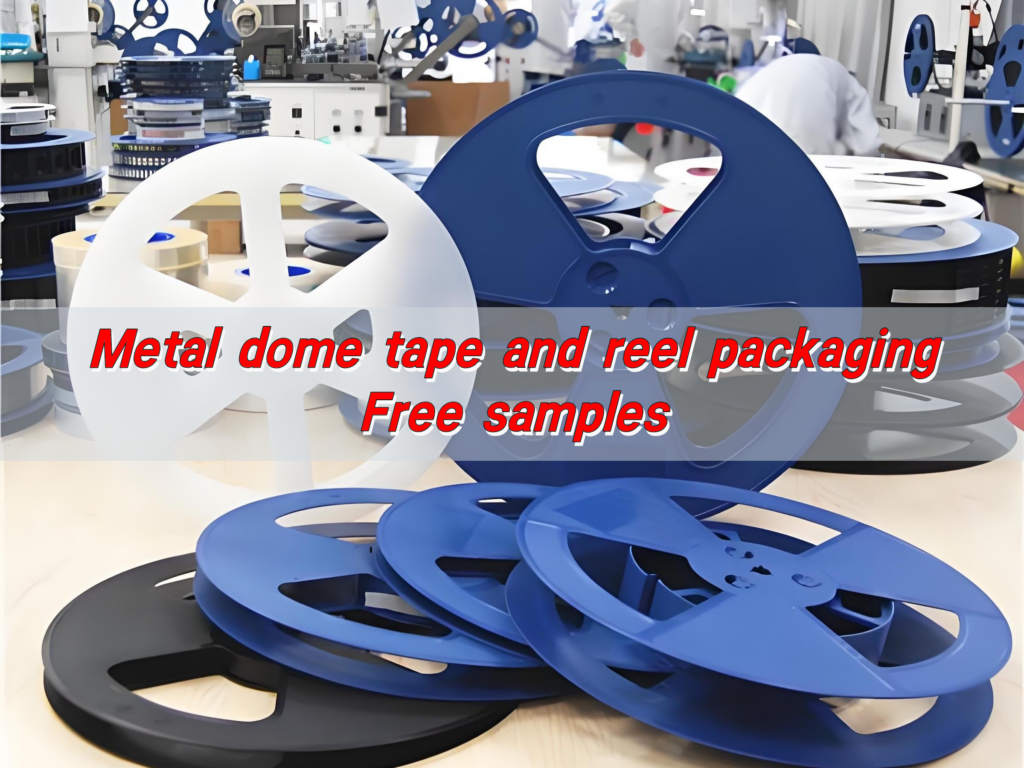

Metal dome tape and reel packaging is made for high-speed pick & place machines. Each dome is sealed in a tape pocket and ready for instant use, No manual handling needed. It’s precise, fast, and reliable. Best of all? We offer free samples so you can try it with zero risk.

What is metal dome tape & reel packaging?

Tape and reel packaging is designed for high-speed automated pick & place machines. Instead of packaging metal domes in bulk or tubes, each dome is sealed in an individual socket on a continuous tape. This tape is then wound on a reel.

Just like how SMT components—resistors or capacitors—are placed, tape & reel domes can be picked and mounted at high speed. This makes them fully compatible with automated lines, removing the need for manual placement or re-orientation.

The packaging isn’t just about convenience. It’s about delivering domes with consistency, protecting them during handling, and allowing seamless integration with SMT lines.

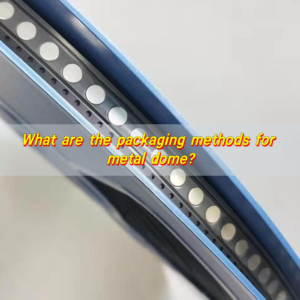

Which domes fit tape & reel packing?

Four-leg metal domes, triangle domes, and round (circle) domes are the most suitable for tape and reel. Why these shapes? Because they offer balanced symmetry, allowing them to be consistently oriented in the correct direction during packing.

These dome types sit securely in each socket on the tape, making them ready for smooth pick & place operation without manual adjustment. Their stable structure also prevents rotation or shifting inside the tape pocket, ensuring high placement accuracy during SMT assembly.

If your application uses any of these shapes, tape & reel is the most efficient and reliable way to streamline your assembly process.

Is tape & reel better than bulk?

When domes are packed in bulk, they’re jumbled together. That means you or your team must manually align, pick, and place each one. It’s time-consuming, increases the chance of errors, and adds unnecessary labor.

Tape & reel domes, on the other hand, are ready to go. Pop the reel onto the machine, and you’re good to start assembly. The alignment is near-perfect, thanks to the precision socket placement—±0.05mm accuracy, to be exact.

Labor cost is another big one. Reel packaging cuts labor needs dramatically. And when you’re mounting four times faster, you save time and money.

How does reel packaging save time?

With tape and reel, the domes are lined up and sealed in precise positions. There’s no sorting, no flipping, no aligning. SMT machines can now pick and place up to 20,000–100,000 domes per hour, depending on the equipment used.

That means more boards done per hour, fewer stoppages, and no bottlenecks in your assembly line. Plus, since the domes are protected within the tape, you reduce the risk of contamination or damage during handling.

What are the advantages of Tape & Reel?

- Precision Placement: Every dome is aligned with ±0.05mm contact accuracy.

- Improved Durability: Domes tested for over 1 million actuations. That’s performance you can trust.

- Massive Time Savings: 4× faster mounting compared to bulk-packed domes.

- Labor Reduction: Cut manual labor needs by 37%. That’s real cost-efficiency.

- Damage Prevention: Sealed sockets keep domes clean and undamaged.

- Machine Friendly: Fully compatible with SMT pick & place systems.

- Consistency Across Boards: Each dome lands exactly where it should—every time.

These benefits aren’t just technical—they’re operational. They influence how fast you ship, how consistent your product is, and how reliable your output stays under pressure.

Why choose our tape and reel metal dome?

At our facility, every dome we deliver on tape & reel meets the highest precision and durability standards.

- Accuracy You Can Count On: Our array designs offer ±0.05mm contact accuracy, so you get pinpoint alignment every time.

- Built for Longevity: Each dome is engineered to last over 1 million presses, ensuring durability in real-world use.

- Cost-Effective Pricing: We offer a 12–15% discount on bulk orders, giving you top-tier performance at a competitive rate.

- Efficiency That Pays: Our clients experience a 4× boost in mounting speed, and 37% savings in labor costs. That’s how you scale smarter.

- Faster Delivery: Our standard lead time is just 2-3 days. Compare that to the industry average of 7, and the time savings are clear.

- Certifications Ready: All samples come with ROHS/REACH documents, plus a full technical parameter sheet. You don’t have to ask twice.

- Responsive Support: We commit to a 48-hour technical response upon sample arrival. Your questions won’t go unanswered.

Do we provide free samples?

Yes. Every sample includes:

- A fully functional tape & reel demo of your selected dome shape.

- Detailed technical parameter sheets to help with setup.

- ROHS and REACH compliance certifications, so you meet global standards with ease.

Once you receive your sample, our team is ready. We’ll respond within 48 hours to answer technical questions, help you test, and support your transition from bulk to reel.

We’ve helped hundreds of manufacturers move from tube-packed or bulk domes to fully reel-integrated lines. We’ll help select the right dome style, align with your SMT setup, and get you rolling in no time.

Conclusion:

Tape and reel packaging for metal domes isn’t just a better option—it’s the best one. You’ll save time, cut costs, and boost performance across the board. With accurate placement, faster mounting, and technical support every step of the way, there’s no downside.

Plus, with a free sample, fast delivery, and bulk discounts, there’s zero risk in trying. Ready to start? Contact us now at sales@metal-domes.com and request your free tape & reel sample today.