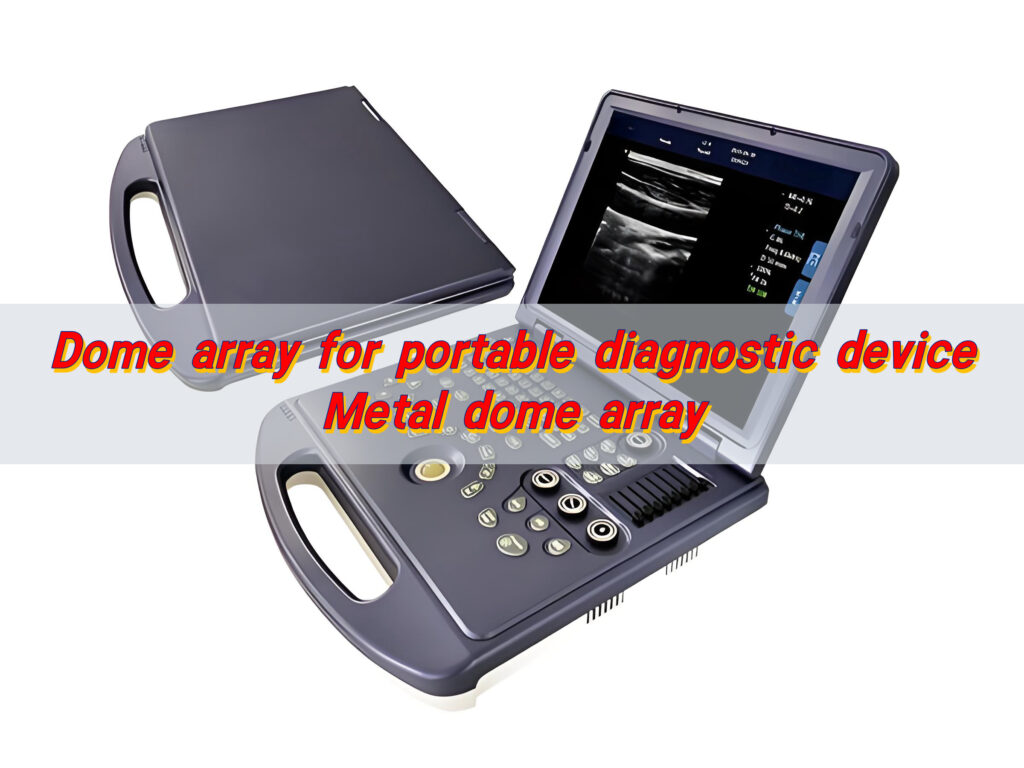

What Is a Dome Array for Portable Diagnostic Device?

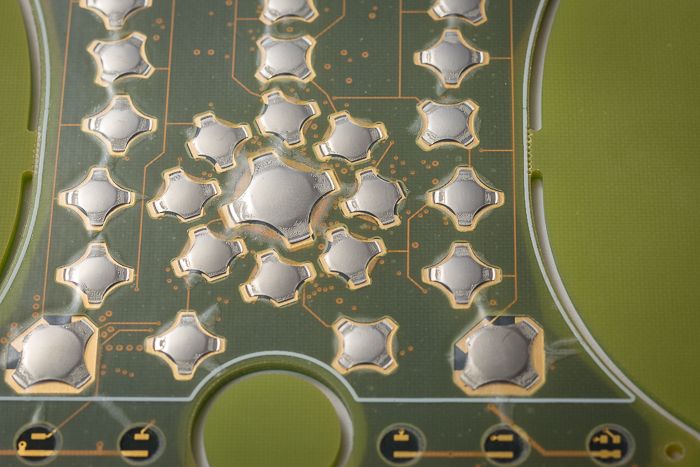

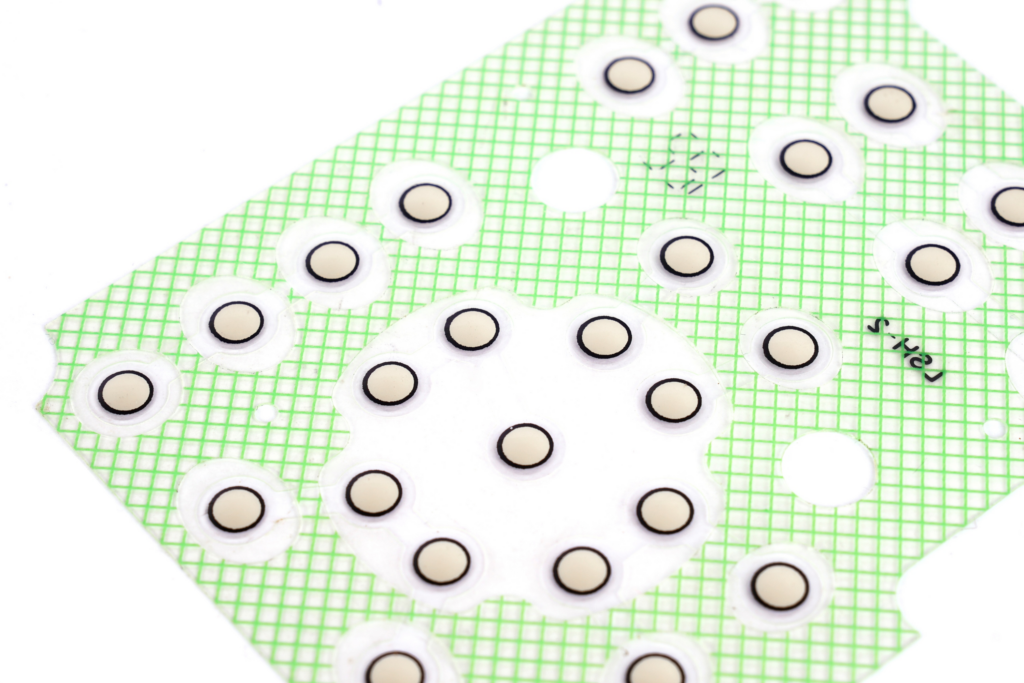

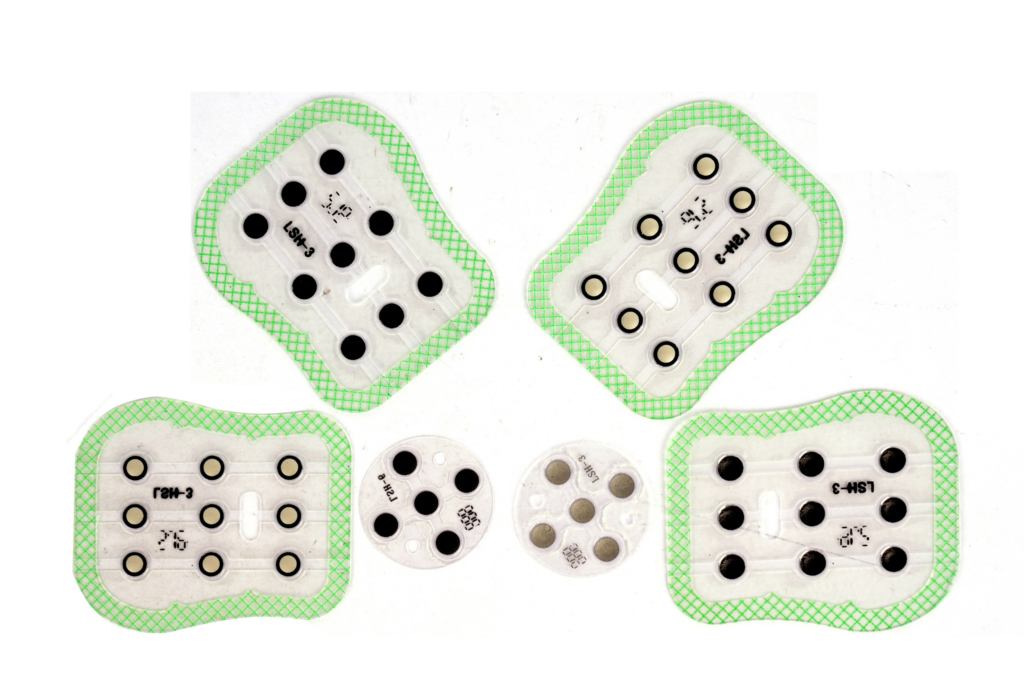

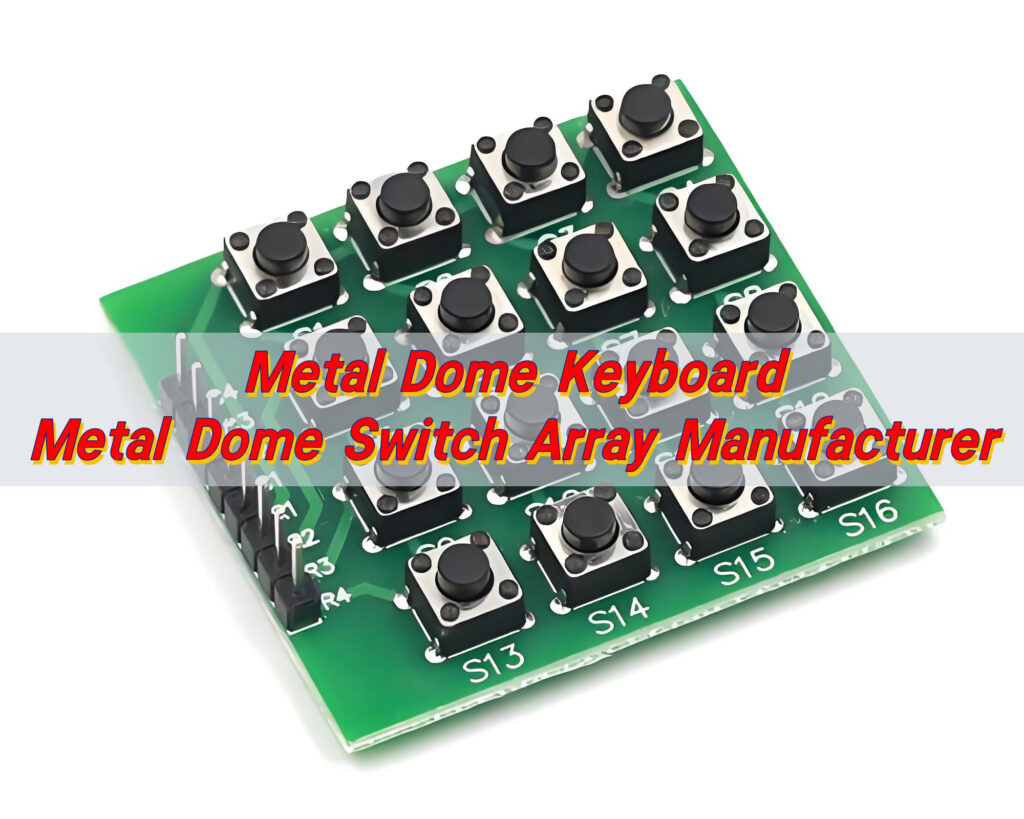

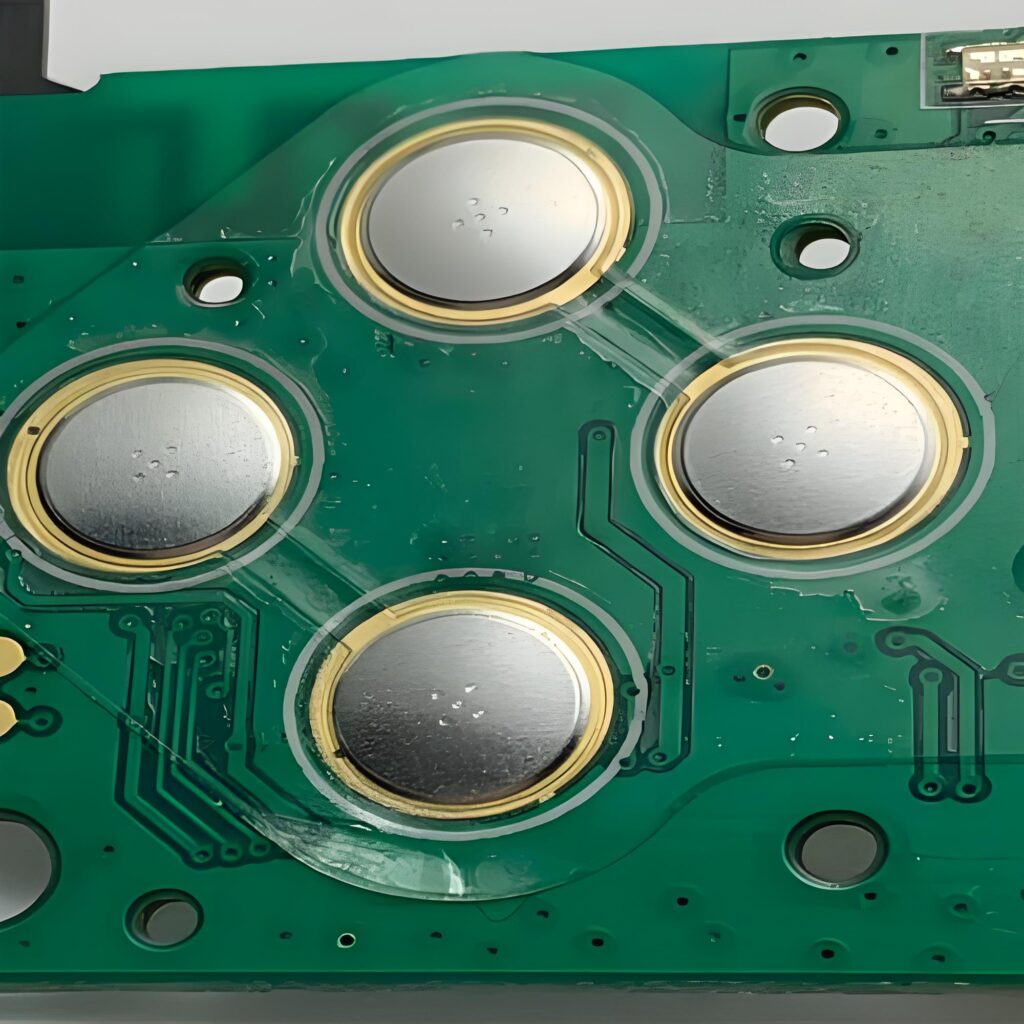

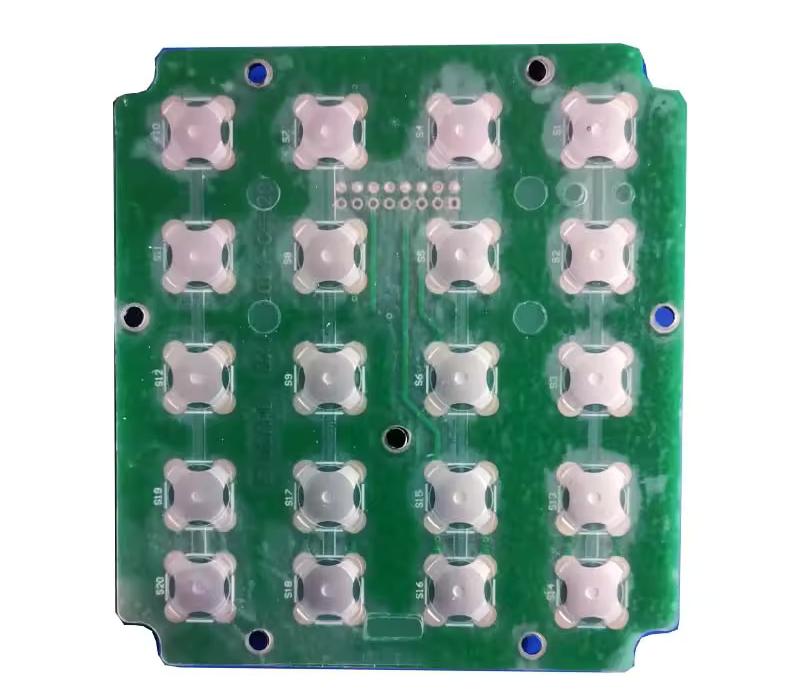

Dome array is a thin layers-based keypad structure used under the surface of many handheld medical devices. It contains multiple metal domes arranged on an adhesive layer.

When you press a button on a device, the force transfers to the dome. The dome responds with a snap. This action creates a crisp tactile click. It also closes the circuit to send the signal.

Many portable diagnostic tools rely on this mechanism. These include glucose meters. They include handheld ECG screens. They include mobile blood analyzers. They include rapid-test devices. They include portable respiratory testers.

Portable diagnostic equipment is often used in sensitive moments. A doctor may need to check vitals. A nurse may need to collect data from a patient. A patient may track statistics at home. Pressing a key must feel right. A dome array helps deliver this confidence.

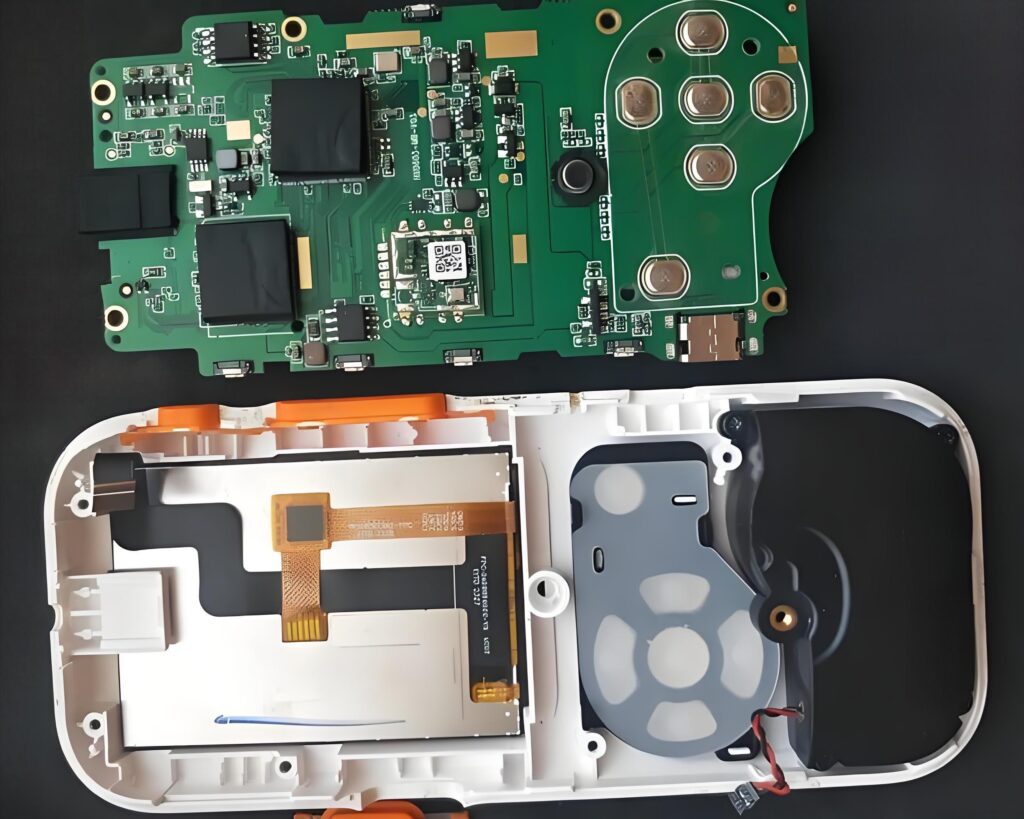

In addition, dome arrays support slim designs. Modern portable health tools rely on compact form factors. The design often includes stainless steel domes. These metals ensure high resilience. They deliver a consistent life cycle. A good dome can survive hundreds of thousands of presses. Even millions.

How Does a Metal Dome Array Boost Portable Diagnostics?

Metal dome arrays bring big gains to portable diagnostics in several ways. First, they offer immediate tactile feedback. That small “click” matters more than many people realize. It confirms each press. It speeds up operations. It reduces second-guessing.

Second, metal domes improve accuracy. A device must register each press without delay. A reliable dome structure ensures the circuit closes in the right moment. Every actuation has consistent force.

Third, metal dome arrays support mobility. Portable diagnostics require lightweight tools. Heavy buttons or bulky switches would slow things down. Metal dome arrays are light. They keep devices sleek. They help maintain comfortable handling.

Fourth, they boost long-term performance. Medical tools often face repeated use. They work in different temperatures. They handle constant touching. Metal domes resist wear better than many other switch structures. Their spring-back design stays stable. Long-term stability makes the device feel fresh even after months of use.

Fifth, metal dome arrays improve the emotional connection with the product. A smooth, crisp click feels good. A poor button makes a device feel cheap. When a nurse or doctor feels confident in each press, it increases trust in the reading and the device itself.

Sixth, dome arrays help minimize errors. When a press feels clear, users make fewer repeated inputs. Fewer missed presses mean better efficiency and less frustration. Portable diagnostics depend on smooth workflows.

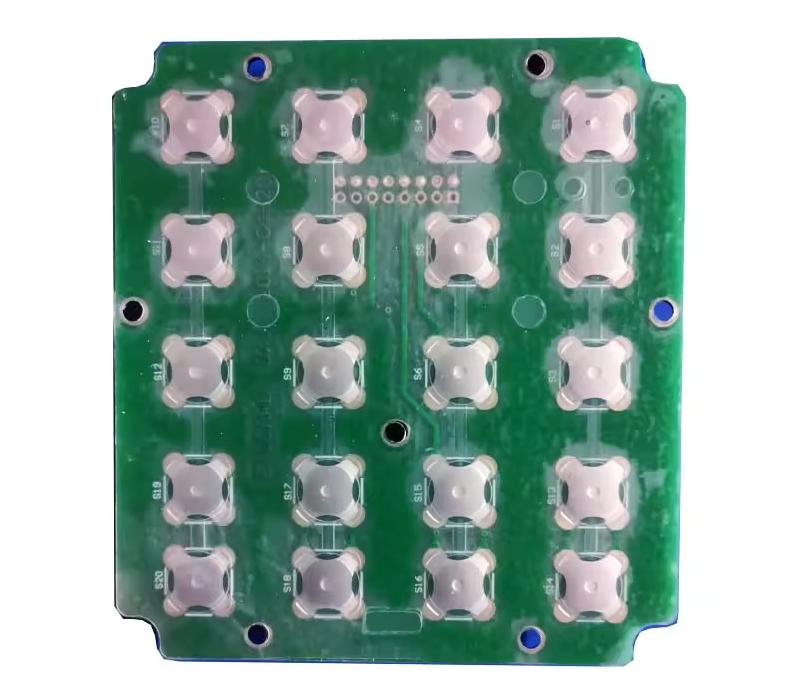

Lastly, the metal dome array supports modern UI layouts. Dome arrays make multi-button layouts simple to build. They align cleanly. They maintain consistent spacing. They follow high precision.

Which Metal Dome Array Fits Your Portable Diagnostic Device?

Choosing the right dome array is vital. Some focus on durability. Others focus on a softer press. Some need very small domes to fit tight spaces. Others need bigger domes for high tactile strength. Here are the most important factors to consider.

- 1. Desired tactile force

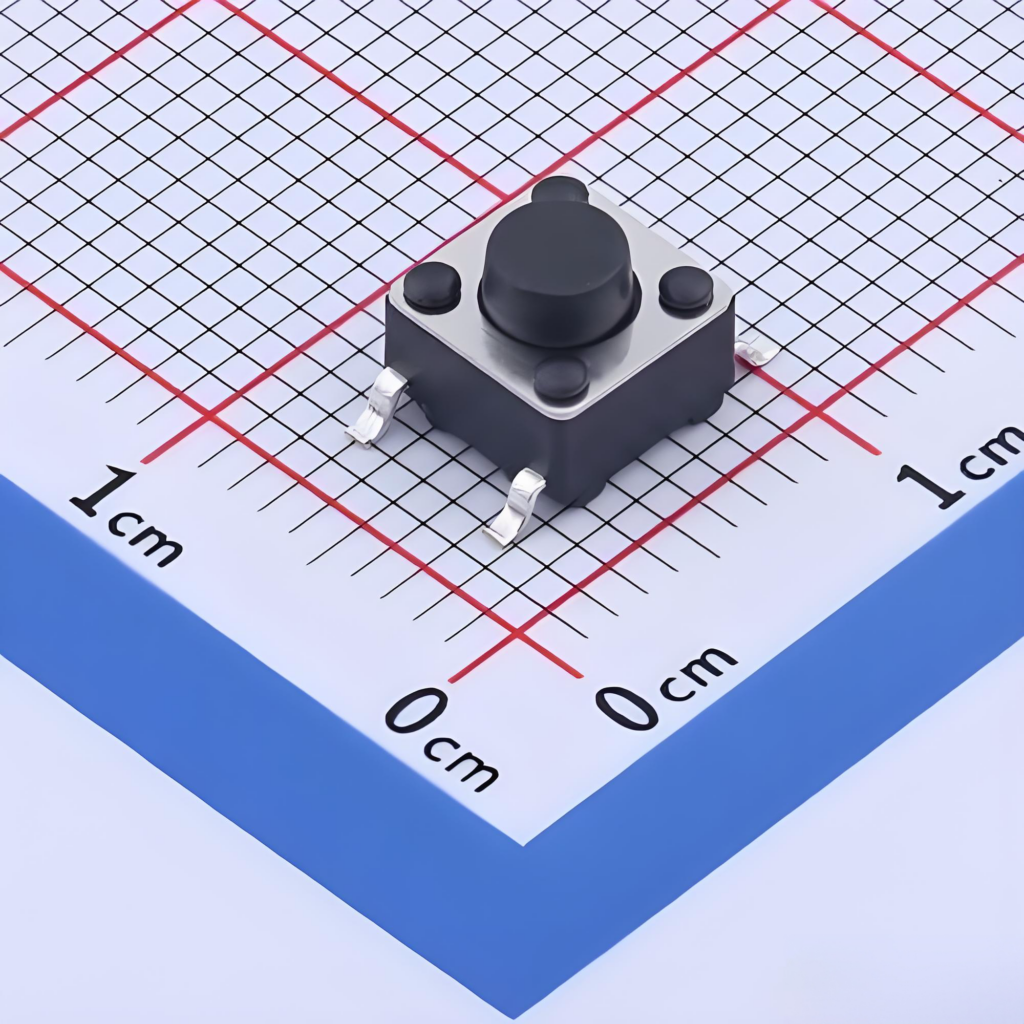

The actuation force defines how firm each press feels. Common ranges run from 100g to 500g. Portable diagnostic tools often choose mid-range forces. Users want both comfort and accuracy. Lighter forces suit frequent use. Stronger forces suit critical tasks where confirmation matters.

- 2. Dome size and shape

Different dome shapes create different sensations. Round domes feel smooth. Four-leg domes feel crisp and centered. Triangle domes deliver sharp feedback.

Portable diagnostics often require precision. Four-leg domes are popular because they ensure even actuation. Size also affects device feel. Small domes respond faster. Large domes offer bigger, more noticeable snaps.

- 3. Electrical contact area

Some devices require fast and solid electrical closure. Dome arrays offer stable contact, but the size of contact points varies. A reliable design ensures smooth conductivity even after heavy use.

- 4. Environmental conditions

Will the device face humidity? Cold environments? Frequent travel?

Metal domes made of high-quality stainless steel maintain shape in tough conditions. Devices for clinics, ambulances, or remote testing benefit from stable performance.

- 5. User experience goals

Some products aim for comfort. Some aim for precision. Others focus on reducing user fatigue.

- 6. Interface layout

Button spacing matters. If your product has many features, it may need small domes with tight tolerances.

- 7. Expected service life

Most dome arrays last long. But demand varies. Home-use devices may need moderate durability. Hospital-grade equipment needs extreme endurance. Many metal dome arrays easily reach millions of cycles.

What Benefits Do Metal Dome Arrays Bring to Portable Diagnosis?

Metal dome arrays offer a treasure of benefits that strengthen portable diagnosis. They support precision. They improve performance. They enhance the emotional feel of the equipment. And they bring real-world value to patients and professionals.

- Strong Tactile Feedback: The crisp snap of a metal dome is unmistakable. It builds confidence. It delivers a sense of control.

- Reliable Clicking Performance: Metal domes return to their original shape instantly. This gives them a stable feel across thousands of presses.

- Long Life Cycle: Portable diagnosis tools must last. Metal dome arrays can survive heavy daily use. Many models reach over one million actuations.

- Slim Structure: The thin design is perfect for small devices. It keeps equipment light and portable. Users enjoy comfort during every session.

- Steady Electrical Conductivity: A reliable connection reduces errors. It cuts delays. It creates smooth workflows.

Metal dome arrays lift user satisfaction. They make tools more dependable. They bring a premium feel without adding bulk.

How to Ensure Durability of a Dome Array in Portable Diagnostic Device?

Durability matters in medical environments. But you can maximize durability in several practical ways.

- Choose High-Grade Stainless Steel Domes: High-quality metals maintain spring action longer. They resist fatigue. They hold shape even under heavy workloads.

- Select the Proper Dome Size: A small dome may feel sharp. A larger dome may feel smoother. But size also affects durability. The stress must match the dome’s structure.

- Use Professional Adhesive Layers: The adhesive layer keeps domes in place. A strong adhesive prevents shifting. It resists humidity. It avoids uneven feedback.

- Protect Against Moisture and Dust: Portable devices often face unpredictable environments. Protective layers or sealed structures can keep domes clean. Clean domes last longer and respond better.

- Avoid Excessive Force Requirements: Heavy forces can look strong. But they also shorten lifespan.

- Test Under Real Usage Conditions: Simulated cycling tests are critical.

- Pick a Trusted Supplier: A dome array’s durability depends heavily on its manufacturing precision.

When all these elements align, the dome array becomes a powerful support system for the device. It serves users with confidence. It keeps performance alive for years.

What Makes Metal Dome Array Feedback Better for Portable Diagnostics?

Metal dome feedback stands out. It feels crisp. It feels sharp. It feels clean. That tactile quality gives the device an edge. Users sense the exact moment of activation. This reduces confusion. It energizes the experience.

- Instant Response: The metal dome’s structure returns instantly after pressing. This gives immediate feedback. It speeds operations. It helps users stay focused.

- Clear Actuation Point: Each press feels deliberate. The moment the dome snaps, users know the input registered.

- High Precision Under Repetition: Even after long usage, domes maintain accuracy. They do not soften quickly. They stay consistent.

- Reduced Input Fatigue: Smooth tactile feedback reduces strain. Users press confidently. They do not need to repeat presses.

- Better Control in Stressful Situations: Portable diagnostics sometimes happen in busy environments. In these moments, confident feedback reduces stress. It supports quick action.

Simply put, metal domes deliver superior tactile experience. They make portable devices feel premium. They help every press feel right.

How to Pick the Best Dome Array for Portable Diagnosis Performance?

Selecting the best dome array can influence the entire user experience. Here are the factors that matter most when choosing the perfect match.

- 1. Understand the Device’s Purpose

Is it used by medical professionals? Or home users? Professional devices may need sharper feedback. Home-use devices may need softer, more comfortable tactile feel.

- 2. Set Target Press Force

Make sure the force suits your user group. Too soft may cause accidental presses. Too strong may cause fatigue.

- 3. Match Dome Size to Design Space

Compact tools need small domes. Larger devices can use bigger domes for more powerful clicks.

- 4. Pick the Right Dome Shape

Some shapes fit better under wide buttons. Some shapes deliver more stability. Some shapes give a specific click style.

- 5. Consider Environmental Demands

Portable devices may face heat. They may face travel. They may face humidity.

- 6. Test the Tactile Experience

A real test tells you everything. Press the dome. Feel the click. Check the sound.

- 7. Confirm Life Cycle Requirements

Medical devices often need long lifespan. Ensure your dome array passes required cycles. Many high-grade arrays last beyond a million presses.

- 8. Work With Experienced Manufacturers

Precision matters. Dome arrays with tight tolerances ensure consistent feel. Skilled manufacturers also provide advice, samples, and custom designs.

Conclusion:

A dome array for portable diagnostic device plays a major role in how medical tools feel and perform. Metal dome arrays deliver crisp tactile feedback. They boost accuracy. They support long-term durability. They also enhance the emotional appeal of portable diagnostics.

For product inquiries or custom dome array support, contact: sales@metal-domes.com