The metal dome prototype is a design model or preliminary sample of the metal dome. It is used to test and verify the performance of the dome in actual applications, such as tactile feedback, conductivity, and durability. Through prototyping, the shape, size, and material selection of the dome can be optimized to ensure its reliability and stability in devices such as membrane switches.

How do you design a metal dome prototype?

Before the shrapnel is formed, its purpose needs to be clarified. Once the function is clear, the design follows. The dome shape, size, and actuation force are chosen based on user interaction. Some projects need a feather-light touch. Others demand a firm press with a sharp snap.

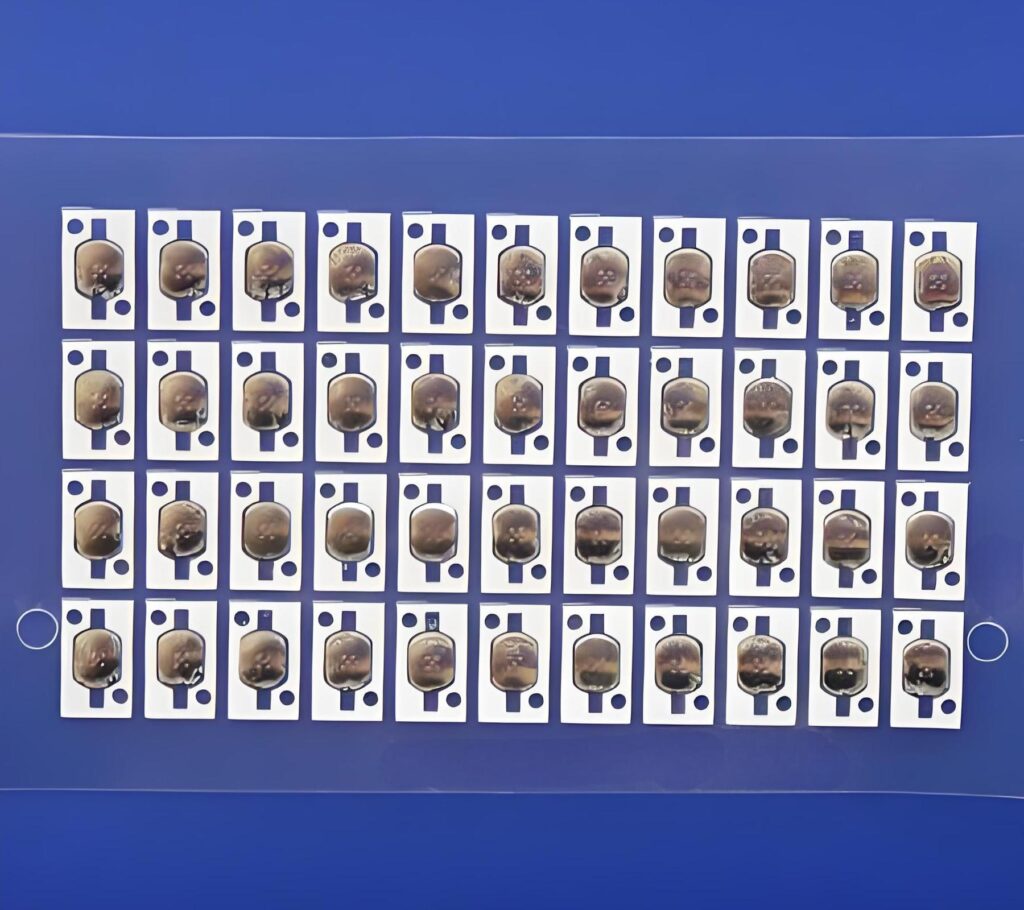

Then comes layout. You can use a single dome or an entire dome array depending on the device. Arrays are often printed on flexible circuits and arranged for multi-button devices.

Next, the materials are selected. Stainless steel is common, but other metals are used based on feedback, strength, or resistance needs. The metal is then precision-stamped, usually with laser or die-cut methods.

What is a metal dome prototype used for?

A metal dome prototype allows developers to test how a product feels and reacts before mass production. Prototyping helps catch flaws early, reduce costs, and deliver a better product.

These domes are often used in industries where performance and feedback matter. That includes medical devices, telecom equipment, control panels, smart remotes, security devices, and more.

For example, a medical device might need a low-resistance dome with a silent click. A military device might demand a high-resistance dome with solid tactile feedback. A metal dome prototype makes all this possible before final production.

How does a snap dome switch work?

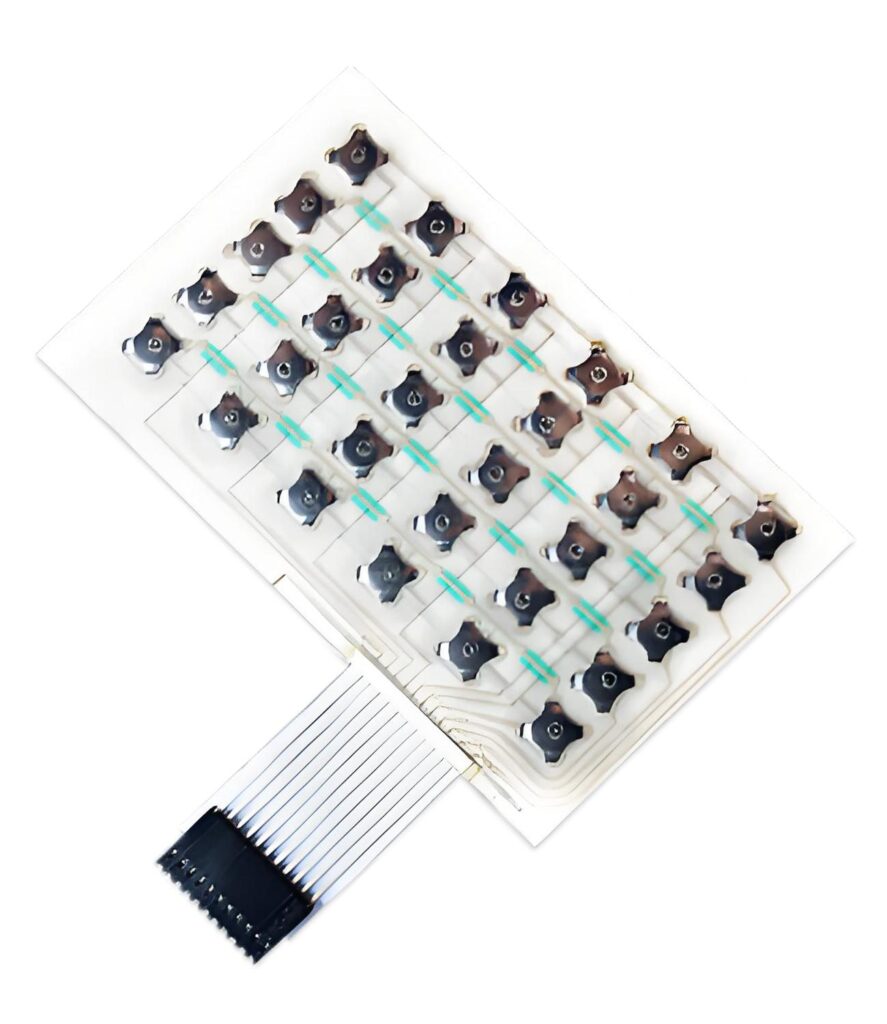

The core of the system is the snap dome switch. Each dome sits between two conductive layers. When you press it, the dome collapses and makes contact with the lower circuit, closing the circuit and sending a signal. Once released, the dome springs back to its original shape. This creates a fast, tactile response with a satisfying snap.

It gives clear feedback, reduces errors, and improves user confidence. A good snap dome switch delivers thousands—or even millions—of cycles without failing.

These switches are compact, reliable, and affordable, which makes them perfect for tight spaces where mechanical switches can’t fit.

What makes dome arrays ideal for switch designs?

When a single dome isn’t enough, dome arrays offer the perfect solution. They’re collections of domes mounted on flexible or rigid substrates, arranged in a precise pattern.

This design brings many benefits. First, it saves space. A thin dome array fits into devices where larger mechanical switches can’t go. Second, it simplifies assembly. Instead of placing domes one by one, you install a whole set in one step.

Third, it allows for multi-button designs. Whether you’re building a keypad, a control board, or a custom interface, dome arrays make it fast and easy. You also get consistent feel and pressure across all buttons, which boosts user satisfaction.

For product designers, dome arrays bring peace of mind. They deliver uniform quality, speed up production, and give users a clean, responsive interface.

Why choose a metal dome over other switch types?

Compared to rubber dome switches, capacitive sensors, or mechanical keyboards, metal domes offer distinct advantages.

First and foremost, they’re tactile. Each press is crisp and clear, giving users immediate feedback.

They’re also ultra-durable. Most metal domes last for millions of cycles without degradation. That’s miles ahead of many other switch types.

In terms of cost, metal domes are efficient. They offer high-end performance at a lower cost than mechanical switches, especially in large quantities. Their thin profile makes them perfect for slim devices, from medical tools to handheld electronics.

And when it comes to customization, metal domes offer unmatched flexibility. You can change the shape, size, pressure, layout, or even the finish to match your exact needs.

What’s the difference between metal domes and dome arrays?

Though often used together, they’re not the same. A metal dome is a single tactile element—one button, one click, one circuit. You can place them individually or in limited quantities.

A dome array, however, is a collection of domes arranged and mounted together, often as part of a complete switch layer.

Think of it this way: if a metal dome is a single key, a dome array is a full keypad. Both are essential. But while domes offer versatility in placement, arrays shine in structured, multi-button setups.

You might use individual domes for low-volume or specialized products. But for fast assembly, consistency, and cost-efficiency, dome arrays take the lead.

Can you customize a metal dome prototype?

Absolutely. In fact, custom metal dome prototypes are one of the most requested services today. Every application is different. What works for a medical tool won’t suit a rugged outdoor device.

You can customize nearly every part of the dome. Choose actuation force—light, medium, or heavy. Pick a shape—four-leg, triangle, round. Adjust size for space or pressure distribution. Even the surface finish can be modified for better conductivity or wear resistance.

Beyond the dome itself, you can design the array layout, overlay materials, adhesive layers, and dome placement. Custom printing, laser cutting, and tactile overlays are also available.

Working with an experienced supplier means your metal dome prototype can evolve into a perfect final product—without compromise.

Where can I buy metal dome prototypes?

If you’re searching for metal dome prototypes for sale, you need more than just a supplier—you need a trusted partner. Best Technology has you covered. With years of experience and a focus on precision, we provide high-performance snap dome switches, dome arrays, and custom metal dome solutions tailored to your project.

We understand that each product is unique. That’s why we offer design support, prototyping, testing, and quick-turn services to keep your development on schedule. Whether you’re just testing or ready for mass production, we’re ready to deliver.

Conclusion:

Metal dome prototypes are essential tools for creating responsive, high-performance switch solutions. They offer precise tactile feedback, long-lasting durability, and versatile customization. From standalone snap dome switches to complete dome arrays, these components support everything from medical devices to industrial controls.

Whether you’re testing a new idea or preparing for mass production, a well-designed metal dome prototype helps you move forward with confidence. For expert advice, tailored solutions, and fast delivery, reach out to us today at sales@metal-domes.com