Metal dome for the electronics industry often doubles as metal dome. It bends under pressure, connects a circuit, and snaps back to its original shape—providing fast, reliable feedback. Used in keypads, control panels, and dome switches, it’s essential for quick response and clear tactile feel.

Common materials include SUS 301 stainless steel, nickel-plated steel, and phosphor bronze. SUS 301 is preferred for its strength, elasticity, and long life. Though small, metal dome plays a big role in making electronic devices more responsive and dependable.

Which metal dome material offers the best durability?

In the electronics industry, durability means everything. The right metal dome material can determine whether the product’s service life lasts for months or years.

Among all materials available today, SUS 301 stainless steel remains the top choice. It offers outstanding resilience, with excellent fatigue strength and corrosion resistance. For devices requiring over 1 million clicks, SUS 301 proves reliable.

BEST Technology use nickel-plated stainless steel or copper alloys. While they’re cost-effective, they can’t match the long-term stability and tactile consistency of SUS 301. This material not only resists oxidation and deformation but also maintains its tactile strength over time. It ensures that each press feels just as responsive as the first one.

What is a metal dome used for in the electronics industry?

In modern electronics, responsiveness is crucial. That’s where metal domes come in. Whenever someone presses a button on a handheld device, medical panel, or industrial machine, there’s a high chance a metal dome is behind it.

Metal domes are widely used in membrane switches, keypads, and user interfaces across several fields. In medical devices, they provide tactile confirmation, even through gloves.

In industrial control panels, they offer clear, fast feedback under tough environments. Consumer electronics like TV remotes and gaming controllers rely on dome switches for satisfying response and durability.

Their role is simple but vital. Metal domes complete the electric circuit when pressed and then instantly return to their original shape. This snap action gives users confidence that the action has been registered.

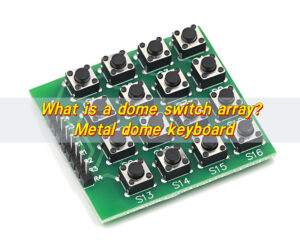

How does a metal dome switch work?

Dome is placed over a printed circuit board. When pressed, the dome flexes downward and connects the two contact pads on the PCB. This completes the circuit and sends a signal to the device. Once released, the dome springs back to its original shape, breaking the connection.

This click mechanism is mechanical, not electronic, making it highly reliable and easy to control. The dome’s shape, force, and material determine how it feels to the user.

When precision is necessary, as in medical devices or safety systems, the metal dome switch provides immediate, tactile feedback that users can rely on.

The shape of the dome—whether round, four-leg, or triangle—affects the feel and function. Four-leg domes offer stability. Round domes offer space savings. Triangle domes are ideal for custom arrays.

Why choose a tactile dome switch for your device?

Tactile dome switches deliver one major benefit: feedback. In environments where speed and precision matter, tactile response can reduce input errors and increase efficiency. This is critical in fields like medical diagnostics, aerospace, and automotive systems.

Tactile dome switches are also more durable than many alternatives. They resist wear, perform consistently, and allow for repeated actuation without losing strength. For devices used in low-light conditions or while wearing gloves, tactile feedback is essential.

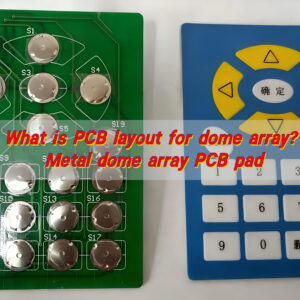

What is a dome switch PCB?

The dome switch PCB contains the conductive traces that complete the circuit when the dome is pressed. Without this board, the dome would have nothing to connect.

High-quality dome switch PCBs are engineered with precision. Each contact area must align perfectly with the dome’s center to ensure actuation. Even a tiny misalignment can cause poor performance or inconsistent clicking.

Modern PCB design allows for multiple dome switches on a single board. This enables compact, efficient interfaces—especially in consumer electronics and medical keypads. Can customize the layout to fit any shape or size while maintaining optimal tactile response.

Pairing a durable dome with a well-designed PCB ensures strong conductivity, long lifespan, and reliable feedback.

What’s the difference between dome switch vs membrane?

Membrane switch uses several layers of flexible film and conductive ink. It’s thin, smooth, and often has no tactile response unless combined with a dome. It works well in low-cost products or sealed environments where the user doesn’t need clear feedback.

Dome switch, on the other hand, uses a metal dome to provide a mechanical response. When pressed, it clicks. The user knows the action happened. That tactile feedback builds trust and improves usability.

Compared to membrane-only switches, dome switches:

- Last longer (1 million+ actuations)

- Offer better tactile feel

- Reduce accidental presses

- Are easier to use with gloves or in motion

For products that require frequent interaction or operate in critical settings, dome switches offer a superior user experience. Membrane switches have their place, but for performance and feedback, dome switches win every time.

How does a snap dome switch improve tactile response?

Snap dome switches elevate the user experience. Unlike soft or mushy alternatives, snap domes give a clear “click” that confirms action. This matters most in environments where feedback needs to be instant and unmistakable.

The unique design of a snap dome lets it flex under pressure and spring back with force. This movement isn’t just efficient—it’s emotionally satisfying.

Snap domes are available in various sizes, shapes, and forces. Whether you want a soft press for wearable tech or a firm click for industrial control panels, there’s a snap dome that fits.

Where are dome switch buttons commonly used?

Dome switch buttons are everywhere. From everyday gadgets to mission-critical machines, they form the backbone of user input systems.

In medical devices, dome switches help doctors operate machinery without looking down. In military equipment, they ensure feedback in the toughest conditions. In industrial control panels, they hold up to dust, vibration, and moisture.

Consumer products rely on them too. Think about your TV remote, your fitness tracker, or your microwave oven. All of them likely have dome switches beneath the surface. Why? Because dome switches provide that unmistakable “click” users expect.

Other applications include:

- Automotive dashboards

- Home automation systems

- Test equipment interfaces

- Communication devices

- Portable diagnostic tools

The versatility of dome switch buttons makes them essential in any product where feedback, durability, and responsiveness matter.

Conclusion:

Metal domes are essential components in the electronics industry, offering reliable tactile feedback and long-term durability. Among various materials, SUS 301 stainless steel stands out for its excellent resilience and consistent performance. Used in everything from medical devices to industrial controls, metal dome switches provide a crisp, responsive feel that enhances user confidence.

For expert support or to get started on your custom solution, contact us at sales@metal-domes.com