How to select a metal dome manufacturer in Australia? This blog is mainly about a detailed selection guide for Australian metal dome manufacturer.

Top Metal Dome Manufacturers in Australia

- Local HMI Component Providers

- Advantages: Convenient communication; Fast sampling for simple dome sheets; Familiarity with local medical and industrial compliance.

- Production Capability: Small to medium-scale dome sheets, dome arrays, and assemblies.

- Lead Time: Typical prototype cycles range from 1–2 weeks. Small production orders require 2–4 weeks.

- Main Business: Membrane switches, dome arrays, tactile overlays, industrial control panels.

- EMS Companies with Dome Integration

- Advantages: One-stop panel assembly; Better alignment between PCB and dome array positions;

- Production Capability: Dome sheet production is limited, but assembly and testing are strong.

- Lead Time: Varies between 2–5 weeks depending on the assembly load.

- Main Business: PCBA, interface modules, control panels, industrial and automotive electronics.

- Specialized Importers and Distributors

- Advantages: Stable access to diverse dome sizes and forces; Quick response without long communication loops.

- Production Capability: No local manufacturing, but consistent inventory for standard domes.

- Lead Time: 1–3 days for stocked items, 2–3 weeks if sourcing from overseas.

- Main Business: Standard metal domes, tactile switch domes, repair parts for mobile and consumer devices.

How to Select A Metal Dome Manufacturer in Australia?

Below Is A Detailed Selection Guide to Australian Metal Dome Manufacturer:

Step 1: Clarify Your Specific Requirements

Before contacting any supplier, clearly defining your needs is the foundation for efficient screening.

- Product Type: Confirm whether you require micro-metal dome switches for electronic products like keyboards and remote controls or large metal dome structures for construction or industrial applications. The manufacturer groups for these two categories are entirely different.

- Technical Specifications: Define key parameters including size, shape (circular, cruciform), force, stroke, expected lifespan (e.g., >1 million cycles) and required surface treatments (e.g., nickel plating for corrosion resistance).

- Compliance Requirements: Identify mandatory standards such as RoHS/REACH environmental directives, ISO 9001 quality systems, and any relevant Australian local standards (e.g., AS/NZS).

- Procurement Model: Determine whether it is OEM (manufacturing based on your design) or ODM (requiring manufacturer involvement in design), and specify initial order quantities and long-term expectations.

Step 2: Search and Initial Screening of Potential Suppliers

Australia has limited professional manufacturers of micro-metal domes, requiring flexible strategies.

- Identify Local Integrators: Seek Australian manufacturers or assemblers that incorporate metal domes as part of their final products (e.g., membrane switches, control panels). They handle procurement and integration, serving as key local resources.

- Evaluate Global Specialized Manufacturers: Leading global micro-metal dome manufacturers are primarily located in Asia. Many Australian companies secure their supply chains by partnering with these internationally certified overseas factories. Directly assess these specialized factories as potential suppliers.

- Conduct Initial Verification: Quickly assess professional compatibility by reviewing company websites, industry directories (e.g., ThomasNet) or B2B platforms to understand their history, core business, and typical client cases.

Step 3: In-Depth Evaluation of Technical and Management Capabilities

After initial screening, conduct a thorough technical and quality management audit of shortlisted suppliers.

Quality and Compliance Certifications:

- Prioritize manufacturers holding valid ISO 9001 certification as the foundation of quality management.

- For specific industries (e.g., automotive, medical), verify specialized certifications such as IATF 16949 or ISO 13485.

- Confirm their understanding and compliance with Australian/New Zealand standards (AS/NZS), e.g., welding processes meeting AS/NZS 1554.1.

Engineering and R&D Support:

- Assess whether their engineering team can provide design optimization support, e.g., improving dome array layouts to enhance tactile feel and reliability.

- Inquire about their prototype development capabilities and speed, critical for design validation.

Production and Quality Control Strength:

- Understand their production equipment, such as precision stamping, laser cutting, and automated optical inspection (AOI) systems.

- Request to review product test reports, including lifespan testing, force curve analysis, and environmental testing (thermal shock, salt spray).

Supply Chain and Sustainability:

- Inquire about the sources of key raw materials (e.g., stainless steel), preferring reputable, traceable suppliers.

- Confirm compliance with RoHS and REACH regulations, and ask about their environmental (e.g., ISO 14001) and social responsibility policies.

Step 4: Assess Commercial Terms and Communication

Reliable technical capabilities must be paired with smooth commercial cooperation.

- Obtain Detailed Quotations: Request itemized quotes clearly listing mold costs, unit prices, minimum order quantities (MOQ), payment terms, and lead times.

- Sample Testing Process: Understand their sample provision policies. Strict internal testing of samples is the most direct way to verify claimed performance.

- Evaluate Communication Efficiency: Assess the responsiveness, professional English communication skills, and adaptability to European/American time zones of their sales and technical support teams. Clear communication significantly reduces project risks.

- Reference Client Cases: Request client references or evaluations from similar industries or scales in Europe and America (subject to confidentiality agreements).

Step 5: Execute Collaboration and Build Long-Term Relationships

After selecting a supplier, initiate cooperation through standardized processes and lay the foundation for long-term relationships.

- Sign Clear Contracts: Ensure contracts detail technical specifications, acceptance criteria, delivery schedules, intellectual property ownership, confidentiality clauses, and quality dispute resolution mechanisms. Clear contracts are key to avoiding future disputes.

- Implement Stage Audits: For critical projects or new suppliers, arrange initial production inspections. Personally or commission third parties to audit during early mass production to ensure process consistency with samples.

- Establish Quality Monitoring Systems: Agree with suppliers on clear incoming inspection (IQC) and outgoing inspection (OQC) standards and procedures. Regularly review their quality control data.

- Plan Continuous Improvement: Treat suppliers as partners, conduct regular business reviews, and discuss opportunities for cost optimization, technological upgrades, and continuous improvement to jointly address future challenges and evolving needs.

Types of Metal Domes Available from Australian Metal Dome Manufacturer

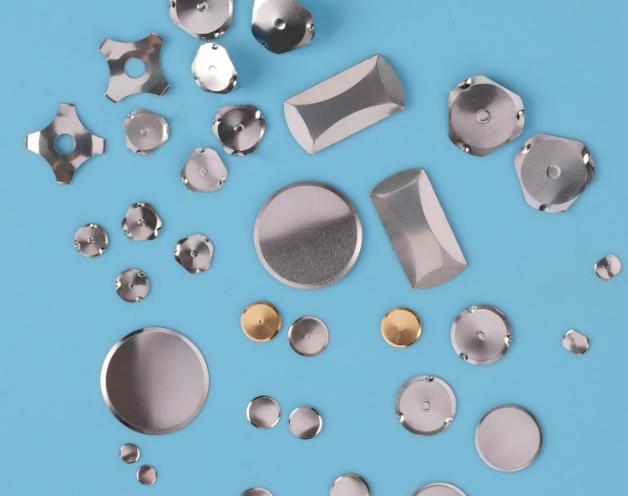

Circular Metal Domes

- Diameter range: 3mm–30mm.

- Trigger force: 50gf–5600gf.

- Made from Stainless Steel 301/304 or Beryllium Copper.

- Widely used in membrane switches, PCB contact points, and automotive electronic buttons, such as mobile phone HOME keys and remote control buttons.

Cross-shaped/Four-corner Domes

- Special design with diameter up to 20mm.

- Trigger force: 100gf–400gf.

- Suitable for dust-proof and anti-static requirements.

- Commonly applied in control panels of industrial automation equipment.

Triangular/Oval Metal Domes

- Designed for non-standard key layouts, such as emergency buttons in medical devices and touch areas in vehicle navigation systems. Provides precise tactile feedback.

Rectangular Metal Domes

- Customizable dimensions, commonly used in smart device sliding switches, mechanical keyboard axes, and supports IP67 waterproof rating.

Redditt’s Pain Points with Australian Metal Dome Suppliers

- Unstable Quality & Hidden Defects: “Dead key” issues affect 3 – 5% of batches (vs. global acceptable rate of 1%), pressing force deviations reach ±50 gf (exceeding the standard ±20 – 30 gf range), and products lack environmental resistance—service life shortens 30 – 50% in high temperatures, with high cracking risk below – 40?.

- Unreliable Lead Times & Fragile Supply Chains: Standard orders take 2 – 4 weeks (global average 7 – 10 business days), 60% of users face delays, and custom orders extend to 6+ weeks. Australia’s 95.83% small – scale electronics businesses are vulnerable to stockouts.

- Weak Customization Capabilities: Local suppliers only offer 5 – 8 standard sizes, with high MOQs (200+ square meters) vs. international 100 – unit minimums. Complex customization programming takes 7x longer than standard products.

- Prohibitive Costs: Pricing is 30 – 40% higher than Asian imports; logistics account for 25 – 35% of total costs, severely squeezing margins for small manufacturers (average business age 3.5 years).

- Inadequate After – Sales & Technical Support: 70% of technical queries get responses after 3 business days (no 24/7 support), refund processing takes up to 6 weeks, and only 15% provide preventive guidance (e.g., dustproof assembly).

Our Solutions to these Pain Points of Metal Dome

Regarding the Above Pain Points of Australian Metal Dome Manufacturer, the Following Solutions Provided By Best Technology for Your Reference:

Precision Quality Control to Eliminate Hidden Defects

- Adopt medical-grade 301 stainless steel for raw materials, ensuring excellent high-temperature resistance and corrosion resistance.

- Implement a 3-stage strict quality inspection process: raw material performance testing ? in-production pressing force real-time calibration ? finished product environmental aging tests.

- Guarantee core quality indicators: “dead key” defect rate below 0.5% (surpassing the global 1% standard), pressing force tolerance strictly within ±20 gf.

- Ensure wide temperature adaptability: products maintain stable performance in -50? to 120? environments, extending service life by 40% compared to local Australian suppliers.

- Provide a formal quality assurance certificate for each batch to help customers avoid product failure risks in subsequent production.

Optimized Supply Chain for Reliable Lead Times

- Build a dual-warehouse layout: local Australian warehouse + regional Asian hub, stocking over 100 standard metal dome models.

- Clarify stable delivery timelines: standard orders delivered within 7 – 10 business days (consistent with global benchmarks); custom orders with a maximum lead time of 3 weeks (50% shorter than local suppliers).

- Launch a “stock guarantee plan” for small-scale electronics businesses (accounting for 95.83% of the market): reserve 5% of their monthly demand to prevent stockouts during peak production seasons.

Flexible Customization Capabilities for Niche Needs

- Expand standard product portfolio to more than 20 sizes, covering most mainstream application scenarios.

- Lower custom order threshold: minimum order quantity (MOQ) for custom metal domes reduced to 100 units (matching international standards, far below local 200-square-meter requirements).

- Upgrade production technology: deploy advanced 5-axis CNC machines, reducing programming time for complex curved products by 80% (from 7x to 1.4x standard time).

- Provide one-stop customization services: cover special coatings, non-standard shapes, and tactile feedback adjustment to meet demands of hobbyists, startups, and niche manufacturers.

Cost-Efficient Pricing Strategy to Boost Profit Margins

- Reduce overall costs through large-scale raw material procurement and optimized international logistics routes.

- Offer competitive pricing: products priced 15 – 20% lower than local Australian suppliers, and 5 – 10% more cost-effective than Asian imports (after including shipping and import fees).

- Launch long-term cooperative discount plans: provide up to 10% off for customers with annual orders exceeding the set threshold.

- Implement transparent cost management: provide detailed cost breakdowns to help small manufacturers (average business age 3.5 years) effectively control procurement budgets.

Comprehensive After-Sales & Technical Support

- Establish a 24/7 multilingual technical team (English-speaking included), ensuring responses to all queries within 12 hours (covering installation guidance, failure analysis, and usage tips).

- Provide targeted value-added services: free dustproof assembly guides and pressing force optimization consultations to reduce customers’ post-purchase operational costs.

- Offer on-site technical training for bulk order customers, helping their production teams master efficient assembly and maintenance skills.

Metal Dome Customize Service We Can Offer You

Below Are Custom Options of Metal Domes We Can Offer You:

- Non-Standard Shapes: Can produce snap domes in specialized shapes like cruciform, polygonal, or other custom geometries based on client drawings.

- Special Structures & Processes: Supports adding features such as dimples, center holes, or tailored leg shapes to optimize tactile feedback and travel performance.

- Specific Performance Requirements: Allows adjustment of actuation force curves, travel distance, and snap-back speed to align with precise functional needs.

- Surface Treatments & Packaging: Offers multiple electroplating options and flexible delivery formats including reel packaging, tube packaging, or loose packaging to accommodate automated assembly or manual installation workflows.

Why Australian Clients Choose Best Technology as Metal Dome Manufacturer?

Reasons Why Australian Clients Choose Best Technology as Metal Dome Manufacturer:

- Free Sample Support: We provide free sample services for Australian clients, enabling pre-verification of snap dome performance and compatibility. This reduces procurement risks by ensuring products meet requirements before bulk orders are placed.

- Small-Batch Customization Specialist: As a snap dome manufacturer, we focus on flexible small-batch customization services, supporting orders from single units to hundreds of pieces. This meets R&D, testing, and small-scale production needs while avoiding inventory buildup.

- Full-Range Snap Dome Supply: We offer a comprehensive series of snap domes including metal, silicone, and composite materials, covering varied thickness, curvature, tactile feel, and durability requirements. These suit diverse scenarios such as electronic devices, industrial keypads, and precision instruments.

- Complimentary Technical Support System: Our dedicated engineer team provides free technical consultations, covering snap dome design optimization, material selection, and production feasibility analysis. This supports clients in resolving technical challenges and accelerating R&D cycles.

- Stringent Quality Control: Adopting ISO-certified production processes, we implement full-chain quality monitoring from raw material inspection to final product testing. This ensures consistency, fatigue resistance, and environmental adaptability (e.g., high-temperature resistance, corrosion resistance) in line with international standards.

- Rapid Response Delivery: Through efficient production scheduling and logistics coordination, Australian clients benefit from reliable delivery timeframes. Urgent orders receive priority handling to ensure supply chain timeliness and project acceleration.

- Cost Optimization Solutions: By analyzing material substitutes, refining processes, and leveraging bulk procurement advantages, we deliver cost-effective snap dome solutions that maximize value while maintaining quality.

- Long-Term Partnership Assurance: We establish dedicated client service archives to track product usage feedback continuously. Lifetime technical support and periodic maintenance recommendations foster stable, long-term partnerships, driving sustained business growth for clients.

Welcome to contact us to get a free metal dome sample: sales@metal-domes.com.