”

Top 10 Tape & Reel Metal Dome manufacturers in Austria

| Company Name | Process Capability | Advantage |

|---|---|---|

| BEST Technology | Metal Dome / Tape & Reel / Array Design / SMT Adaptation | High mounting success rate, engineering-oriented |

| AT&S | PCB Manufacturing | Industrial electronics experience |

| Zollner Austria | EMS (Electronic Manufacturing Services) | System integration capability |

| EGSTON | Electronic Component Manufacturing | Industrial-grade products |

| Knill Gruppe | Electronics Manufacturing | Local service |

| Infineon (Supply Chain) | Semiconductor Ecosystem | Industrial standards |

| ENICS Austria | EMS | Automated production lines |

| Katek Austria | Electronic Systems | Project management |

| S&T Group | Industrial Electronics | System integration |

| Local EMS Supplier | Electronic Assembly | Local response |

How to Choose an Austria Tape & Reel Metal Dome Manufacturer?

When choosing a Tape & Reel Metal Dome manufacturer in Austria, the real selection logic isn’t “who can do Tape & Reel,” but rather who can provide a stable supply under high-speed SMT conditions. The evaluation criteria should focus on the following key points:

- Does the manufacturer design the Metal Dome structure based on the pick-and-place machine’s operating conditions?

Many suppliers only focus on the size of the dome itself, neglecting the contact area of ??the suction nozzle and vacuum stability. EBest Circuit (Best Technology), from the design stage, adjusts the dome’s top curvature and force center based on the SMT suction nozzle diameter, negative pressure range, and placement speed, ensuring stable and repeatable pick-and-place operations.

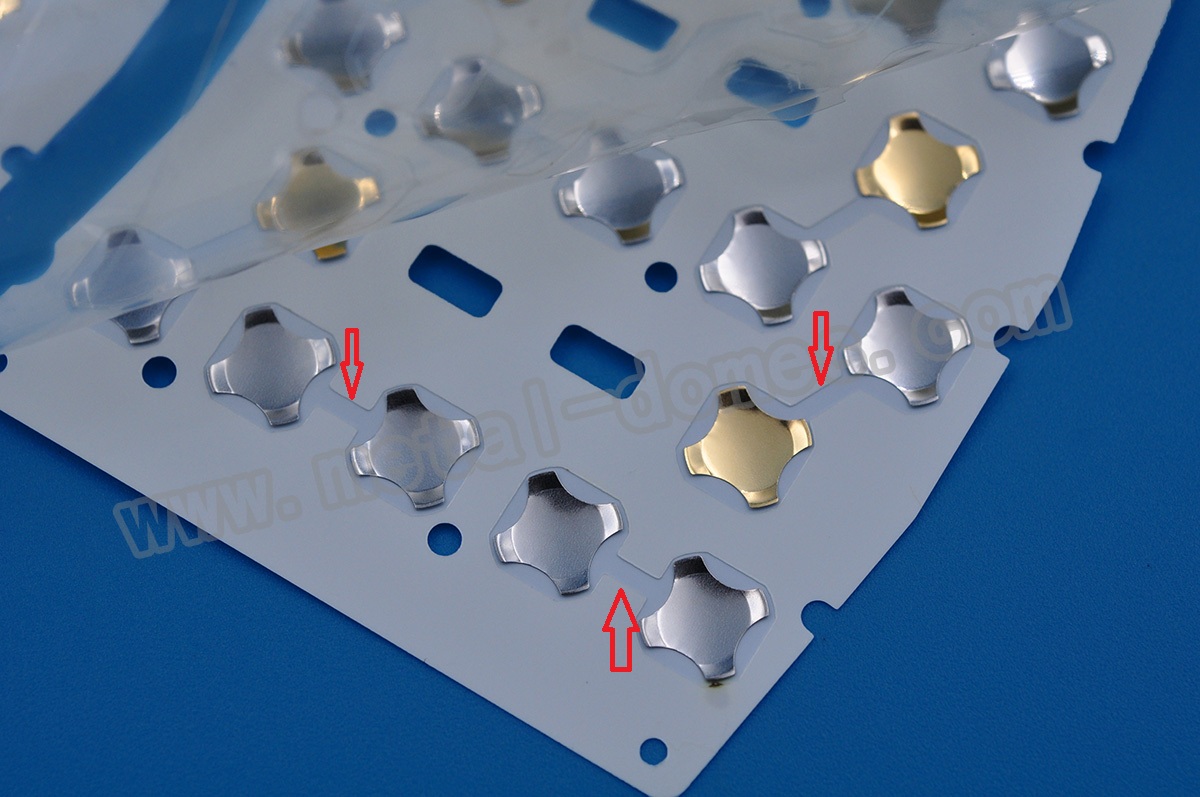

- Does the manufacturer control directional consistency in the Tape & Reel?

Even small deviations in the dome’s orientation within the carrier tape can be amplified into failures during high-speed placement. EBest Circuit (Best Technology) uses array design and carrier tape pocket structure to achieve physical directional constraints, rather than relying on manual or visual correction.

- Does the manufacturer verify high-speed placement during the sample stage?

Many problems only become apparent at actual placement speeds. EBest Circuit (Best Technology)’s Tape & Reel samples are verified using the same feeding method as mass production, ensuring that what is approved is not just a “demonstration sample,” but a version ready for mass production.

- Does the manufacturer understand the customer’s entire SMT production line, not just deliver a single component?

EBest Circuit (Best Technology)’s engineering support focuses on placement cycle time, line downtime risks, and adjustment frequency, aiming to reduce the number of interventions on the client’s production line.

Core Pain Points of Austria Tape & Reel Metal Dome Manufacturers

Based on actual SMT project experience, Austrian customers encounter highly concentrated and repetitive problems with Tape & Reel Metal Domes:

- Dropping or flipping during high-speed placement

The fundamental reason is the unreasonable design of the dome’s center of gravity and adsorption surface. EBest Circuit (Best Technology) controls the dome’s molding height and material elasticity distribution, ensuring that the force on the suction nozzle always falls within a stable range, reducing the probability of flipping.

- Different batches require recalibration of machine parameters

This often stems from inconsistencies in dome height and rebound force distribution. EBest Circuit (Best Technology) locks in key parameter ranges during the molding and screening stages, avoiding the problem of “same specifications, different performance.”

- Tape & Reel works normally at low speeds but fails at high speeds

This is a typical case of “not designed for actual use scenarios.” EBest Circuit (Best Technology) uses high-speed placement as the default target, not an additional test item.

- The supplier cannot explain the cause of failure

Because they do not understand SMT behavior. EBest Circuit (Best Technology)’s engineering feedback directly corresponds to the pick-and-place actions (picking, moving, and releasing), rather than focusing solely on the product’s appearance.

How to analyze the production capacity of an Austrian Tape & Reel Metal Dome manufacturer?

The production capacity of Tape & Reel Metal Domes is not equivalent to “how many types of metal domes can be made,” but rather whether they can consistently and reliably produce “domes that can be reliably placed”:

- Can they stably control the dome forming height distribution?

- Do they understand the impact of height deviation on pick-and-place success rate?

- Do they possess array design and consistency management capabilities?

- Do they have engineering control over Tape & Reel carrier tape dimensions and tolerances?

- Do they continuously monitor key parameters during mass production?

EBest Circuit (Best Technology)’s production system does not rely on one-time experience, but rather forms a reproducible and stable output capability through fixed molds, material sources, and process windows. This ensures consistent performance of Tape & Reel Metal Domes during continuous mass production.

How to evaluate the delivery time of an Austrian Tape & Reel Metal Dome manufacturer?

Whether the delivery time is reliable depends on whether the supplier has specifically designed a fast delivery process for Tape & Reel Metal Domes:

- Do they have stock of commonly used dome and carrier tape specifications?

- Is the Tape & Reel process separated?

- Do they use the same process for prototyping and mass production?

- Do they reduce manual intervention steps?

- Are they familiar with the trial production rhythm of European customers?

EBest Circuit (Best Technology) can achieve 2-3 day sample delivery for Tape & Reel Metal Domes, not by compressing testing, but by standardizing frequently used specifications and establishing a dedicated Tape & Reel process path, allowing samples and mass production to operate under the same logic, avoiding repeated preparation and rework.

When choosing among the top 10 Tape & Reel Metal Dome manufacturers in Austria, the real difference lies not in the packaging format, but in understanding the logic of high-speed surface mount technology (SMT); only those Austrian top 10 Tape & Reel Metal Dome manufacturers who can produce Tape & Reel Metal Domes as “stable SMT components” are worthy of long-term cooperation.