S8.4F-350-N metal domes are tactile components widely used in membrane keypads and electronic control panels to provide a precise and reliable clicking response. The part number itself reveals key specifications: “S8.4” indicates an 8.4 mm diameter, “F” stands for the four-leg dome shape, “350” represents a 350-gram actuation force, and “N” means no dimple on the surface.

What Are S8.4F-350-N Metal Domes?

S8.4F-350-N metal domes are high-performance tactile domes designed for surface-mount and membrane switch applications. They are made from stainless steel or copper alloys, providing durability and consistent feedback. Their compact size, measured at 8.4 mm in diameter, allows them to fit in tight spaces while maintaining excellent mechanical performance.

These domes are often used in keypads, control panels, medical devices, and automotive electronics where reliable tactile response is critical. Unlike ordinary switches, S8.4F-350-N domes do not require extensive mechanical assemblies, which reduces cost and simplifies the design.

What sets these domes apart is their precise actuation force and consistent travel. This ensures every press produces the same tactile sensation.

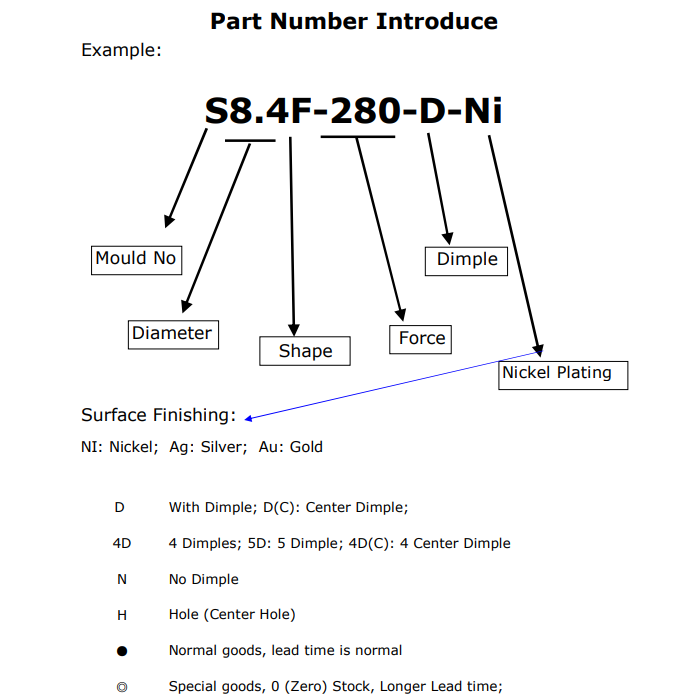

What Does S8.4F-350-N Mean?

Understanding part number S8.4F-350-N is crucial. It contains key information about the metal dome’s dimensions, structure, and performance.

- S: Refers to the mold number used in production. This ensures consistent shape, precision, and quality across all domes produced in this series.

- 8.4: Indicates the dome diameter, 8.4 mm. This dimension is crucial for ensuring compatibility with your switch design.

- F: Indicates the dome type. Typically, “F” represents a four-leg design, which provides stability and even force distribution.

- 350: Denotes the actuation force in grams. In this case, 350 grams of force is needed to fully depress the dome, giving a firm and reliable tactile response.

- N: No dimple. The dome surface is smooth without a center dimple, offering uniform contact and a cleaner “click” experience.

By decoding this number, a suitable metal dome can be quickly located. Matching drive force, size, and plating ensure mechanical reliability.

What Does the Metal Dome’s Diameter Affect?

The diameter of a metal dome significantly impacts both tactile feel and performance. A larger diameter dome, like the S8.4F-350-N, provides a more stable “click” and distributes force evenly across the dome’s surface.

Conversely, smaller domes may require less space but can feel less substantial when pressed. They may also be more susceptible to uneven actuation forces, which can lead to inconsistent tactile feedback.

Additionally, the diameter affects the dome’s lifespan. A properly sized dome for the application reduces mechanical stress and wear, extending the product’s operational life. This makes the S8.4F-350-N ideal for devices that see repeated use or require high reliability over thousands of actuation cycles.

Transitioning from diameter to design, it’s also worth noting that the dome’s legs or anchoring method interacts with diameter.

What Are the Characteristics of Four-Leg Metal Domes?

Four-leg metal domes, indicated by “F” in S8.4F-350-N, are engineered for stability and even actuation. The four legs anchor the dome to the PCB or membrane layer, preventing side-to-side movement. This structure ensures uniform force distribution across the dome when pressed.

Advantages include:

- Consistent tactile response: Each press feels identical.

- Enhanced durability: Four legs reduce stress on the dome material.

- Reduced misalignment risk: The dome stays in place during assembly and operation, improving reliability.

These benefits make four-leg designs preferable for critical applications, including medical devices, automotive controls, and industrial switches.

What Are the Differences Between Metal Domes with Different Actuation Forces?

Actuation force defines how much pressure is needed to compress the dome fully and register a signal. Metal domes like S8.4F-350-N, which require 350 grams of force, provide a firm tactile response suitable for devices where accidental presses must be minimized.

Lower force domes, such as 180–250 grams, are easier to press but may feel “soft” or less precise. These are ideal for light-touch keypads, handheld devices, or applications where user fatigue is a concern.

Higher force domes, around 400 grams or more, ensure strong feedback and prevent unintended actuation. They are often used in industrial controls or environments where accidental presses could cause errors or safety issues.

Selecting the correct actuation force is essential. Too soft, and the dome feels flimsy; too hard, and user comfort suffers.

What Are the Advantages of No-Dimmed Metal Domes?

The “N” in S8.4F-350-N indicates a no-dimple design, meaning the dome surface is smooth. This simple feature carries several benefits:

- Uniform tactile feedback: Without a center dimple, pressure is evenly distributed across the surface, producing a consistent press every time.

- Cleaner electrical contact: Smooth surfaces reduce the risk of uneven circuit contact, which enhances switch reliability.

- Reduced wear: Dimples can concentrate stress in the center of the dome. A flat, no-dimple design spreads stress across the entire surface, prolonging dome life.

- Modern aesthetic: Devices with no-dimple domes often have a sleeker, cleaner appearance.

No-dimple domes are particularly advantageous in high-precision applications like medical devices, industrial keypads, and automotive controls, where both tactile feel and reliability are paramount.

What is S8.4F-280-D-Ni?

S8.4F-280-D-Ni is another variant in the S-series of metal domes. It differs from S8.4F-350-N primarily in actuation force and plating:

- 280 g actuation force: Slightly lighter than the 350 g dome, providing a softer tactile response suitable for devices that require frequent pressing.

- Dimpled design (D): Includes a small center dimple, creating a more pronounced “snap” effect for certain tactile feedback preferences.

- Nickel plating (Ni): Enhances durability and ensures reliable electrical performance, even under high cycles or harsh environments.

What Are the Advantages of Nickel-Plated Metal Domes?

Nickel plating is a standard enhancement for high-quality metal domes. Its benefits include:

- Enhanced durability: Nickel prevents corrosion and protects the dome from mechanical wear over thousands of cycles.

- Improved conductivity: Nickel ensures stable electrical contact, reducing resistance and ensuring signal integrity.

- Better soldering performance: Domes with nickel plating are easier to solder, supporting automated assembly processes.

- Resistance to harsh environments: Nickel-plated domes are suitable for devices exposed to moisture, oils, or other contaminants.

For S8.4F-350-N and S8.4F-280-D-Ni, nickel plating ensures long-lasting performance without compromising tactile feel. This makes these domes a favorite for automotive electronics, medical devices, and industrial keypads.

Conclusion:

Selecting the right metal dome ensures a superior user experience, reduces mechanical failures, and improves overall device quality. Whether designing industrial keypads, consumer electronics, or automotive controls.

For more information or to source high-quality metal domes for your projects, contact sales@metal-domes.com