Metal dome SMT assembly is an automated process that mounts metal domes directly onto a PCB using high-speed SMT equipment. Instead of manually placing each dome, the domes are packed in tape-and-reel format and picked by SMT machines like standard electronic components. This method ensures precise alignment, consistent actuation force, and much faster production speed — ideal for high-volume device manufacturing.

How to Install Metal Domes on Printed Circuit Board?

The process of mounting metal domes on printed circuit boards involves careful surface preparation, alignment, and precise placement to ensure consistent tactile response and conductivity.

Typically, metal domes are placed on top of gold-plated PCB pads. The domes can be installed manually for prototypes or by automated pick-and-place machines during SMT assembly.

In SMT metal dome assembly, BEST Technology often use preformed dome arrays on adhesive sheets. These sheets hold the domes in precise locations, making it easier for machines to mount them quickly. After placement, the adhesive keeps the domes secure until final sealing.

Cleanliness is vital before installation. Any dust or oil can interrupt electrical contact or weaken adhesion. Using clean-room conditions or ESD-safe workstations keeps the surface pristine.

Once installed, the domes are typically covered by a poly dome sheet or membrane layer,. This layer protects the domes from environmental stress and guarantees consistent tactile feel throughout the device’s lifetime.

How Does a Metal Dome Switch Work on a PCB?

A metal dome switch is an ingenious design that blends simplicity with performance. It works like a spring-loaded contact. When you press it, the dome collapses downward, creating a momentary electrical connection between two PCB traces.

Once the pressure is released, the dome returns to its original shape, breaking the circuit. The dome’s curvature, height, and material thickness control the tactile force. A slightly higher dome delivers a softer click, while a low-profile dome produces a crisp, sharp feel.

In SMT applications, precision is key. Even a fraction of misalignment can change the actuation force or delay contact timing. That’s why dome switches are often tested under multiple pressing cycles — sometimes over a million actuations — to verify durability.

Which Metal Dome Material Is Suitable for SMT Process?

Choosing the right metal dome material determines how well it survives the heat and stress of SMT production. Most domes are made from stainless steel, especially SUS301 or SUS304. These grades offer excellent spring characteristics, corrosion resistance, and heat tolerance.

For high-reliability devices like medical or aerospace controls, domes are sometimes plated with nickel or gold to enhance conductivity and protect against oxidation.

During reflow, the dome must maintain its shape and tactile force. Stainless steel’s elasticity allows it to withstand temporary temperature peaks around 260°C, which occur in typical SMT reflow ovens.

Meanwhile, the plating improves electrical consistency and contact stability over time.

The dome’s surface finish also plays a part. A mirror-polished surface improves smoothness, while micro-textured finishes reduce sticking between layers during handling.

In short, stainless steel with protective plating is the most reliable metal dome material for modern SMT applications. It resists deformation, retains its click feel, and ensures lasting electrical performance.

What Is a Metal Dome Sheet in SMT Production?

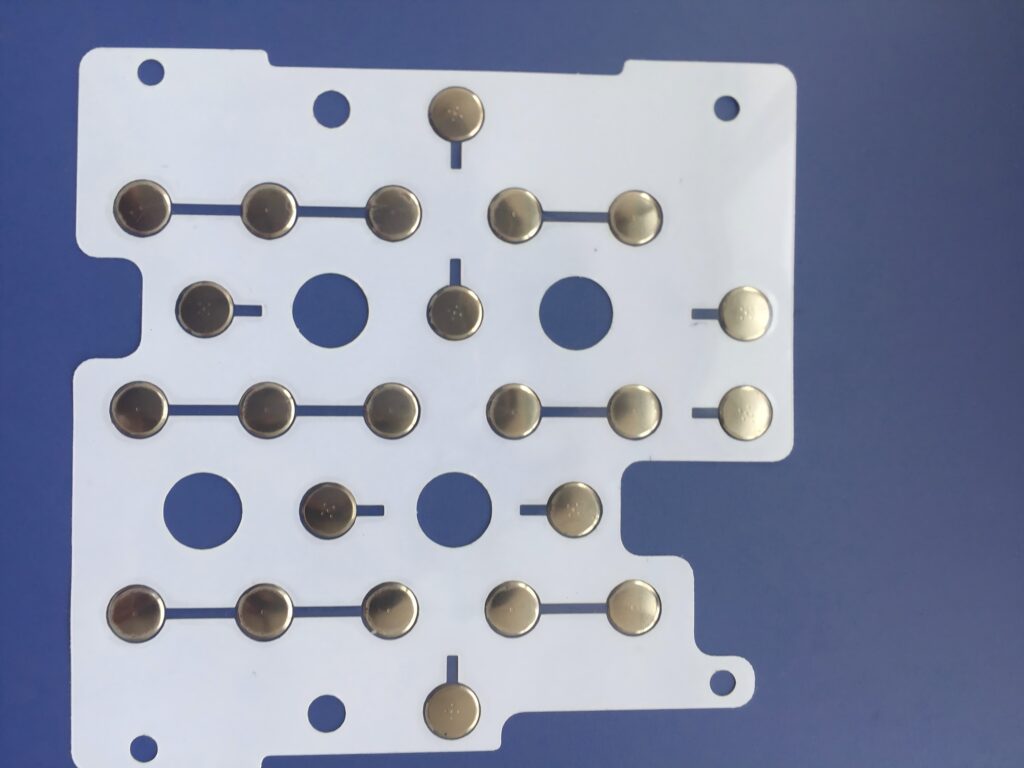

A metal dome sheet — also called a dome array or dome carrier — is an adhesive film preloaded with multiple domes positioned accurately according to the PCB layout.

This sheet simplifies mass production. Instead of picking up individual domes, a machine can place an entire array in one motion. The adhesive backing keeps each dome in the exact position until final assembly.

The top layer is usually made of PET or polyimide, while the bottom holds pressure-sensitive adhesive that bonds to the PCB. The metal domes sit between these two layers, ready to be pressed into function.

Using a dome sheet also reduces handling errors. Since domes are pre-aligned, the chances of misplacement drop dramatically. It speeds up SMT production and improves yield rates.

When paired with automated pick-and-place systems, dome sheets make metal dome SMT assembly faster, cleaner, and far more consistent than manual mounting.

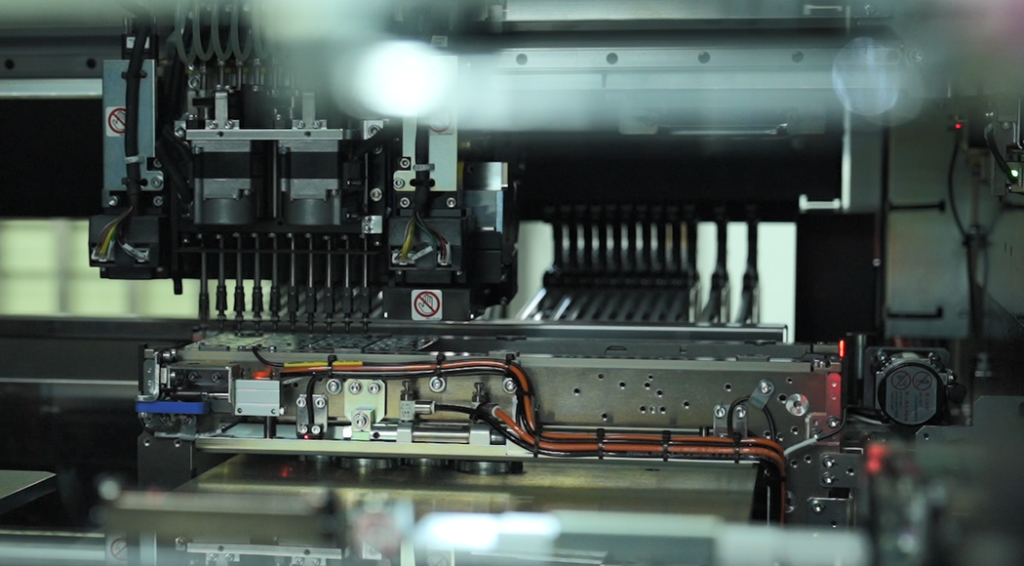

How Is a Metal Dome Array Used in Automated Pick-and-Place?

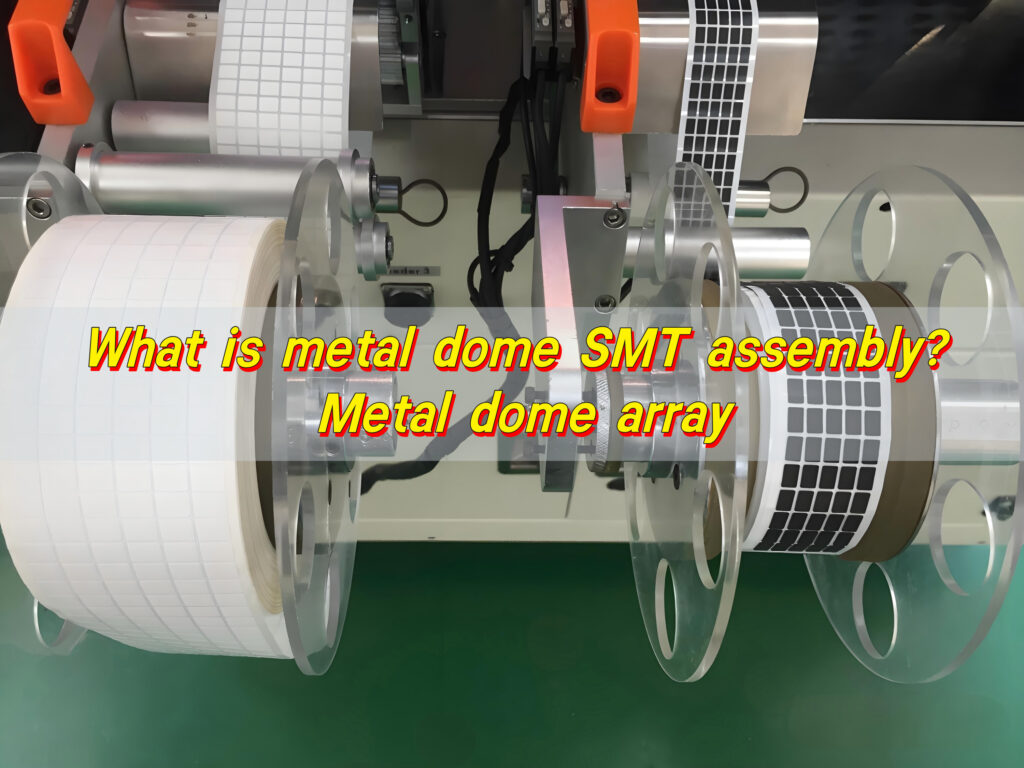

Automation revolutionized dome installation. These arrays are supplied in tape & reel packaging, compatible with standard SMT feeders. Each dome or dome sheet is precisely indexed so the pick-and-place head can grab it without human intervention.

During operation, the system identifies fiducial marks on the sheet for alignment. It then picks the dome and places it onto the PCB with controlled pressure and accuracy, usually within ±0.1mm.

Because the domes are delicate, the vacuum pressure must be calibrated carefully. Too much suction may deform the dome, while too little might cause drop-offs during transfer.

Automated metal dome array feeding not only saves time but also minimizes contamination risks, ensuring every dome lands perfectly centered on its contact pad.

Why Is Tape & Reel Packing Important for SMT Metal Domes?

Tape & reel packing is more than just a packaging method. For SMT metal domes, consistent feeding into pick-and-place machines is crucial. Tape & reel keeps each dome in a fixed position and orientation, protected from dust and mechanical stress.

This packaging method follows JEDEC standards and includes pockets precisely shaped to match the dome’s contour. The cover tape seals the pockets, preventing domes from bouncing or shifting during transport.

It also helps in automation — feeders can continuously draw domes from the reel, reducing downtime.

Another advantage is traceability. Each reel comes with a label containing lot numbers, material type, and dimensions, making it easy to track components in MES or ERP systems.

In short, tape & reel packaging ensures smooth production, consistent feeding, and complete traceability in modern metal dome SMT assembly lines.

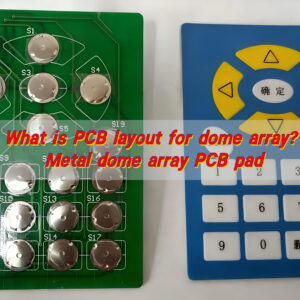

What PCB Pad Design Is Needed Before Assembly?

Before you can start assembly, the PCB pad design must be optimized for tactile domes.

A typical dome pad includes two concentric rings or a cross-shaped contact pattern. The dome bridges these contacts when pressed. The gold-plated surface improves conductivity and prevents oxidation.

Pad size directly affects click sensitivity. Too small, and you risk unstable contact. Too large, and the tactile feel becomes mushy.

A smooth solder mask opening around the contact pads helps the dome sit flat without wrinkles or bubbles. Also, remember to include vent holes under the pad area if the design has a sealed top layer. This allows trapped air to escape when the dome is pressed, maintaining consistent actuation.

Can Metal Domes Go Through Reflow Safely?

Yes. Metal domes can safely pass through reflow soldering if the material and process settings are properly controlled. Stainless steel domes, especially those with nickel or gold plating, can tolerate typical reflow profiles up to 260°C.

However, it’s important that domes aren’t under mechanical stress during heating. If they’re pre-mounted under adhesive sheets, the adhesive must be rated for reflow temperatures. Otherwise, deformation or bubbling could occur.

BEST Technology prefer post-reflow dome placement to avoid exposure to high heat entirely. In this case, the domes are mounted after all other SMT components are soldered.

So, while metal dome SMT assembly can go through reflow safely, success depends on the right combination of material quality, adhesive type, and temperature control.

How to Avoid Misalignment During SMT Mounting?

Misalignment is one of the most common challenges in metal dome SMT assembly, but it’s preventable.

- First, fiducial marks on both the PCB and the dome array sheet are critical. Automated systems use these marks for alignment correction before every placement.

- Second, controlling the vacuum pickup force helps prevent domes from twisting or flipping during transfer. Modern pick heads often use custom nozzles shaped to fit dome curvature, which improves grip and alignment accuracy.

- Third, environmental control plays a role. Excessive humidity can affect adhesive tackiness, causing domes to slide slightly after placement.

- Visual inspection after placement is also key. AOI (Automated Optical Inspection) systems can detect misalignment within 0.05mm and trigger rework alerts before final sealing.

In essence, alignment success depends on precision design, stable environmental conditions, and reliable automation calibration.

What SMT Metal Dome Assembly Mistakes to Avoid?

There are some common pitfalls that can be encountered when working with metal dome SMT assembly. Avoiding these pitfalls can help keep your production line running smoothly and cost-effectively.

- Incorrect pad size: Too small pads reduce contact area, while too large pads affect click response.

- Low-quality adhesive: Weak adhesives can lead to dome shifting or detachment after reflow.

- Skipping cleanliness: Dust or oil between dome and pad disrupts electrical contact.

- Overheating during reflow: Exceeding temperature limits can deform domes or damage plating.

- Ignoring alignment marks: Neglecting fiducials often causes long-term misalignment problems.

Regular inspection and process control can eliminate nearly all of these issues.

Conclusion:

Metal dome SMT assembly, from material selection to PCB pad design, every step is crucial to the touch. Choosing the right metal dome material, maintaining alignment accuracy, and applying the right adhesive and packaging methods are key to achieving consistency and longevity in your product.

If you’re searching for reliable metal dome SMT assembly solutions, high-quality dome sheets, or custom tactile arrays, reach out to us today. Contact us: sales@metal-domes.com