Metal dome for side keys are widely used in smartphones, smartwatches, walkie-talkies, and medical devices. These small buttons are pressed thousands of times during their service life. These tiny but powerful components provide precise tactile response and improve durability.

Why do side keys use metal domes?

Side keys are not just functional parts of a device. They are also part of the user’s experience. A button that feels unresponsive or soft can reduce confidence in the device.

Metal domes provide a distinct tactile click. Each press gives feedback you can feel and often hear. This sensation assures the user that the device received the input. In situations where accuracy matters—like medical equipment or two-way radios—this feedback is critical.

Another reason is durability. Metal domes withstand repeated use far better than many alternatives. While a rubber dome may wear down after tens of thousands of presses, a well-designed snap dome can last well over one million actuations. This makes them perfect for side keys, which often see heavy use.

Finally, metal domes help reduce assembly issues. They are easy to mount on a dome switch PCB, keeping alignment consistent. With tape-and-reel packaging, placement can even be automated in mass production, speeding up manufacturing while keeping quality high.

How are domes mounted on a PCB for side keys?

Mounting metal domes correctly is essential. A dome switch only works well when it is aligned properly on the PCB. The following methods are generally used:

- Direct Placement: The dome is placed on the PCB pads, then covered with a polyester or adhesive layer. This keeps the dome fixed while allowing it to flex.

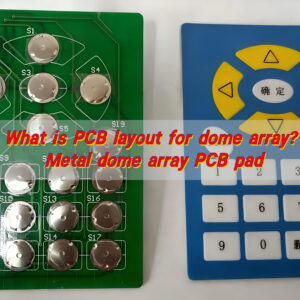

- Dome Arrays: Multiple domes are pre-positioned on a sheet, called a dome array. This sheet is aligned with the PCB, making placement faster and more precise.

- Tape & Reel Packaging: For high-volume production, domes are supplied on a reel. Automated pick-and-place machines can quickly mount them, ensuring speed and accuracy.

For side keys, space is often limited. That makes accuracy even more important. A slightly misplaced dome can cause inconsistent pressing force or even failure to register. This is why snap domes designed for side buttons are manufactured with tight tolerances, often within ±0.05mm.

When properly mounted, domes provide reliable contact every time the side key is pressed. They bridge the circuit instantly, ensuring smooth electrical performance with no delays.

How does a dome’s size and shape affect the feel of side keys?

Not all metal domes feel the same. The size and shape play a major role in how the key press feels to the user.

- Round Domes: Common and versatile, they give a balanced tactile response.

- Four-Leg Domes: These offer strong stability and excellent click consistency.

- Triangle Domes: Compact, ideal for smaller spaces without losing feedback.

- Cross Domes: Used in designs requiring very precise actuation.

Larger domes usually produce a softer but broader feel, while smaller domes feel sharper and more defined. The choice depends on the type of device. A smartwatch may need smaller domes for slim side buttons, while an industrial handheld may require larger domes for stronger feedback.

Height also matters. A taller dome often gives a stronger click, while a flatter dome feels softer.

Can metal domes be customized for different actuation forces?

Yes. Every device has different requirements, and the actuation force—the pressure needed to press the key—can be tailored.

Typical actuation forces range from 100g to 500g. For wearable electronics, a lighter touch may be ideal, around 120g. For rugged equipment, a stronger force, perhaps 350g or more, prevents accidental presses.

Customization does not end with force. Metal domes can also be designed to control travel distance, tactile ratio, and even sound level. Some applications require a quiet press, while others benefit from a loud click.

This flexibility is why metal dome switches are found in such a wide range of products. From consumer electronics to military devices, they can be adapted to meet specific needs.

What quality factors ensure a long-lasting metal dome for side key?

Durability is a key concern. Quality domes avoid this problem by focusing on several factors:

- Material: High-quality stainless steel ensures elasticity and prevents fatigue.

- Surface Treatment: Nickel or gold plating improves conductivity and resists corrosion.

- Precision: Tight dimensional tolerances guarantee consistent feel across every dome.

- Clean Manufacturing: Contaminant-free production prevents failure due to dirt or dust.

Another factor is testing. BEST Technology perform life-cycle testing, often simulating one million presses. Only domes that maintain their snap and conductivity after testing are shipped to customers.

With these quality checks, dome switch keyboards and side keys can perform reliably for years, even under demanding use.

How do metal domes improve durability in side key applications?

Durability is not just about lasting longer. It is also about maintaining the same tactile response over time. Rubber domes, for example, often lose elasticity. They start out crisp but grow mushy after heavy use.

Metal domes, on the other hand, retain their performance far longer. Thanks to their spring steel construction, they bounce back to shape even after countless presses. Their snap action remains consistent, ensuring that the side key always feels the same.

They are also resistant to heat and environmental stress. In outdoor devices, side keys may face extreme temperatures or humidity. Metal domes handle these conditions without significant loss in performance.

This makes them especially valuable in automotive, aerospace, and industrial applications where long-term reliability is critical.

What makes a tactile dome switch ideal for side button design?

Side buttons are different from main keypads. They are smaller, often narrower, and pressed at different angles.

The tactile feedback guides the user’s finger, even without looking at the device. This is useful for activities like adjusting volume on a phone or using a walkie-talkie in the dark.

In addition, tactile domes are versatile. They can be used under plastic side keys, rubber buttons, or even metal housings. This flexibility enables their integration into nearly any product design.

What are the advantages of using metal domes over rubber domes in side keys?

Rubber domes are still used in many devices. However, they have clear limitations compared to metal domes.

- Tactile Clarity: Metal domes give a sharper, more defined click. Rubber often feels dull.

- Durability: Metal domes last far longer, with millions of actuations.

- Consistency: Every press feels the same, even after heavy use.

- Compact Design: Metal domes fit slim side keys without sacrificing feel.

Environmental Resistance: Metal withstands temperature swings and moisture better.

If you are designing a product that requires reliable and satisfying side keys, Choosing the right metal dome manufacturer is crucial. BEST Technology can help you. For more details or to request samples, contact us at sales@metal-domes.com