What is a snap dome?

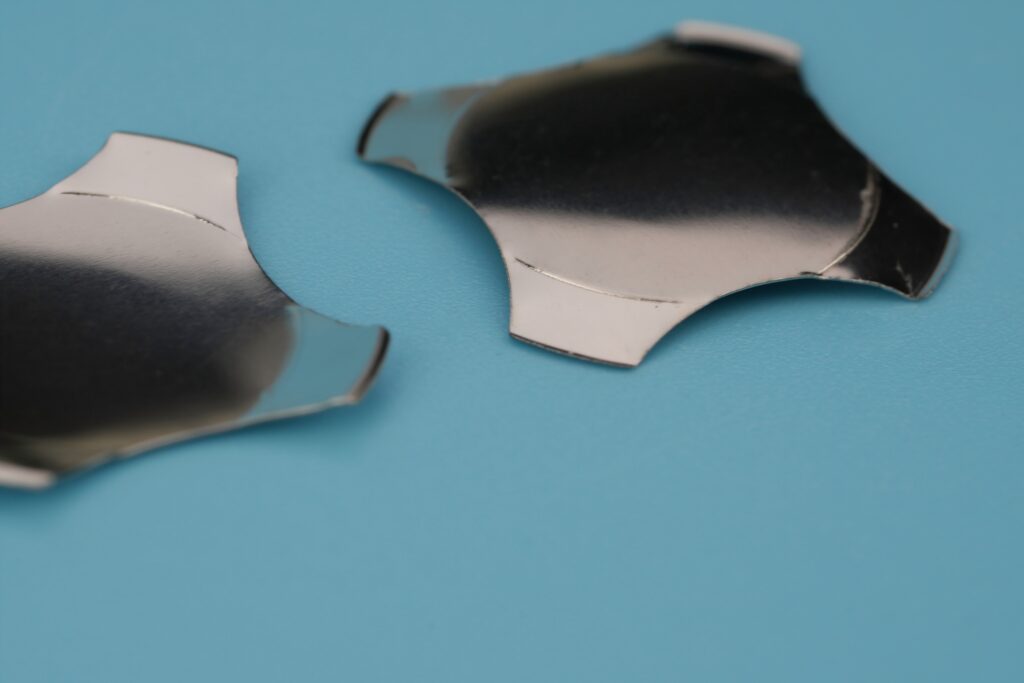

Snap dome is a tiny, responsive metal switch that “snaps” when pressed. It’s often placed on a PCB or within a membrane switch structure. When a user presses on it, the dome collapses, creating electrical contact. The dome then bounces back when pressure is released.

The tactile feedback it delivers is sharp and noticeable. That “snap” is more than just sound—it’s the feel that reassures users their command has been registered.

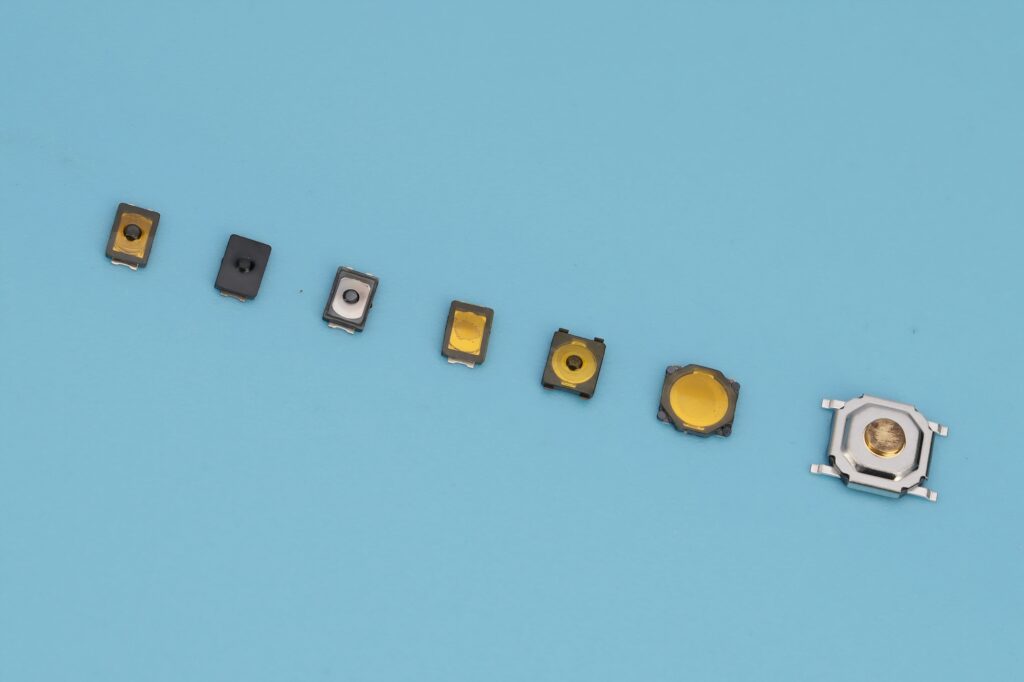

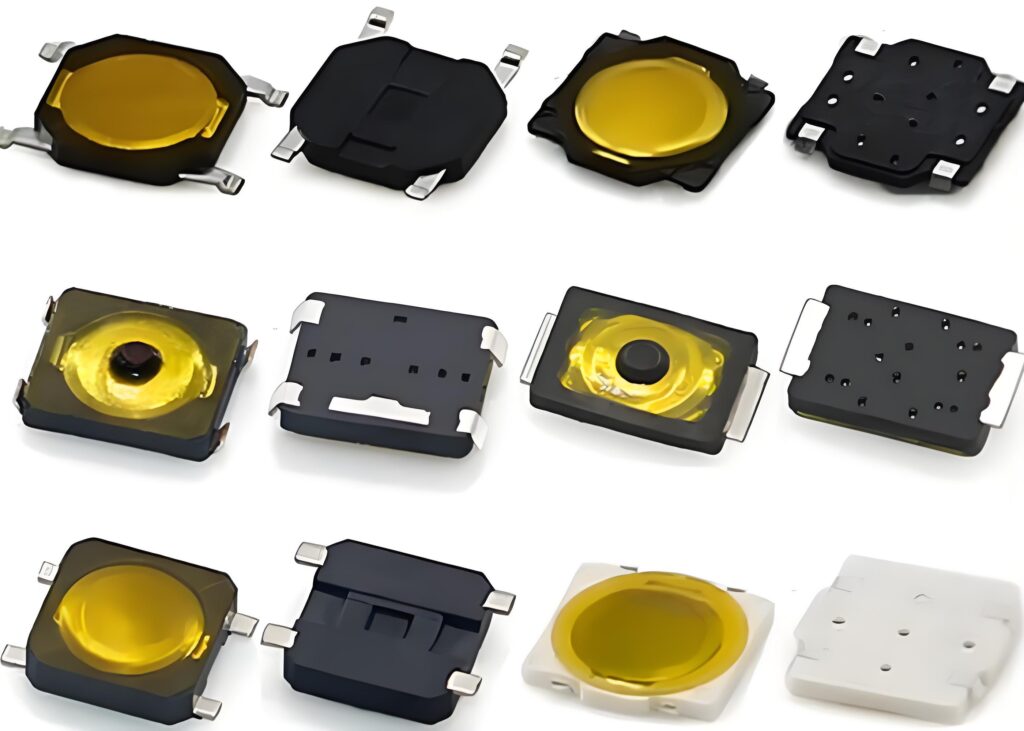

Snap domes come in many shapes: round, triangle, oblong, and four-leg. The shape affects how it responds under pressure and how it fits into your design.

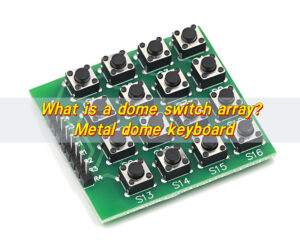

How do dome switches work?

When the user presses the top layer of the switch, they push the metal dome switch down onto a conductive trace on the PCB. This action closes the circuit, sending the signal. Once pressure is released, the dome springs back to its original form, reopening the circuit.

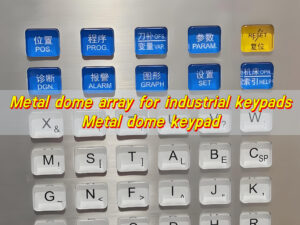

Users get a physical response they can feel and often hear. This is especially important in settings where visual feedback is limited—like dark environments or industrial machinery.

Some switches also integrate LEDs, resistors, or light guide films (LGFs) to increase functionality. But no matter the features, the core mechanism stays the same: pressure, contact, release.

How to pick the right metal dome switch?

Here’s what to consider:

- Force: How much pressure is needed to activate the dome? Lighter forces work well for consumer electronics, while heavier forces are better for industrial gear.

- Click ratio: This measures how tactile the dome feels. A higher click ratio delivers a stronger snap.

- Size: The diameter and height of the dome determine its tactile profile.

- Material: Stainless steel is the most common. It’s corrosion-resistant and long-lasting.

- Shape: Choose between four-leg, triangle, round, or oblong domes based on the product’s space and layout.

Don’t overlook mounting options either. Whether you’re using adhesive tape, dome array sheets, or SMT-compatible domes, the right assembly approach ensures performance and reliability.

What is the click ratio for metal dome?

The click ratio defines how “clicky” a dome feels. It’s the difference between the tactile drop and the total travel of the dome.

A typical dome has a click ratio between 40% and 60%. A higher ratio means the tactile feel is more noticeable. Lower ratios create a softer feel.

Let’s say your dome has 1.2mm total travel and 0.6mm of tactile drop. That gives a click ratio of 50%, which is quite balanced. Domes used in medical or military equipment often aim for higher ratios to ensure positive feedback, even with gloves.

Choosing the right ratio comes down to your user’s needs. For premium products, a crisp click often makes a product feel more high-end.

What is a snap dome in dome switch design?

The snap dome is the centerpiece of any dome switch design. It defines the switch’s tactile response, electrical contact, and lifecycle.

In a typical dome switch design, the dome sits between the graphic overlay and the circuit board. When pressure is applied from the top, the dome flexes and touches the lower circuit layer, closing the loop.

Here’s why it’s important in the design:

- It sets the tactile force.

- It dictates the switch’s actuation point.

- It affects electrical performance and lifespan.

A well-designed dome ensures consistent behavior over millions of cycles. Many high-quality domes last over 1 million presses.

Steps in a dome switch design guide

Designing a dome switch keyboard or interface isn’t complicated, but it does require a clear plan.

- Understand your application: Consider the environment—humidity, temperature, vibration, etc.

- Choose your dome: Pick the shape, force, and click ratio. Also decide if you want individual domes or a pre-loaded dome array.

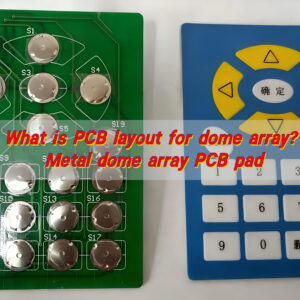

- Design your PCB layout: Include pads for electrical contact and allow space for dome placement.

- Decide on overlay materials: Your top layer affects tactile feel. Choose PET or polycarbonate for durability and light transmission.

- Add supporting layers: This could be LEDs, LGF films, spacers, and adhesive sheets.

- Test and validate: Ensure domes bounce back properly, and circuits don’t short out.

- Prepare for manufacturing: Once finalized, design for production.

Which materials suit contact dome designs best?

The most common choice is stainless steel, especially SUS301 or SUS304. These alloys offer excellent resilience, corrosion resistance, and form memory. That means they snap back reliably and last longer.

Other key materials include:

- PET sheets: Used for dome carriers or spacer layers. They’re flexible and easy to process.

- Conductive ink: Applied to the PCB or FPC for signal transmission.

- 3M adhesive: Bonds the switch layers without damaging tactile feel.

Choosing the right material blend increases switch performance and extends product life. A well-chosen stainless steel dome can easily survive over one million actuations—without losing its shape or click.

What are common dome switch design errors?

Here are some traps to avoid:

- Misaligned dome placement: If the dome isn’t centered, it won’t snap cleanly or make proper contact.

- Wrong actuation force: Too high, and the switch becomes uncomfortable. Too low, and it may trigger by accident.

- Incorrect spacing: Improper stack height can damage domes or block rebound.

- Overlooking environment: Dust, water, and chemicals can ruin contact unless properly sealed.

- Skipping prototypes: Testing early helps identify weak points in feel, durability, and usability.

A rushed design can kill the tactile feel or even cause complete failure in the field. Always prototype, test, and refine before you commit to full production.

Conclusion:

Snap dome switch isn’t just a component—it’s the heart of the user interface. It connects users to machines through touch, feel, and responsiveness. Whether you’re building a dome switch keyboard, medical panel, or industrial controller.

For expert help with your dome switch projects or to request samples, reach out to us at sales@metal-domes.com