Choosing the right metal dome manufacturer in Portugal directly impacts product reliability, tactile consistency, and production efficiency. A professional Portugal metal dome manufacturer must support custom dome array design, stable mass production, and fast response from sampling to delivery – this is exactly where BEST Technology excels.

Are you facing the following problems?

- Local suppliers only offer standard parts; custom metal domes are difficult to obtain.

- Long sampling cycles and slow response to design modifications.

- High costs for small batch orders and lack of engineering support.

- Unstable dome click force, with noticeable differences in feel between different batches.

- Insufficient array alignment accuracy, affecting assembly yield.

- Uncertain delivery times, impacting overall project schedule.

Full-Process Guarantee from Requirements to Delivery: Our Solution

As a professional metal dome and custom dome array manufacturer, BEST Technology adopts an engineering-driven delivery model:

- Requirements Clarification: Starting from application scenarios, lifespan requirements, and click force range.

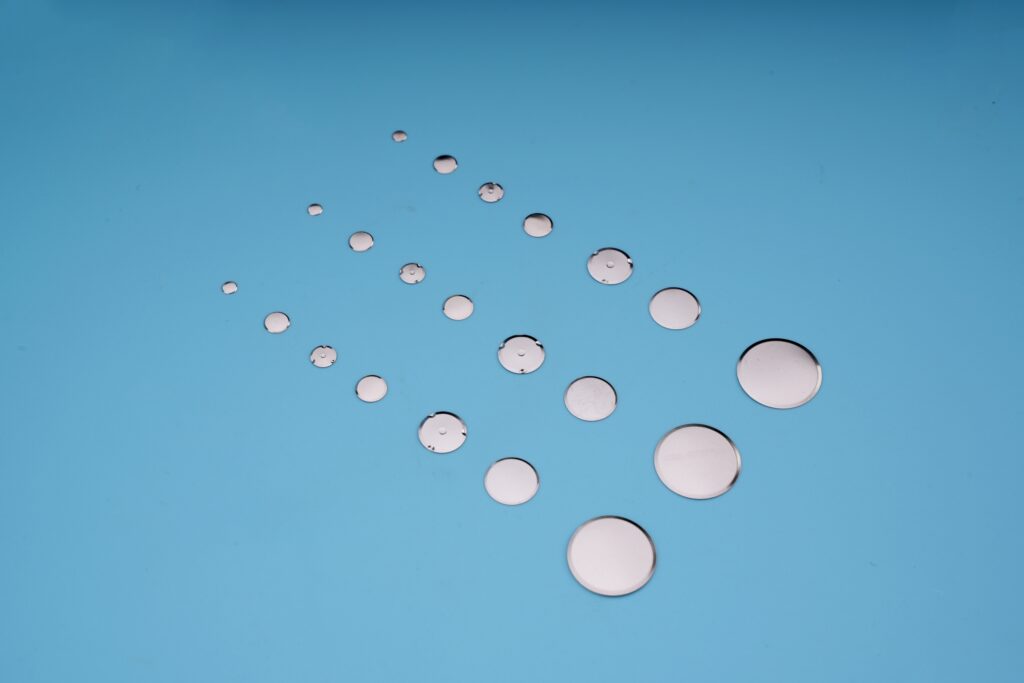

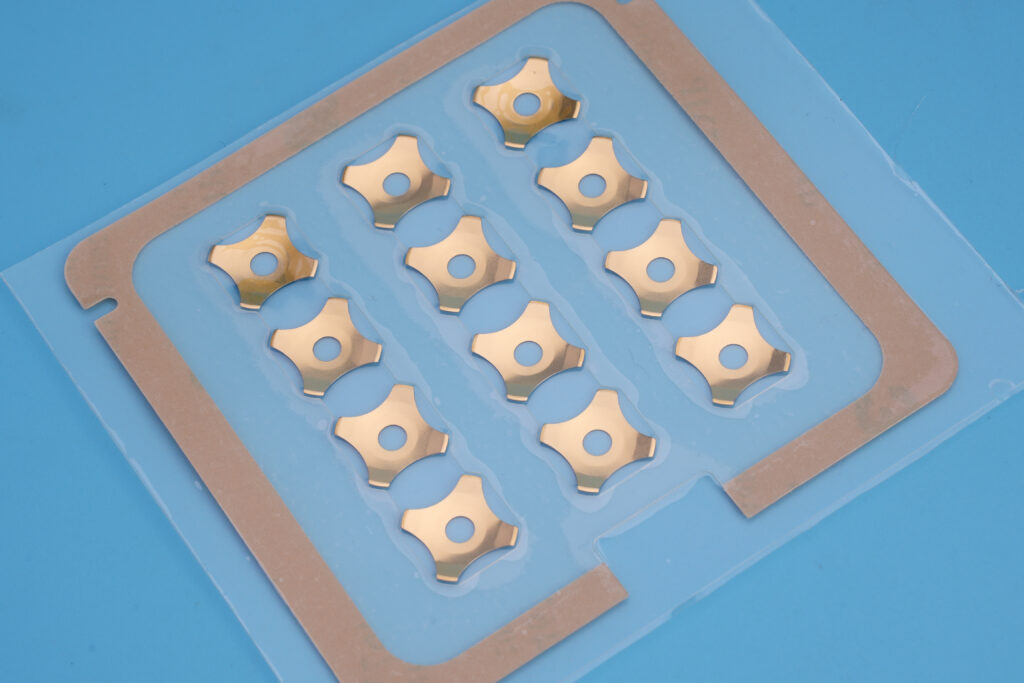

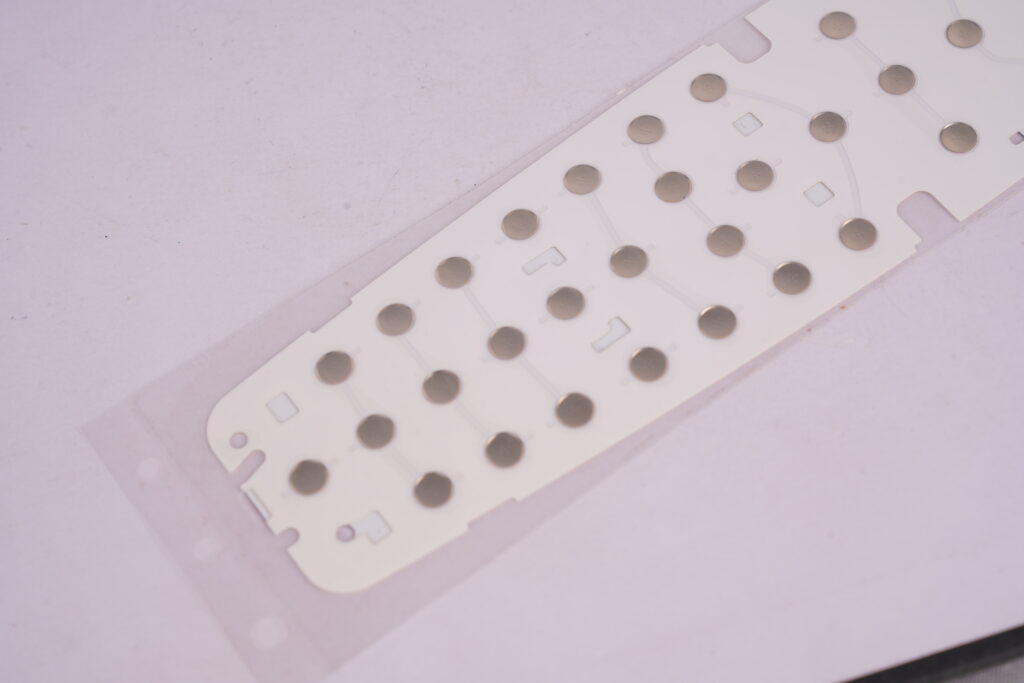

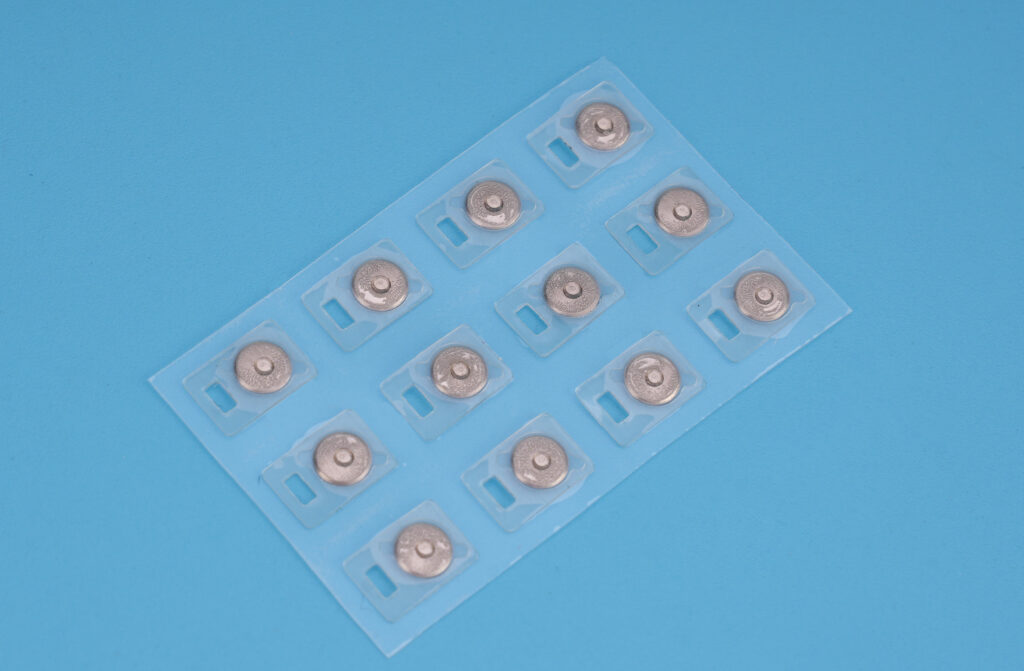

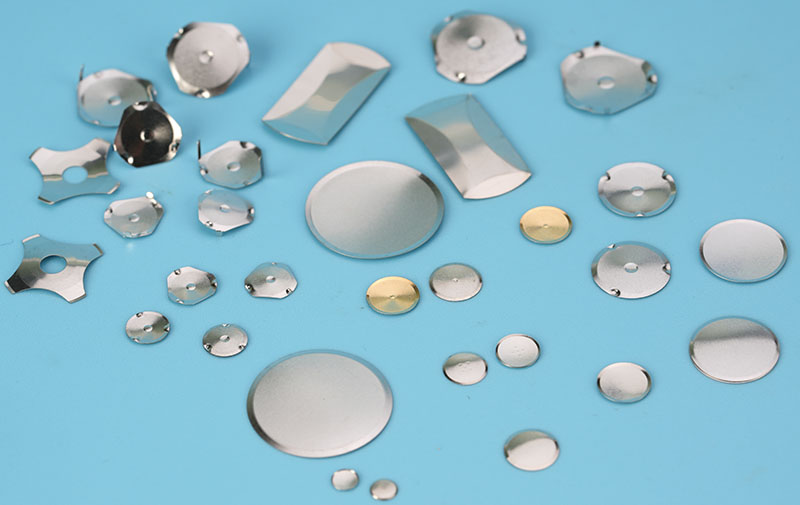

- Structure and Tactile Design: Assisting in optimizing dome shape, thickness, and arrangement.

- Mass Production-Grade Sampling: Samples use the same materials and processes as mass production.

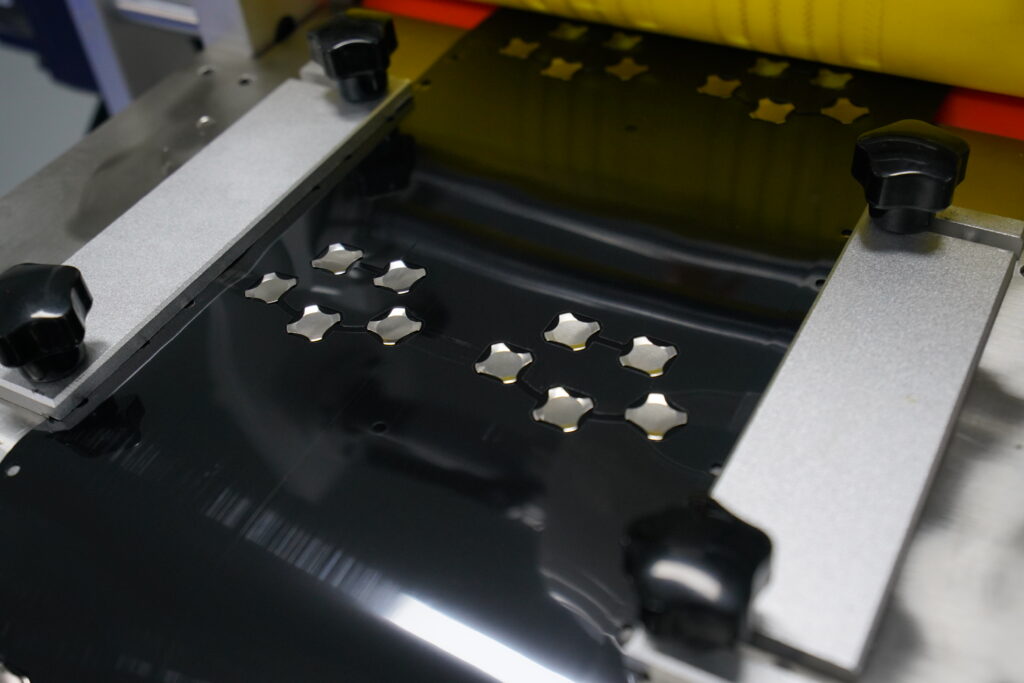

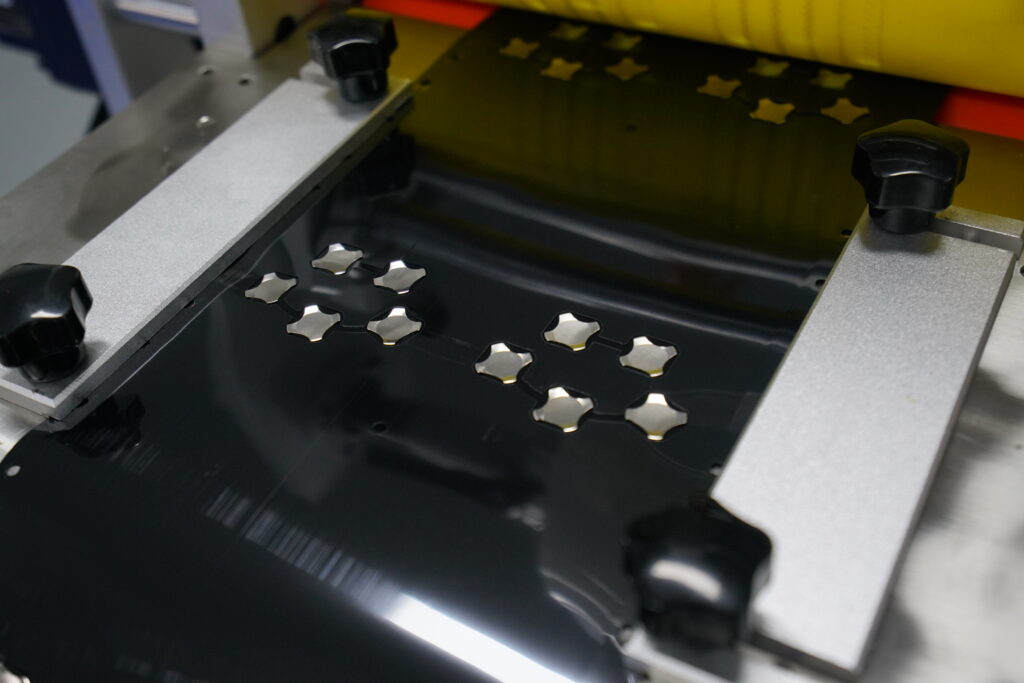

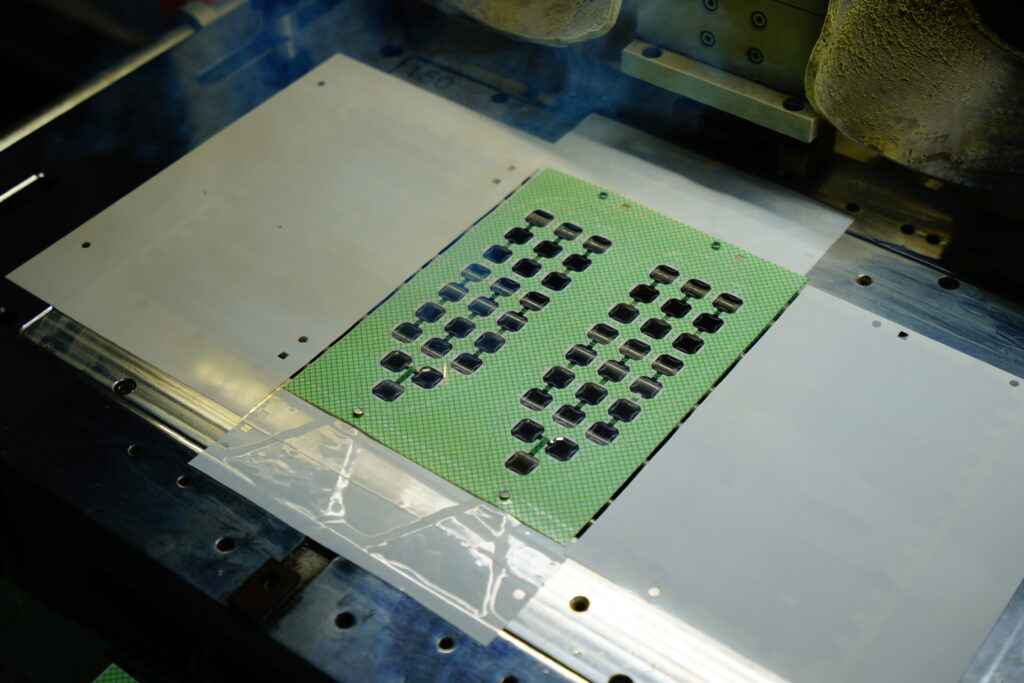

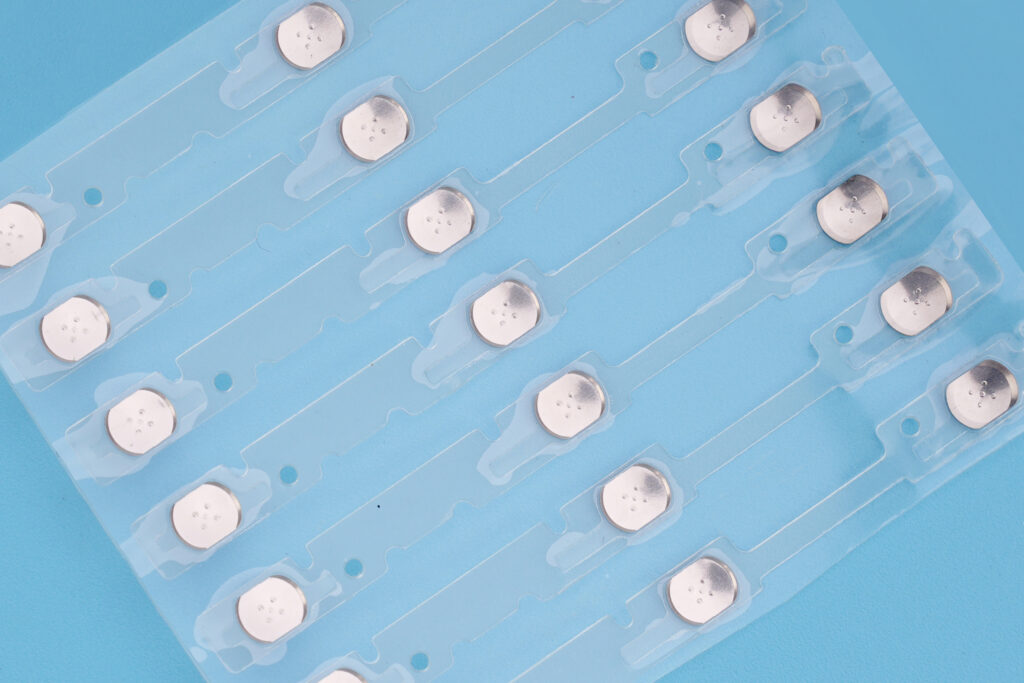

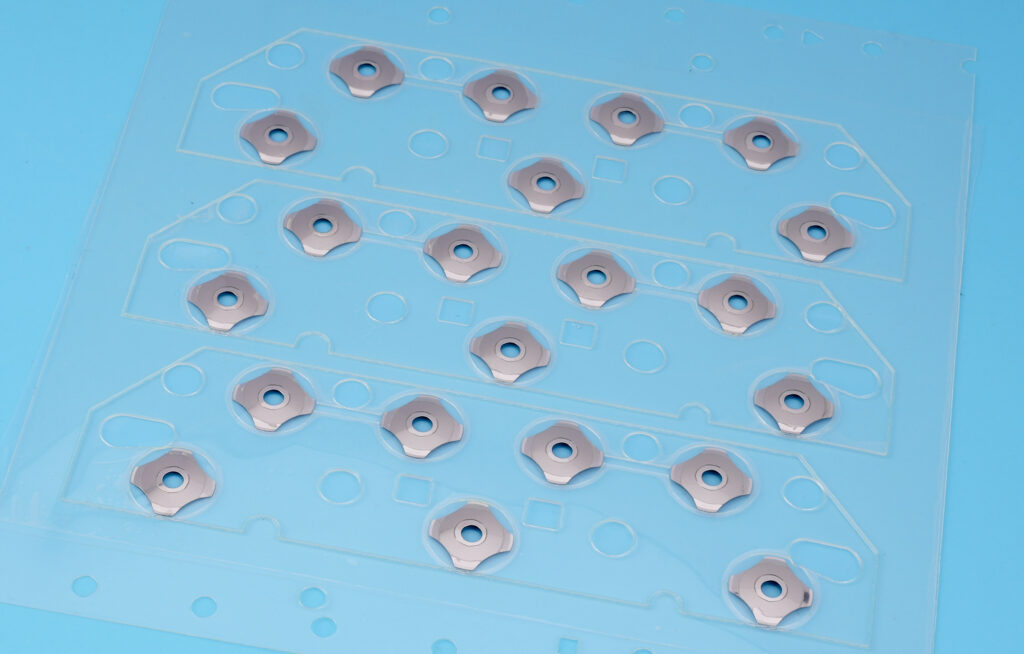

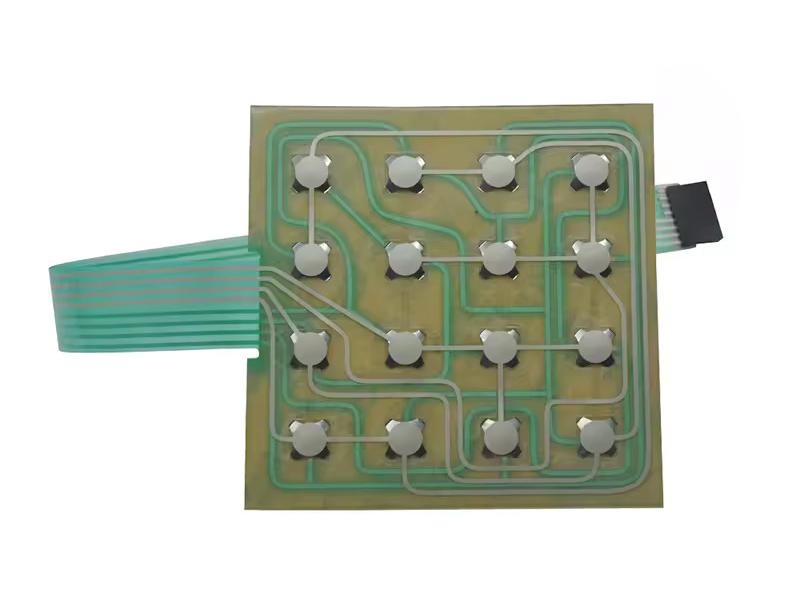

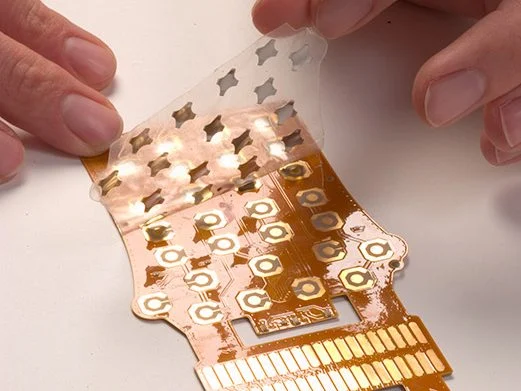

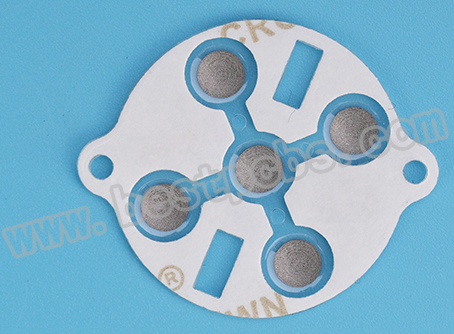

- Precision Array Manufacturing: Ensuring long-term stable alignment of the dome array.

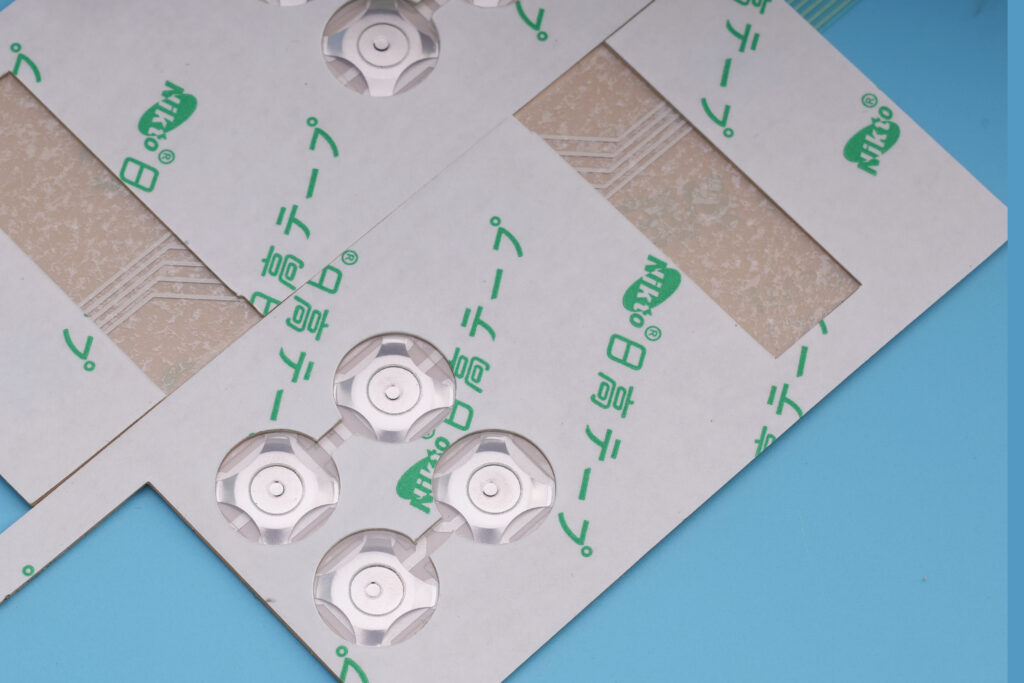

- Automated Packaging: Supporting maximized SMT placement efficiency.

- Fast Delivery Mechanism: Mature solutions can be shipped within 2-3 days.

This process allows Portuguese customers to see mass production results during the customization phase, giving them confidence to place orders.

Why Choose Us? BEST Technology’s Core Advantages

- 20+ years of professional metal dome manufacturing experience

- Supports custom metal domes & dome arrays

- Array alignment accuracy ±0.05mm

- Lifespan exceeding 1,000,000 presses

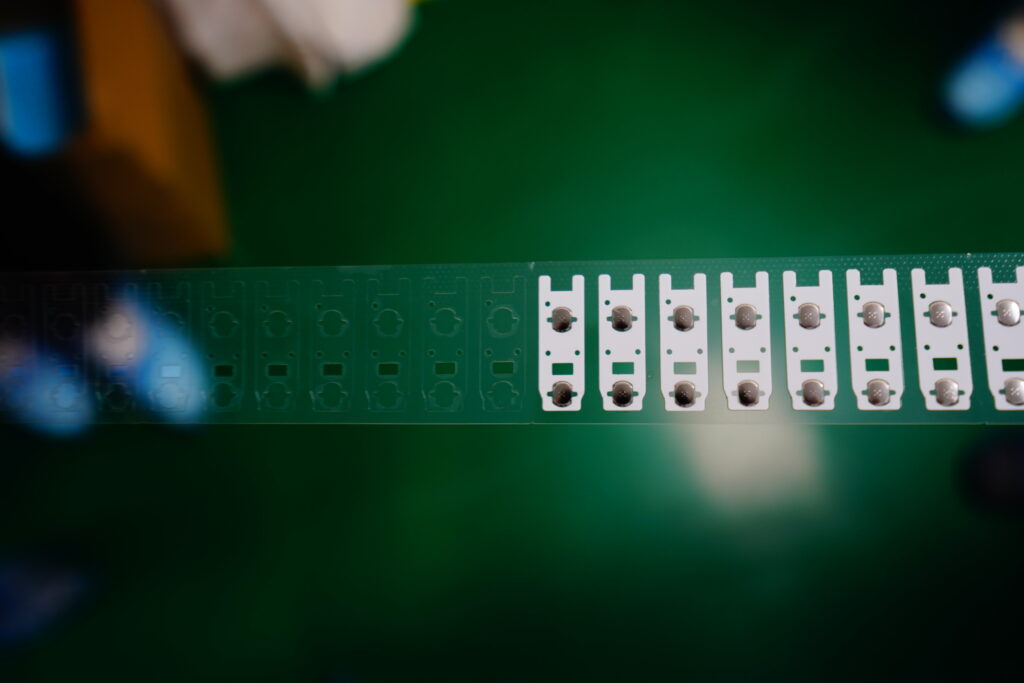

- Tape & Reel automated packaging capabilities

- Direct engineer support, fast response

List of Portugal Metal Dome Array Manufacturers

Top 10 metal dome array manufacturers in Portugal

| Company Name | Process Capability | Advantage |

|---|---|---|

| BEST Technology | Metal dome, custom dome array, Tape & Reel | High precision, stable lifespan, fast delivery |

| Bosch Portugal | Industrial electronics manufacturing | Automotive-grade quality system |

| Siemens Portugal | Industrial control components | Industrial application experience |

| TE Connectivity Portugal | Connectors and components | Brand and scale |

| Continental Portugal | Automotive electronics | System-level manufacturing |

| Jabil Portugal | EMS services | High-volume capability |

| Flex Portugal | Electronics manufacturing | Global delivery |

| Critical Manufacturing | Industrial electronics | Software + manufacturing |

| Efacec | Industrial electronic systems | Engineering capability |

| Vestas Portugal | Industrial equipment | Project-based manufacturing |

How to choose a Portugal metal dome manufacturer?

- Does the manufacturer have specialized experience in metal dome manufacturing?

- Does it support custom dome array design?

- Is the dome click force precisely controllable?

- Is the array alignment accuracy consistently stable?

- Does it provide engineering optimization suggestions?

- Does it support automated assembly?

- Are the samples and mass-produced products manufactured using the same process?

- Can it handle multi-batch orders?

Why is BEST Technology your best choice?

BEST Technology is not a general electronics contract manufacturer, but specializes in metal dome and array manufacturing. We are involved from the design stage, and through mold, material, and process control, we ensure that after small-batch verification, subsequent batches for our Portugal customers maintain the same feel, accuracy, and reliability, significantly reducing repeated verification costs.

Core pain points of Portugal metal dome manufacturers

- Insufficient customization capabilities, only accepting standard domes

- Poor consistency in feel, large batch variations

- Unstable array alignment, low assembly yield

- Weak engineering support, long modification cycles

- Low level of automation, high human error

- Delivery time is greatly affected by order size

How does BEST Technology solve these problems?

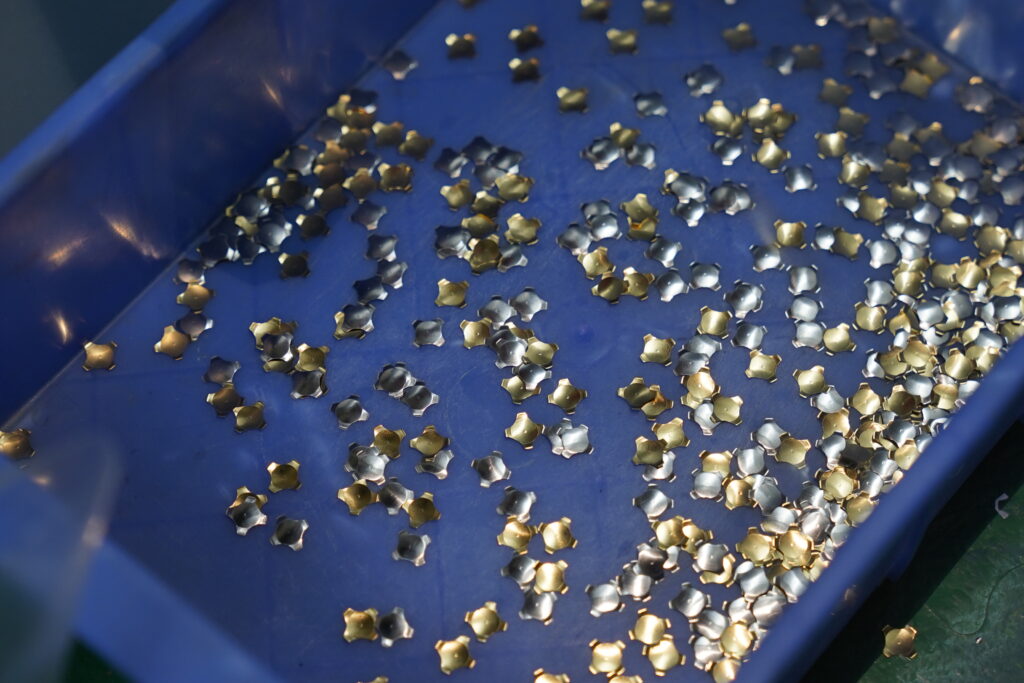

- Supports in-depth customization through its own mold and stamping system

- Ensures consistency through click force grading and life testing

- Controls alignment errors through high-precision array attachment process

- Provides quick response to modifications through direct engineer contact

- Improves stability and efficiency through Tape & Reel automated packaging

How to evaluate the production capabilities of a Portugal metal dome manufacturer?

- Does it have its own dome stamping production line?

- Does it support multiple dome structures?

- Array precision control capabilities

- Automated attachment and packaging capabilities

- Batch consistency and yield

- Life and reliability testing capabilities

- Is it certified under the ISO quality system?

- Does it support long-term stable supply?

BEST Technology’s production strength

We have complete metal dome stamping, molding, array attachment, and Tape & Reel packaging capabilities, and are certified under the ISO9001:2015 management system, ensuring that every batch of products shipped to Portugal maintains high consistency in accuracy, feel, and lifespan.

How to evaluate the delivery time of Portugal metal dome manufacturers?

- Is the prototyping cycle controllable?

- Does it support quick repeat orders?

- Is there a mature inventory of standard specifications?

- Is the level of automation sufficient?

- Responsiveness to order changes

- Transparency of production plan

- Can a clear delivery date be promised?

- Historical delivery stability

BEST Technology’s Delivery Advantages

Through mature process reserves and automated production line configuration, we can provide Portuguese customers with fast delivery in 2-3 days (for mature solutions), and significantly shorten the overall project cycle even in customized dome array projects.

Portugal Metal Dome Manufacturers Frequently Asked Questions (FAQ)

- Q1: Do you support custom metal domes?

A: Yes, including size, force, shape, and array layout.

- Q2: Are the samples and mass-produced products consistent?

A: Yes, the same materials and processes are used.

- Q3: How do you ensure consistent click force?

A: Through mold control and graded inspection.

- Q4: Do you support SMT assembly?

A: Yes, Tape & Reel packaging is supported.

- Q5: What is the typical delivery time?

A: Mature solutions can be delivered in 2-3 days.

- Q6: Do you provide technical documents?

A: Complete parameters and test data are provided.

By comparing the top 10 metal dome manufacturers in Portugal, BEST Technology has significant advantages in customization capabilities, stable quality, and fast delivery, making it a more suitable professional choice among Portuguese metal dome manufacturers for long-term cooperation.