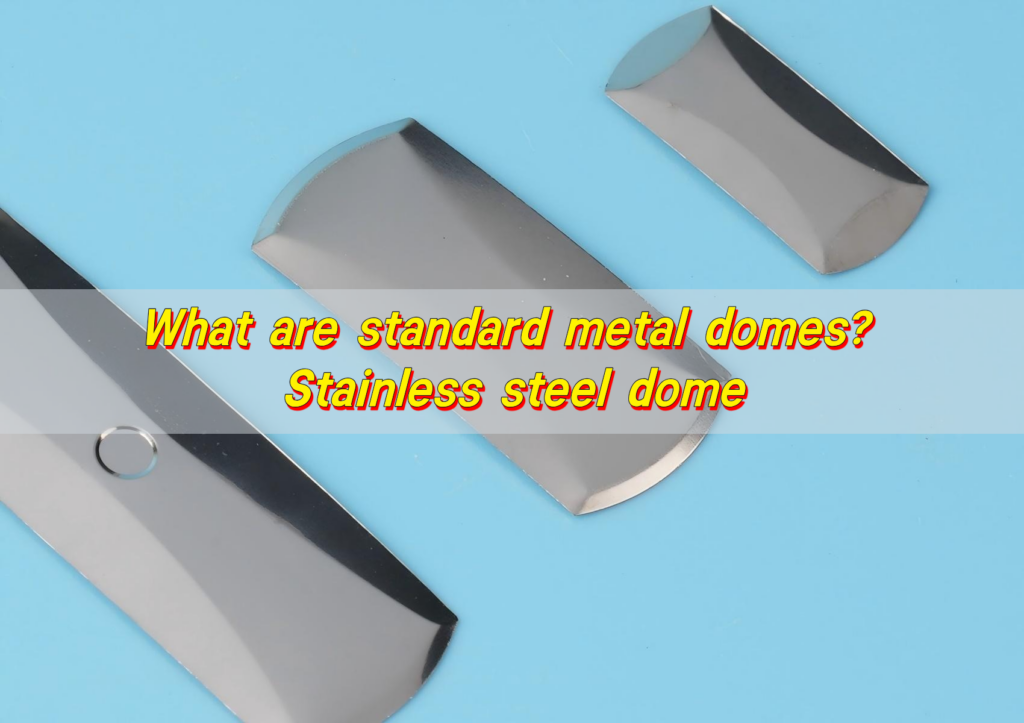

Standard metal domes are based on stainless steel, which has excellent elasticity and corrosion resistance. Its surface is smooth and can effectively resist environmental erosion, especially suitable for humid and chemically corrosive environments. It plays a key role in electronic equipment, automotive parts, medical equipment and other industries.

What is a standard metal dome?

Standard metal dome is a small, curved, thin piece of stainless steel designed to complete a circuit when pressed. It acts as the core part of a snap dome switch, giving users a clear “snap” feel and a tactile response that confirms actuation.

These domes are typically installed inside dome arrays, which are adhesive sheets pre-loaded with domes. Arrays are then applied to printed circuit boards (PCBs), forming the interface in devices like membrane switches, control keypads, or handheld gadgets.

Standard metal domes come in different shapes—round, triangle, four-leg, and oblong. Each shape offers a unique actuation force and feedback level.

Are standard domes made of stainless steel?

Yes. Stainless steel domes are the gold standard in the industry. Their resilience, flexibility, and ability to bounce back after repeated presses make them ideal.

Unlike plastic or rubber components, stainless steel doesn’t wear out easily. It resists corrosion, holds its shape, and maintains performance even after millions of cycles.

That’s why most manufacturers—including us—prefer to craft standard metal domes from SUS301 stainless steel, known for its excellent hardness and elasticity.

Why choose standard metal domes?

There are plenty of reasons to go with standard metal domes. First, they offer precise tactile feedback. This makes them ideal for applications where user feedback matters—like in medical instruments, industrial controls, or high-usage consumer electronics.

Second, they are incredibly durable. Most standard domes are rated for 1 million to 5 million actuations. That means you could press the same button hundreds of times a day for years without performance loss.

Third, assembly is quick and efficient. Domes are pre-loaded on adhesive arrays, making pick-and-place assembly fast and cost-effective. That means reduced labor time, fewer mistakes, and a cleaner production line.

Are standard domes good for tactile feedback?

Absolutely. Unlike rubber buttons that can feel mushy or unresponsive, metal domes offer a clear mechanical snap. The tactile “click” you feel is not only satisfying but also functional. This is essential for products where accurate input is key.

Whether you’re building a rugged device or a sleek controller, tactile feedback builds user confidence and enhances the product experience.

What sizes do standard domes come in?

Standard metal domes are available in a wide range of sizes to fit your exact design.

Typically, the diameter ranges from 4mm to 20mm. Actuation force can vary from 100g to 800g, depending on the size and shape. Smaller dome may offer a softer click, while a larger dome provides firmer resistance.

Common configurations include:

- Round Domes: Known for uniform force distribution.

- Four-Leg Domes: Offer excellent stability and feedback balance.

- Triangle Domes: Ideal for high-precision control.

- Oblong Domes: Great for narrow key shapes or rocker-style switches.

Choosing the right size ensures your product feels intuitive. It also helps in reducing user fatigue during long periods of operation.

Not sure what size fits your needs? Our engineers at sales@metal-domes.com are always ready to help you select the perfect fit.

How do snap domes work?

At rest, the dome arches upward. When pressed, the dome collapses inward and touches the lower circuit contact. This completes the electrical loop and registers an input. Once the pressure is removed, the dome springs back to its original shape.

This snap action is both tactile and audible. It tells the user the button was pressed. This feedback loop improves accuracy and makes the interface more user-friendly.

Better still, this mechanism doesn’t require much space. So standard metal domes can be used in ultra-thin keypads without sacrificing performance.

Where are metal domes used?

Here are a few examples:

- Remote Controls: That firm click you love? It’s a dome.

- Medical Devices: Precise feedback ensures accurate input.

- Industrial Equipment: Durable domes withstand harsh environments.

- Wearable Tech: Ultra-thin and responsive for limited space.

- Automotive Controls: Dome arrays help maintain accuracy even in vibration-heavy setups.

- Consumer Electronics: Used in everything from calculators to smart home panels.

Basically, if it has a button and needs precision, it likely has a metal dome.

How long do standard domes last?

One of the greatest strengths of standard metal domes is their longevity.

Most are rated for over 1 million actuations. High-performance domes—like those made by Best Technology—can exceed 5 million cycles.

This makes them perfect for critical-use cases, such as medical equipment, military hardware, or mission-critical machinery. When failure isn’t an option, reliability becomes everything.

Also, stainless steel resists rust, fatigue, and deformation. It keeps its shape and tactile properties much longer than plastic alternatives. That means fewer replacements, lower costs, and better end-user satisfaction.

Conclusion:

Standard metal domes are essential components in modern electronic keypads, offering precise tactile feedback and exceptional durability. Made from stainless steel, these domes are available in various shapes and sizes to suit any application.

Whether you’re designing a rugged industrial panel or a sleek consumer device, standard domes ensure long-lasting performance, ease of assembly, and user satisfaction. For expert support or free samples, reach out to sales@metal-domes.com