The metal dome is the only metal component in the membrane switch. With technological advancement and changes in market demand, the metal dome, as an indispensable key component, is becoming more and more important in various types of electronic equipment and mechanical equipment. Under the current circumstances, many products use metal domes in a confusing manner, especially in flexible circuits. They are only used as a component to provide tactile feedback, which causes many disadvantages in the performance of membrane switches and even causes the membrane switches to lose their due function. So what are the designs and functions of metal domes? What are the main application environments? Let me take you through it below!

How to Design a Metal Dome?

The metal dome design process involves many factors. First of all, the shape of the metal dome is crucial. Details such as diameter, height, curvature, and contact location need to be carefully considered to ensure that it can provide precise press feedback, stable and reliable conductive performance, and maintain sufficient Travel distance and rebound force. In addition, factors such as corrosion resistance, fatigue resistance and temperature stability under environmental conditions must also be considered during design to adapt to the stringent requirements of different application scenarios.

In terms of material selection, metal domes are usually made of high-quality stainless steel such as SUS301 or 304. These two stainless steels are favored for their excellent elasticity, corrosion resistance and good electrical conductivity. Among them, the ultra-thin (0.05mm-0.1mm) and high-hardness stainless steel 301 metal dome is particularly suitable for occasions that require fine control and long life. Of course, depending on the specific application fields and product requirements, manganese steel or other alloy materials may also be selected and undergo a heat treatment process to obtain ideal mechanical properties and durability.

The design optimization and material selection of the metal dome directly affect the performance, durability and user experience of the product.

What are the functions of metal domes?

1. Use the conductivity of metal to connect the two-pole contacts of the switch.

2. End the rebound of the metal dome and provide tactile feedback to the operator.

Types and specifications of metal domes

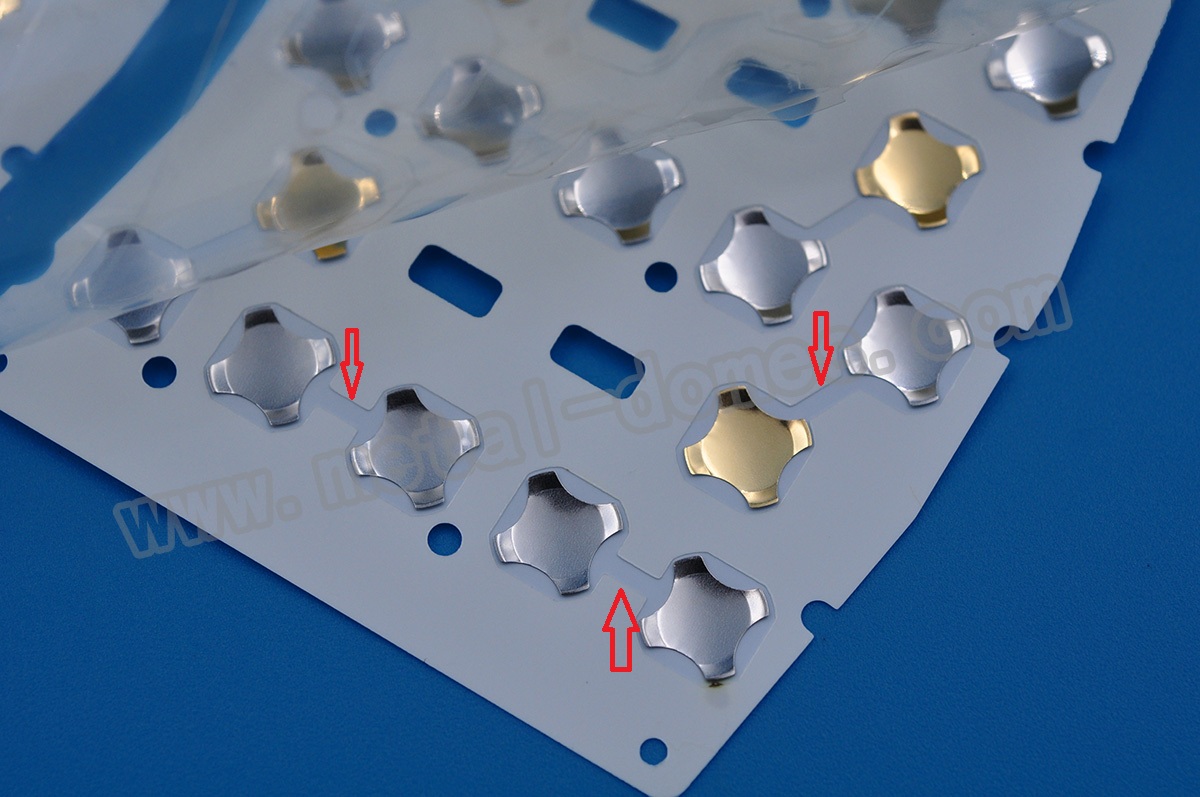

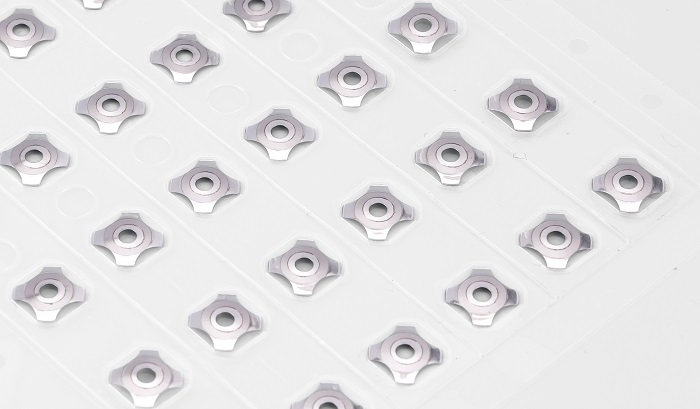

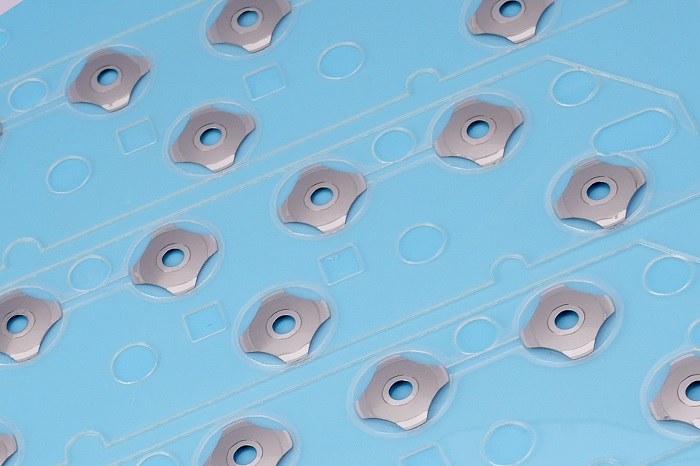

According to the shape, there are circles, triangles and crosses. In order to make the bottom edge of the dome contact smoothly and increase the stroke, as well as to overcome the frictional resistance of the bottom edge to the substrate during metal dome operation and to facilitate scheduling, three equal parts are often punched on the edges of circular and triangular metal domes. The support points rush into arcs at the four legs of the cross-shaped dome.

What are the applications of metal domes?

Metal domes are mainly used in membrane switches of rigid boards such as printed circuit boards, giving full play to the three major characteristics of the dome: conduction, rebound, and feel.

The application of metal domes in flexible membrane switches is mainly to provide tactile feedback. In flexible circuit boards, the movement of the metal dome often exceeds the horizontal plane of its bottom. If too much force is used, the dome will deform in the opposite direction and be difficult to recover.

It has good insulation and heat resistance, high mechanical strength, transparency and air tightness, especially bending resistance and high elasticity. It is an ideal material for making membrane switch circuits.

In terms of practical applications, metal domes can be found in all walks of life. In consumer electronics, they are widely used in membrane switches and touch panels to provide users with tactile feedback while ensuring reliable conduction of current; in industrial fields such as automobiles and machine tools, metal domes serve as balancing devices or electrical contact elements. important role; in medical device manufacturing, its precision and stability are decisive for achieving precise control and safe operation.